|

Hydrafeed Multifeed Ml1 Barfeed (3)

Hydrafeed Multifeed Ml1 Barfeed (3) Specification

- Product Type

- Hydrafeed Multifeed ML1 Barfeed

- General Use

- Automatic loading of bars into CNC lathes

- Material

- Steel body with precision guides

- Type

- Automatic Bar Feeder

- Capacity

- Bar diameter range: 8 mm to 65 mm

- Weight (kg)

- Approx. 385 kg

- Computerized

- Yes

- Automatic

- Yes

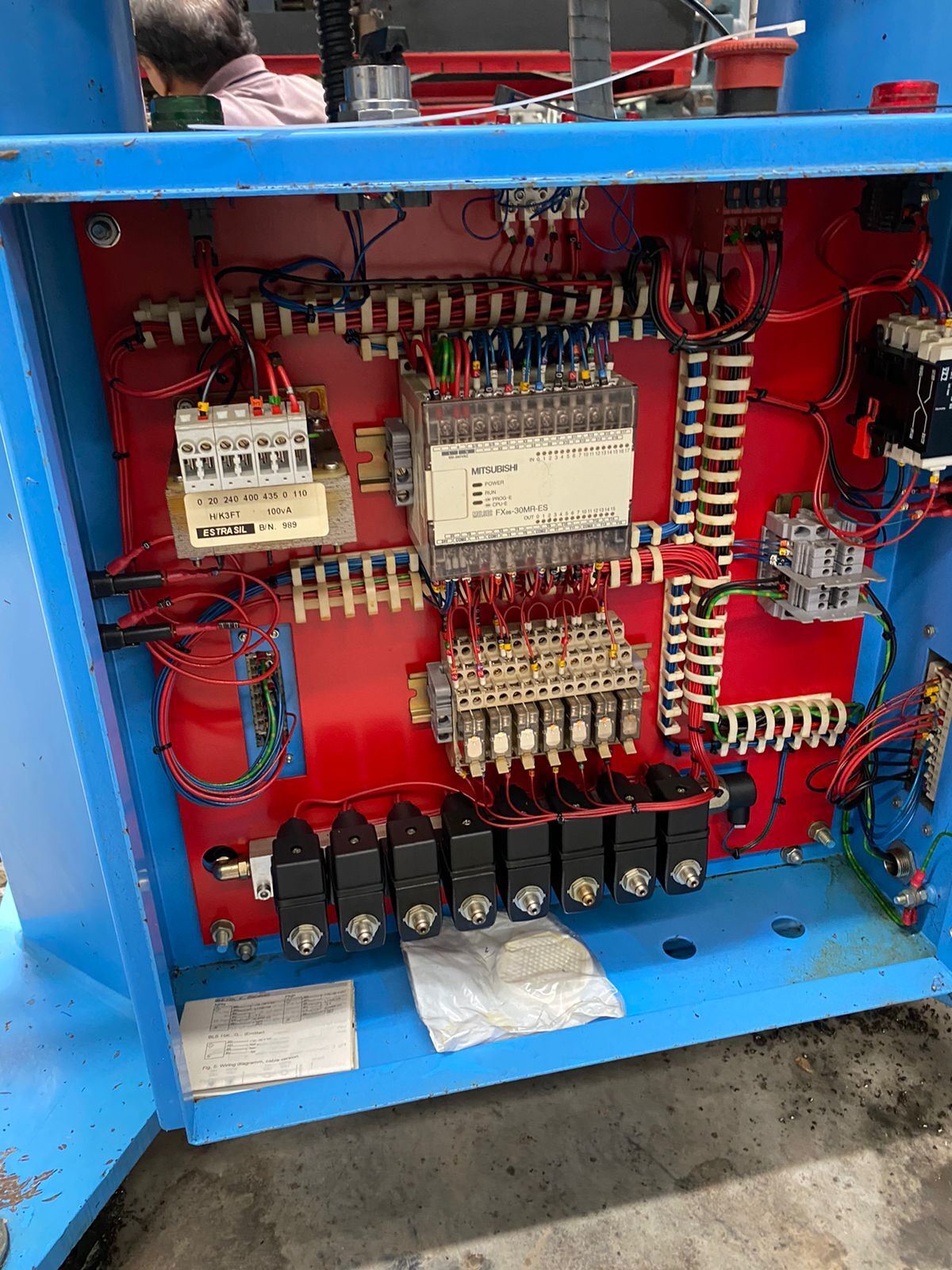

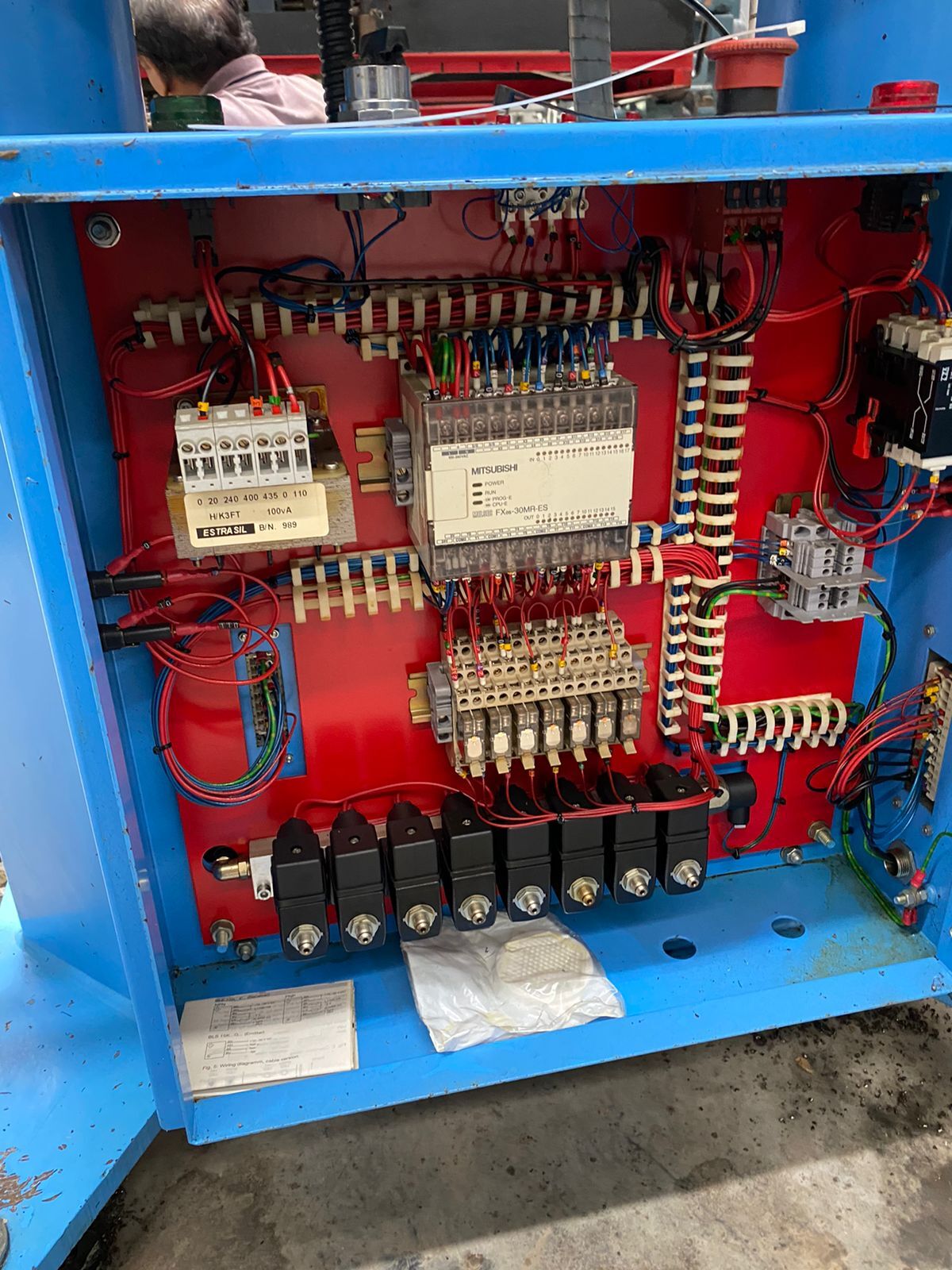

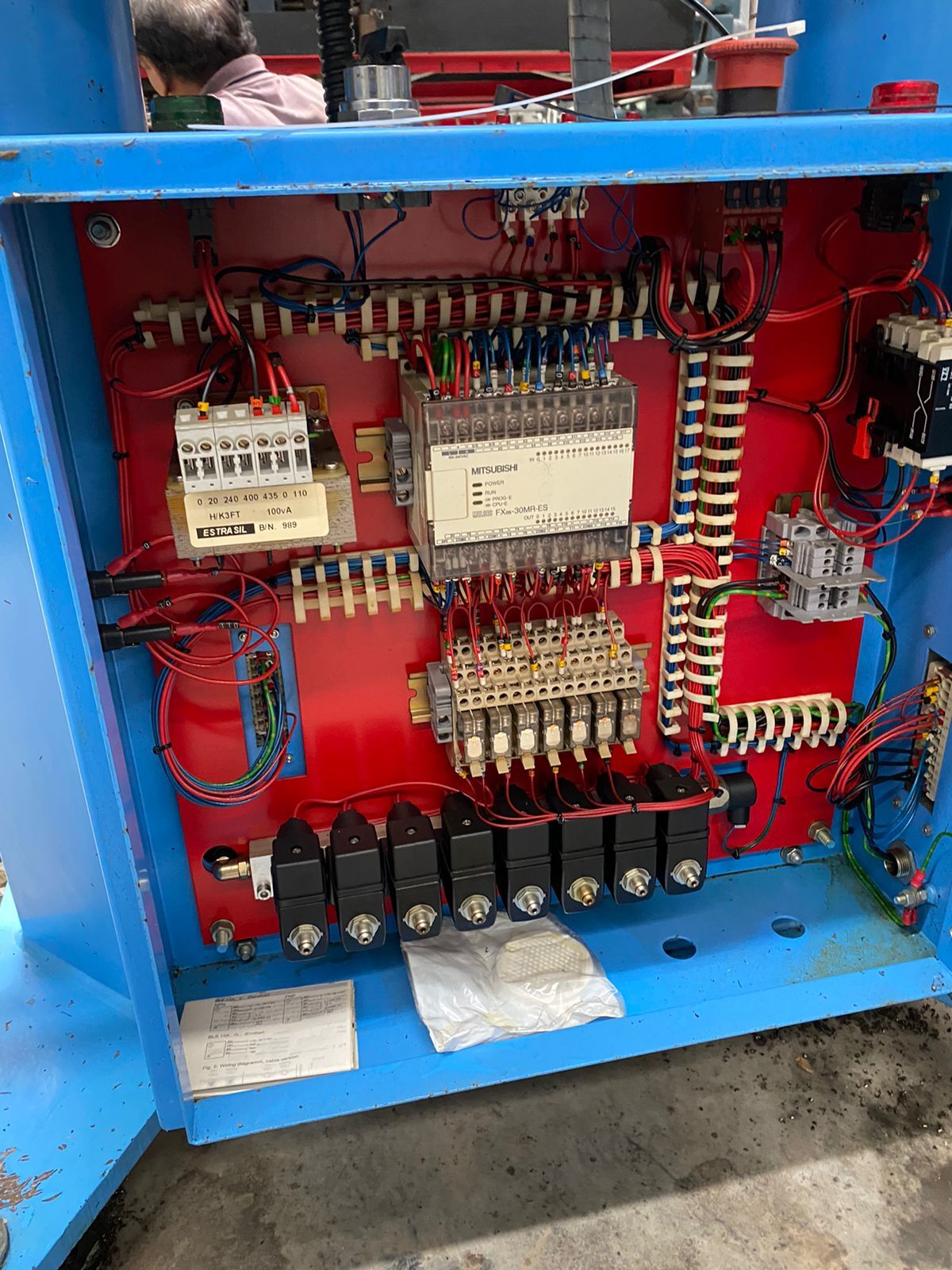

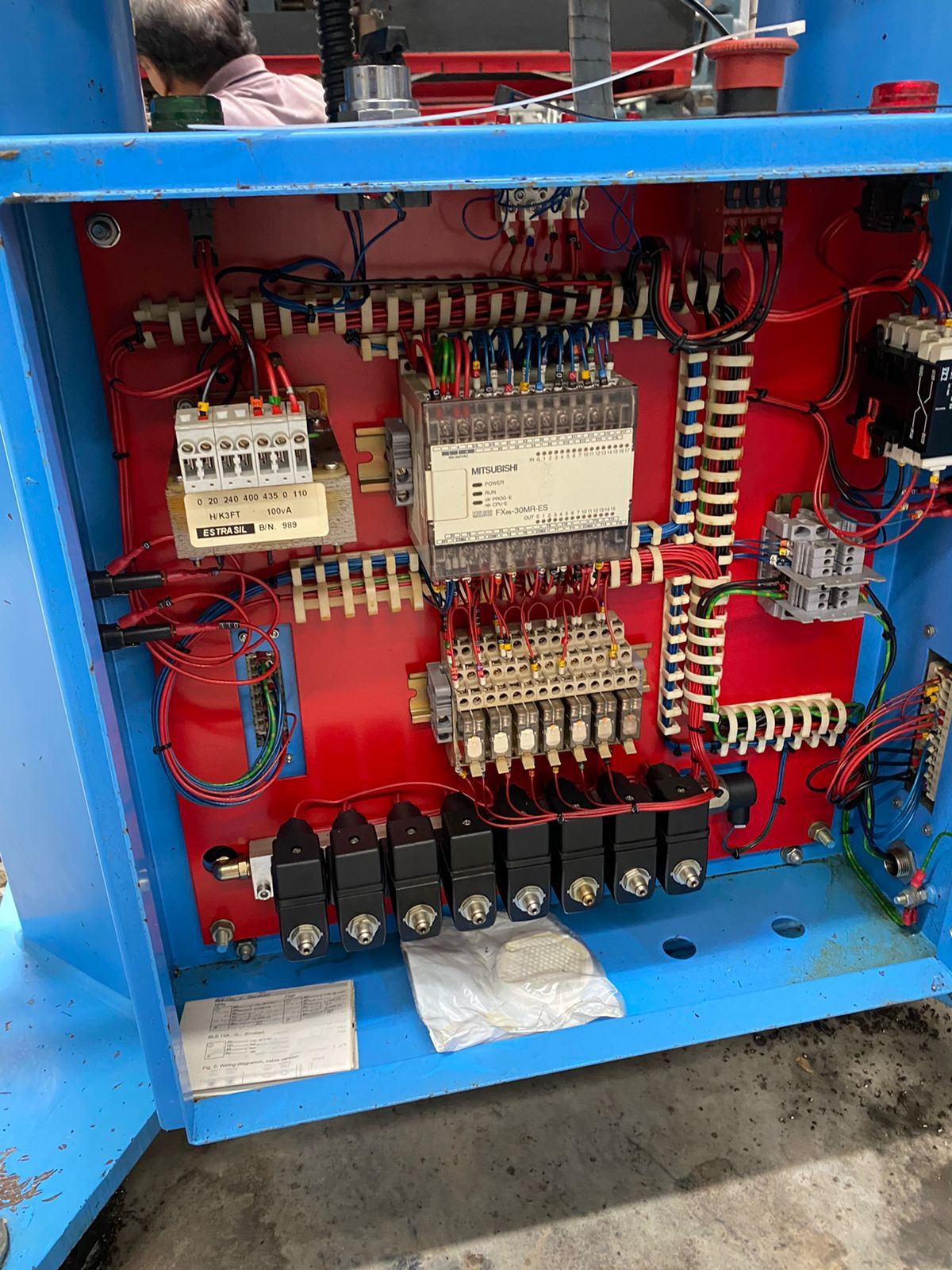

- PLC Control

- Yes

- Bar Feeder

- Yes

- Power Source

- Electric

- Power Consumption

- Approx. 1.5 kW

- Rigidity

- High structural rigidity for minimal vibration

- Voltage

- 230V / 50Hz

- Motor

- Integrated servo motor drive

- Spindle Speed

- Supports high-speed spindle synchronisation

- Axial Choice

- Single or multi-axis positioning

- Dimension (L*W*H)

- Approx. 3200 x 550 x 1250 mm

- Feature

- Full-length barfeed, quick changeover, multi-length capability, CE certified

- Color

- Industrial grey & white

- Compatible Machine Interface

- Selectable for most CNC lathes

- Installation Support

- On-site by manufacturer or distributor

- Operating Temperature

- 5°C to 40°C

- Min/Max Bar Length

- 150 mm / 1500 mm

- Noise Level

- <75 dB

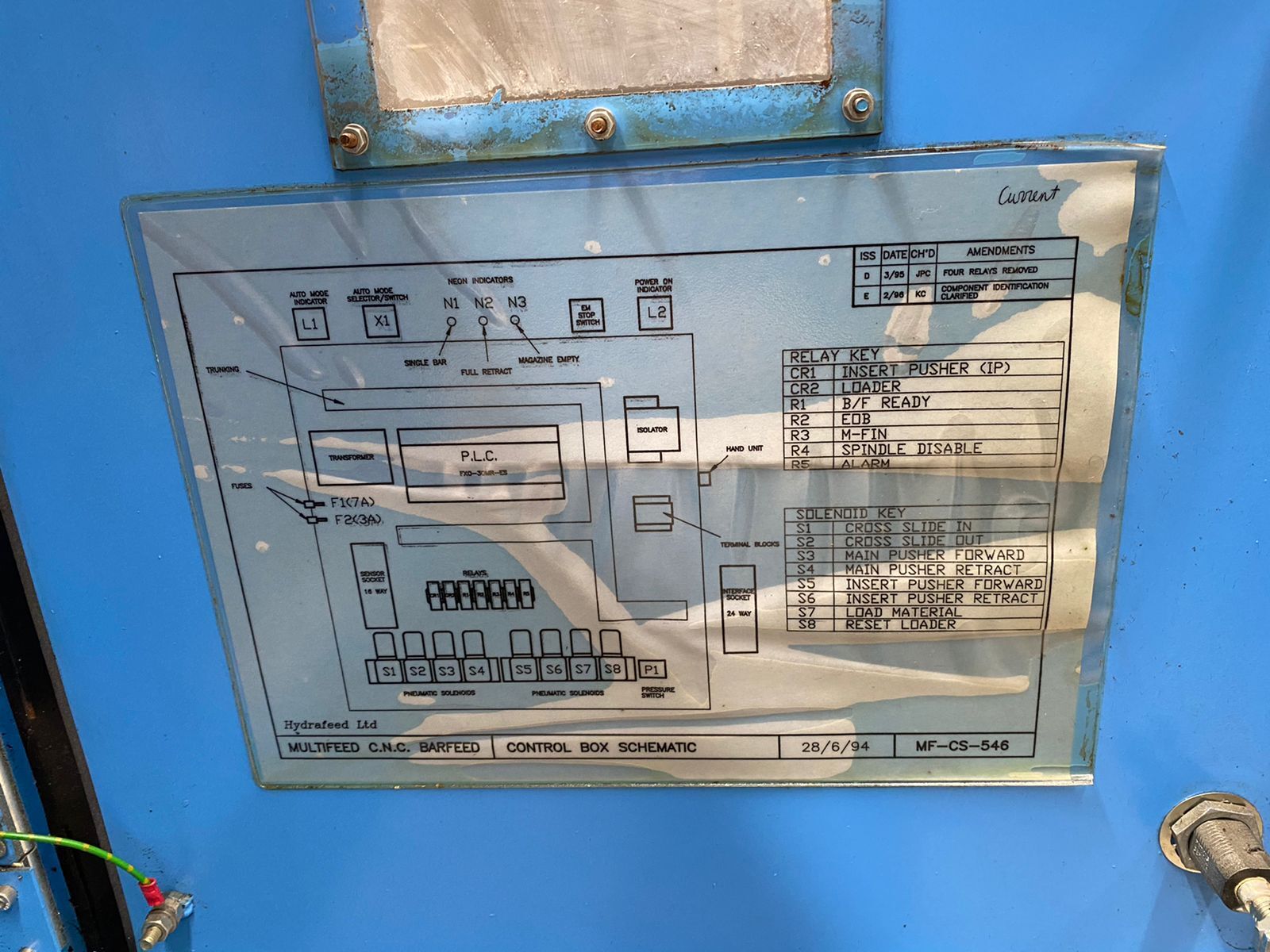

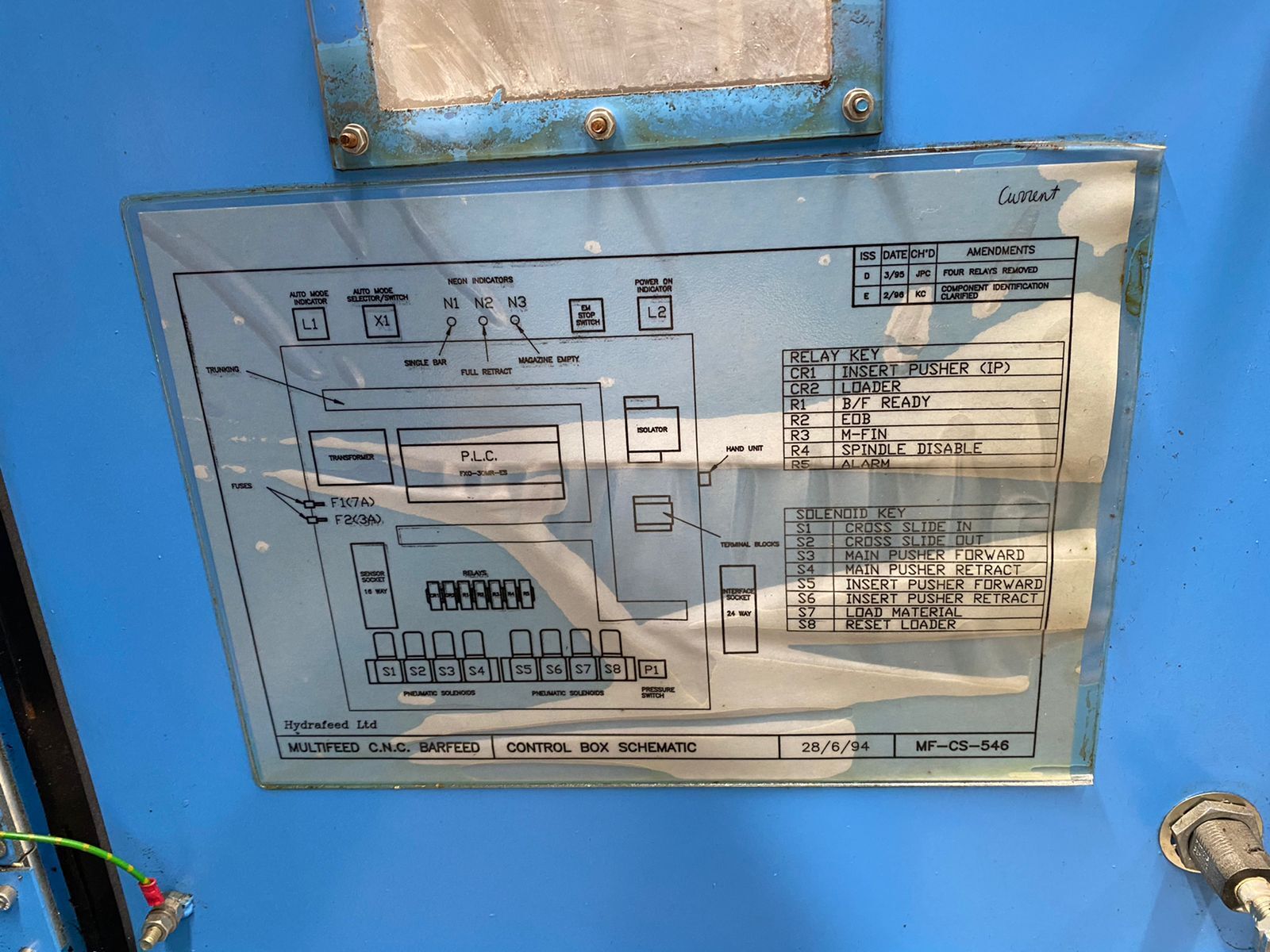

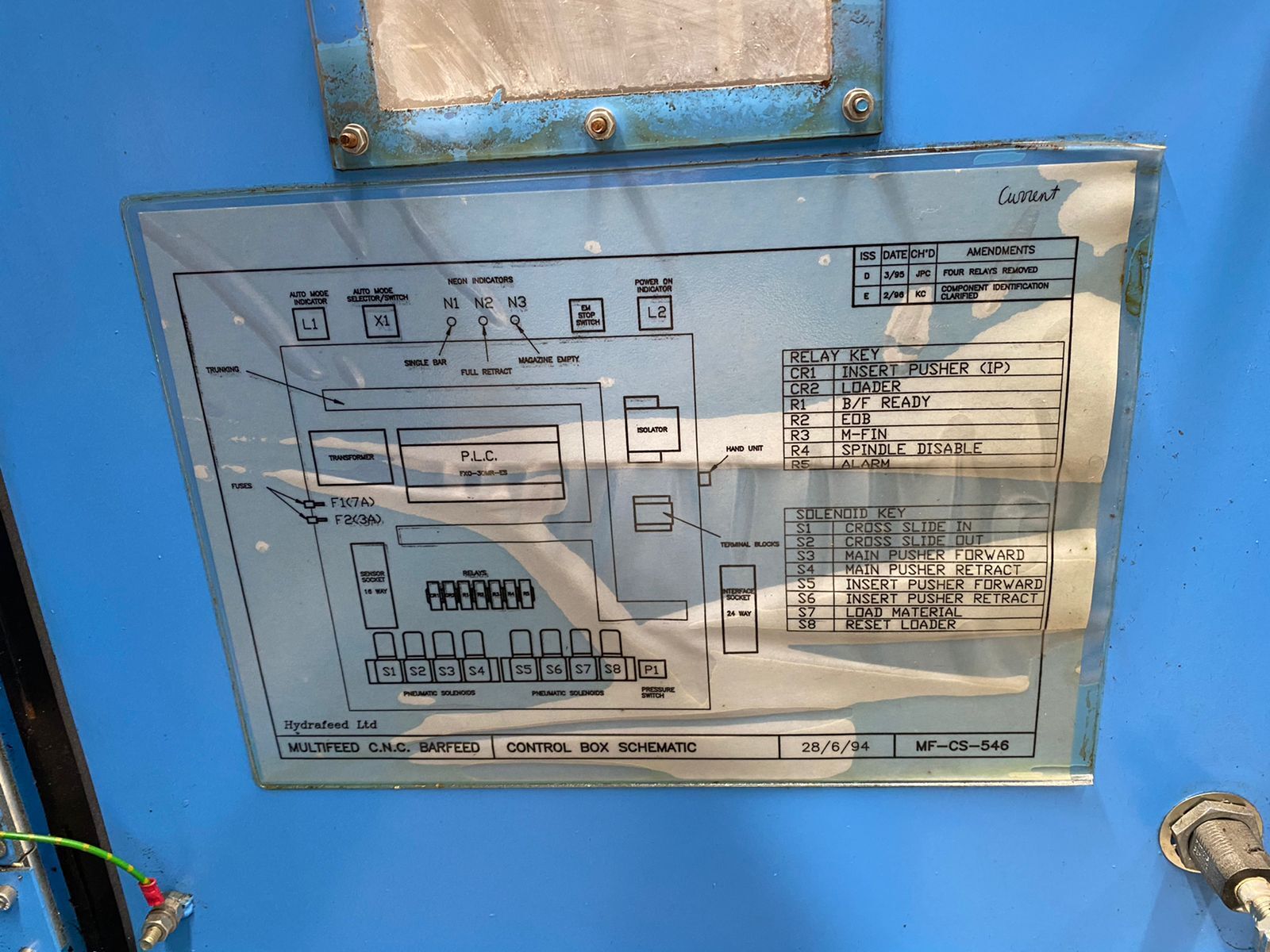

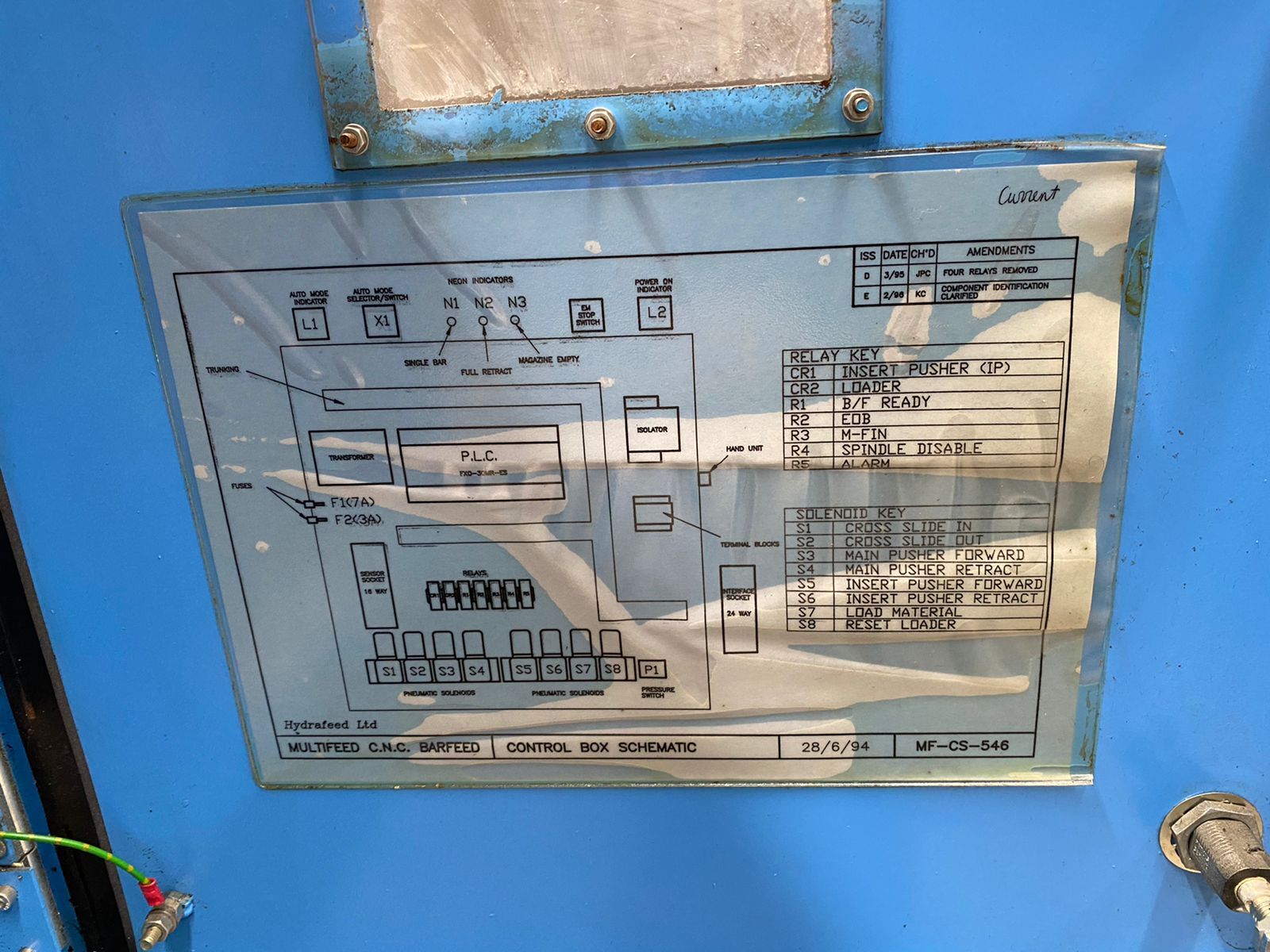

- Control Panel

- Touchscreen, parameter programmable

- Air Supply Required

- 5-7 bar (if applicable for pneumatic features)

- Max Bar Changeover Time

- < 30 seconds

- Application

- Suitable for medium to high volume production

- Bar Loading System

- Automatic magazine with pusher

- Footprint

- Compact design for space optimization

- Magazine Loading Length

- Up to 1500 mm

- Lights/Indicators

- LED status indicators on control panel

- Safety Features

- Emergency stop switch, Bar jam detection

About Hydrafeed Multifeed Ml1 Barfeed (3)

Trusted by Industry Leaders Versatile Application & Competitive Edge

The Hydrafeed Multifeed Ml1 Barfeed (3) is preferred by renowned manufacturers, exporters, importers, and suppliers across India. Primarily used in medium to high-volume production environments, it is found in automotive, aerospace, and precision engineering facilities. Its standout competitive advantages include minimal vibration, rapid bar changeover, and an exceptionally compact footprint. This bar feeder is designed to streamline workflows, driving efficiency and elevating productivity for demanding, fast-paced workplaces.

Global Market Reach & Practical Purchase Insights

Our main export markets for the Hydrafeed Multifeed Ml1 Barfeed (3) span Europe, Asia, and the Middle East. Each unit is carefully packaged with secure, industrial-grade materials to minimize expenditure related to potential damages. Sample policy details can be provided upon request, and we estimate the sale price based on specific buyer requirements and regional considerations. Expect transparent communication and comprehensive cost breakdowns to ensure informed, value-driven decisions for every purchase.

FAQs of Hydrafeed Multifeed Ml1 Barfeed (3):

Q: How does the Hydrafeed Multifeed Ml1 Barfeed (3) facilitate quick bar changeovers?

A: The advanced design of the Hydrafeed Multifeed Ml1 Barfeed (3) allows for bar changeovers in less than 30 seconds, minimizing production downtime and maximizing throughput in busy environments.Q: What safety measures are incorporated in the operation of the bar feeder?

A: Key safety features include an emergency stop switch and bar jam detection, ensuring operator protection and safe equipment operation at all times.Q: When is the bar feeder suitable for use in manufacturing processes?

A: The Hydrafeed Multifeed Ml1 Barfeed (3) is ideal for medium to high-volume production runs, particularly in sectors such as automotive, precision machining, and general CNC lathe operations.Q: Where can this bar feeder be installed, and is support available?

A: Installation support is provided on-site by either the manufacturer or a qualified distributor, ensuring correct setup in a wide range of industrial facilities across India and export markets.Q: What are the benefits of using the Multifeed Ml1 for CNC lathes?

A: Main benefits include its seamless automatic bar loading, compatibility with most CNC lathes, programmable controls, and high-precision operation, leading to increased productivity and reduced manual effort.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Category

Raybrook 300 Precision Honing Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Industrial Bearing and Cylinder Honing

Motor : Other, Three Phase Induction Motor

Material : Other, Cast Iron, Mild Steel

Product Type : Precision Honing Machine

Pee Wee Thread Roller

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Thread Rolling

Motor : Other, 3 HP

Material : Other, High Grade Steel

Product Type : Thread Roller Machine

Midsaw Vertical Saw

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Cutting Metal Sheets and Rods

Motor : Other, Heavy Duty Induction Motor

Material : Other, Mild Steel

Product Type : Vertical Saw

Iemca Vip 80 Barfeed

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Automatic feeding of bars to machine tools

Motor : AC Motor

Material : Other, Steel and Alloy

Product Type : Bar Feeder

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |