|

Mori Seiki Sl 80 Cnc Lathe

Mori Seiki Sl 80 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Turning Operations, Heavy-Duty Machining

- Material

- Cast Iron Body, Steel Components

- Type

- Horizontal CNC Turning Center

- Capacity

- Swing Over Bed: 1100 mm, Max Turning Diameter: 900 mm, Max Turning Length: 2000 mm

- Weight (kg)

- Approx 26000 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 38 kVA

- Rigidity

- High Rigidity Construction

- Voltage

- 400V / 50 Hz

- Motor

- Spindle Motor AC 55 kW

- Spindle Speed

- Max 750 RPM

- Axial Choice

- 2 Axis (X, Z)

- Dimension (L*W*H)

- 6562 mm x 3400 mm x 3540 mm

- Feature

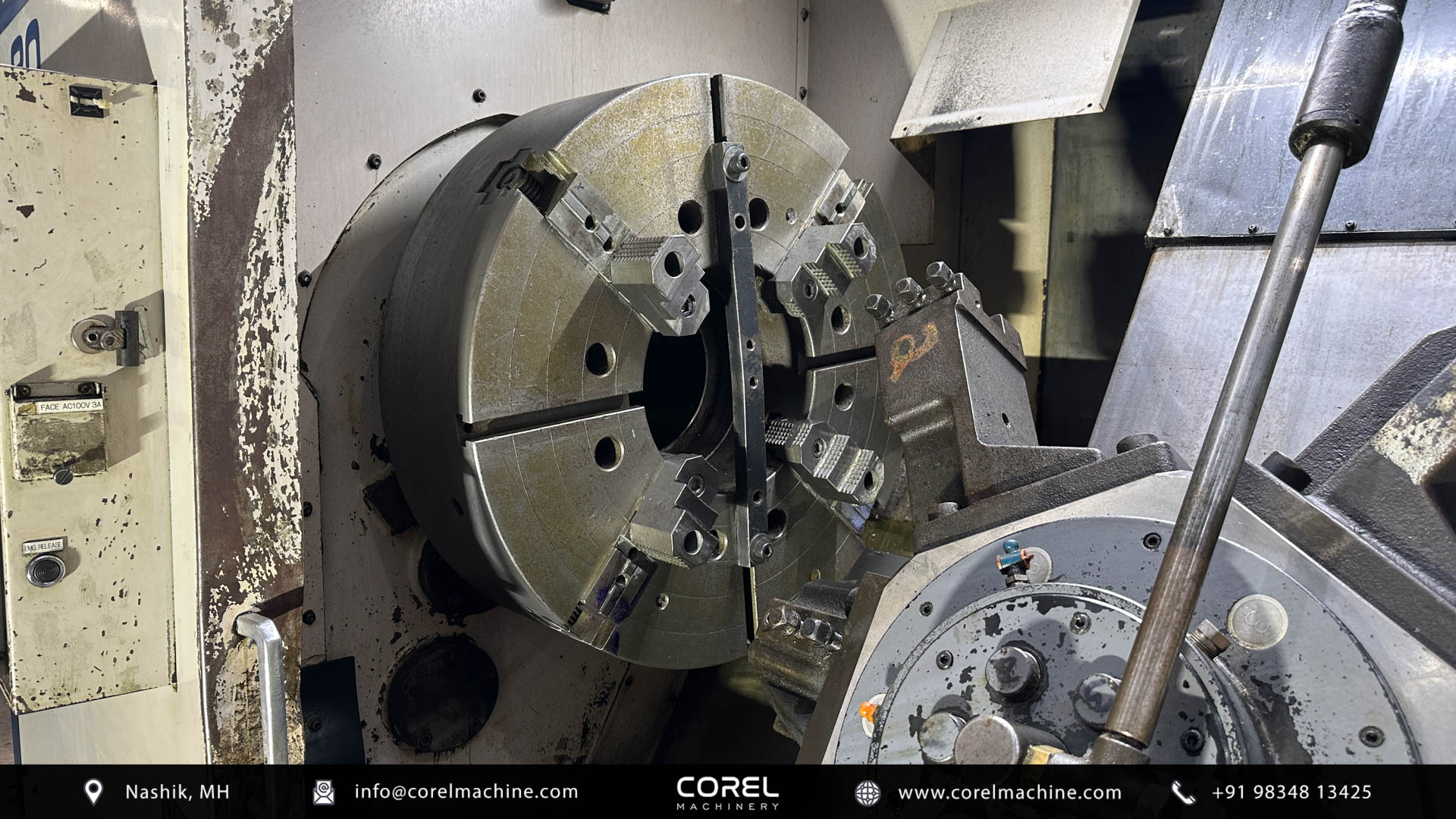

- Heavy Duty Cutting, Precision Turning, Hydraulic Chuck

- Color

- Standard Industrial Grey

- Noise Level

- Low Noise Operation (as per industrial standards)

- Coolant System

- Standard High Pressure

- Hydraulic System

- Integrated, Industrial Grade

- Rapid Traverse Rate (X/Z)

- 8/10 m/min

- Tool Holders

- Heavy Duty

- Bed Width

- 900 mm

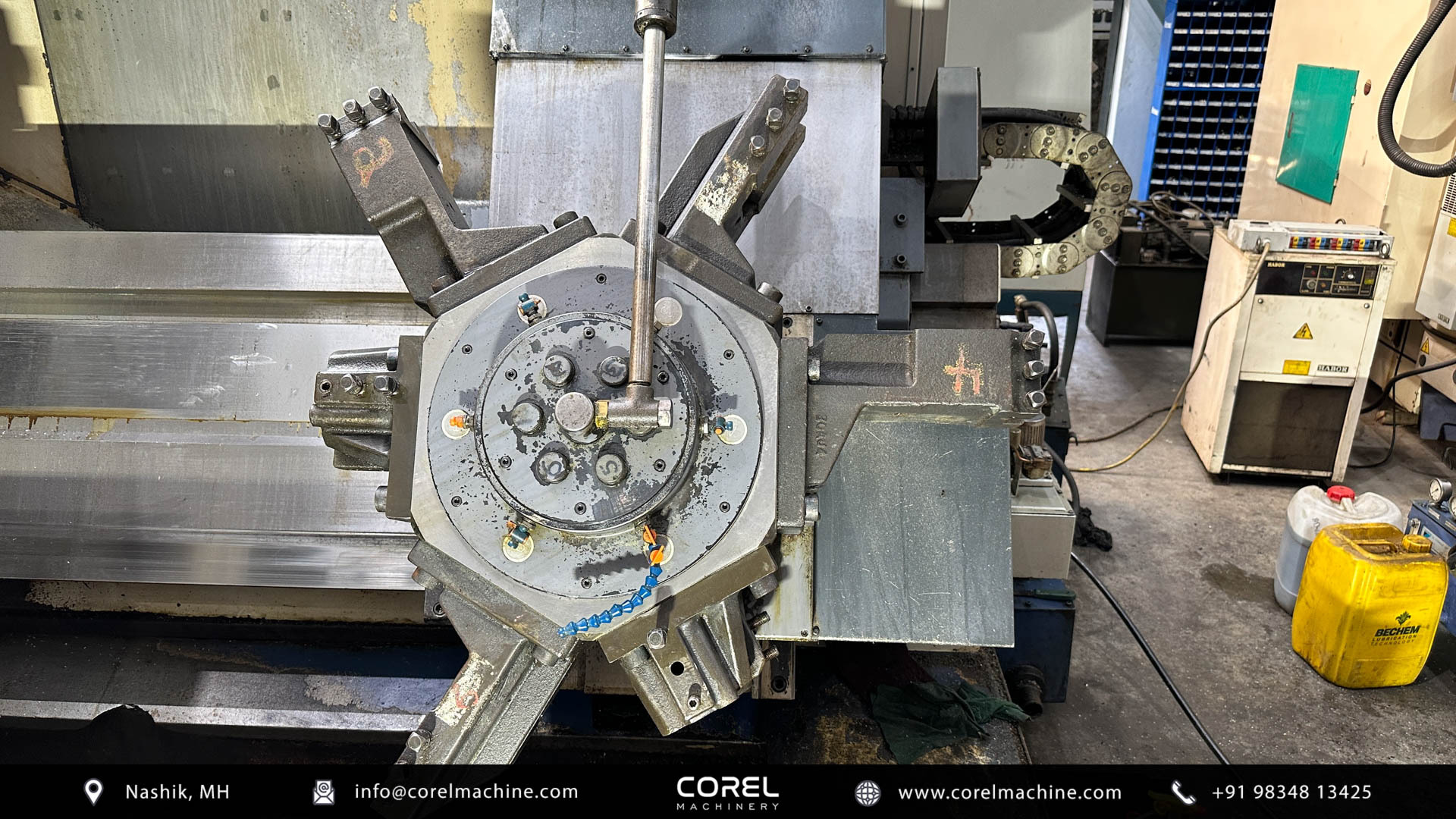

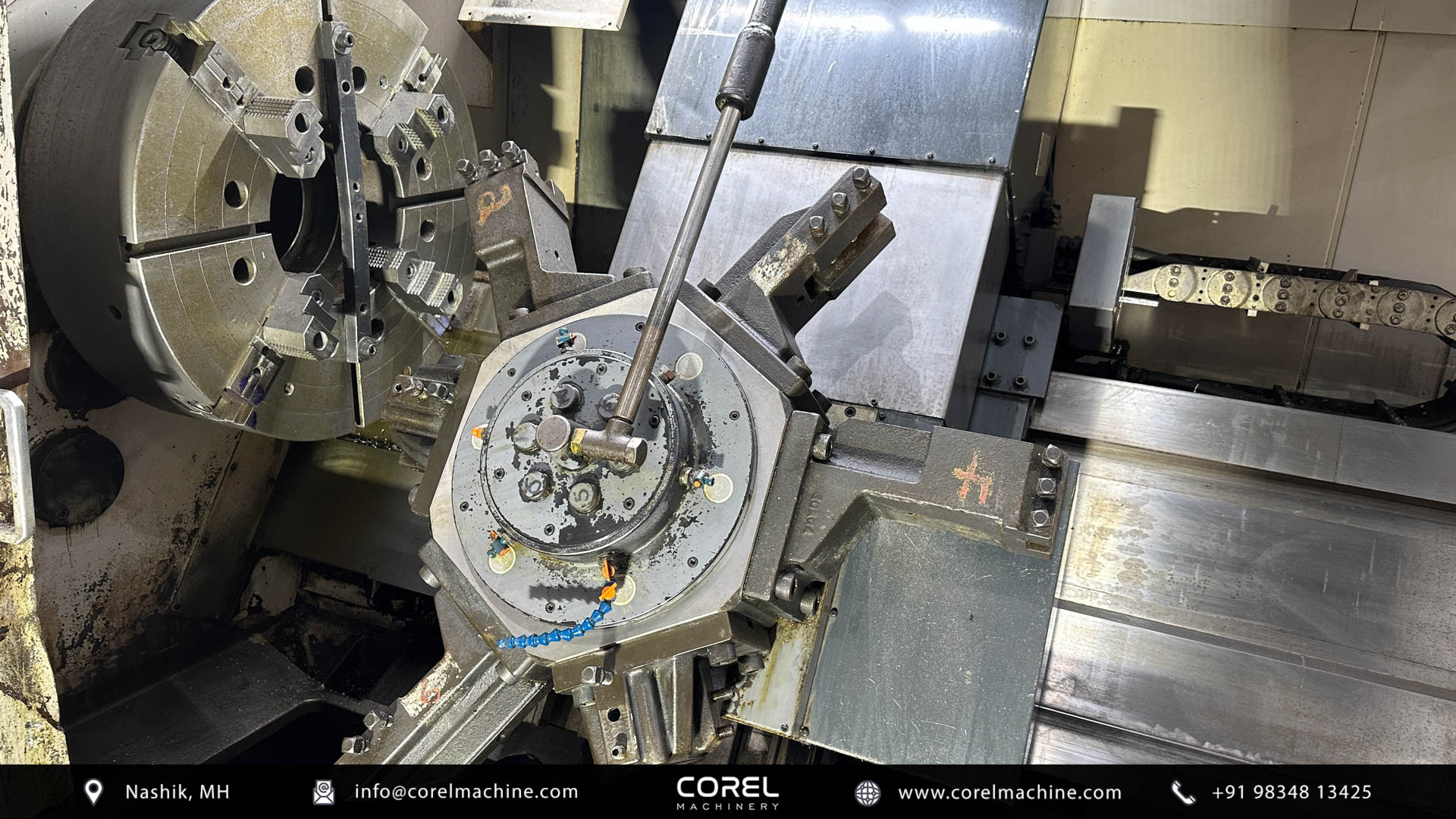

- Turret

- 12-Station Automatic Turret

- Lubrication System

- Automated Centralized

- Safety Features

- Emergency Stop, Interlock Door, Overload Protection

- Chuck Size

- 32 inch (800 mm)

- Tailstock

- Programmable, Heavy Duty

- Control Unit

- FANUC CNC Control System

- Spindle Bore

- 355 mm

About Mori Seiki Sl 80 Cnc Lathe

*MORI SEIKI SL 80 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 900 x 250 mm

YEAR OF CONSTRUCTION : 1990

Reference No: 5311

Video Link: https://youtu.be/pdUqsj0msBs

Technical Specifications:

37/45 kW Spindle Motor

32 Chuck

Specs Sheet Attached

High-Capacity Precision Turning

The Mori Seiki SL 80 excels in heavy-duty turning and precise machining tasks. With a maximum turning diameter of 900 mm and swing over bed of 1100 mm, it can handle large workpieces efficiently. The advanced FANUC CNC control ensures accurate performance for both high-volume and custom production runs.

Engineered for Industrial Demands

Designed with industrial standards in mind, this lathe combines durability, a high-rigidity cast iron body, and a 38 kVA power consumption. Its automated features, from centralized lubrication to high-pressure coolant delivery, streamline operations, minimize maintenance, and enhance productivity in any manufacturing setting.

FAQ's of Mori Seiki Sl 80 Cnc Lathe:

Q: How does the FANUC CNC control enhance the operation of the Mori Seiki SL 80 lathe?

A: The FANUC CNC control system provides precise, real-time management of all machine functions. This advanced controller improves machining accuracy, optimizes tool paths, and offers intuitive programming, making operations user-friendly and efficient, even during complex or high-volume production.Q: What materials can be machined on the Mori Seiki SL 80 CNC lathe?

A: Thanks to its heavy-duty construction and powerful spindle motor, the SL 80 can process a wide range of materials, including steel, cast iron, and various hard alloys. This versatility makes it ideal for industries requiring robust turning solutions for tough or oversized components.Q: When should the automated lubrication and high-pressure coolant systems be maintained?

A: Both the automated centralized lubrication and the high-pressure coolant systems are designed for continuous industrial use, requiring minimal manual intervention. However, regular maintenance as specified in the operator's manual - typically every few thousand operational hours - will ensure optimal functioning and extend the machine's lifespan.Q: Where can this CNC lathe be installed, and what are the installation requirements?

A: The Mori Seiki SL 80 is best suited to factories, machine shops, or manufacturing plants with sufficient space to accommodate its large dimensions (6562 mm x 3400 mm x 3540 mm) and a stable power supply (400V, 50Hz). A reinforced foundation is recommended due to its weight and operational demands.Q: What is the process for changing tools on the 12-station automatic turret?

A: Tool changes are performed automatically by the 12-station turret, controlled through the FANUC CNC system. Operators can pre-program tool sequences, significantly reducing downtime and manual handling, which boosts productivity and machining precision.Q: How does the programmable tailstock benefit heavy-duty turning operations?

A: The programmable tailstock provides additional support for long or heavy workpieces during turning. It can be precisely positioned via the control system, ensuring optimal alignment and minimizing deflection or vibration, which is especially critical in heavy-duty and precision machining.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Cmz Tbi-480 Cnc Turning Center

Minimum Order Quantity : 1 Piece

Color : Other, White/Grey

Motor : Other, Main spindle motor: 22 kW

Automatic : Yes

Spindle Speed : 3000 rpm

Microsprint 50

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Green / White

Motor : Other, Induction Motor

Automatic : Yes

Spindle Speed : Up to 6000 RPM

Citizen B20 Cnc Sliding Head

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White & Grey

Motor : Other, AC Servo Motor

Automatic : Other, Fully automatic operation

Spindle Speed : Max 10,000 rpm

Schiess Germany Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Blue and Grey

Motor : Other, Siemens AC Spindle Motor

Automatic : Yes

Spindle Speed : 4~315 rpm

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |