|

Fadal 6030 Vmc

Fadal 6030 Vmc Specification

- Product Type

- Vertical Machining Center

- General Use

- Industrial metal milling, high-precision machining

- Material

- Cast Iron Base, Steel Construction

- Type

- CNC Vertical Machining Center

- Capacity

- 1500 kg (max load on table)

- Weight (kg)

- 9200 kg

- Computerized

- CNC Controlled

- Automatic

- Fully Automatic

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 18 kVA

- Rigidity

- High

- Voltage

- 220 V / 440 V

- Motor

- Spindle Motor 15 HP

- Table Size

- 63 x 30 (1600 mm x 762 mm)

- Spindle Speed

- 10000 rpm

- Axial Choice

- X/Y/Z

- Dimension (L*W*H)

- 170 x 118 x 116 (4320 mm x 2990 mm x 2950 mm)

- Feature

- Heavy-Duty Construction, Large Work Area

- Color

- White & Blue

- Travel (X/Y/Z)

- 60" x 30" x 30" (1524 mm x 762 mm x 762 mm)

- Rapid Traverse Rate (X, Y, Z)

- 900 IPM

- Repeatability

- 0.0002" (0.005 mm)

- Air Requirement

- 85 psi

- Minimum Input Increment

- 0.0001" (0.0025 mm)

- Feed Rate

- 0.1400 IPM

- Floor Space Required

- 210" x 140" (5334 mm x 3556 mm)

- Tool Magazine Capacity

- 24 Stations

- Way System

- Box Way

- Coolant System

- Standard

- Spindle Taper

- CAT 40

- Main Drive

- Direct Drive

- Tool Change Time

- 4.5 seconds (tool-to-tool)

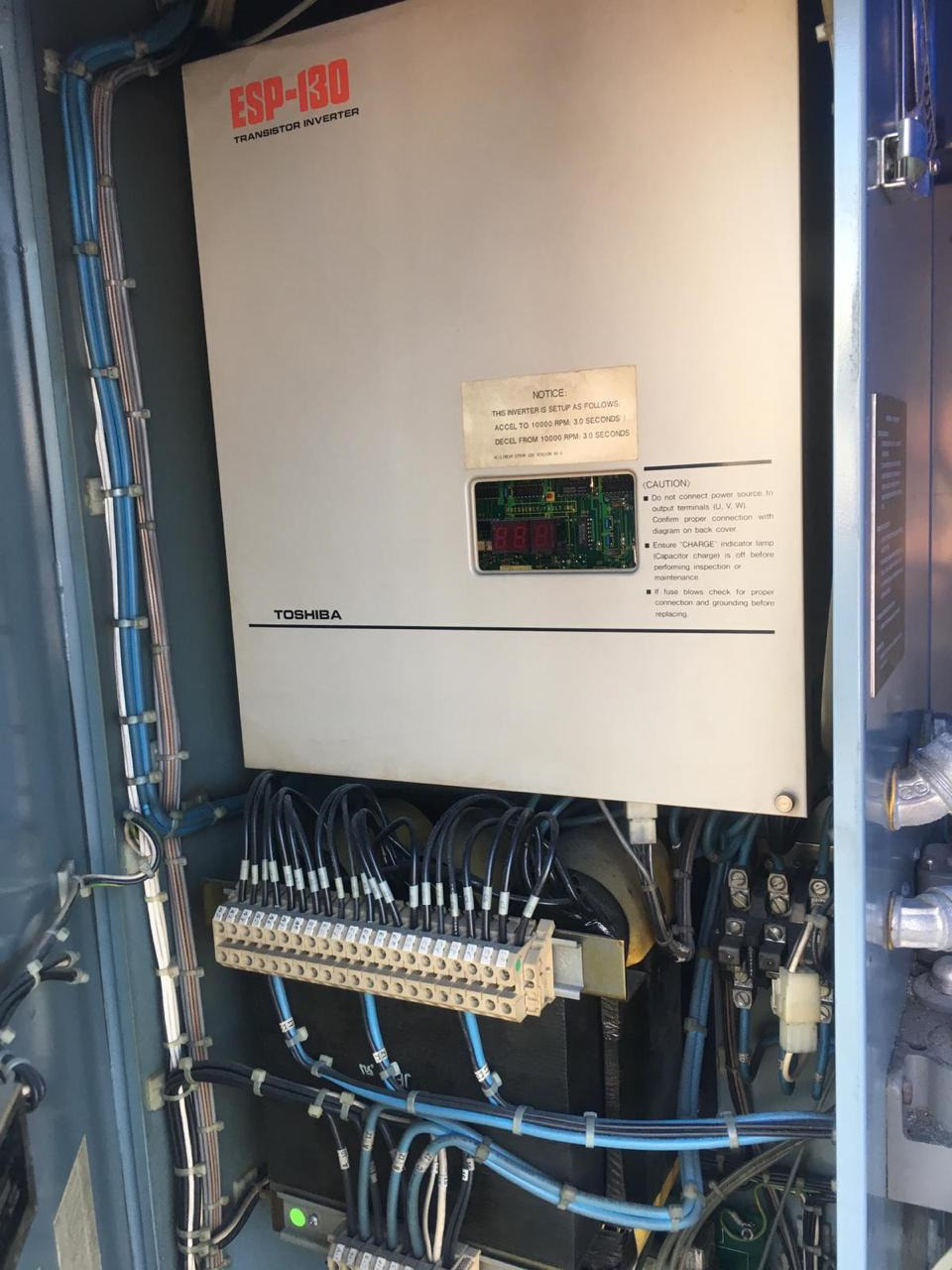

- Controller Type

- Fadal CNC 88HS

- Positioning Accuracy

- 0.0004" (0.01 mm)

About Fadal 6030 Vmc

*FADAL 6030 VMC*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 60 x 30 x 30

Reference No: 510

Technical Specifications:

WORKING CAPACITY

Table Size: 62.5 x 30

Travels (XYZ): 60 x 30 x 30

CNC

Control: Fadal

SPINDLE

Spindle Taper: BT40

Spindle Speeds: 10000 RPM

Spindle Motor: 22.5 HP

Max Torque: 230 ft-lb @ 500RPM

ATC

Tool Change Capacity: 21 Tools

ATC Type: Umbrella

Max Tool Weight: 7 Kg

Machine Dimensions

L x W x H: 162 x 104 x 125

Aprox. Weight: 9 T

10000 RPM High Precision Spindle

Programmable coolant

Telescopic way covers

Flood Coolant system

Superior Precision and Performance

Engineered for demanding industrial environments, the Fadal 6030 VMC delivers outstanding accuracy with a repeatability of 0.0002" and positioning accuracy of 0.0004". Fast traverse speeds and a robust spindle motor enhance your machining capabilities while minimizing cycle times.

Large Work Envelope and Capacity

Boasting a 60-inch X-axis travel and a spacious 63" x 30" table, this machine accommodates larger components and a maximum table load of 1500 kg. Whether for prototyping or high-volume production, it delivers the versatility required for a broad range of applications.

User-Friendly Automation and Controls

Equipped with the intuitive Fadal CNC 88HS controller and a 24-station automatic tool changer, programming, and operational efficiency are seamlessly integrated into your workflow. PLC control enhances automation, ensuring consistent and reliable operations for every machining cycle.

FAQ's of Fadal 6030 Vmc:

Q: How does the Fadal 6030 VMC ensure precision during milling operations?

A: The Fadal 6030 VMC achieves high precision with box way construction for stability, repeatability of 0.0002 inches (0.005 mm), positioning accuracy of 0.0004 inches (0.01 mm), and a minimum input increment of 0.0001 inches (0.0025 mm). This combination allows for intricate and consistent metal machining.Q: What is the process for automatic tool changing on this machine?

A: The VMC features a 24-station automatic tool magazine that enables fast tool changes with a tool-to-tool time of just 4.5 seconds. This is managed via PLC control and the CNC 88HS system to minimize downtime and enhance machining productivity.Q: When should I use the Fadal 6030 VMC for my industrial manufacturing needs?

A: This machine is ideal for projects requiring high-precision metal milling and heavy-duty machining, such as producing large or complex components. Its operational efficiency and robust structure make it suitable for continuous, high-volume production environments.Q: Where is the Fadal 6030 VMC best utilized?

A: Due to its size, versatility, and capacity, the Fadal 6030 VMC is best utilized in industrial workshops, fabrication facilities, and manufacturing plants specializing in precision metal work, mold making, and large-scale component manufacturing.Q: How does the machine benefit high-production enterprises?

A: The Fadal 6030 VMC improves high-production businesses by combining speed (rapid traverse of 900 IPM), automation (fully automatic with PLC), and a large tool magazine. These features streamline production, reduce manual intervention, and maintain consistent machining quality.Q: What maintenance is recommended for optimal performance?

A: Regularly inspect the coolant system, check and maintain air supply at 85 psi, keep the box way system lubricated, and ensure timely replacement of cutting tools. Periodic calibration of the CNC ensures sustained accuracy and machine reliability.Q: What are the energy and space requirements for installation?

A: The machine requires an electrical power supply of 18 kVA, voltage options of 220V or 440V, and a floor space of approximately 210" x 140" (5334 mm x 3556 mm), making it necessary to plan for substantial installation space and allow for accessibility around the unit.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Mori Seiki Cv-500 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Capacity : Maximum Loading 350 kg per pallet

Axial Choice : X, Y, Z

Power Source : Electric

Hamai (Japan) 5va Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Capacity : Max Table Load 800 kg

Axial Choice : 3 Axis (XYZ)

Power Source : Electric

Leadwell 610 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Capacity : Pallet Maximum Load: 250 kg

Axial Choice : XYZ Axis

Power Source : Electric

Crawford Cnc Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : Other, High Rigidity Construction

Capacity : 600 kg

Axial Choice : 3 Axis

Power Source : Electric

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |