|

Lumsden Rotary Grinder

Lumsden Rotary Grinder Specification

- Product Type

- Rotary Surface Grinder

- General Use

- Precision Surface Grinding

- Material

- Cast Iron, Steel

- Type

- Industrial Machinery

- Capacity

- Up to 650 kg load

- Weight (kg)

- Approx. 4600 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 18 kW

- Rigidity

- Heavy Duty Construction

- Voltage

- 415V, 3 Phase

- Motor

- Main Spindle 15 HP

- Table Size

- 1000 mm diameter

- Spindle Speed

- Up to 1450 rpm

- Axial Choice

- Vertical Axis

- Dimension (L*W*H)

- 2800 mm x 2200 mm x 2200 mm

- Feature

- Magnetic Chuck, Coolant System

- Color

- Industrial Grey

- Max Grinding Height

- 300 mm

- Wheel Size

- 350 mm x 50 mm x 127 mm

- Lubrication System

- Automatic centralized

- Table Rotation

- Variable Speed

- Chuck Type

- Electromagnetic Round Chuck

- Coolant Capacity

- 120 Litres

- Application

- Suitable for surface finishing and material removal of ferrous components

- Grinding Head Movement

- Vertical (Manual/Automatic)

- Control Panel

- Push Button Panel

About Lumsden Rotary Grinder

*LUMSDEN ROTARY GRINDER*

CATEGORY : SURFACE GRINDERS

CAPACITY : 36 inches Magnet

Reference No: 1044

Technical Specifications:

WORKING CAPACITY

Table Diameter: 915 mm

Segmental Wheel Diameter: 559 mm

Max Height Capacity: 280 mm

Spindle Speed: 700 RPM

Spindle Motor: 30 kW

Auto Feed: 0.1 - 1.0 mm/min

Precision Surface Grinding for Heavy Loads

Built to accommodate ferrous components up to 650 kg, the Lumsden Rotary Grinder ensures precise, consistent surface finishing. Its sturdy construction and variable-speed table rotation are engineered for rigorous use, making it ideal for demanding industrial environments. The 1000 mm diameter table and 350 mm grinding wheel handle sizable workpieces effectively, with a design optimized for operational stability.

Advanced Features Enhance Operator Efficiency

With an electromagnetic round chuck, automatic centralized lubrication, and a 120-litre coolant system, this grinder simplifies maintenance and supports prolonged operation. The convenient push button panel streamlines machine control, while semi-automatic functions reduce manual intervention. Combined with robust safety measures, the Lumsden Rotary Grinder maximizes productivity and ensures user comfort.

FAQ's of Lumsden Rotary Grinder:

Q: How does the Lumsden Rotary Grinder handle cooling during extended operations?

A: The grinder is equipped with a 120-litre coolant system that continuously cools the work area, minimizing heat buildup and ensuring dimensional accuracy even during long grinding cycles.Q: What types of materials can be processed with this machine?

A: This rotary grinder is specifically designed for machining ferrous components such as cast iron and steel, making it highly suitable for heavy-duty industrial applications.Q: When is it recommended to use the automatic vertical grinding head movement?

A: Utilize the automatic head movement during repetitive or large-scale jobs to maintain uniform material removal and improve process efficiency, whereas manual control offers flexibility for special finishing requirements.Q: Where is the Lumsden Rotary Grinder most commonly used?

A: This machine is widely adopted in industrial workshops, manufacturing plants, and metal fabrication facilities, where high-precision surface grinding of heavy ferrous parts is essential.Q: What is the process for operating the electromagnetic round chuck?

A: The operator uses the push button panel to activate the electromagnetic chuck, securely holding round or flat workpieces in place during grinding for accurate and safe operation.Q: What benefits does the automatic centralized lubrication system offer?

A: Automatic centralized lubrication extends machine lifespan by consistently supplying oil to key components, reducing wear and minimizing downtime for maintenance.Q: How does the machine ensure precise grinding results for large components?

A: The rotary table, combined with variable speed control, a stable heavy-duty structure, and automatic lubrication, enables the machine to deliver precise, repeatable grinding outcomes for workpieces up to 650 kg and 1000 mm in diameter.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinders Category

Chevalier Manual Surface Grinder

Minimum Order Quantity : 1 Number

Spindle Speed : 2800 rpm

Motor : Other, 1.5 HP Spindle Motor

Table Size : 460 x 150 mm

PLC Control : No

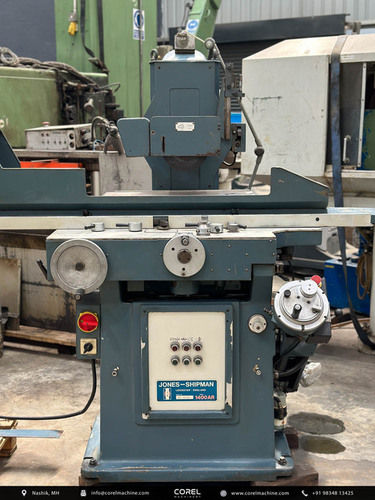

Jones Shipman 1400ar Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Spindle Speed : 1440 RPM

Motor : Other, 2.25 kW (Approx)

Table Size : 27 x 8 (685 mm x 203 mm)

PLC Control : No

Kent Surface Grinder (450 X 150)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Spindle Speed : 2800 RPM

Motor : Other, 1 HP Spindle Motor

Table Size : 450 x 150 mm

PLC Control : No

Favretto Tc70 Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Spindle Speed : 1450 RPM

Motor : Other, Main Motor 7.5 HP

Table Size : 700 x 400 mm

PLC Control : No

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |