|

Hardinge Conquest Sp Cnc Turning Center

Hardinge Conquest Sp Cnc Turning Center Specification

- Product Type

- CNC Turning Center

- General Use

- Metalworking / Industrial production

- Material

- Cast iron base, steel components

- Type

- Horizontal Turning Center

- Capacity

- Max turning diameter 250 mm; Max turning length 350 mm

- Weight (kg)

- Approx. 3200 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Included

- Power Source

- Electric

- Power Consumption

- 11 kVA

- Rigidity

- High rigidity structure designed for precision machining

- Voltage

- 220-415 V

- Motor

- Spindle Motor 7.5/11 kW

- Spindle Speed

- 50 5000 RPM

- Axial Choice

- 2-Axis (X, Z)

- Dimension (L*W*H)

- 2200 x 1600 x 1750 mm

- Feature

- High precision, automated operation, robust structure

- Color

- Standard Hardinge gray/blue

- Hydraulic System

- Integrated hydraulic power pack

- Repeatability

- ±2.5 micron

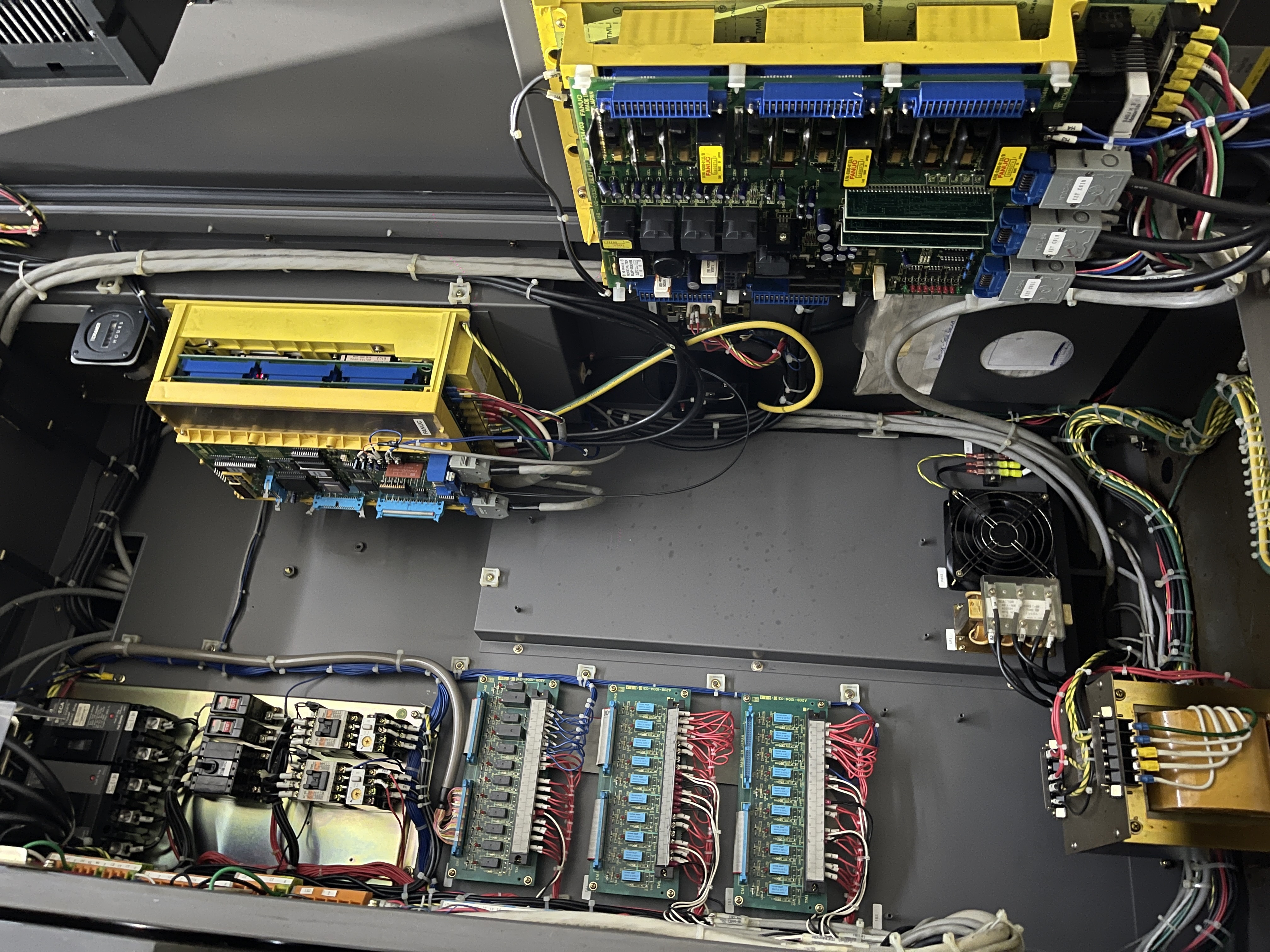

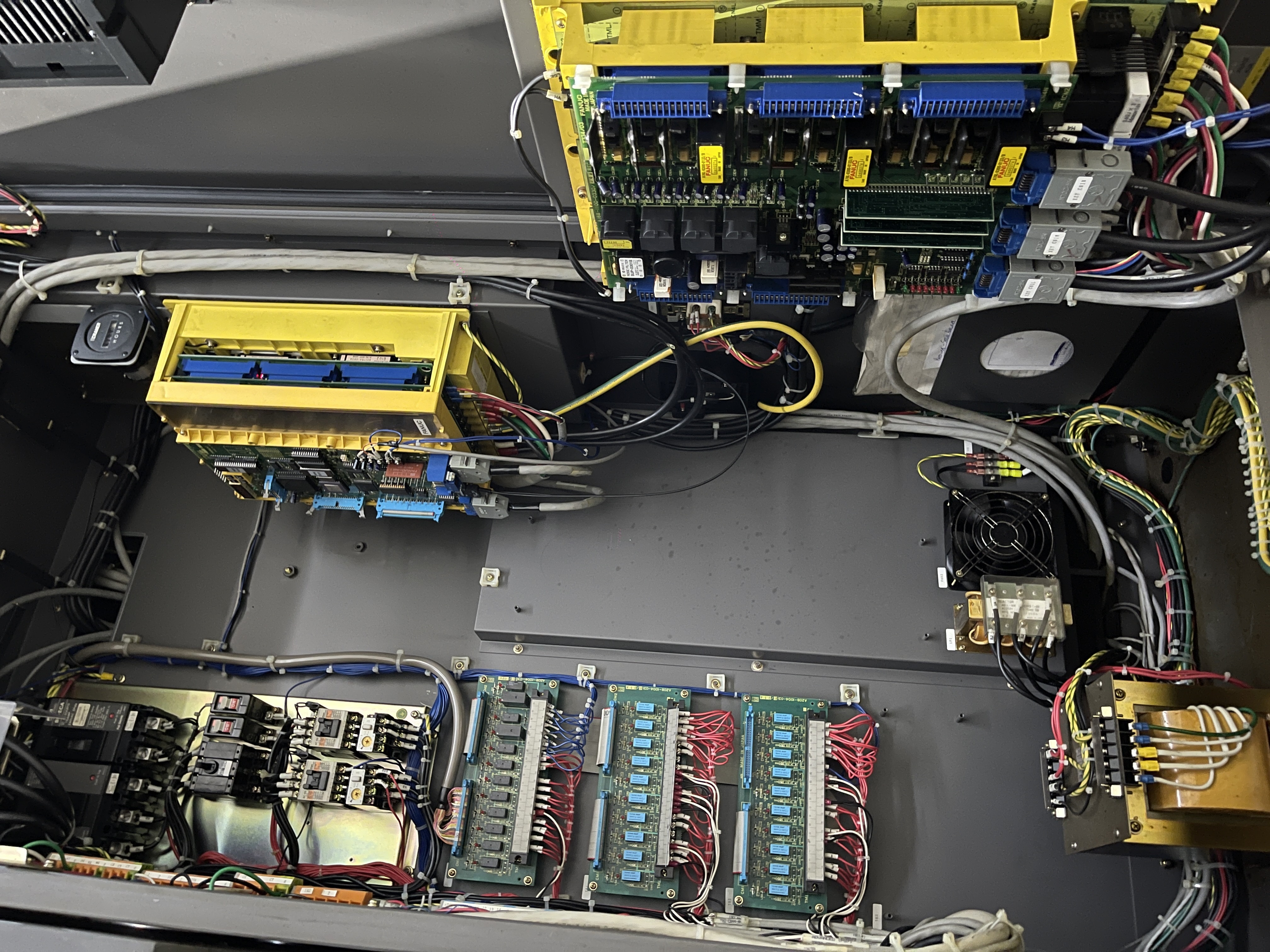

- Controller

- Fanuc CNC Control

- Max Bar Capacity

- 51 mm

- Floor Space Required

- 2500 x 1750 mm

- Operating Interface

- Touchscreen and manual switches

- Coolant System

- High-pressure coolant system included

- Rapid Traverse Rate

- X: 24 m/min, Z: 30 m/min

- Safety Features

- Interlocked guarding, emergency stop, overload protection

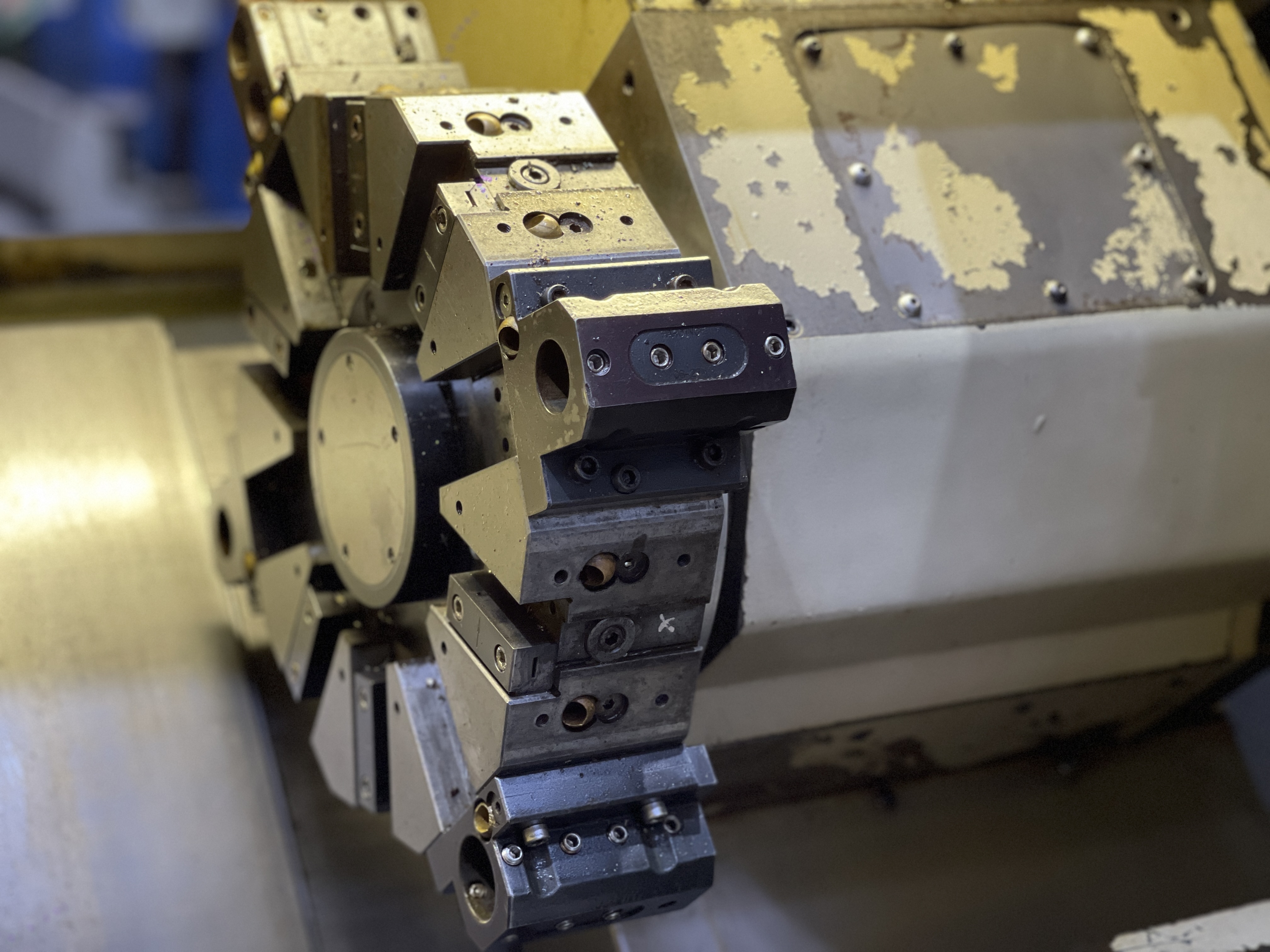

- Chuck Size

- 200 mm (8 inch)

- Lubrication System

- Automatic centralized lubrication

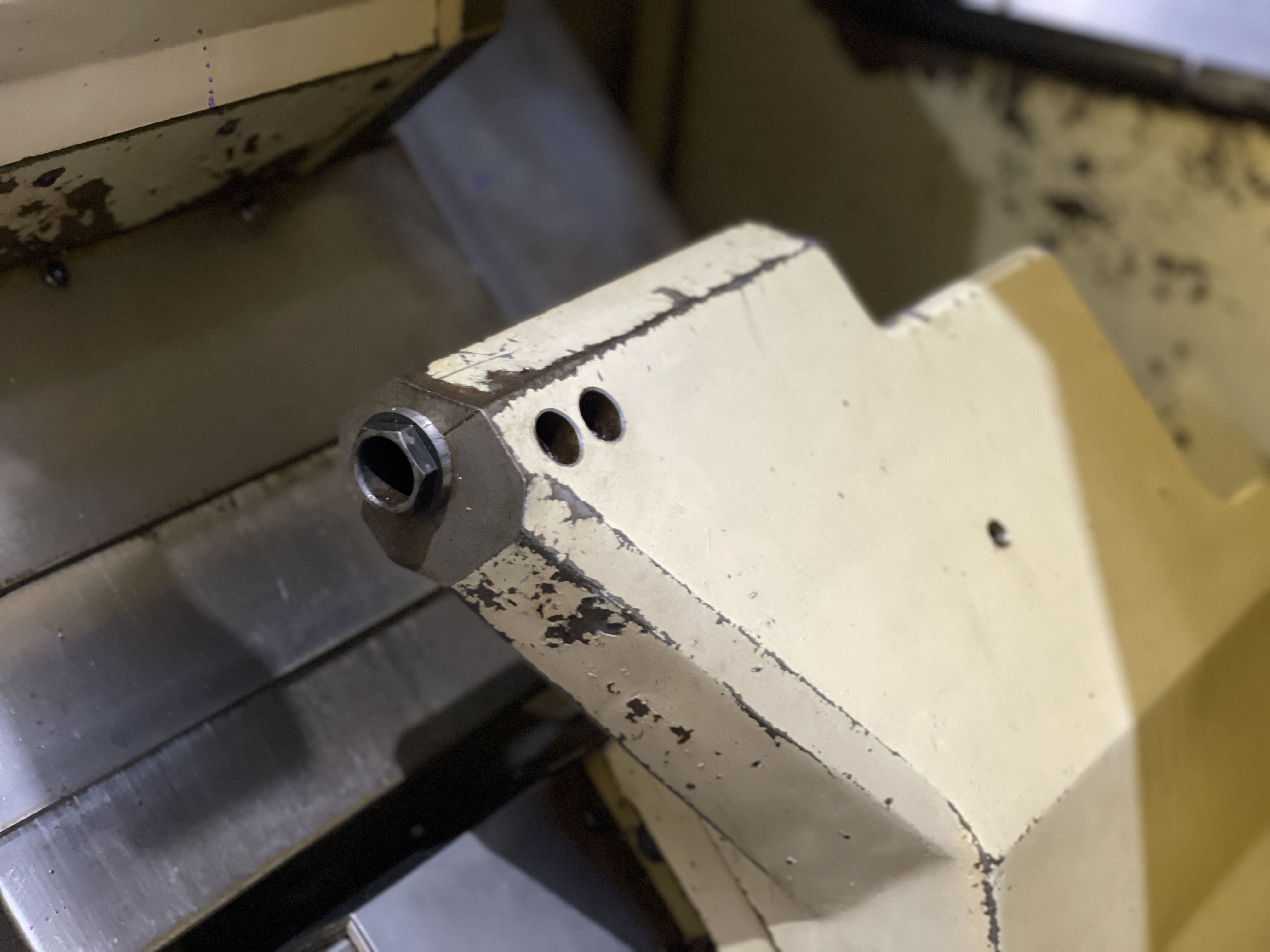

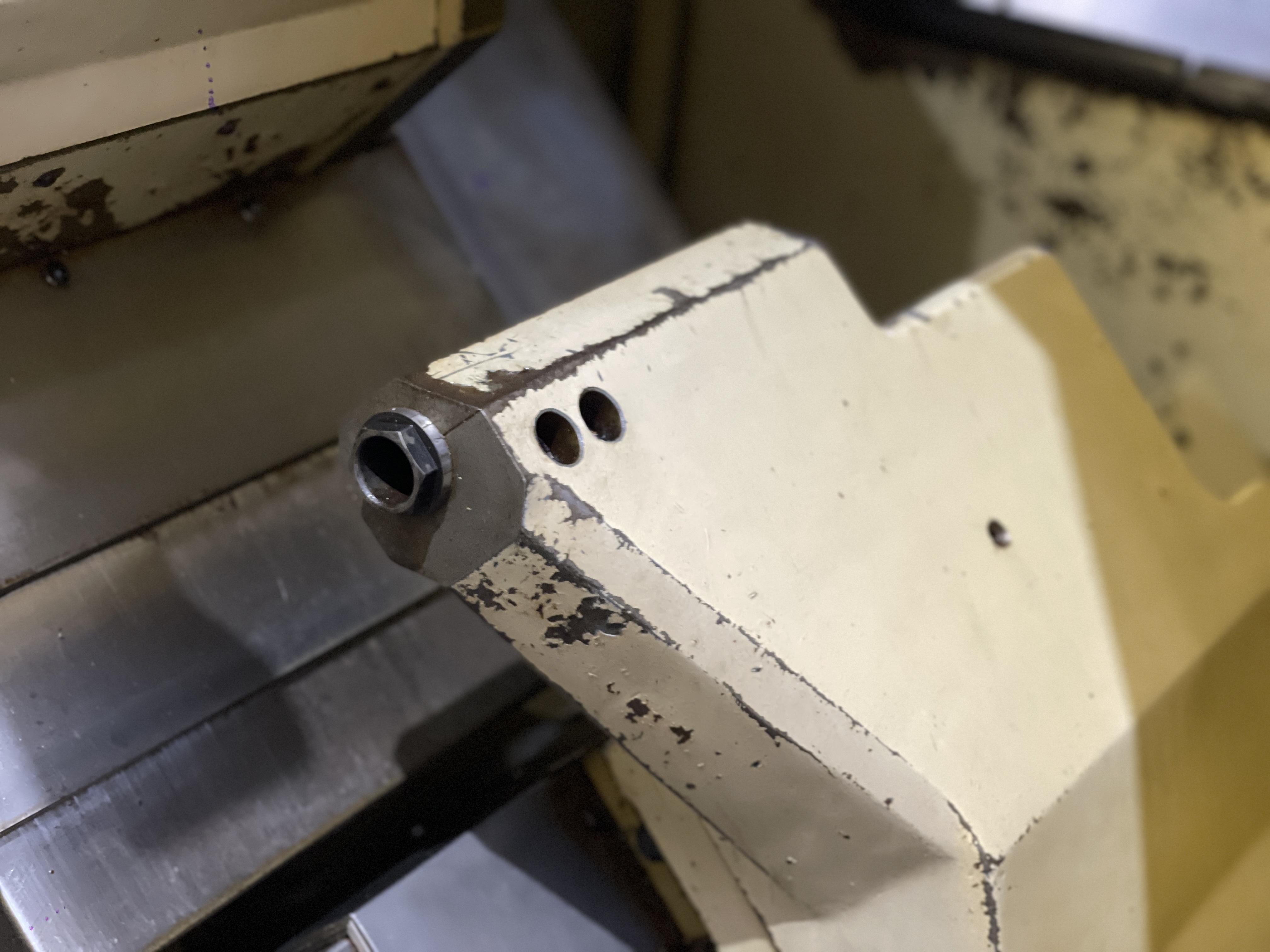

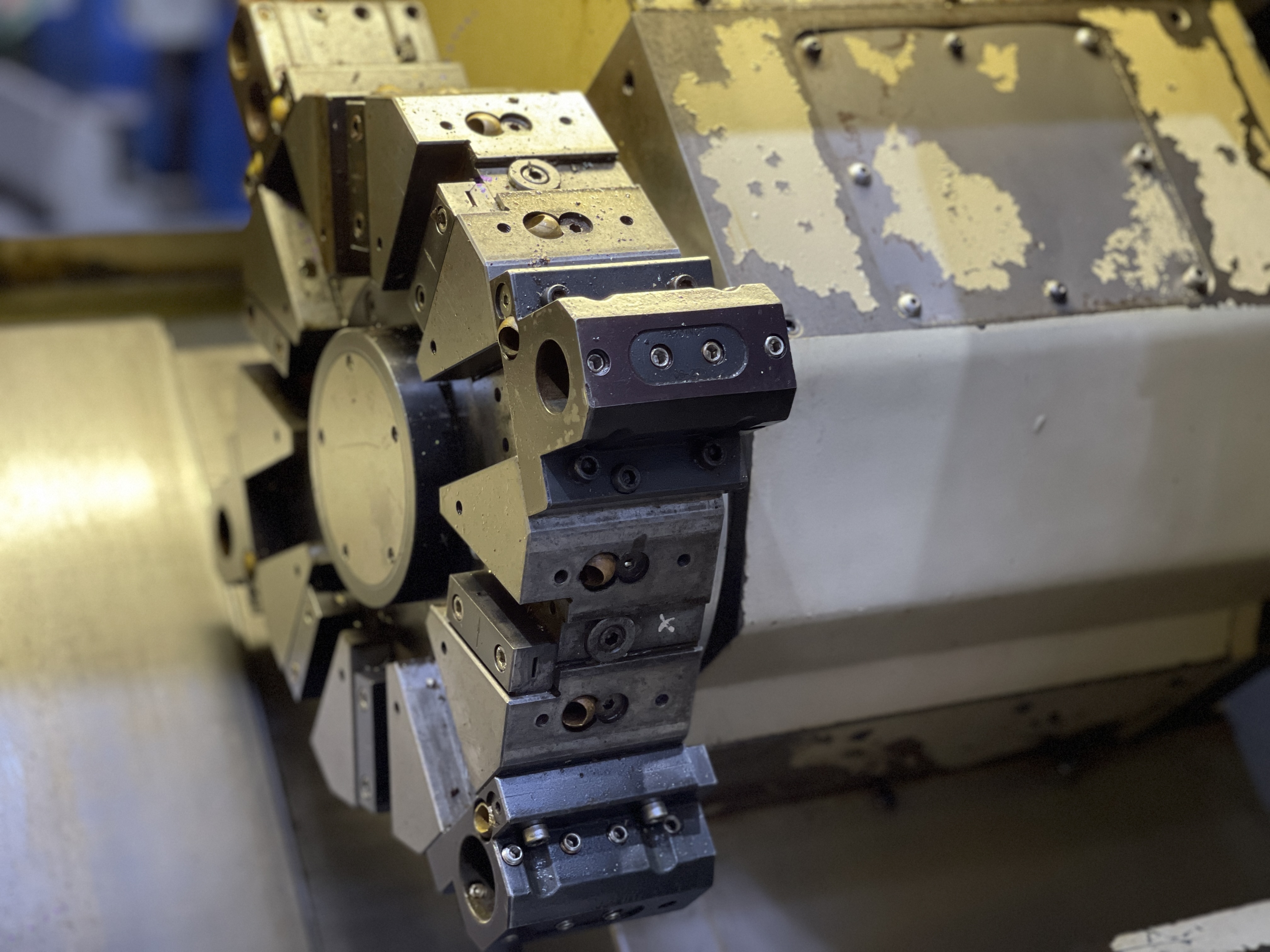

- Tool Turret

- 12-station turret

- Tailstock

- Programmable

About Hardinge Conquest Sp Cnc Turning Center

*HARDINGE CONQUEST SP CNC TURNING CENTER*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 230 x 350 mm

YEAR OF CONSTRUCTION : 1995

Reference No: 2944

Video Link: https://youtu.be/JWS-OeGvnT8

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 230 mm

Max Turning Length: 350 mm

Distance Between Centers: 350 mm

Chuck Equipped: 165 mm

Travels (X / Z): 135 / 350 mm

CNC

Control: Fanuc OT

SPINDLE

Spindle Bore: 42 mm

Spindle Nose: A2-5

Spindle RPM: 5000 TBC

Spindle Power: 7.5kW

TURRET

Turret: 10 Stations

Engineered for Precision and Efficiency

The Hardinge Conquest SP CNC Turning Center boasts precise repeatability and rapid traverse speeds, ensuring consistent high-quality results. Its high rigidity structure minimizes vibration, optimizing dimensional accuracy. This automated system, equipped with a programmable tailstock and a 12-station turret, streamlines tooling changes and maximizes productivity for demanding metalworking tasks.

User-Friendly Interface and Automation

Featuring an intuitive touchscreen control alongside manual switches, operators can efficiently program and monitor production. The integrated PLC and Fanuc CNC controller provide extensive customization for various machining processes. Automated systems like centralized lubrication, bar feeder, and high-pressure coolant enhance reliability during continuous operation.

FAQ's of Hardinge Conquest Sp Cnc Turning Center:

Q: How does the Hardinge Conquest SP CNC Turning Center improve machining accuracy?

A: It achieves high accuracy through its rigid cast iron base, precise Fanuc CNC control, and repeatability of 2.5 micron, enabling consistent production of complex components with tight tolerances.Q: What materials can be processed with this CNC turning center?

A: The machine is designed for processing metal components in industrial environments, suitable for a range of ferrous and non-ferrous metals, thanks to its robust construction and high-power spindle motor.Q: When is it optimal to use the automated features such as the bar feeder and programmable tailstock?

A: Automated features like the bar feeder and programmable tailstock are best utilized during high-volume, repetitive production cycles, minimizing manual intervention and boosting overall throughput.Q: Where can the Hardinge Conquest SP CNC Turning Center be installed?

A: Its compact footprint of 2200 x 1600 x 1750 mm makes it suitable for installation in industrial workshops, metalworking facilities, and manufacturing plants across India and worldwide.Q: What is the process for setting up different tool configurations on the 12-station turret?

A: Tooling setups can be quickly changed by programming the turret for different operations. The Fanuc CNC controller streamlines the process, allowing users to customize tool arrangements for various turning tasks.Q: How is safety maintained during operation?

A: Safety is prioritized through interlocked guarding, emergency stop features, and overload protection, which ensure operator security and prevent equipment damage during operation.Q: What benefits does the high-pressure coolant system offer?

A: The high-pressure coolant system effectively manages heat dissipation, improves chip removal, and extends tool life, resulting in smoother finishes and increased machining efficiency.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Mori Seiki Sl-25 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Horizontal CNC Lathe

Automatic : Yes

Color : Other, White & Blue

Feature : Other, Fanuc control, high precision, quick tool change

Tsugami Bs26 Cnc Sliding Head

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, CNC Automatic Lathe

Automatic : Other, Fully automatic operation

Color : Other, Standard industrial gray

Feature : Other, Automatic operation, high precision, fast cycle time, multitool turret

Nakamura Tome Tmc-4 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Horizontal lathe

Automatic : Yes

Color : Other, White & Blue

Feature : Other, Automatic operation, high precision turning

Colchester Tornado 100 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Horizontal CNC Lathe

Automatic : Yes

Color : Other, Industrial Grey/Blue

Feature : Other, High Precision, Compact Design, UserFriendly Interface

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |