|

Minini Surface Grinder

Minini Surface Grinder Specification

- Product Type

- Surface Grinder

- General Use

- Industrial Surface Grinding

- Material

- Cast Iron, Hardened Steel

- Type

- Manual

- Capacity

- Heavy Duty

- Weight (kg)

- Approx. 700 kg

- Computerized

- No

- Automatic

- Optional

- PLC Control

- No

- Power Source

- Electric

- Power Consumption

- 2 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3 HP (High Efficiency)

- Table Size

- 225 x 450 mm

- Spindle Speed

- 2800 rpm

- Axial Choice

- Manual / Automatic

- Dimension (L*W*H)

- 1100 x 1000 x 1600 mm

- Feature

- Precision Ground Surface, Robust Construction

- Color

- Blue / Grey

- Grinding Wheel Size

- 200 x 13 x 31.75 mm

- Wheel Guard

- Enclosed Steel Guard

- Maximum Distance Spindle Center to Table

- 250 mm

- Table Travel (Longitudinal)

- 450 mm

- Standard Accessories

- Coolant Tank, Wheel Flange, Spanners

- Machine Base

- Heavy-Duty Cast Iron Base

- Coolant System

- Provided

- Lubrication System

- Automatic Lubrication

- Table Travel (Cross)

- 225 mm

- Hydraulic System

- Optional

- Surface Finish Achievable

- Up to 1 Micron

- Hand Wheels

- Graduated for Precision DIY Setting

- Chuck Type

- Magnetic Chuck

- Table Surface

- Ground and Hardened

About Minini Surface Grinder

*MININI SURFACE GRINDER*

CATEGORY : SURFACE GRINDERS

CAPACITY : 1050 x 810 mm

Reference No: 3299

Technical Specifications:

Working Capacity

Magnetic Chuck: 1000 x 610 mm

Longitudinal movement of table: 1050 mm

Transverse movement Cross: 810 mm

Vertical Traverse: 500 mm

Pendent Control, Metric Variable Speeds & Feeds, Overarm Wheel Dresser

Exceptional Precision and Surface Finish

The Minini Surface Grinder is engineered to deliver immaculate surface finishes as fine as 1 micron. Graduated precision hand wheels and a rigid cast iron base underpin outstanding accuracy. A magnetic chuck ensures secure material holding, making this grinder suitable for demanding industrial tasks on hardened steel or cast iron.

Built for Durability and Heavy Duty Use

With its heavy-duty cast iron construction, enclosed steel wheel guard, and ground, hardened worktable, the Minini Surface Grinder is made to last, even under continuous industrial workloads. Its high efficiency 3 HP motor and robust design guarantee reliable performance and longevity.

Flexible Operation and Enhanced Control

The machine offers both manual and optional automatic operations for adaptability in various environments. The precise table traverses, coupled with automatic lubrication, minimize manual intervention and ensure consistent results. Cooling and lubrication systems are standard, safeguarding components and the workpiece during extended use.

FAQs of Minini Surface Grinder:

Q: How is the grinding precision achieved with the Minini Surface Grinder?

A: The Minini Surface Grinder utilizes graduated hand wheels for precise adjustments and a magnetic chuck for secure material placement. Its heavy-duty cast iron construction minimizes vibration, while the ground and hardened table surface ensures tight tolerances, allowing surface finishes up to 1 micron.Q: What materials can be ground using this surface grinder?

A: This surface grinder is designed for industrial use on materials such as hardened steel and cast iron, making it suitable for toolrooms, manufacturing units, and maintenance workshops that demand rugged and precise operations.Q: When should I choose manual versus automatic operation modes?

A: Manual operation is ideal for unique or low-volume grinding tasks where specialized control is needed, whereas the optional automatic mode increases efficiency and consistency during repetitive or bulk grinding operations. The flexibility in operation suits diverse industrial requirements.Q: Where is the Minini Surface Grinder typically used?

A: The grinder is widely employed in industrial settings across India, especially by exporters, importers, suppliers, and traders for tasks demanding high-precision surface finishing. It is commonly found in machine shops, factories, and large maintenance facilities.Q: What is the process for routine maintenance on this machine?

A: Routine maintenance involves ensuring the automatic lubrication system is functioning, checking coolant levels, inspecting the wheel guard and magnetic chuck, and cleaning the table and accessories after use. Standard accessories like spanners and wheel flanges aid these tasks.Q: How does the coolant system benefit the grinding process?

A: The integrated coolant system prevents overheating of both the workpiece and grinding wheel, resulting in a smoother finish, prolonged tool life, and minimized risk of thermal distortion during extended grinding operations.Q: What are the main benefits of using the Minini Surface Grinder for industrial applications?

A: Key benefits include high rigidity for stable operation, precision grinding capabilities, robust and durable construction, seamless switching between manual and automatic modes, and reduced maintenance due to the automatic lubrication and enclosed guard systems.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinders Category

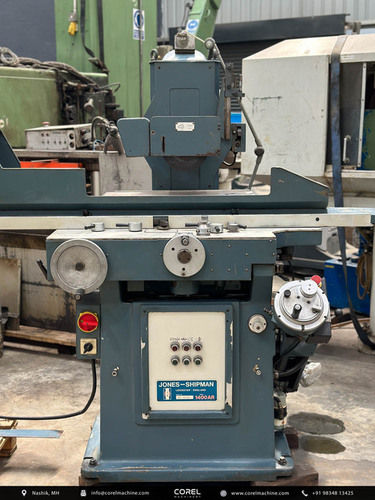

Jones Shipman 1400ar Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Surface Grinder

Power Source : Electric

Rigidity : Other, Heavy Duty, Robust Construction

Automatic : Other, SemiAutomatic

Kent Manual 6 X 18 Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Manual Surface Grinder

Power Source : Electric

Rigidity : High

Automatic : No

Waldrich Coburg 30 Fs 3030 Slideway Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Slideway Grinder

Power Source : Electric

Rigidity : Other, High structural rigidity

Automatic : Other, SemiAutomatic

Magerle F-10 Hydraulic Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Hydraulic Surface Grinder

Power Source : Electric

Rigidity : Other, High Rigidity Body

Automatic : Yes

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |