|

Richmond Cnc Radial Drill

Richmond Cnc Radial Drill Specification

- Product Type

- CNC Radial Drill

- General Use

- Metal Drilling, Industrial Workshop

- Material

- Alloy Steel and Cast Iron

- Type

- Radial Drill Machine

- Capacity

- Drilling Capacity 50 mm

- Weight (kg)

- 3100 kg

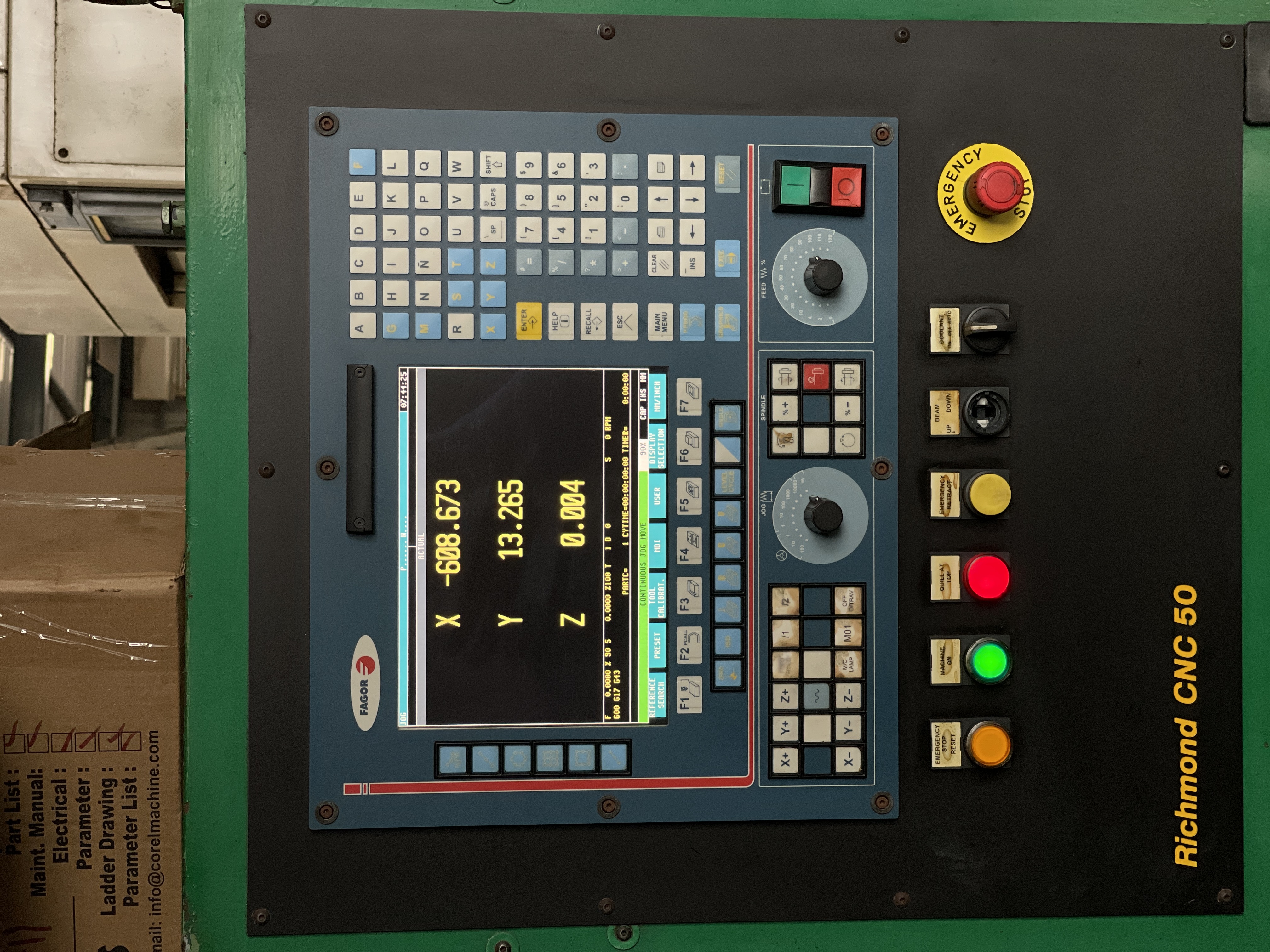

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- 7.5 kW

- Rigidity

- High Rigidity Cast Iron Construction

- Voltage

- 415V 3 Phase

- Motor

- 7.5 HP main motor

- Table Size

- 1200 x 1000 mm

- Spindle Speed

- 40 2000 RPM (variable)

- Axial Choice

- X, Y, Z Axes programmable

- Dimension (L*W*H)

- 2450 x 1100 x 2900 mm

- Feature

- Automatic Operation, Digital Readout, Precision Gearbox

- Color

- Blue & White

- Coolant System

- Integrated

- Spindle Taper

- Morse Taper No. 5

- Clamping Method

- Hydraulic

- Quill Travel

- 315 mm

- Applications

- Heavy Duty Drilling, Boring, Tapping

- Safety Features

- Emergency Stop, Overload Protection

- Repeatability

- ±0.01 mm

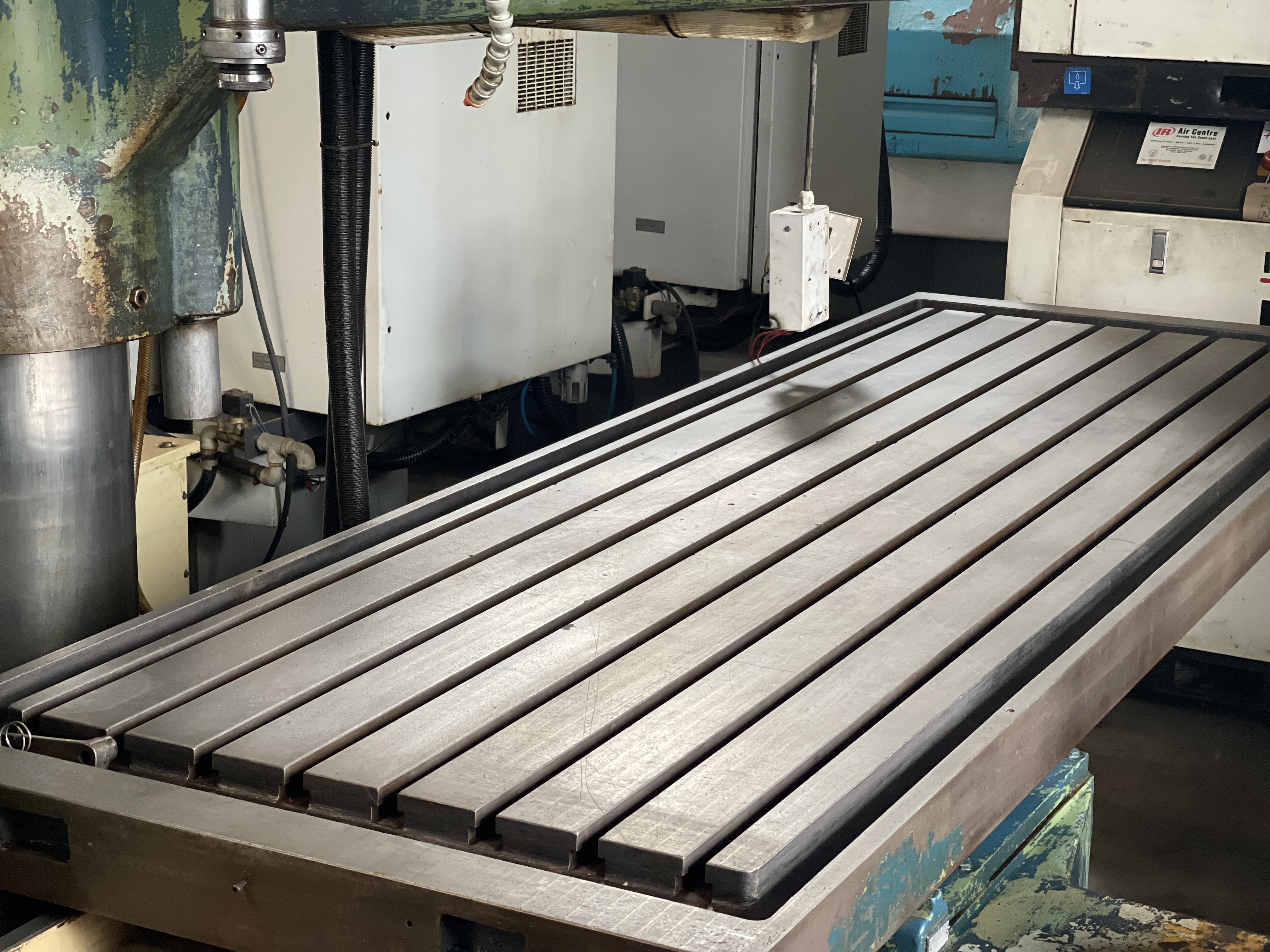

- Work Table Type

- Rotary Table with T-Slots

- Lubrication System

- Centralized Automatic Lubrication

- Arm Length

- 1600 mm

- Column Diameter

- 320 mm

- Traverse Speed

- Programmable- 5 to 600 mm/min

- Control Interface

- Touchscreen CNC Panel

About Richmond Cnc Radial Drill

*RICHMOND CNC RADIAL DRILL*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 2745 x 915 mm

Reference No: 2152

Video Link: https://youtu.be/k2PpazJMyGE

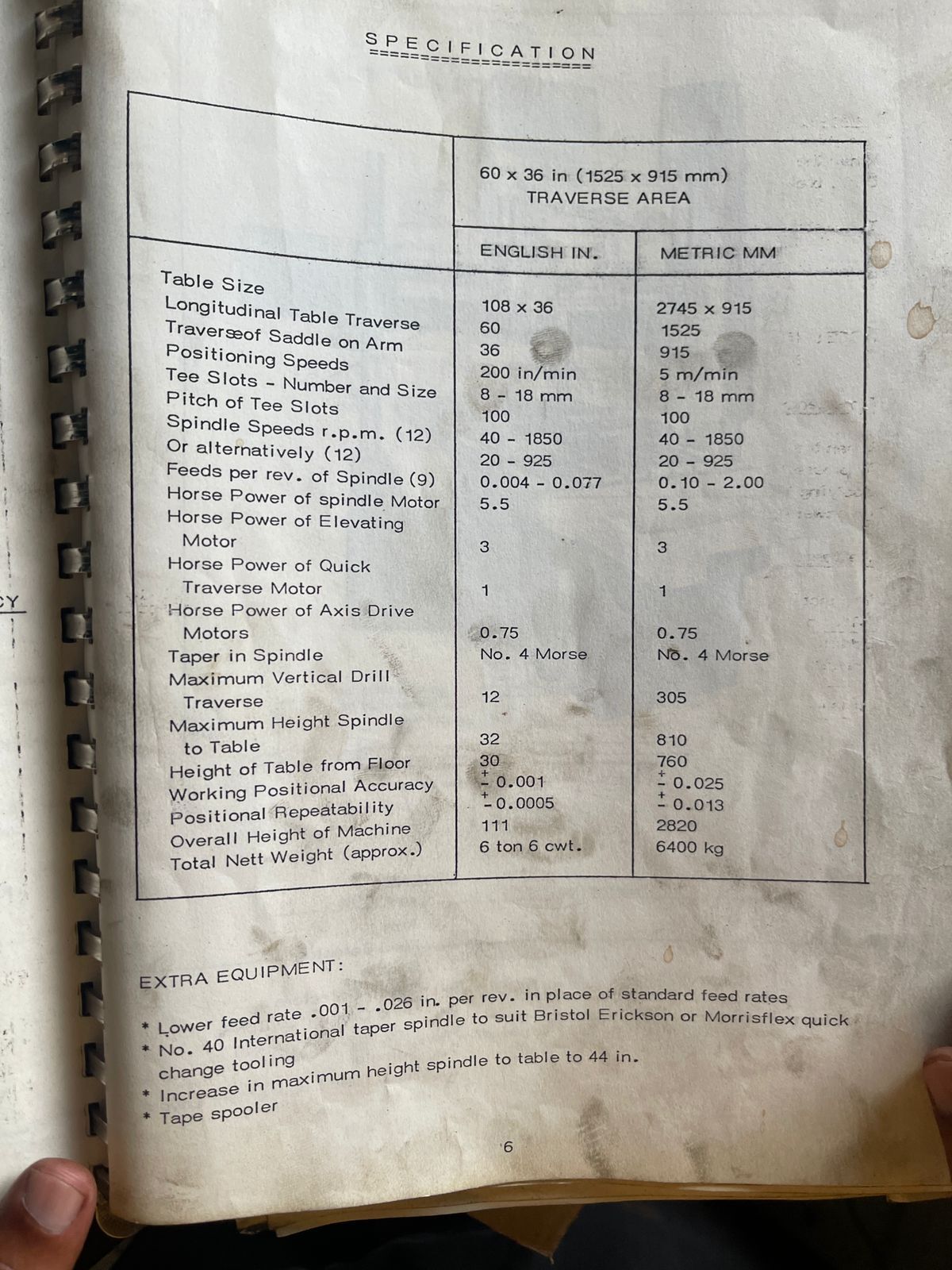

Technical Specifications:

Table Size: 2745 x 915 mm

Traverse Area: 1525 x 915 mm

Spindle Speeds: 20-1850 RPM

Spindle Motor: 5.5 HP

Spindle Taper: MT4

Machine Weight: 7T

Advanced CNC Control for Maximum Precision

Equipped with a modern touchscreen CNC panel and PLC control, the Richmond CNC Radial Drill allows effortless programming of drilling cycles, spindle speeds, and traverse movement across X, Y, and Z axes. The digital readout and automatic operation capabilities ensure consistent accuracy with 0.01 mm repeatability, essential for complex machining tasks in high-volume production settings.

Integrated Safety and Maintenance Systems

This machine incorporates emergency stop and overload protection features, guaranteeing operator safety during continuous operation. The centralized automatic lubrication minimizes manual maintenance, improving uptime and extending the lifespan of critical moving components. The high rigidity cast iron construction further boosts operational stability and safety in demanding industrial environments.

Versatile Application and Superior Workholding

The rotary table with T-slots, programmable traverse speed (5-600 mm/min), and hydraulic clamping enable secure holding and flexible positioning of various metal workpieces. The Richmond CNC Radial Drill's automatic operation streamlines heavy-duty drilling, boring, and tapping, making it a preferred choice for industrial workshops involved in metal fabrication and precision engineering.

FAQ's of Richmond Cnc Radial Drill:

Q: How does the programmable traverse speed enhance the machine's drilling process?

A: The programmable traverse speed (5 to 600 mm/min) allows operators to adjust movement rates for optimal tool feed and accurate positioning. This flexibility leads to improved hole quality, reduced cycle times, and less tool wear during drilling, boring, and tapping processes.Q: What are the benefits of the centralized automatic lubrication system?

A: The centralized automatic lubrication system regularly delivers oil to critical bearings and moving parts, reducing friction, minimizing manual maintenance, and increasing the machine's operational lifespan while ensuring peak performance during prolonged use.Q: When should the emergency stop and overload protection features be utilized?

A: Operators should engage the emergency stop in case of unexpected hazards or malfunction, while overload protection automatically activates during excessive load conditions, preventing damage to the machine and ensuring safe operation at all times.Q: Where can the Richmond CNC Radial Drill be installed for optimal usage?

A: This machine is ideally placed in industrial workshops or metal fabrication facilities that require high precision, automated drilling, and heavy-duty performance. Its robust design suits environments focusing on metalworking and component manufacturing.Q: What types of materials can the Richmond CNC Radial Drill process?

A: The drill is constructed from alloy steel and cast iron, designed to handle a range of metals including steel, cast iron, and non-ferrous alloys. Its rigid frame and adjustable settings enable precision machining on various industrial-grade materials.Q: How does the hydraulic clamping method contribute to operational efficiency?

A: Hydraulic clamping securely holds the workpiece during machining, enabling fast setup and reliable positioning without manual intervention. This results in enhanced repeatability, reduced downtime, and greater safety for the operator.Q: What are the main benefits of the touchscreen CNC panel and PLC control?

A: The CNC panel with PLC control simplifies machine programming, operation, and monitoring. It provides quick access to digital readouts, enables customization of drilling sequences, and aids in precision management, streamlining workflow and minimizing human error.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Kitamura Mycenter 7x Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Axial Choice : 3 Axis

Capacity : Maximum Table Load 1500 kg

Material : Other, Suitable for steel, aluminum, cast iron

Dimension (L*W*H) : 3880 mm x 3450 mm x 3260 mm

Yang Smt 500 Drill Tap Center (2 Off)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Axial Choice : 3 Axis

Capacity : 24 Tools ATC

Material : Other, Cast Iron Body

Dimension (L*W*H) : 1800 x 2000 x 2100 mm

Crawford Cnc Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Axial Choice : 3 Axis

Capacity : 600 kg

Material : Other, Cast Iron, Alloy Steel

Dimension (L*W*H) : 2000 x 1800 x 2200 mm

Hamai (Japan) 5va Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Axial Choice : 3 Axis (XYZ)

Capacity : Max Table Load 800 kg

Material : Other, Cast Iron Body

Dimension (L*W*H) : 2150 x 2360 x 2550 mm

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |