|

Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed

Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed Specification

- Product Type

- CNC Turning Center

- General Use

- Industrial Metal Turning

- Material

- Cast Iron, Alloy Steel

- Type

- Horizontal

- Capacity

- Bar Dia. up to 51 mm

- Weight (kg)

- 2500 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- PLC Control

- Yes

- Bar Feeder

- Included

- Power Source

- Electric

- Power Consumption

- 12 kW

- Rigidity

- High

- Voltage

- 380 V

- Motor

- AC Servo Motor

- Table Size

- Standard

- Spindle Speed

- 4500 rpm

- Axial Choice

- 2-Axis

- Dimension (L*W*H)

- 2200 mm x 1400 mm x 1700 mm

- Feature

- High Precision, Fast Cycle Time

- Color

- White & Grey

- Floor Type

- Mounted

- Safety Features

- Interlocked Doors, Emergency Stop

- CNC System

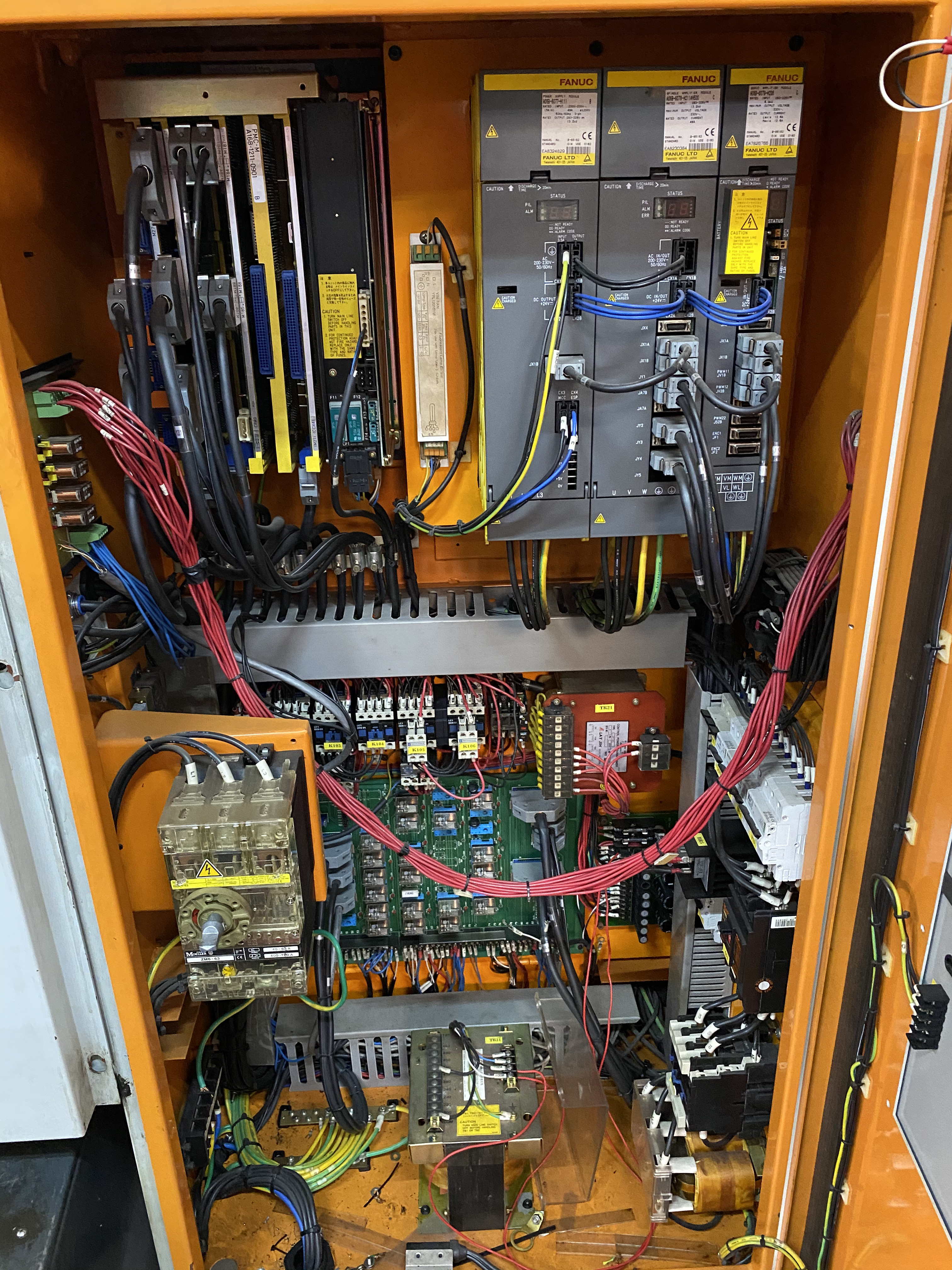

- Fanuc Oi-T

- Bar Feeding Length

- 1.5 meters

- Environment

- Suitable for Production Lines

- Operation

- Low Noise, Vibration Free

- Machine Construction

- Slant Bed

- Max Turning Diameter

- 200 mm

- Spindle Bore

- 54 mm

- Coolant System

- Integrated

- Control System

- Fanuc / Siemens

- Tailstock

- Programmable

- Input Frequency

- 50/60 Hz

- Repeatability

- ±0.008 mm

- Lubrication System

- Automatic Centralized

- Chuck Size

- 8 Inch

- Max Turning Length

- 350 mm

- Tool Turret

- 8 Station Turret

- Rapid Traverse

- 24 m/min (X Axis), 30 m/min (Z Axis)

- Installation Space Required

- 2600 mm x 1600 mm

About Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed

*Gildemeister LEADWELL CT 200 CNC TURNING CENTER WITH BARFEED*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 200 x 300 mm

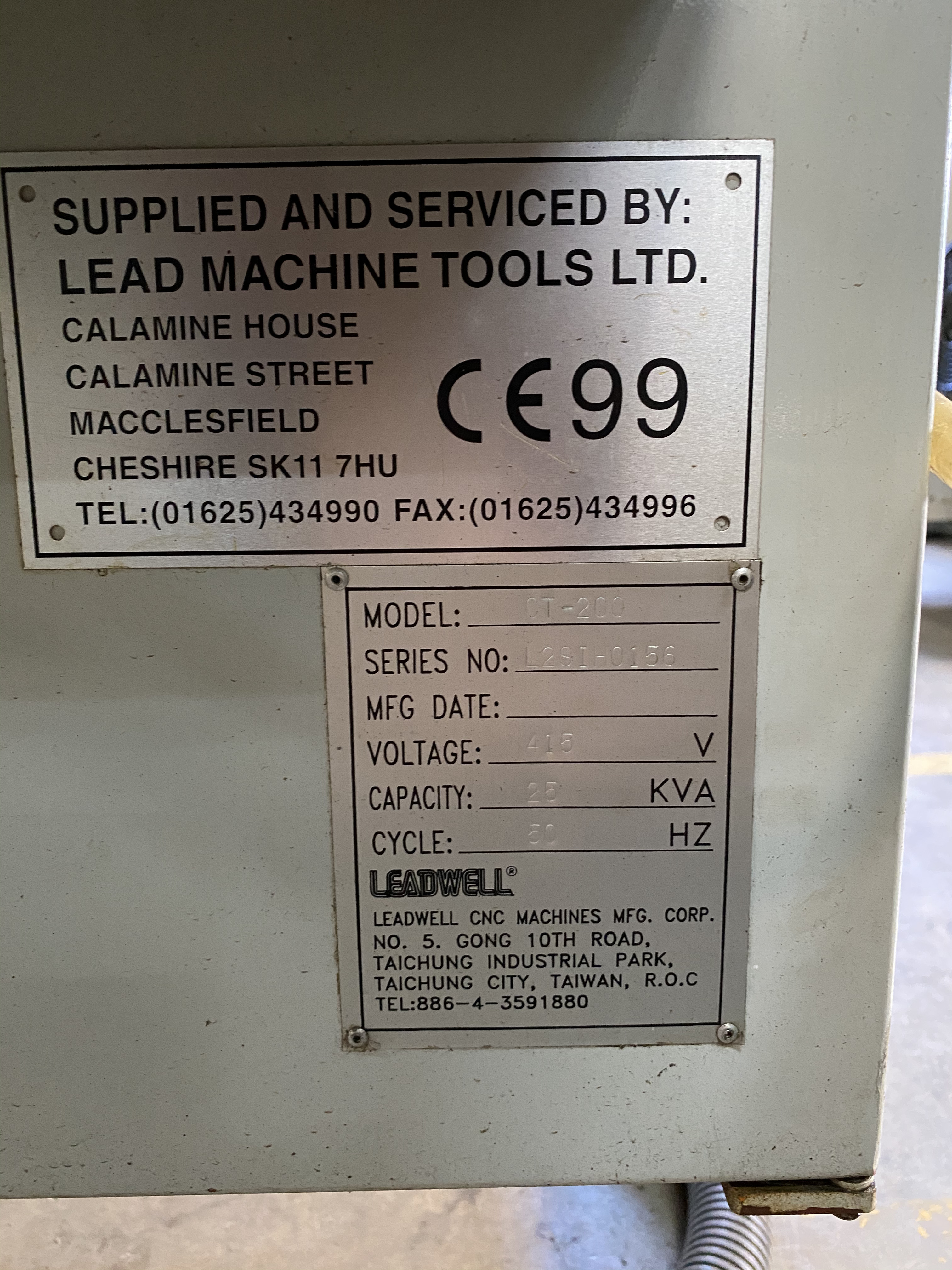

YEAR OF CONSTRUCTION : 1999

Reference No: 349

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 210 mm

Max Turning Length: 370 mm

Swing: 375 mm

Chuck Equipped: 200 mm (HOWA)

CNC

Control: Fanuc OT (Alpha Drives)

SPINDLE

Max Rotation Speed: 5000 RPM

Spindle Nose: A2-5

Spindle Bore: 42 mm

Spindle Motor Power: 7.5 kW

TAILSTOCK

Tailstock: Yes

TURRET

Turret: 8 Stations

Parts catcher / Tool setter / Hydrafeed magazine bar feed

Superior Precision and Efficiency

With high repeatability (0.008 mm), advanced control system, and a slant bed design, the Gildemeister Leadwell CT 200 CNC Turning Center ensures consistent, accurate machining. The integrated bar feeder and programmable tailstock streamline workflows, making it perfect for high-volume production lines.

Optimized for Industrial Demands

Engineered from robust cast iron and alloy steel, this turning center is tailored for intensive industrial use on production floors. Its fully automatic operation, low vibration, low noise profile, and energy-efficient 12 kW AC servo motor enhance performance while minimizing workplace disruption.

Comprehensive Safety and User-Friendly Features

Safety is paramount with features like interlocked doors and emergency stop systems. The CNCs user interfacepowered by Fanuc Oi-Tfacilitates easy programming and monitoring, while the automatic centralized lubrication and efficient coolant systems support extended, worry-free operation.

FAQs of Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed:

Q: How does the integrated bar feeder enhance the CNC turning process?

A: The integrated bar feeder accommodates materials up to 1.5 meters, allowing continuous, automatic feeding of bars up to 51 mm diameter. This eliminates manual loading, reduces downtime, and improves cycle time, making the turning center ideal for high-volume production.Q: What are the main benefits of the programmable tailstock?

A: The programmable tailstock provides precise support for long workpieces, reducing deflection and ensuring dimensional accuracy throughout the machining process. It can be automatically positioned, enhancing both efficiency and workpiece integrity.Q: When should I use the high-speed rapid traverse feature?

A: The rapid traverse speeds24 m/min for the X axis and 30 m/min for the Z axisare used when quickly positioning the turret between machining cycles, helping to significantly reduce non-cutting time and improving overall productivity.Q: Where is this CNC turning center best utilized?

A: This turning center is best suited for industrial environments, especially production lines requiring efficient, high-precision turning of cast iron and alloy steel. Its sturdy construction, automation, and safety features make it ideal for both exporters and suppliers in metalworking industries.Q: What materials can be machined using the Gildemeister Leadwell CT 200?

A: The machine is designed for high-precision turning of industrial metals, specifically cast iron and alloy steel, supporting a range of bar diameters up to 51 mm with a maximum turning length of 350 mm.Q: How does the machine ensure operator safety during operation?

A: Safety is ensured through features like interlocked doors, an emergency stop button, and robust construction. These mechanisms protect operators from moving parts and allow for immediate shutdown in case of emergencies.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Hardinge Conquest T51 Cnc Turn Mill Center

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power Consumption : 18 kW

General Use : Metal/Component Turning and Milling

Dimension (L*W*H) : 3200 mm x 1780 mm x 2050 mm

Cmz Tbi-480 Cnc Turning Center

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Consumption : 18 kW

General Use : Turning operations for metal parts

Dimension (L*W*H) : 3500 x 1850 x 2200 mm

Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Consumption : 22 kVA

General Use : Metal Turning, Milling, Drilling

Dimension (L*W*H) : 3600 x 2530 x 2270 mm

Mori Seiki Sl 5h CNC Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Consumption : ~30 kVA

General Use : Industrial Turning Operations

Dimension (L*W*H) : Approx. 4800 x 2200 x 2200 mm

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |