|

Colchester Tornado 100 Cnc Lathe

Colchester Tornado 100 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Turning, Threading, Facing, Boring

- Material

- Cast Iron Base, Steel Components

- Type

- Horizontal CNC Lathe

- Capacity

- Maximum Turning Diameter 210 mm

- Weight (kg)

- 2100

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 7.5 kW

- Rigidity

- High

- Voltage

- 400 V

- Motor

- Main Spindle 7.5 kW

- Spindle Speed

- 50-5000 rpm

- Axial Choice

- 2 Axis (X/Z)

- Dimension (L*W*H)

- 1950 x 1450 x 1700 mm

- Feature

- High Precision, Compact Design, User-Friendly Interface

- Color

- Industrial Grey/Blue

- Application

- Automotive, Aerospace, General Engineering

- Tailstock

- Optional

- Swing Over Bed

- 350 mm

- Noise Level

- < 78 dB

- Hydraulic System

- Standard

- Z-Axis Travel

- 300 mm

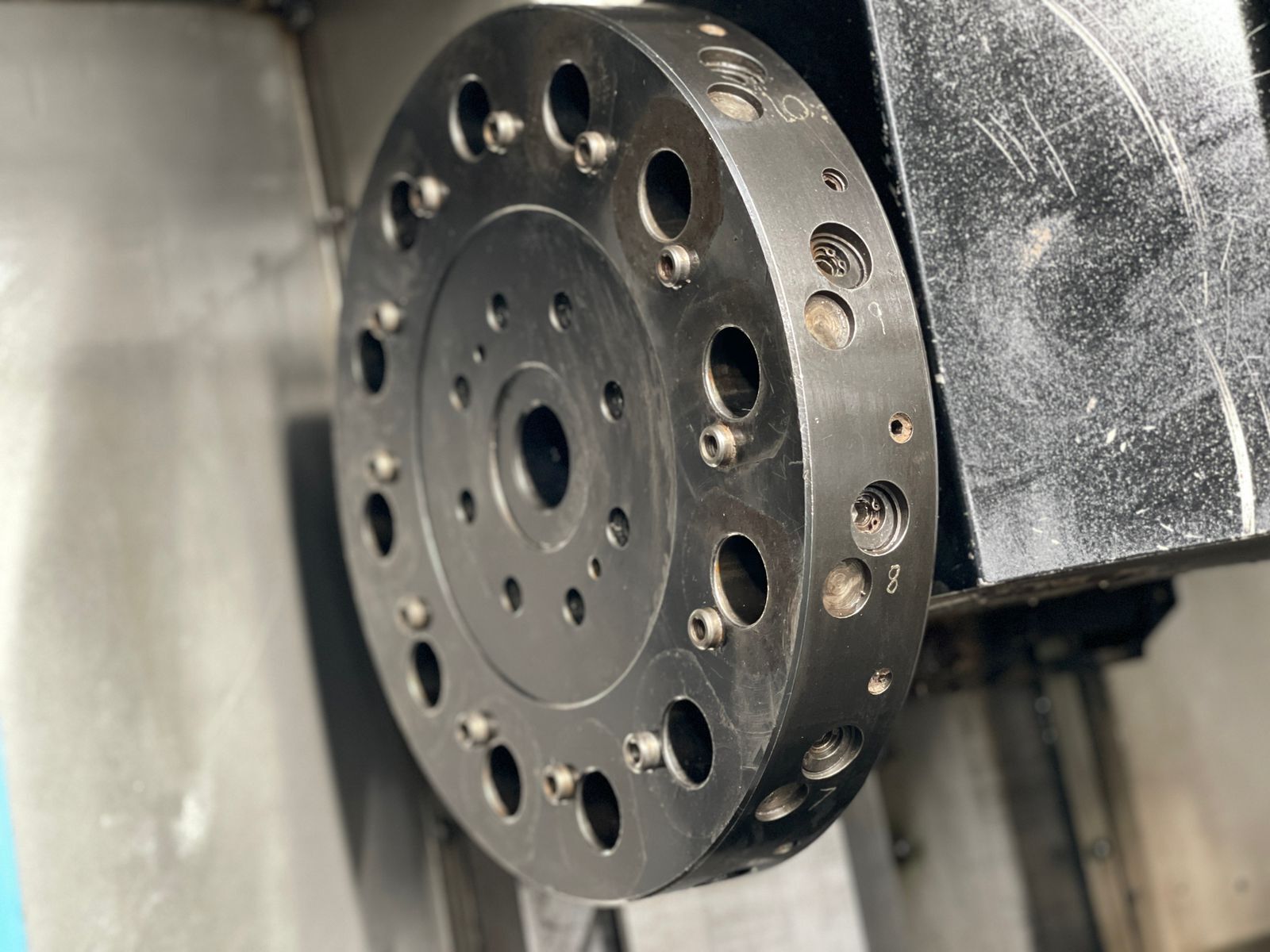

- Turret Stations

- 8-Station Turret

- X-Axis Travel

- 150 mm

- Spindle Bore

- 42 mm

- Max Turning Length

- 300 mm

- Controller

- Fanuc / Siemens CNC

- Distance Between Centers

- 450 mm

- Coolant System

- Yes

- Rapid Traverse Rate

- 24 m/min (X/Z)

- Lubrication System

- Automatic

- Chuck Size

- 150 mm

About Colchester Tornado 100 Cnc Lathe

*COLCHESTER TORNADO 100 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 186 x 350 mm

YEAR OF CONSTRUCTION : 1996

Reference No: 2315

Video Link: https://youtu.be/rdkUYHnrX-Y

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 186 mm

Max Turning Length: 350 mm

Swing: 420 mm

Distance Between Centers: 380 mm

Travels (X / Z): 180 / 350 mm

Rapid Travels (X/Z): 10/15 m/min

CNC

Control: Fanuc OT (Alpha Drives)

SPINDLE

Max Rotation Speed: 4000 RPM

Spindle Nose: A2-5

Spindle Bore: 61 mm

Spindle Motor Power: 5.5 / 7.5 kW

TAILSTOCK

Tailstock: Yes

TURRET

Turret: 12 Stations (VDI 30)

Machine Dimensions

Weight: 2.5T

Floor Space: 2.98 Sq. Meter

High Precision Engineering

The Colchester Tornado 100 CNC Lathe is built for reliability and high-precision machining. Its robust cast iron base, steel components, and high rigidity design ensure stability and accuracy during extended operations, making it the preferred choice for intricate turning tasks in demanding industries.

User-Friendly Controls

Featuring CNC control options from Fanuc or Siemens, this lathe offers a user-friendly interface for seamless programming and operation. PLC control and automatic features such as lubrication simplify processes, reduce manual intervention, and deliver consistent, high-quality results.

Versatile Applications

Engineered for automotive, aerospace, and general engineering applications, the Tornado 100 handles a diverse range of materials and machining tasks. Its 8-station turret, optional bar feeder, and range of spindle speeds empower users to perform turning, threading, and boring with efficiency and precision.

FAQ's of Colchester Tornado 100 Cnc Lathe:

Q: How does the automatic lubrication system benefit daily operation?

A: The automatic lubrication system ensures continuous and optimal lubrication of moving parts, reducing maintenance requirements, extending component lifespan, and preventing operational interruptions.Q: What materials can be processed with the Colchester Tornado 100 CNC Lathe?

A: Constructed with a rigid cast iron base and steel components, the lathe is designed to machine a variety of materials commonly used in automotive, aerospace, and general engineering applications, such as steel, aluminum, and certain non-ferrous metals.Q: When is it recommended to use the optional tailstock and bar feeder?

A: The optional tailstock is recommended for supporting longer workpieces during turning to prevent deflection, while the bar feeder is ideal for high-volume production or when processing bar stock, improving automation and efficiency.Q: Where is the Colchester Tornado 100 CNC Lathe typically used?

A: This CNC lathe is widely utilized in workshops, manufacturing plants, and facilities within the automotive, aerospace, and general engineering sectors across India and globally, due to its versatility and robust design.Q: What is the process for setting up and programming this CNC lathe?

A: The lathe is equipped with a user-friendly CNC controller from Fanuc or Siemens, allowing operators to efficiently program machining tasks, input parameters, and monitor operations via an intuitive interface, streamlining setup and reducing learning curves.Q: What are the primary benefits of using this lathe for production?

A: Key benefits include high precision, rapid traverse rates, automatic operation, low noise levels (<78 dB), efficient power utilization (7.5 kW), and compact footprint, resulting in increased productivity with reduced operational costs.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Bar Feeder : Other, Optional

Voltage : 400 V

Type : Other, Horizontal CNC Lathe

Computerized : Yes

Tsugami Bs26 Cnc Sliding Head

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Bar Feeder : Other, Yes, integrated automatic bar feeder

Voltage : AC 200 V / 3 phase

Type : Other, CNC Automatic Lathe

Computerized : Yes

Emcoturn 320 Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Bar Feeder : Other, Optional

Voltage : 400 V, 3phase

Type : Other, CNC Lathe

Computerized : Yes

Mori Seiki Sl 80 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Bar Feeder : No

Voltage : 400V / 50 Hz

Type : Other, Horizontal CNC Turning Center

Computerized : Yes

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |