|

Pee Wee Thread Roller

Pee Wee Thread Roller Specification

- Product Type

- Thread Roller Machine

- General Use

- Thread Rolling

- Material

- High Grade Steel

- Type

- Two-Roll Thread Rolling Machine

- Capacity

- Up to 50 mm Diameter

- Weight (kg)

- 1500 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- Available (Optional)

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 2.2 kW

- Rigidity

- High

- Voltage

- 380 V

- Motor

- 3 HP

- Table Size

- Standard

- Spindle Speed

- 0-160 rpm

- Axial Choice

- Adjustable

- Dimension (L*W*H)

- 1280 x 1250 x 1230 mm

- Feature

- High Precision, Durable, Easy to Operate

- Color

- Green / Grey

- Roller Shaft Diameter

- 54 mm

- Application

- Fastener Manufacturing, Automotive, Engineering Components

- Roller Die Size

- 120 x 50 mm

- Noise Level

- Below 80 dB

- Safety Features

- Overload Protection, Emergency Stop

- Min Thread Diameter

- 5 mm

- Rolling Pressure

- Up to 12 Tons

- Coolant System

- Integrated

- Max Thread Length

- 70 mm

About Pee Wee Thread Roller

*PEE WEE THREAD ROLLER*

CATEGORY : MISCELLANEOUS

Reference No: 855

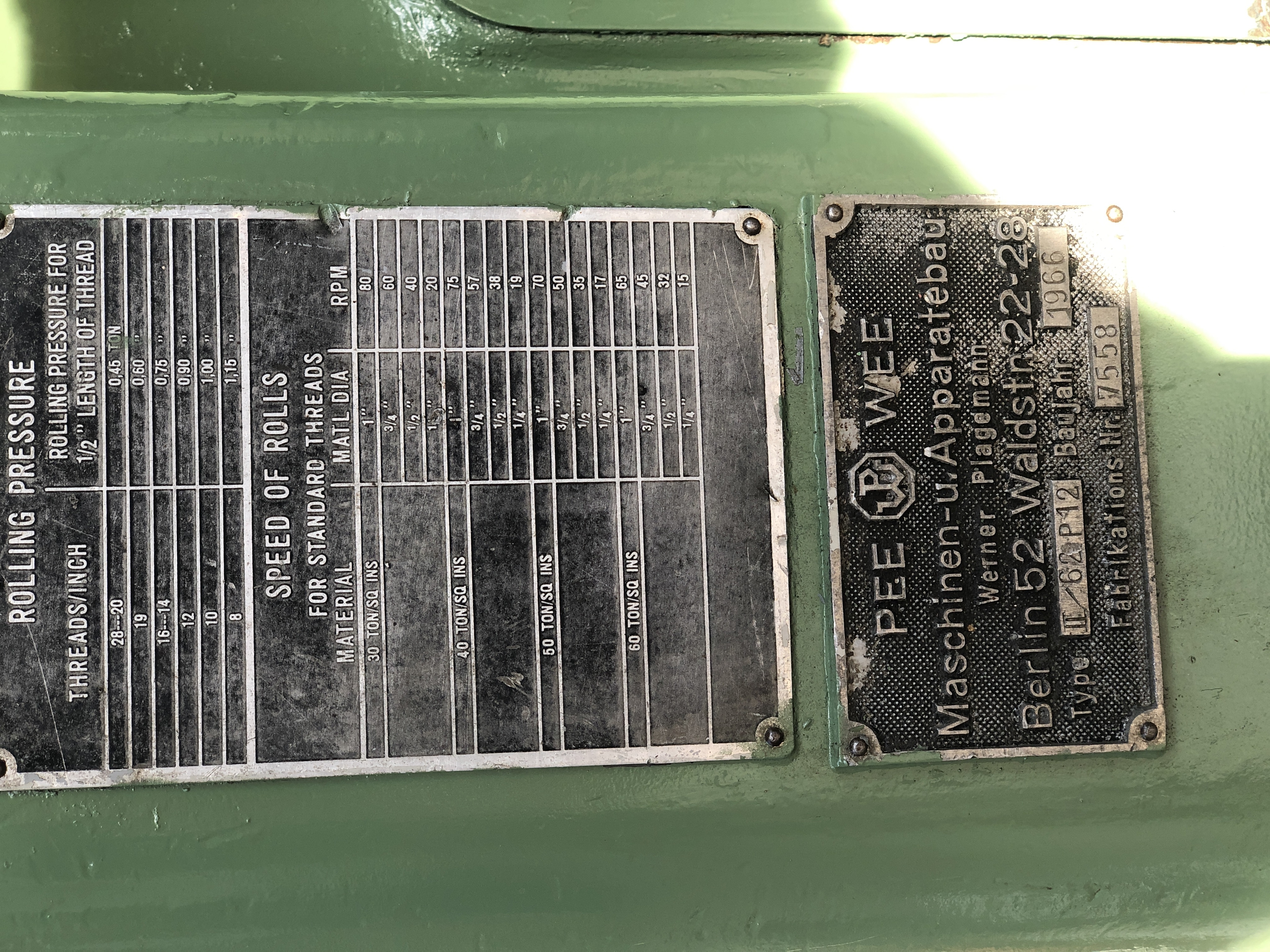

Technical Specifications:

Make: PEE-WEE

Type: II/62-P12

diameter range: 12 50 mm

Forging power: 12 t

thread length plunge method: 130 mm

max. pitch: 3mm

roller width: 160 mm

roller bore: 54 mm

rpm: 18-100

Precision Thread Rolling for Demanding Applications

Engineered for fastener manufacturing, automotive, and engineering component production, the Pee Wee Thread Roller ensures consistently high-quality threads on parts up to 70 mm long and 50 mm in diameter. Its durable construction and high-precision operation are ideal for both small workshops and industrial facilities seeking reliability and efficiency.

Safety and Efficiency Combined

Operator safety is paramount, thanks to features like overload protection and an emergency stop. With a noise level below 80 dB and integrated coolant system, the machine minimizes workplace hazards and ensures smooth, quiet processing. Rigid construction prevents vibration, supporting longevity and trouble-free operation.

Flexible Operation and Customization Options

Users can take advantage of adjustable axial settings and optional PLC controls for enhanced flexibility. The optional bar feeder further streamlines batch processing, making the Pee Wee Thread Roller suitable for small runs as well as high-production environments. Its user-friendly design promotes easy setup and operation.

FAQ's of Pee Wee Thread Roller:

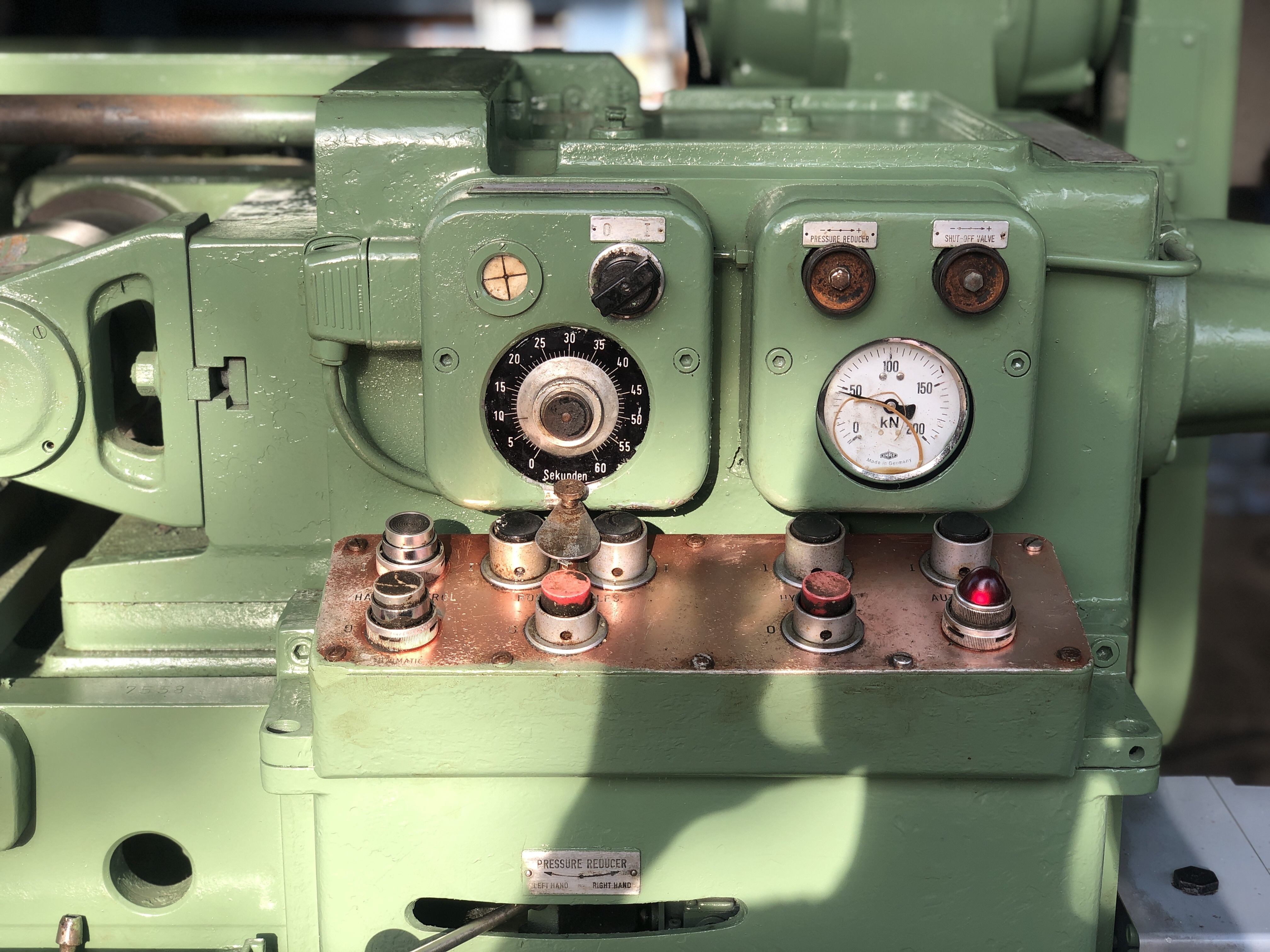

Q: How is the Pee Wee Thread Roller operated and what is its level of automation?

A: The machine is semi-automatic and features user-friendly controls. Operators can also opt for PLC control for advanced automation, making it easy to use for both skilled and less experienced workers.Q: What types of threads and materials can this thread roller process?

A: Designed for fastener manufacturing and engineering applications, it can roll threads on components made from high-grade steel ranging from 5 mm up to 50 mm in diameter and up to 70 mm in length.Q: When should the integrated coolant system be used during operation?

A: The integrated coolant system should be used during all rolling operations to prevent overheating, reduce tool wear, and ensure high-quality thread formation on every workpiece.Q: Where can this machine be installed and used effectively?

A: With dimensions of 1280 x 1250 x 1230 mm and a noise level below 80 dB, the machine is suitable for both large manufacturing facilities and smaller workshops focused on precision part production.Q: What safety features are included with the Pee Wee Thread Roller?

A: Safety is ensured with built-in overload protection and an emergency stop button, safeguarding users and machinery during unexpected situations or excessive loads.Q: What is the process for adjusting the axial setting on this machine?

A: The axial setting can be easily adjusted using the provided controls. This enables precise thread rolling suited to various part specifications and production requirements.Q: What are the main benefits of using this thread rolling machine?

A: The Pee Wee Thread Roller offers high precision, exceptional durability, and ease of operation. Its integrated coolant system, safety mechanisms, and optional features make it an efficient solution for consistent thread quality and production throughput.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Category

Delapena Speed Hone Precision Honing Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

PLC Control : No

Weight (kg) : 350 kg

Material : Other, Mild Steel Body

Raybrook 300 Precision Honing Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

PLC Control : Other, Available

Weight (kg) : 1200 kg

Material : Other, Cast Iron, Mild Steel

Delapena Speed Hone Precision Honing Machine 2

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

PLC Control : No

Weight (kg) : Approx. 260 kg

Material : Other, Mild Steel Frame

Midsaw Vertical Saw

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

PLC Control : Other, Optional

Weight (kg) : 950 kg

Material : Other, Mild Steel

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |