|

Colchester Combi K4 Slant Bed Cnc Lathe

Colchester Combi K4 Slant Bed Cnc Lathe Specification

- Product Type

- Slant Bed CNC Lathe

- General Use

- Industrial Metal Machining

- Material

- Cast Iron Bed

- Type

- CNC Lathe

- Capacity

- Swing over bed: 400 mm, Turning length: 650 mm

- Weight (kg)

- 3850 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 18 kVA

- Rigidity

- High rigidity monoblock slant bed design

- Voltage

- 400 V

- Motor

- Main spindle motor 15 kW

- Spindle Speed

- 3500 rpm (max)

- Axial Choice

- 2 Axis (X & Z)

- Dimension (L*W*H)

- 3380 x 1725 x 2100 mm

- Feature

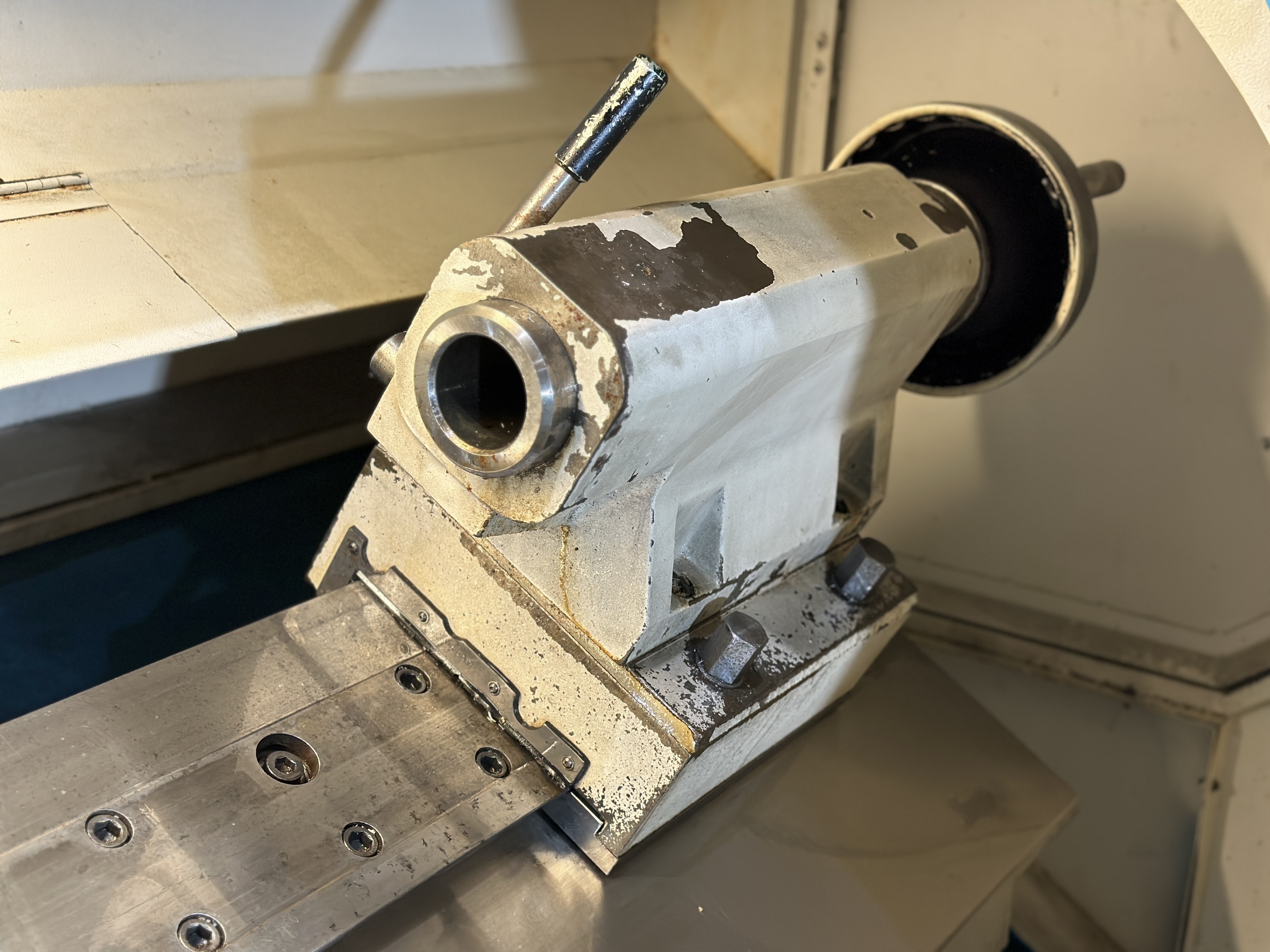

- Slant bed, high precision, C axis (optional), hydraulic tailstock

- Color

- Colchester Grey/Blue

- Spindle Bore

- 62 mm

- Tailstock Quill Diameter

- 75 mm

- Repeatability

- 2 microns

- Tool Turret

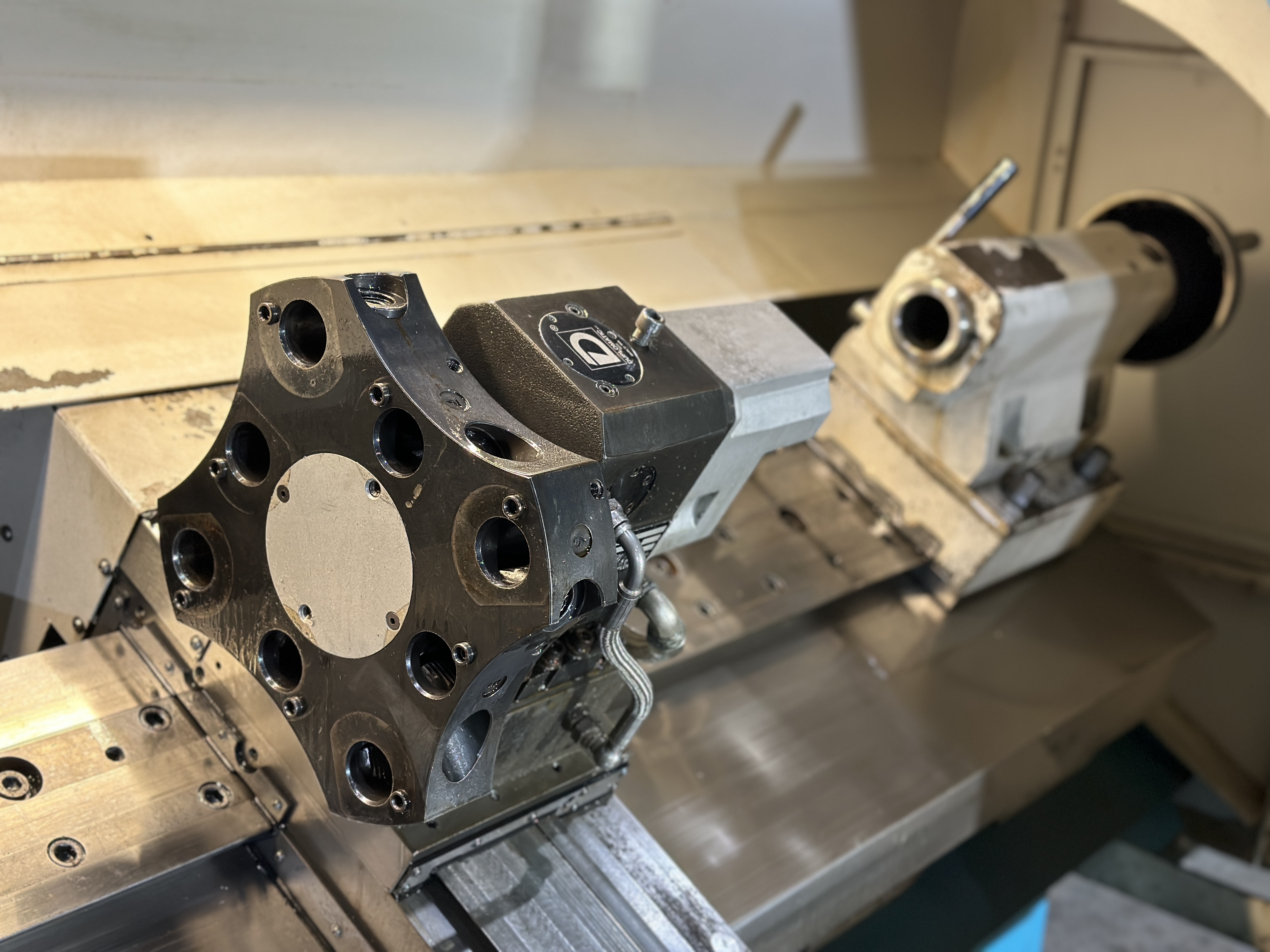

- 8/12 station turret (automatic indexing)

- Positioning Accuracy

- 4 microns

- Noise Level

- Below 75 dB

- Max Turning Diameter

- 310 mm

- Hydraulic Unit

- Integrated for chuck and tailstock

- Tailstock Quill Stroke

- 100 mm

- Z Axis Travel

- 690 mm

- Lubrication

- Fully automatic centralized lubrication

- Coolant System

- Integrated

- Max Turning Length

- 650 mm

- Operating Interface

- Color Graphic Touchscreen

- X Axis Travel

- 210 mm

- Chuck Size

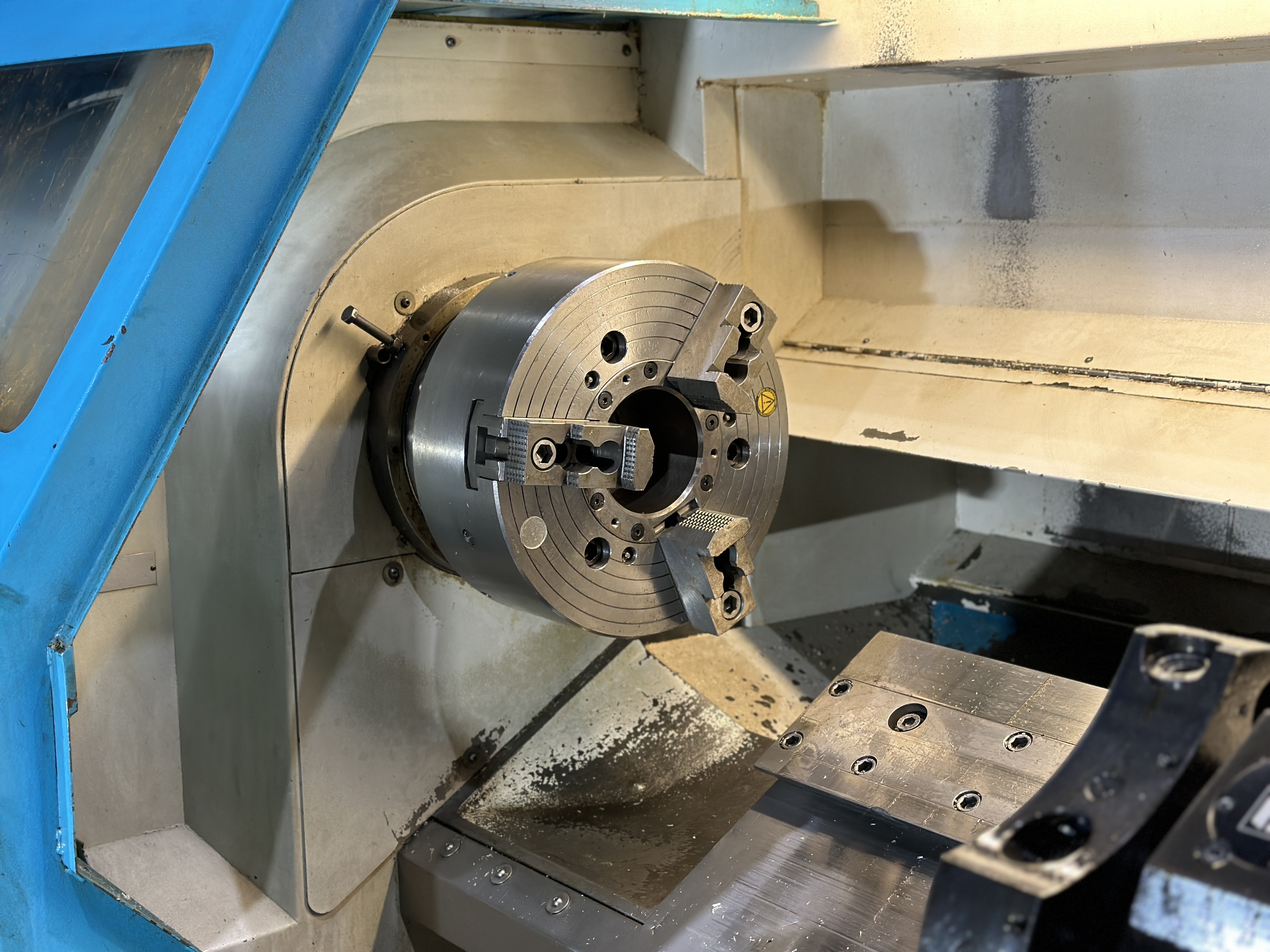

- 250 mm (10) 3-jaw hydraulic

- Backlash Compensation

- Programmable

- Control System

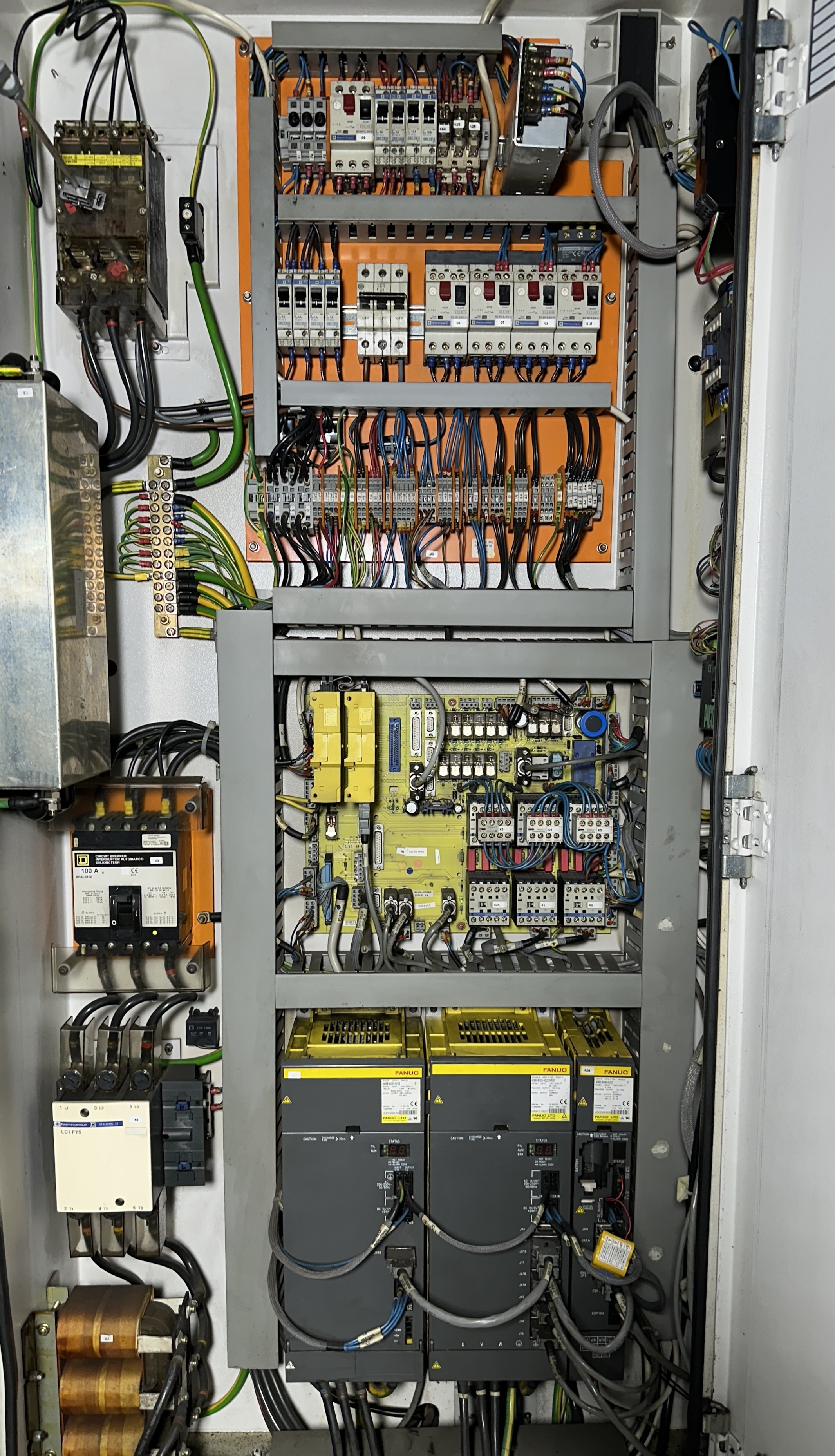

- Fanuc / Siemens / Fagor CNC control (option selectable)

- Rapid Traverse Rate

- X: 24 m/min, Z: 30 m/min

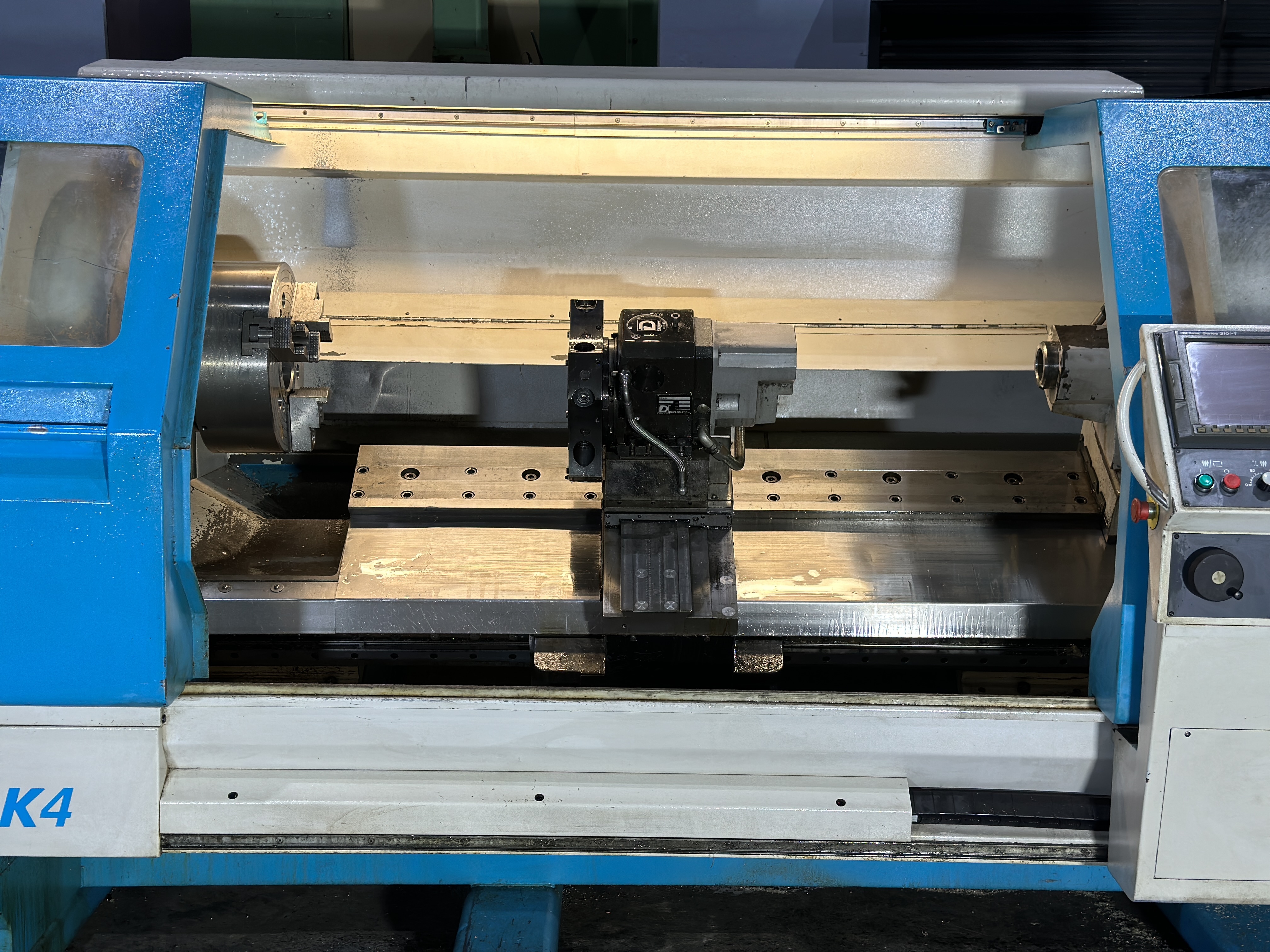

About Colchester Combi K4 Slant Bed Cnc Lathe

*COLCHESTER COMBI K4 SLANT BED CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 1500 mm

YEAR OF CONSTRUCTION : 2001

Reference No: 3433

Video Link: https://youtu.be/stimDA_CQWo

Technical Specifications:

Swing over bed 554mm

Swing over cross slide 370mm

Distance between centres 1500mm

Spindle nose (Camlock) D1-11

Spindle bore 102mm

Spindle motor 18.5/22kW

Spindle speeds (programmable) 4-1800rpm

Tailstock quill taper No. 6 MT

Tailstock quill travel 145mm

Bedway width (30 degree slant) 405mm

Complete with:-

3 Jaw chuck, steady, jaws, manual

8 station VDI turret

Fanuc 210iT control

Engineered for Precision and Reliability

The Colchester Combi K4 slant bed CNC lathe is crafted from a high rigidity monoblock cast iron bed, delivering exceptional vibration damping and structural stability. This ensures consistently high-precision results, making it an ideal solution for diverse industrial machining tasks, from single prototypes to batch production. The machine supports users with features like backlash compensation, programmable automation, and seamless PLC integration.

Efficient Operation and User-Friendly Interface

The Combi K4 features a color graphic touchscreen, providing operators with a modern, intuitive control experience. The lathe can be configured with a choice of Fanuc, Siemens, or Fagor CNC systems, accommodating a wide range of programming preferences. Automatic indexing tool turret and an integrated coolant system further streamline machining processes, contributing to faster setup and reduced downtime.

Versatile Capabilities and Customization Options

Supporting a maximum turning diameter of 310 mm and a length of 650 mm, this CNC lathe is versatile enough for a variety of metalworking applications. Optional features like C-axis capability and a bar feeder expand its operational flexibility. The CNC lathe's compact footprint and integrated systems (lubrication, hydraulics) allow easy installation and hassle-free maintenance in industrial settings.

FAQ's of Colchester Combi K4 Slant Bed Cnc Lathe:

Q: How does the Colchester Combi K4 ensure high machining precision?

A: The Combi K4 utilizes a high-rigidity slant bed monoblock cast iron design, fully automatic centralized lubrication, and programmable backlash compensation. With a positioning accuracy of 4 microns and repeatability of 2 microns, it ensures consistent and precise results.Q: What type of workpieces can be machined using this CNC lathe?

A: This machine supports a maximum turning diameter of 310 mm and a turning length of up to 650 mm, making it suitable for medium to large metal components in industrial manufacturing. The spindle bore of 62 mm allows for substantial stock sizes.Q: When should I consider using the optional bar feeder and C-axis features?

A: The bar feeder is ideal for continuous or automated production runs, minimizing manual loading. The optional C-axis provides additional machining flexibility, such as for complex milling or off-center operations, enhancing part versatility for specialized tasks.Q: Where can the Colchester Combi K4 be installed?

A: With its compact dimensions (3380 x 1725 x 2100 mm) and integrated systems, the Combi K4 is suitable for most industrial shop floors, machine shops, or manufacturing facilities that require high-precision turning on a robust platform.Q: What control systems are available with the Combi K4 lathe?

A: The machine can be equipped with your choice of Fanuc, Siemens, or Fagor CNC control systems, all featuring a user-friendly color touchscreen interface for quick programming and operational efficiency.Q: How does the automatic tool turret benefit my machining process?

A: The 8/12 station automatic indexing tool turret allows for rapid tool changes during operations, reducing cycle times and enabling multi-step machining without manual intervention, thus increasing productivity.Q: What maintenance processes are involved with this lathe?

A: Routine maintenance is minimal due to the fully automatic centralized lubrication system and integrated coolant and hydraulic units. Periodic inspection of these systems and general cleaning keeps the lathe running in optimal condition.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Colchester Cnc-2000l Cnc Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Yes

Weight (kg) : 4200 kg

Capacity : Swing over bed: 400 mm, Max turning length: 1000 mm

Automatic : Yes

Citizen B20 Cnc Sliding Head

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Available

Weight (kg) : Approx. 2200 kg

Capacity : Bar capacity up to 20mm diameter

Automatic : Other, Fully automatic operation

Schiess Germany Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Siemens PLC

Weight (kg) : 18500

Capacity : Max Workpiece Diameter 1600 mm

Automatic : Yes

Nakamura Tome Superturn 4 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Yes

Weight (kg) : Approx. 7,000 kg

Capacity : Max swing over bed: 530 mm; Max turning length: 830 mm

Automatic : Yes

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |