|

Cincinnati Double Spindle Universal Milling

Cincinnati Double Spindle Universal Milling Specification

- Product Type

- Universal Milling Machine

- General Use

- Heavy Milling Operations

- Material

- Cast Iron & Steel

- Type

- Double Spindle Universal Milling Machine

- Capacity

- Robust heavy-duty milling

- Weight (kg)

- Approx. 2800 kg

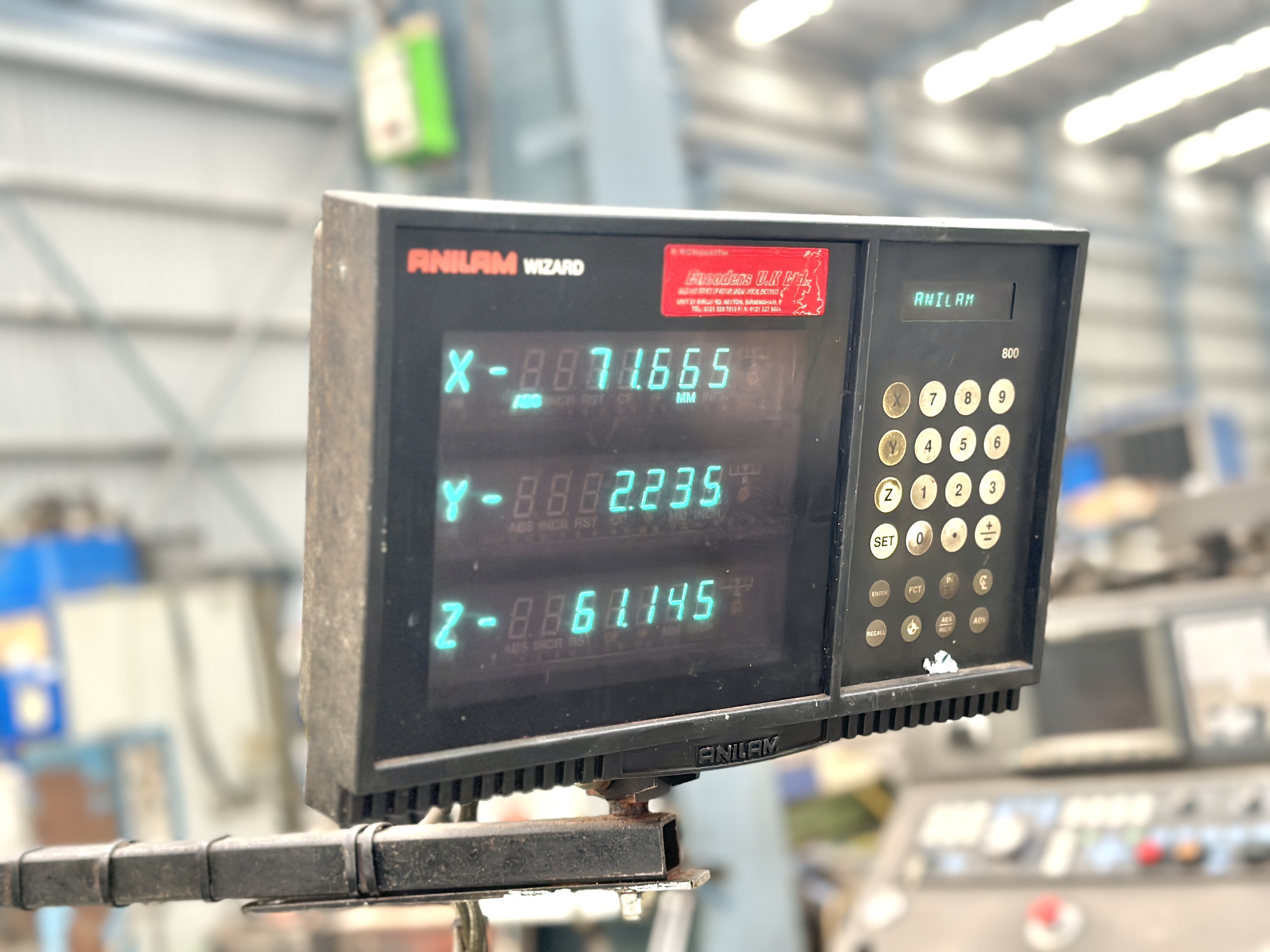

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- Approx. 5-7 HP

- Rigidity

- High

- Voltage

- 415 V

- Motor

- Cincinnati 5 HP Electric Motor

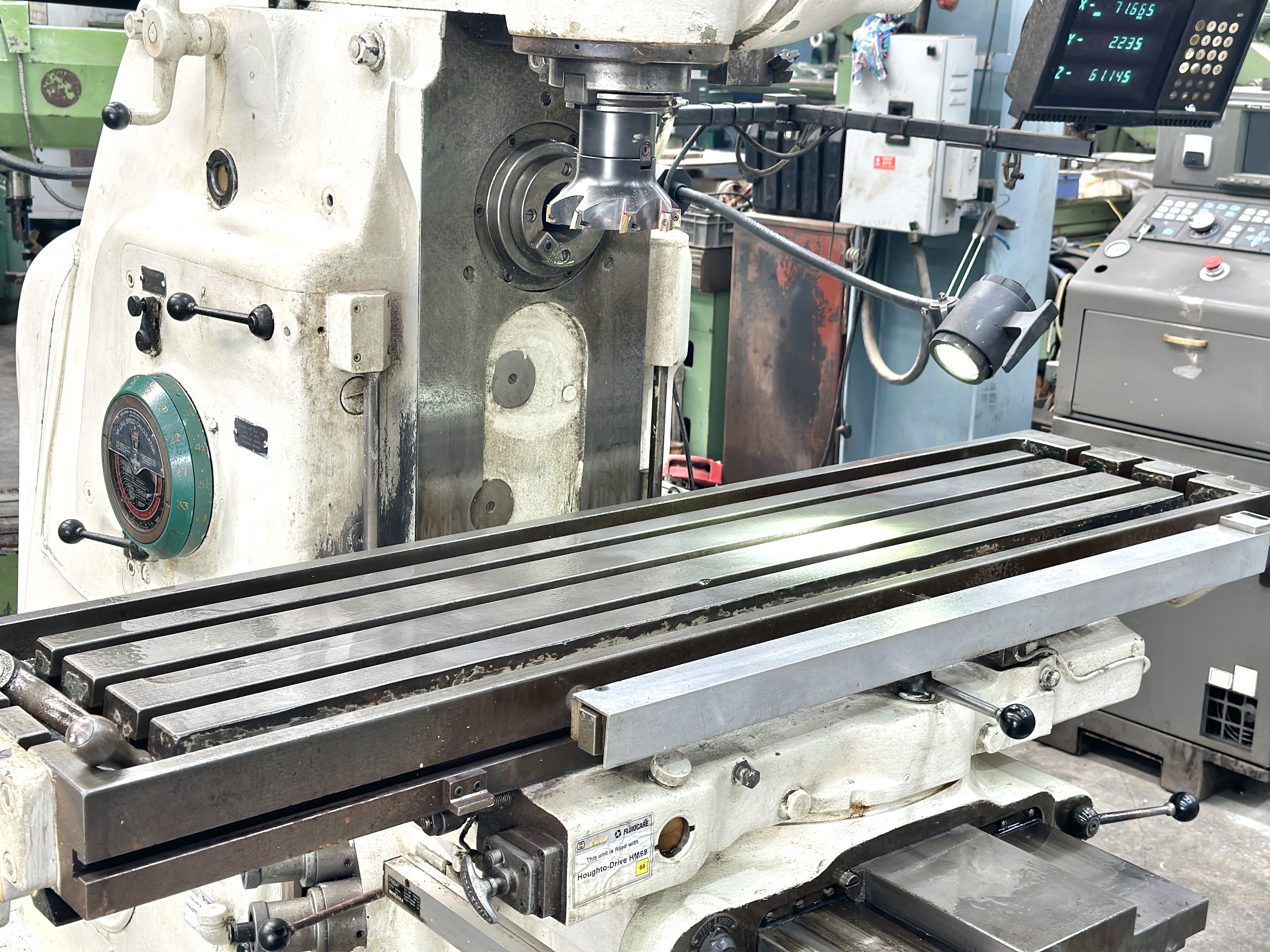

- Table Size

- 1600 mm x 355 mm

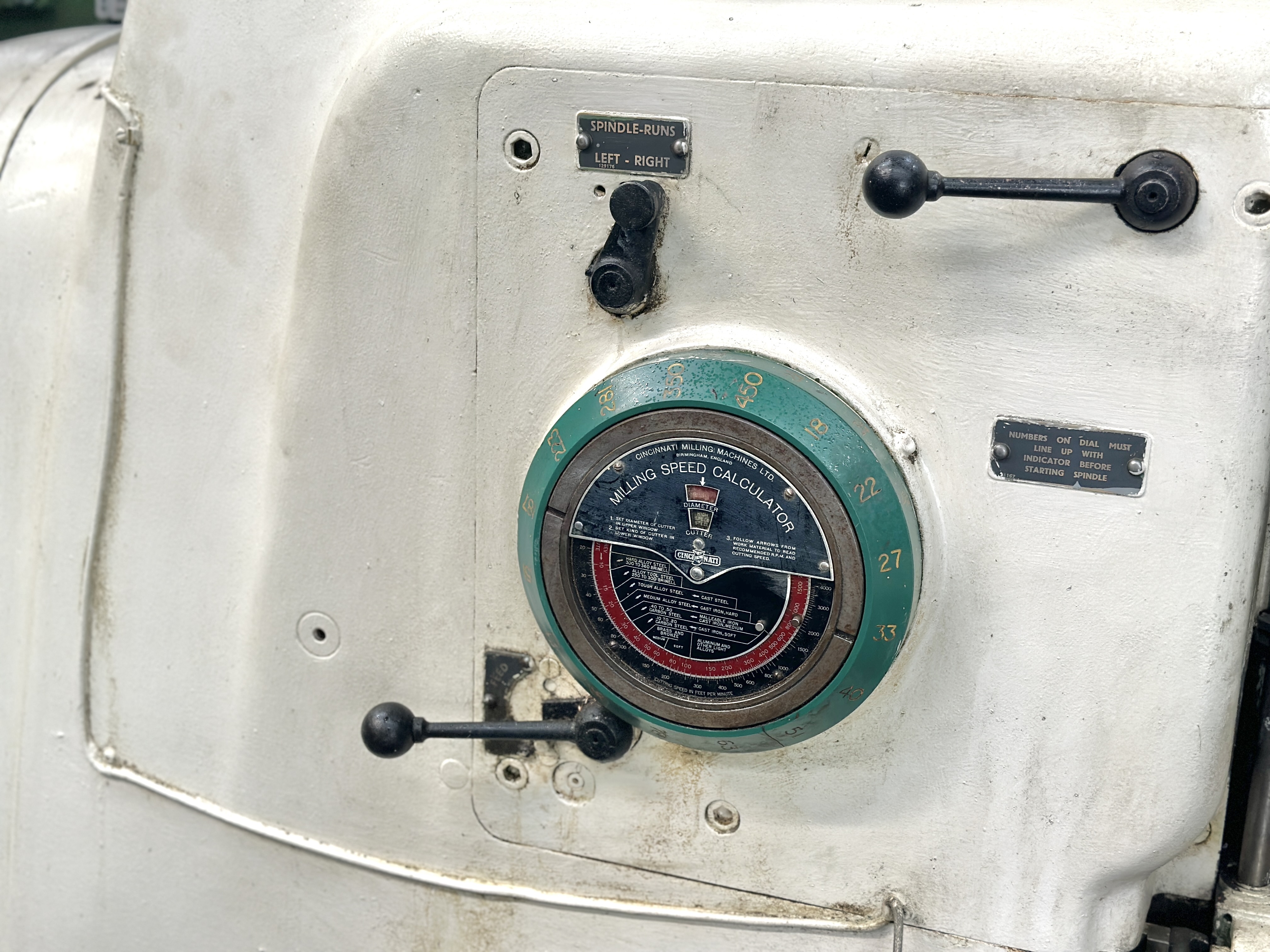

- Spindle Speed

- 45 to 1125 rpm

- Axial Choice

- Horizontal & Vertical

- Dimension (L*W*H)

- 2300 mm x 1800 mm x 1800 mm (approx)

- Feature

- Double Spindle, Universal Type, Precision Gear Box, Adjustable Feed

- Color

- Industrial Green

- Spindle Taper

- ISO 50

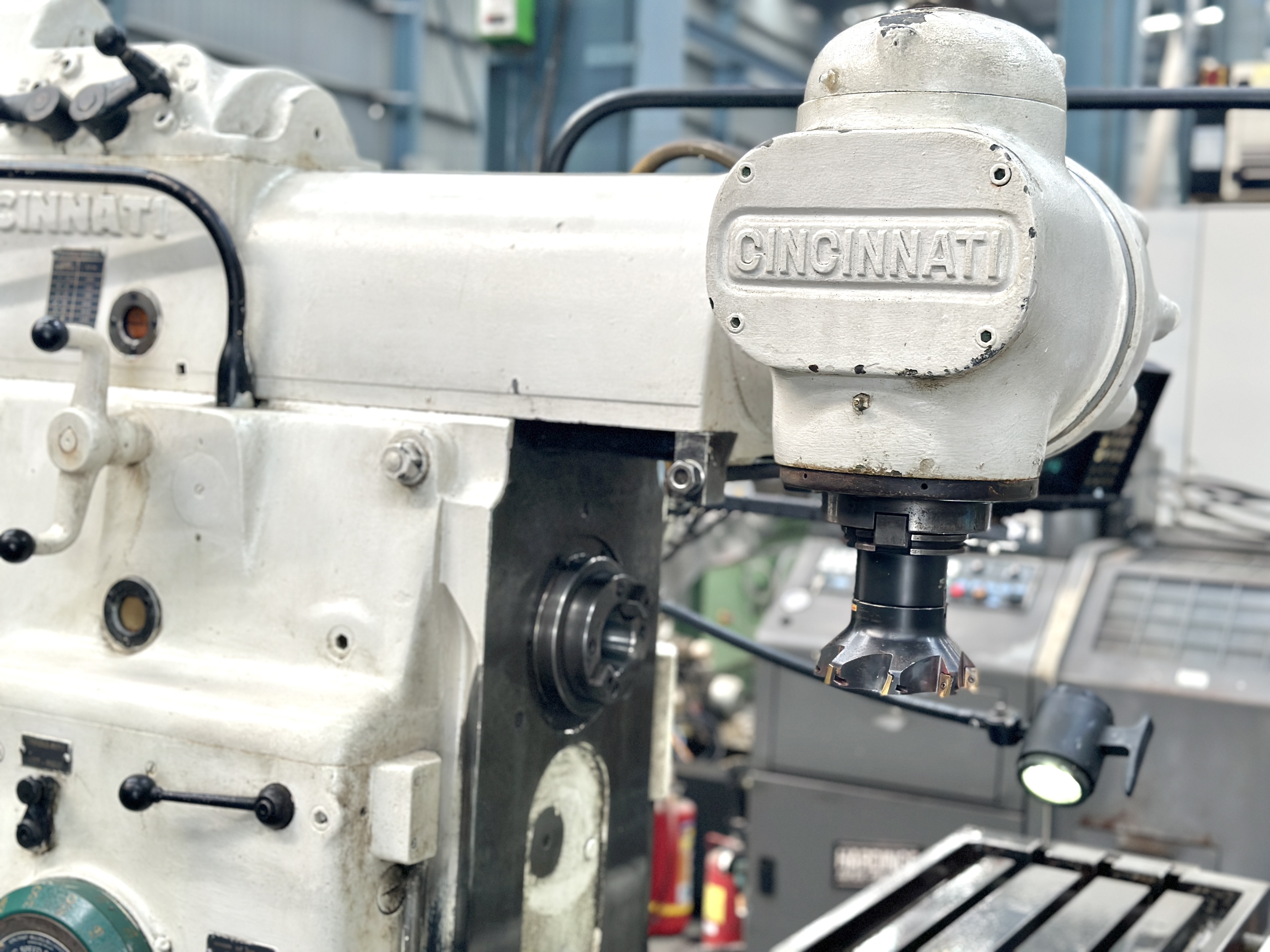

- Number of Spindles

- 2

- Maximum Distance Between Spindles

- 350 mm

- Overarm Travel

- 450 mm

- Vice Holding Capacity

- 250 mm

- Table Feed

- Automatic with hand adjustment

- T-Slot Width

- 16 mm

- Table Vertical Travel

- 430 mm

- Working Surface Height

- 900 mm

- Table Cross Travel

- 355 mm

- Lubrication

- Centralized

- Coolant System

- Integrated Pump

About Cincinnati Double Spindle Universal Milling

*CINCINNATI DOUBLE SPINDLE UNIVERSAL MILLING*

CATEGORY : MILLING MACHINES

CAPACITY : 1600 x 385 mm

Reference No: 3640

Video Link: https://youtu.be/vvFN09HrXvc

Technical Specifications:

Table: 1600 x 385 mm

ISO 50 Taper

Double Spindle

Advanced Double Spindle Design

Benefit from simultaneous operations with dual spindles, maximizing productivity during demanding milling tasks. The maximum distance between spindles reaches 350 mm, allowing versatile workpiece arrangements and reducing cycle time for complex jobs.

Precision and Versatility in Milling

The milling machine supports horizontal and vertical axes, made possible by a universal configuration and a robust precision gear box. Adjustable table feed and practical hand adjustments allow fine-tuning to meet exact milling requirements, ensuring consistent precision.

Integrated Cooling and Lubrication

For seamless long-duration operation, the machine incorporates an integrated coolant pump and centralized lubricant system. These ensure optimal performance, reduce component wear, and maintain ideal working conditions for cast iron and steel construction.

FAQ's of Cincinnati Double Spindle Universal Milling:

Q: How does the automatic table feed with hand adjustment improve milling operations?

A: The automatic table feed allows for consistent material movement during milling, enhancing accuracy and efficiency. Manual adjustment provides operators with the flexibility to precisely control feed speed and position according to the specific task requirements.Q: What are the key benefits of having two spindles on this universal milling machine?

A: Dual spindles enable simultaneous machining of two surfaces or multiple operations, which significantly reduces processing time and increases throughput. This configuration is ideal for heavy-duty or high-volume industrial milling applications.Q: When is it advisable to use the Cincinnati Double Spindle Universal Milling Machine?

A: This machine is best employed in heavy-milling operations that demand high rigidity, precision, and versatility-such as those encountered in manufacturing, metalworking, or industrial fabrication environments.Q: Where should the Cincinnati Double Spindle Universal Milling Machine be installed for optimal performance?

A: It is recommended to place the machine in a well-ventilated, dedicated industrial manufacturing area with stable electric supply and proper space for material handling. Its dimensions are approximately 2300 x 1800 x 1800 mm and weight is around 2800 kg.Q: What process does the integrated coolant system and centralized lubrication support?

A: These systems facilitate continuous cooling and effective distribution of lubricant during operations, minimizing heat generation and friction. This enhances tool life and ensures consistent quality in milled products.Q: How can operators utilize the machine's adjustable feed and precision gear box?

A: Operators can fine-tune feed rates and engage the precision gear box for customized speed and torque control, providing greater adaptability to different materials and milling tasks, thereby improving milling precision and productivity.Q: What usage advantages does the universal milling machine offer over single spindle models?

A: The double spindle design delivers higher work efficiency, expanded machining options, and reduced tool change time, making it a superior choice for production facilities requiring reliable, accurate multi-operation milling solutions.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Butler 21 Production Slotter With 45 Rotary Table

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Axial Choice : 45 rotary indexing

Capacity : 21 inches max slotting stroke

Rigidity : Other, High Rigidity Machine Structure

Color : Other, Industrial Blue & Silver Grey

Bridgeport M1tr Turret Dro Milling Machine 1

Minimum Order Quantity : 1 Number

Axial Choice : X, Y, Z

Capacity : Table Load 200 kg

Rigidity : High

Color : Other, White & Blue

Gambin 11m Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Axial Choice : 3 Axis (X, Y, Z)

Capacity : High precision, Mediumduty

Rigidity : Other, High structural rigidity

Color : Green

Tiel Universal Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Axial Choice : 3 Axis

Capacity : 410 mm (X), 130 mm (Y), 420 mm (Z)

Rigidity : High

Color : Other, Green & White

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |