|

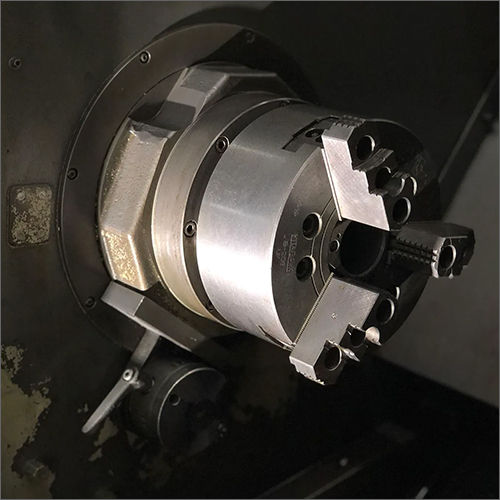

Hardinge Conquest T51 Cnc Turn Mill Center

Hardinge Conquest T51 Cnc Turn Mill Center Specification

- Product Type

- CNC Turn Mill Center

- General Use

- Metal/Component Turning and Milling

- Material

- Cast Iron Base, Hardened Components

- Type

- Horizontal

- Capacity

- 51 mm Bar Capacity

- Weight (kg)

- 5700 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Included

- Power Source

- Electric

- Power Consumption

- 18 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- Servo Motor

- Table Size

- Standard

- Spindle Speed

- 505000 RPM

- Axial Choice

- X, Z, C Axis

- Dimension (L*W*H)

- 3200 mm x 1780 mm x 2050 mm

- Feature

- Precision Turning and Milling, Automatic Tool Changer

- Color

- White & Blue

- Noise Level

- 75 dB

- Max Turning Diameter

- 320 mm

- Tailstock

- Programmable

- Coolant System

- Integrated High Pressure

- Repeatability

- 0.003 mm

- Rapid Traverse Rate

- 24 m/min (X), 30 m/min (Z)

- Lubrication System

- Automatic

- Max Turning Length

- 510 mm

- Torch Interface

- Available

- Main Spindle Motor Power

- 15 kW

- Chuck Size

- 210 mm (8 inch)

- Number of Tool Stations

- 12 (Turret Type)

- Swing Over Bed

- 530 mm

- CNC Controller

- Fanuc 0i-T or Equivalent

- Hydraulic System

- Included

- Safety Features

- Interlocked Guards, Emergency Stop, Overload Protection

Hardinge Conquest T51 Cnc Turn Mill Center Trade Information

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 1 Days

About Hardinge Conquest T51 Cnc Turn Mill Center

Hardinge Conquest T51 CNC Turn Mill Center is unmatched in terms of design and performance. This machine is equipped with high-precision components and parts, which makes it a reliable and functional industrial machine. It is typically used in a plethora of metal processing tasks including milling, slotting, tapping, and cross-drilling. Owing to its robust design and high performance, it is preferred by our customers. Hardinge Conquest T51 CNC Turn Mill Center can be purchased from us at a reasonable price.

WORKING CAPACITY

- Max Turning Diameter: 300 mm

- Max Turning Length: 450 mm

- Swing: 400 mm

- Distance Between Centers: 500 mm

- Chuck Equipped: 200 mm

- Travels (X / Z): 330 / 580 mm

SPINDLE

- Max Rotation Speed: 3500 RPM

- Spindle Nose

- Spindle Bore: 66 mm

- Spindle Motor Power: 11 / 15 kW

TURRET

- Turret: 12 Stations / 6 Live Stations

- Max Live Tool Speed: 3000 RPM

- Live Tool Power: 2.1 kW

- 3 Live Tools, C-Axis

CNC

- Control: Fanuc 18T (Alpha Drives)

TAILSTOCK

- Tailstock: Programmable Tailstock

Machine Dimensions

- Weight: 6.8T

Precision Engineering for Superior Results

Built with a hardened cast iron base and high-rigidity components, the Hardinge Conquest T51 offers exceptional repeatability of 0.003 mm, making it ideal for industries demanding tight tolerances. Its programmable tailstock and servo motors provide additional stability and accuracy during complex turning and milling operations.

Efficient Operation and Versatile Capabilities

Equipped with a 12-station turret and automatic tool changer, this CNC turn mill center supports swift tool changes and continuous operation. The large bar capacity (51 mm) and variable spindle speeds (50-5000 RPM) cater to a range of component sizes and materials, enhancing flexibility for different production needs.

Smart Control and Enhanced Safety

Featuring a user-friendly Fanuc 0i-T controller, the machine ensures precise and programmable machining processes. Comprehensive safety features include interlocked guards, an emergency stop function, and overload protection, allowing for secure and uninterrupted manufacturing in compliance with industrial standards.

FAQ's of Hardinge Conquest T51 Cnc Turn Mill Center:

Q: How does the Hardinge Conquest T51 ensure high precision during turning and milling operations?

A: The machine utilizes a rigid cast iron base, hardened components, servo motor drives, and a programmable tailstock to achieve a repeatability of 0.003 mm, ensuring consistent high-precision results for intricate metal machining jobs.Q: What are the primary applications and industries suited for this CNC turn mill center?

A: Designed for metal and component turning and milling, the T51 is frequently used in automotive, aerospace, tooling, and general manufacturing sectors for producing precision parts, especially where versatility and efficiency are paramount.Q: When should the automatic lubrication and hydraulic systems be maintained?

A: While the T51 comes with automatic lubrication and a built-in hydraulic system, routine checks per the user manual's recommended schedule help maintain optimal performance and prolong component life.Q: Where can this machine be installed, and what are its space requirements?

A: With dimensions of 3200 mm (L) x 1780 mm (W) x 2050 mm (H) and weighing 5700 kg, the T51 requires a robust, level, and well-ventilated workshop floor with an electric supply of 415 V to accommodate its footprint and power needs.Q: What is the typical process workflow using the Conquest T51?

A: The workflow involves loading bars via the included bar feeder, programming machining sequences on the Fanuc 0i-T controller, utilizing the automatic tool changer and programmable tailstock, and performing both turning and milling in a single setup for increased efficiency.Q: How does the integrated coolant and bar feeder benefit daily operations?

A: The high-pressure coolant system provides excellent chip removal and tool life, while the bar feeder enables seamless raw material supply, facilitating faster cycle times and higher productivity during continuous production runs.

Price 100000.00-100000000.00 INR/ Piece

- Minimum Order Quantity

- 1 , , Piece

- Supply Ability

- 5 Pieces Per Month

- Delivery Time

- 1 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Cmz Tbi-480 Cnc Turning Center

Minimum Order Quantity : 1 Piece

Color : Other, White/Grey

Automatic : Yes

Type : Other, Horizontal CNC Lathe

Power Consumption : 18 kW

Nakamura Tome Tmc-4 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White & Blue

Automatic : Yes

Type : Other, Horizontal lathe

Power Consumption : 7.5 kW

Mori Seiki Sl35/700 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White & Blue

Automatic : Yes

Type : Horizontal

Power Consumption : 15 kVA

Colchester Cnc-2000l Cnc Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Standard industrial grey & offwhite

Automatic : Yes

Type : Other, Automated CNC Lathe

Power Consumption : 7.5 kW

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |