|

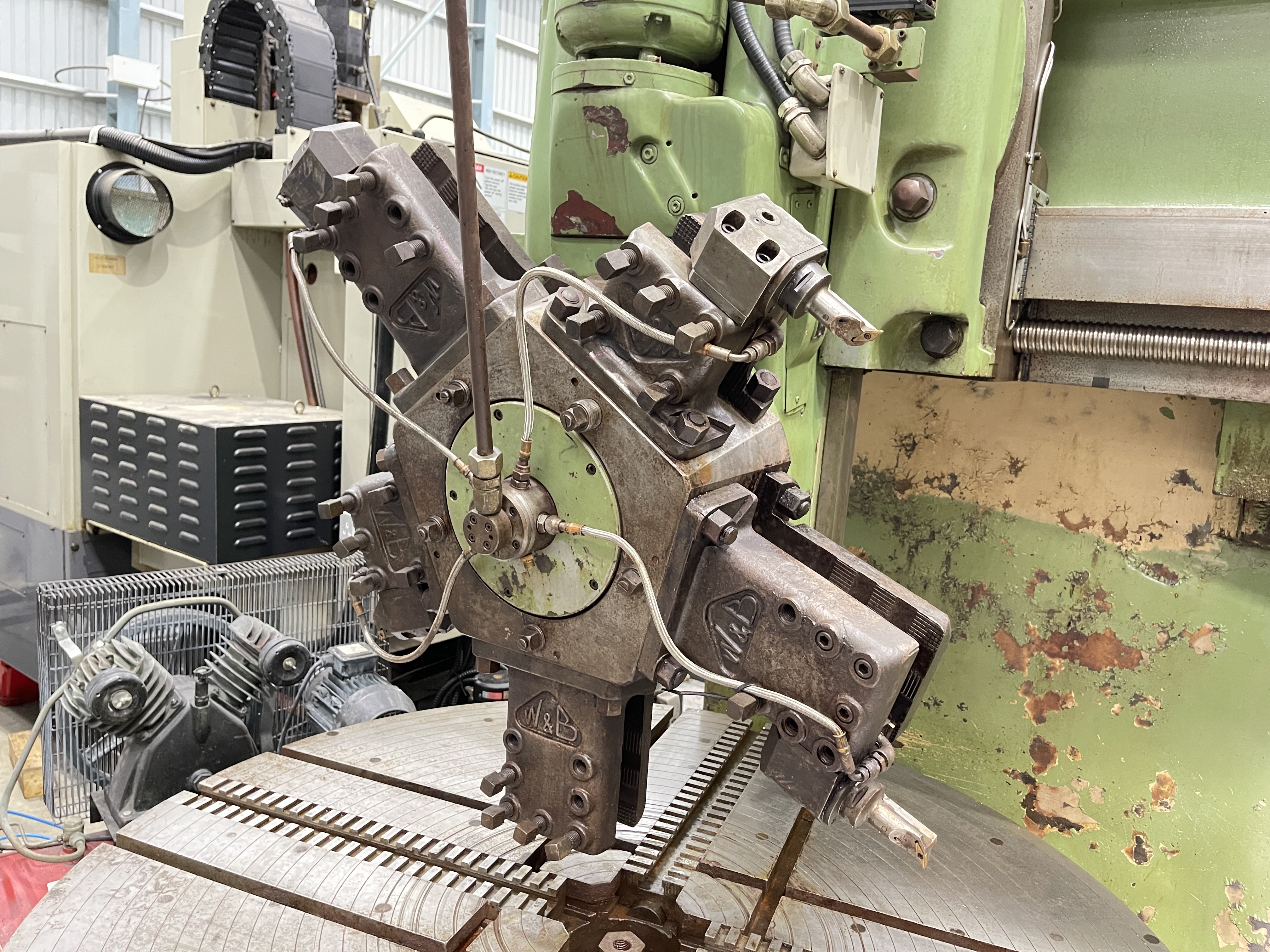

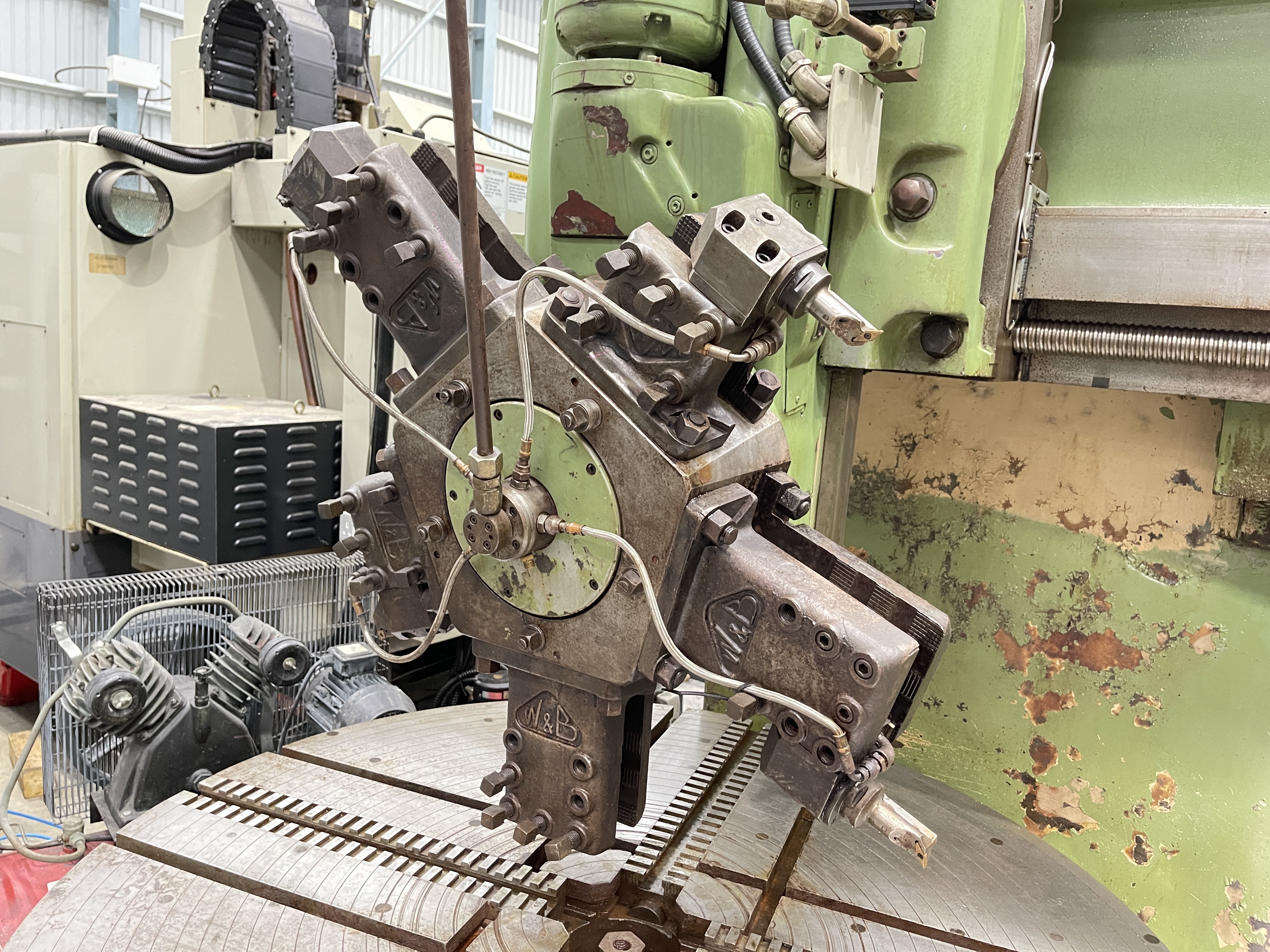

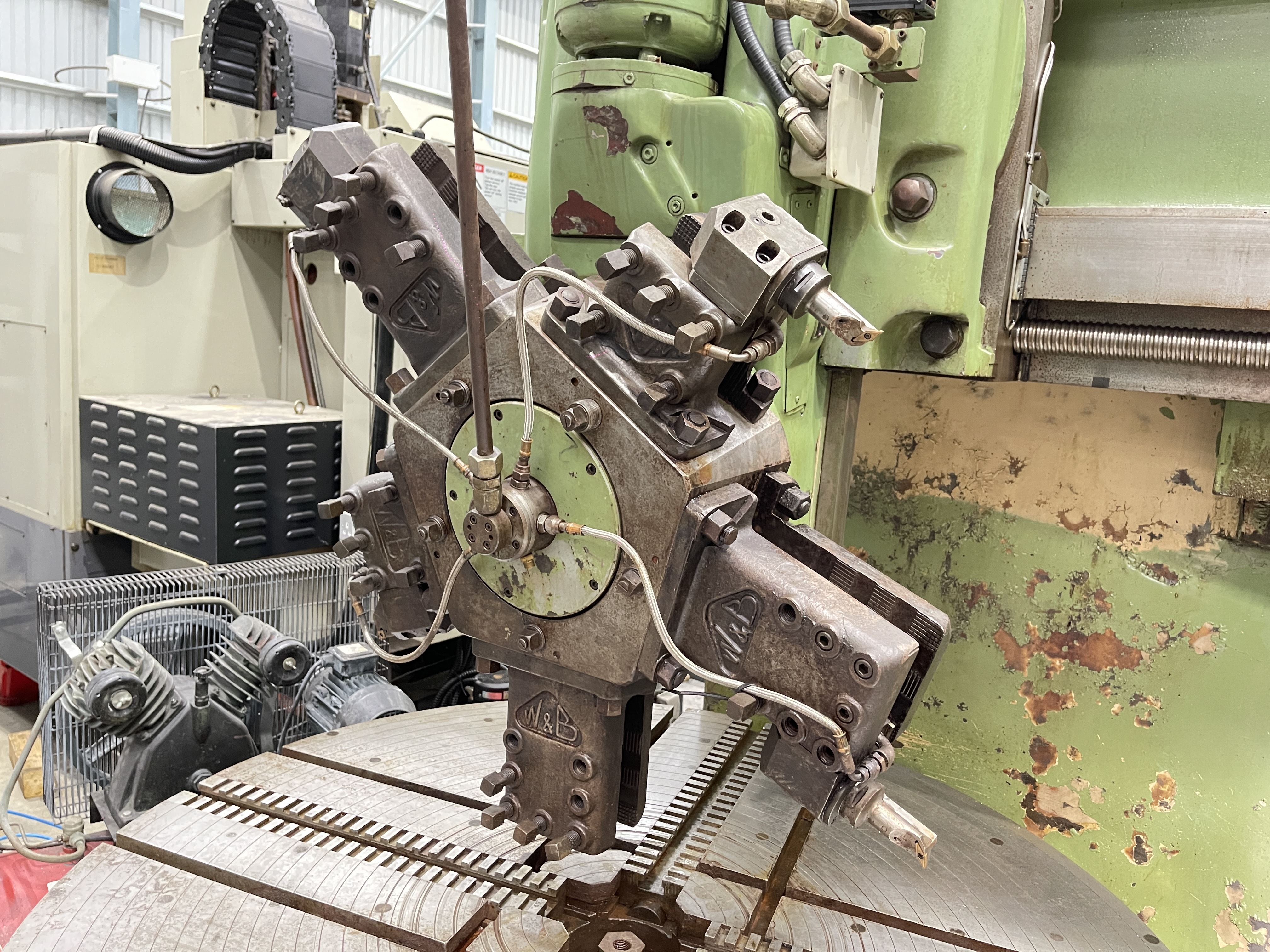

Webster and Bennett 48 CNC VTL

Webster and Bennett 48 CNC VTL Specification

- Product Type

- CNC Vertical Turning Lathe (VTL)

- General Use

- Turning and boring of heavy, large diameter workpieces

- Material

- Cast Iron Base & Table, Alloy Steel components

- Type

- Vertical Turret Lathe

- Capacity

- Maximum turning diameter 48 inches (1219 mm); Maximum workpiece height 36 inches (914 mm)

- Weight (kg)

- Approx. 15000 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- Approximately 25 kW

- Rigidity

- High, heavy-duty cast iron construction

- Voltage

- 415 V, 3 phase

- Motor

- Main drive motor 30 HP

- Table Size

- 48 inches (1219 mm)

- Spindle Speed

- Variable, up to 200 RPM

- Axial Choice

- 2 Axis (X & Z)

- Dimension (L*W*H)

- Approx. 4200 mm x 3500 mm x 4200 mm

- Feature

- CNC Control, Heavy-duty design, Precision machining, Hydraulic locking

- Color

- Industrial Blue & Grey

- Chuck Type

- 4-Jaw Independent Chuck

- Cross Rail

- Manually adjustable, power rise and fall optional

- Repeatability

- ±0.01 mm

- Coolant System

- Integrated

- Made in

- United Kingdom

- Travel X/Z

- X: 32 inch (810 mm)/ Z: 27 inch (685 mm)

- Positioning Accuracy

- ±0.02 mm

- Turret Type

- 8-Station Automatic Tool Changer

- Lubrication System

- Automatic centralized

- Table Load Capacity

- Up to 6000 kg

- Noise Level

- Below 80 dB(A)

- Max Swing Over Bed

- 1372 mm (54 inches)

- Max Workpiece Weight

- 6000 kg

- Condition

- Refurbished / Used (as per image sample)

- Hydraulics

- Yes, for clamping and turret indexing

- Controller Brand

- Fanuc / Siemens CNC system

About Webster and Bennett 48 CNC VTL

Wide Application and Clear Advantage Across Industries

The Webster and Bennett 48 CNC VTL is a stellar choice for machining heavy, large-diameter workpiecesperfect for sectors like aerospace, power generation, railways, oil & gas, and shipbuilding. Its core advantage lies in high rigidity, matchless precision, and user-friendly CNC control, streamlining both turning and boring operations. Widely used by component manufacturers and precision engineering firms, it ensures consistent, efficient production runs while maximizing device longevity and minimizing downtime.

Sample Availability, Reliable Supply, and Swift Delivery Process

Sample units of the Webster and Bennett 48 CNC VTL are available on request to help you analyze outlay and fit before final commitment. Our strong supply ability covers both domestic and global demands, ensuring timely shipped goods through reliable channels. Delivery time depends on transportation mode and destination, but we prioritize efficient logistics and careful handling. End-to-end shipment ensures your masterpiece arrives safely, minimizing operational disruption and allowing a smooth installation process.

FAQs of Webster and Bennett 48 CNC VTL:

Q: How does the Webster and Bennett 48 CNC VTL benefit heavy-duty machining applications?

A: The Webster and Bennett 48 CNC VTL excels by providing high precision, heavy-duty construction, and the capability to handle large, heavy workpieces, making it ideal for industries requiring robust and reliable turning solutions.Q: What control systems are available with this Vertical Turret Lathe?

A: This VTL comes equipped with either a Fanuc or Siemens CNC controller, offering intuitive operation and enhanced programming flexibility for complex machining tasks.Q: When should I consider a refurbished or used Webster and Bennett 48 CNC VTL?

A: A refurbished or used model is recommended when you need advanced capabilities and reliability at a reduced outlay. Each unit is carefully inspected to ensure matchless performance and durability.Q: Where can this machine be installed, and what are the power requirements?

A: The machine is suitable for installation in industrial workshops or factories, requiring a 415 V, 3-phase electric power supply and a stable foundation capable of accommodating its approximate 15000 kg weight.Q: What is the process for arranging shipment and installation?

A: After order confirmation, our team coordinates the packing and shipped goods logistics, with transportation and installation managed according to your specifications. We ensure safe delivery and seamless setup on-site.Q: How is repeatability and positioning accuracy ensured during operation?

A: Thanks to the high-quality construction and computerized CNC control, the machine consistently delivers 0.02 mm positioning accuracy and 0.01 mm repeatability, supported by integrated hydraulic and lubrication systems.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

ZPS S-50 CNC Turn Mill Center

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

PLC Control : Other, Available

Axial Choice : C Axis + Y Axis

Capacity : 50 mm bar diameter

Microsprint 50

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Yes

Axial Choice : Single and Multiple Axial Option

Capacity : Bar diameter 5 mm 50 mm

Mori Seiki Sl-303b/1500 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Available

Axial Choice : 2 Axis (X, Z)

Capacity : Max turning diameter 420 mm, Max turning length 1500 mm

Citizen B20 Cnc Sliding Head

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Available

Axial Choice : 5 to 7 Axis (configurable)

Capacity : Bar capacity up to 20mm diameter

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |