Most Popular Products

|

Drummond Maxicut 2a Gear Shaper

Drummond Maxicut 2a Gear Shaper Specification

- Product Type

- Gear Shaper

- General Use

- Gear Cutting and Shaping

- Material

- Cast Iron Body

- Type

- Automatic Gear Shaper

- Capacity

- Up to 400 mm Diameter

- Weight (kg)

- Approx. 3000 kg

- Computerized

- No

- Automatic

- Yes

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 4 HP

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3-Phase Electric Motor

- Table Size

- 400 mm Diameter

- Spindle Speed

- 40200 RPM

- Axial Choice

- Manual/Automatic

- Dimension (L*W*H)

- 2250 mm x 1500 mm x 2150 mm

- Feature

- Precision, Heavy Duty

- Color

- Blue & White

- Operating System

- Electrical Switchgear Panel

- Maximum Module

- 8 Module

- Stroke Length

- 160 mm

- Surface Finish

- Ground Precision

- Maximum Workpiece Height

- 150 mm

- Table Hole Diameter

- 125 mm

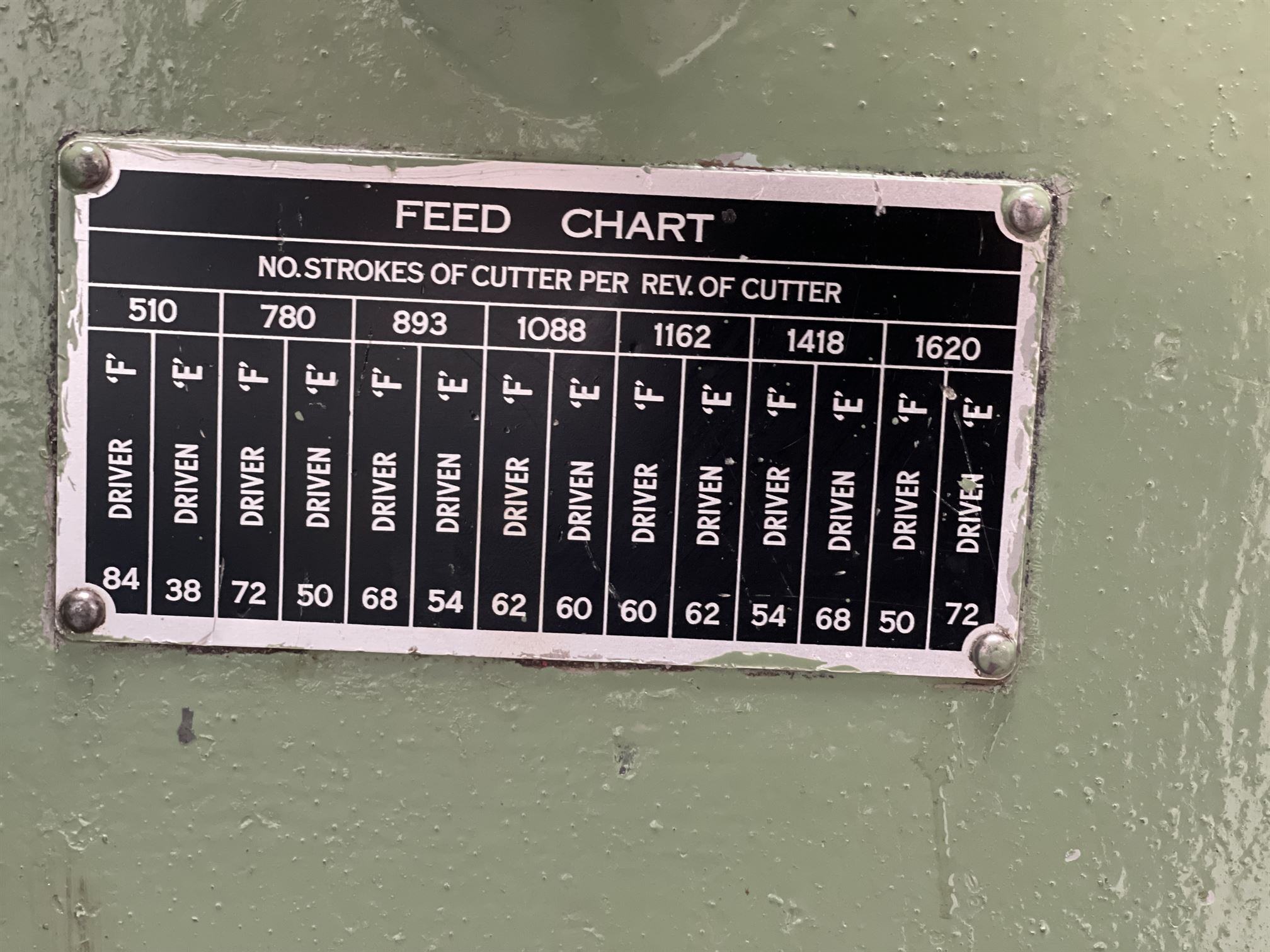

- Feed Range

- 0.22.5 mm/stroke

- Noise Level

- Low

- Machine Construction

- Robust, High-Tensile

- Coolant System

- Integrated

- Maximum Distance Table to Tool Holder

- 160 mm

About Drummond Maxicut 2a Gear Shaper

*DRUMMOND MAXICUT 2A GEAR SHAPER*

CATEGORY : GEAR MACHINES

Reference No: 1568

Technical Specifications:

Make Drummond (England)

Model Maxicut 2A

Max. Gear Diameter 200 mm

Max. Module 4 module

Max. Stroke Length 50 mm

Spindle Diametet 70 mm

Heavy-Duty Precision Engineering

Designed with a high-tensile cast iron body, the Drummond Maxicut 2a Gear Shaper boasts sturdy construction that minimizes vibration and maximizes accuracy. The ground surface finish ensures every gear produced meets exacting industry standards. With its robust design, users can rely on enduring performance and longevity, even under continuous and demanding workloads.

Versatile Gear Cutting Capability

This gear shaper accommodates workpieces up to 400 mm in diameter and 150 mm in height, supporting a wide range of gear cutting and shaping processes. The feed range of 0.2-2.5 mm per stroke and spindle speeds from 40-200 RPM allow for great versatility, making it suitable for diverse gear manufacturing needs and different material requirements.

User-Friendly Operation with Integrated Safety

Equipped with an electrical switchgear panel, the Drummond Maxicut 2a ensures intuitive machine control. Both manual and automatic axial choices are available to optimize workflow. The integrated coolant system and low-noise operation enhance operator safety and comfort, while the reliable electrical power system (415V, 4 HP) supports energy-efficient, continuous use.

FAQ's of Drummond Maxicut 2a Gear Shaper:

Q: How does the Drummond Maxicut 2a Gear Shaper enhance precision in gear cutting?

A: The machine features a robust cast iron construction with ground precision surface finish, and high rigidity components. These design elements minimize vibration and ensure accurate gear profiles, resulting in high-quality, precisely shaped gears.Q: What types of gear cutting jobs can the Maxicut 2a handle?

A: It is designed for both standard and heavy-duty gear cutting and shaping, handling modules up to 8 and workpieces up to 400 mm in diameter. This versatility makes it suitable for a variety of industries, including automotive, manufacturing, and machinery repair.Q: When is it recommended to use the manual versus automatic axial choice?

A: Manual axial mode is preferable for detailed, customized cutting jobs or setup procedures, while automatic mode is ideal for high-volume, repetitive production runs to ensure consistent results and maximize efficiency.Q: Where can the Drummond Maxicut 2a Gear Shaper be installed?

A: The machine is suitable for industrial workshops and manufacturing facilities with adequate space (2250 mm x 1500 mm x 2150 mm footprint) and access to a 415V, 3-phase power supply. It is available through exporters, importers, suppliers, and traders across India.Q: What is the work process for using this gear shaper?

A: Operators mount the workpiece on the 400 mm diameter table, select either the manual or automatic axial mode, adjust feed rate and spindle speed as per the gear specifications, and initiate cutting operations via the electrical switchgear panel. The integrated coolant system maintains temperature for optimal precision during shaping.Q: How does the integrated coolant system benefit the operator?

A: The built-in coolant system reduces heat generation, thus maintaining the integrity of both the tool and workpiece, minimizing wear, and enhancing operator safety by keeping the workspace clean and reducing the risk of overheating.Q: What are the advantages of the Drummond Maxicut 2a's automatic operation?

A: Automatic operation ensures faster production, consistent gear quality, and reduced manual intervention, which significantly boosts productivity, particularly in large-volume manufacturing environments.

- Minimum Order Quantity

- 1 Number

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |