Most Popular Products

|

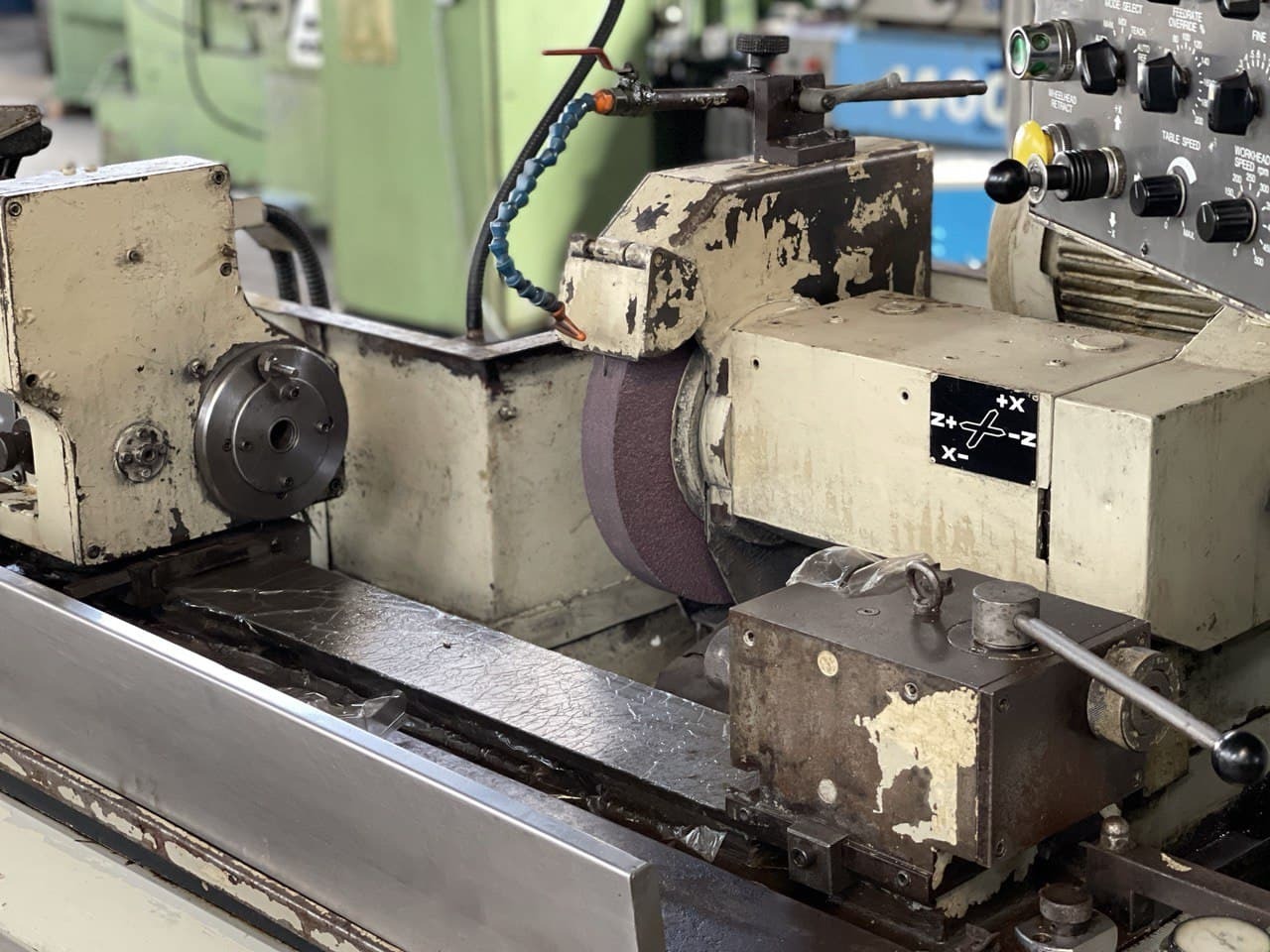

Okamoto Ogm 8.20p Cnc Cylindrical Grinder

Okamoto Ogm 8.20p Cnc Cylindrical Grinder Specification

- Product Type

- CNC Cylindrical Grinder

- General Use

- Cylindrical Grinding

- Material

- Steel/ Cast Iron

- Type

- Ogm 8.20p

- Capacity

- Maximum Grinding Diameter: 200 mm

- Weight (kg)

- Approx. 3500 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Equipped

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 5.5 kW

- Rigidity

- High Rigidity Construction

- Voltage

- 220/380 V

- Motor

- Main Motor 3.7 kW

- Table Size

- 800 x 200 mm

- Spindle Speed

- Up to 1670 rpm

- Axial Choice

- 2-Axis (X/Z)

- Dimension (L*W*H)

- 2560 x 1680 x 1730 mm

- Feature

- Precision Grinding, User-Friendly CNC, Rigid Body

- Color

- White & Gray

- Lubrication System

- Automatic Centralized

- Rapid Traverse Speed

- Max 4000 mm/min (X/Z-Axis)

- Hydraulic System

- Integrated

- Center Height

- 180 mm

- Max Workpiece Weight

- 150 kg

- Coolant System

- Built-in with Filtering

- Control System

- Full CNC (Fanuc) with LCD Touchscreen

- Least Input Increment

- 0.001 mm

- Work Table Swivel

- Yes

- Wheel Size

- 510 x 50 x 203.2 mm

- Chuck Type

- Between Centers / Chuck Mount

- Grinding Length

- 800 mm

About Okamoto Ogm 8.20p Cnc Cylindrical Grinder

*OKAMOTO OGM 8.20P CNC CYLINDRICAL GRINDER*

CATEGORY : CYLINDRICAL GRINDERS

CAPACITY : 200 x 500 mm

Reference No: 773

Technical Specifications:

WORKING CAPACITY

Diameter: 200 mm

Grinding Length: 500 mm

Travels (X/Z): 8" x 25.6"

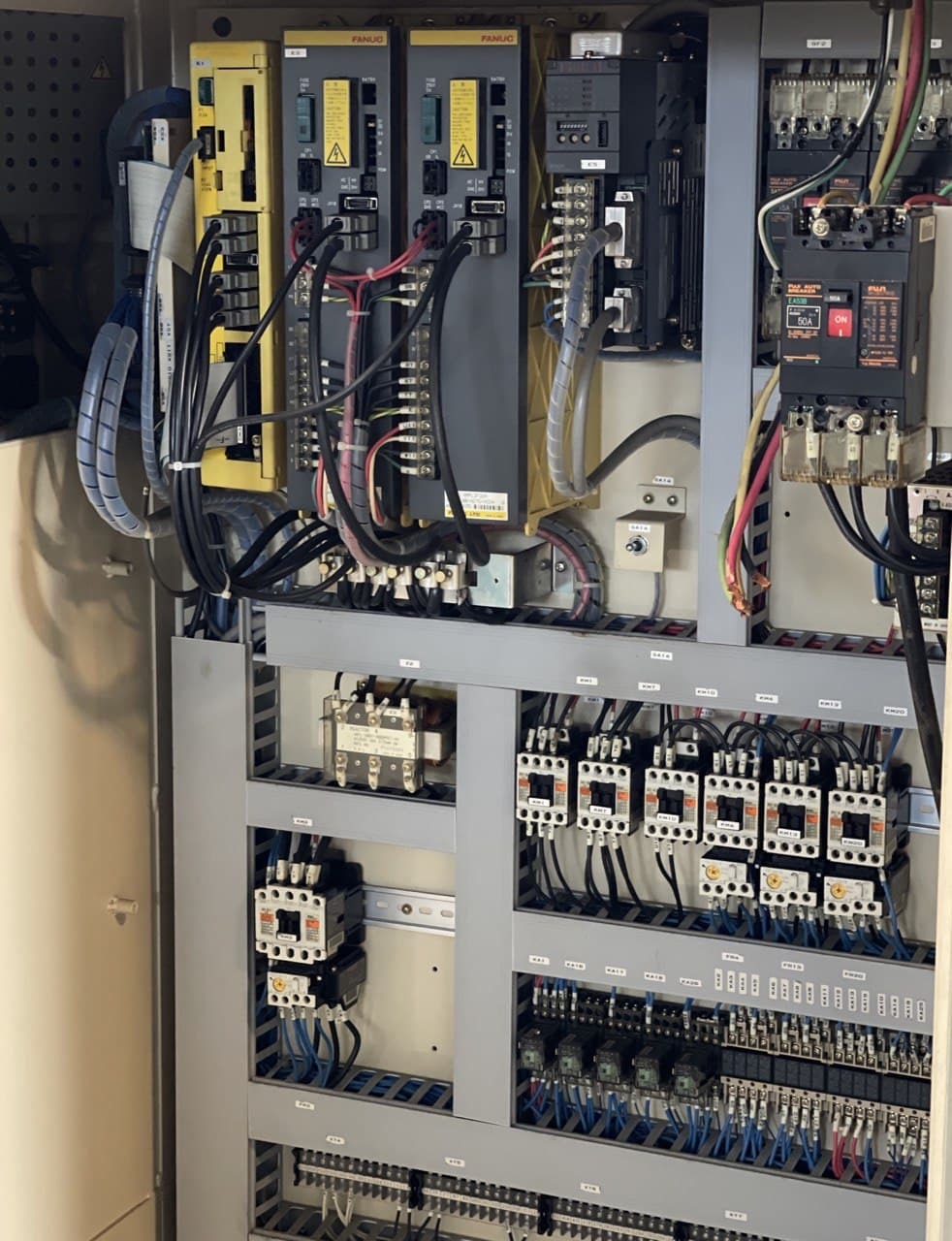

CNC

Control: Fanuc 21G (Alpha Drives)

Advanced CNC Control for Precision

The OGM 8.20P is equipped with a full CNC Fanuc system and LCD touchscreen, ensuring precise programming and real-time monitoring. It features PLC controls, allowing complex grinding cycles and repeatable accuracy. The least input increment is just 0.001 mm, providing outstanding control for demanding tolerance requirements.

Robust Mechanical Design

Built with a high rigidity structure, this cylindrical grinder handles even heavy workpieces (up to 150 kg) while minimizing vibration and deflection. Its main motor delivers 3.7 kW of consistent power, and the stable white and gray body resists wear over extended industrial use, making it a reliable solution for busy workshops.

User-Friendly Operation and Maintenance

Operators benefit from an intuitive interface and centralized automatic lubrication system. The built-in coolant filtering and integrated hydraulic system reduce manual maintenance, while the work table's swivel feature adds flexibility for a variety of job setups. Safety and productivity are both prioritized in the machine's design.

FAQ's of Okamoto Ogm 8.20p Cnc Cylindrical Grinder:

Q: How does the Okamoto OGM 8.20P ensure high precision in cylindrical grinding?

A: This grinder utilizes a full Fanuc CNC system with a touchscreen interface, achieving a minimum input increment of 0.001 mm. Its high rigidity construction minimizes vibration, while automatic lubrication and integrated coolant systems sustain smooth and precise operation.Q: What types of workpieces can be processed with the OGM 8.20P?

A: The machine is suitable for cylindrical grinding steel and cast iron components up to 200 mm diameter, 800 mm length, and 150 kg in weight. It is ideal for general-purpose cylindrical grinding between centers or using a chuck mount.Q: When should I use the work table swivel feature?

A: The work table swivel feature allows you to adjust the angle of the workpiece for increased flexibility during complex grinding operations, such as taper grinding or when specific contouring is required.Q: Where is the Okamoto OGM 8.20P typically used?

A: The OGM 8.20P is widely implemented in precision machining shops, manufacturing plants, and metalworking facilities where high tolerance and repeatability are essential, especially in India by exporters, importers, suppliers, and traders.Q: What is the process for operating the CNC cylindrical grinder?

A: Operators program the grinding sequence via the Fanuc touchscreen, mount the workpiece between centers or in a chuck, and set the required parameters. The integrated hydraulic, coolant, and lubrication systems automate much of the operation for efficient, repeatable grinding.Q: How does the built-in coolant and lubrication system benefit the user?

A: These systems automatically deliver coolant and lubricant to the necessary components, reducing maintenance intervals, enhancing grinding accuracy, and prolonging machine and tool lifespan.Q: What are the energy requirements and power features of the OGM 8.20P?

A: The grinder operates on 220/380 V electric power and consumes 5.5 kW of energy. It is powered by a robust 3.7 kW main motor and is equipped with high-rigidity construction for stable, long-duration operation.

- Minimum Order Quantity

- 1 Number

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Cylindrical Grinder Category

Stanko Production Universal Cylindrical Grinder

Minimum Order Quantity : 1 Number

Rigidity : High

Voltage : 380 V

PLC Control : No

Power Source : Electric

Ribon Rur 800 Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : Other, Highstrength cast iron body

Voltage : 415 V

PLC Control : No

Power Source : Electric

Tschudin Htg 412 Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Voltage : 380 V

PLC Control : No

Power Source : Electric

Jones And Shipman 1078 Production Od Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Voltage : 415 V, 3 Phase

PLC Control : No

Power Source : Electric

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |