|

Leadwell 25 Vmc (4-axis)

Leadwell 25 Vmc (4-axis) Specification

- Product Type

- Vertical Machining Center (VMC) 4-Axis

- General Use

- Metal cutting and precision machining

- Material

- Cast Iron structure with precision components

- Type

- CNC Machine

- Capacity

- Maximum Load 400 kg

- Weight (kg)

- 3500 kg

- Computerized

- Yes

- Automatic

- Fully automatic

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 15 kVA

- Rigidity

- High rigidity with C-type structure

- Voltage

- 380 V

- Motor

- Main Spindle Motor 7.5 kW (10 HP)

- Table Size

- 1000 x 450 mm

- Spindle Speed

- 8000 rpm

- Axial Choice

- 4-Axis (X/Y/Z + Rotational)

- Dimension (L*W*H)

- 2600 x 2150 x 2350 mm

- Feature

- High precision, heavy-duty design, 4th-axis rotary table equipped

- Color

- White & Blue

- Spindle Taper

- BT40

- Air Requirement

- 6 kg/cm²

- Repeatability

- ±0.003 mm

- Travel (X/Y/Z)

- 800/420/510 mm

- Tool Magazine Capacity

- 20 Tools

- Chip Removal

- Auto chip conveyor equipped

- Coolant System

- Standard with coolant pump

- Positioning Accuracy

- ±0.005 mm

- Controller

- FANUC / Mitsubishi / Siemens options

- Rapid Traverse X/Y/Z

- 24/24/20 m/min

About Leadwell 25 Vmc (4-axis)

*LEADWELL 25 VMC (4-Axis)*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 650 x 410 x 410 mm

YEAR OF CONSTRUCTION : 1996

Reference No: 2780

Technical Specifications:

WORKING CAPACITY

Travels (XYZ): 650 x 410 x 410 mm

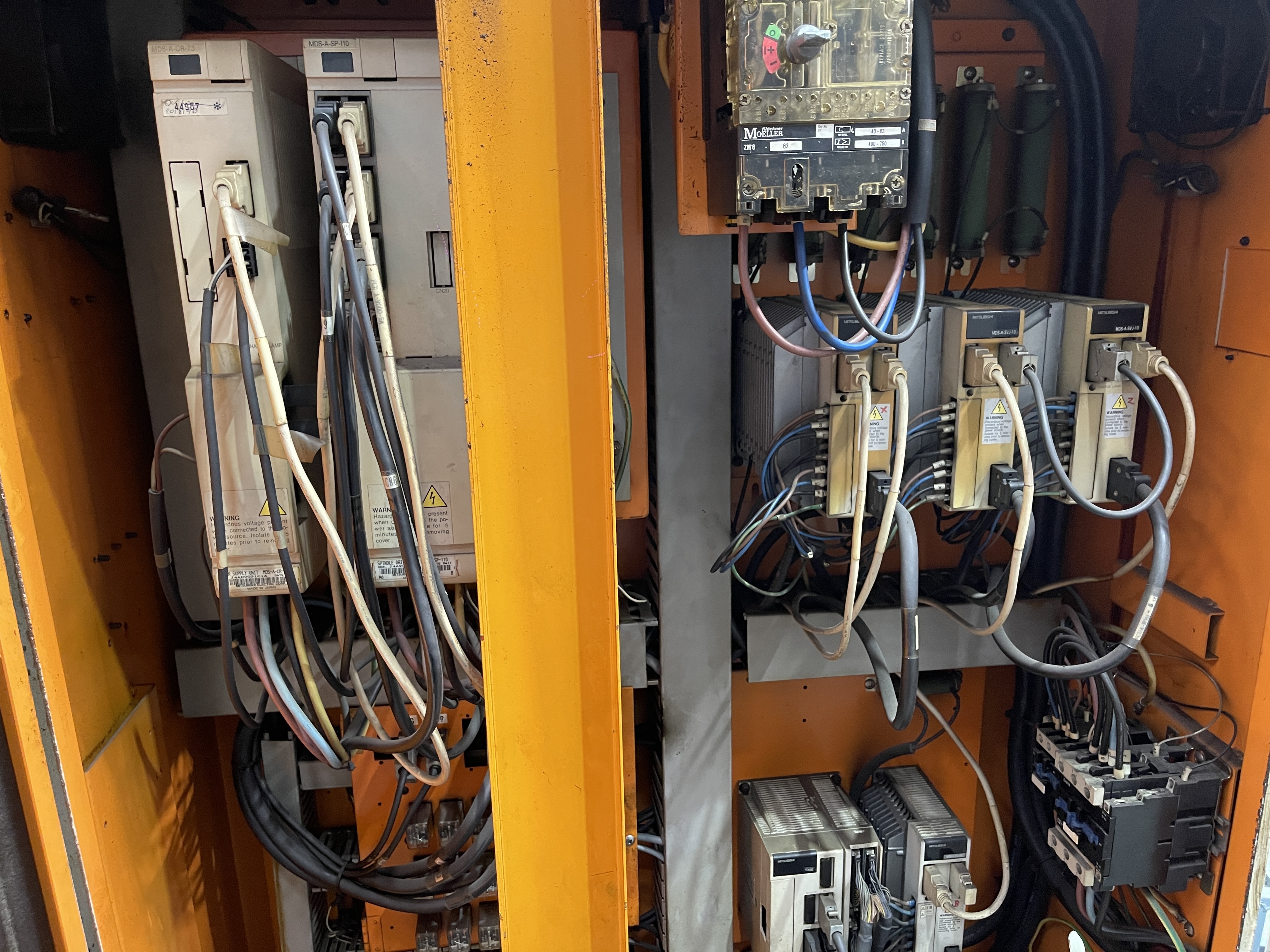

CNC

Control: MITSUBISHI - MELDAS 50.M

SPINDLE

Spindle Taper: BT40

Spindle Speed: 6000 RPM

ATC

Tool Change Capacity: 20 Tools

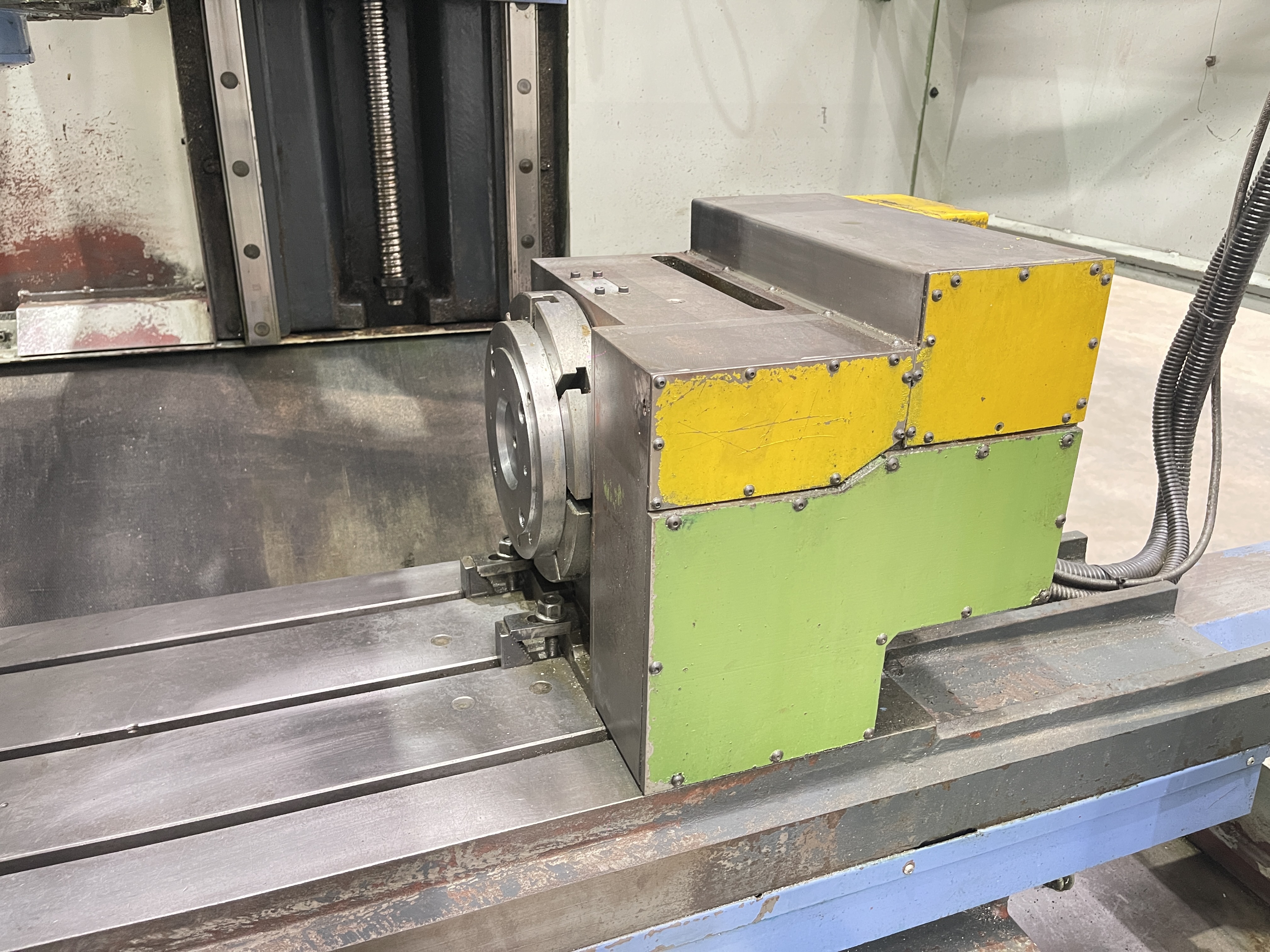

With 4th Axis

Precision and Performance

With up to 0.005 mm positioning accuracy and 0.003 mm repeatability, the Leadwell 25 VMC is tailored for industries demanding meticulous metal cutting results. The heavy-duty cast iron construction, 4-axis capability, and advanced spindle system ensure reliable and consistent performance across diverse machining tasks, minimizing defects and maximizing productivity.

Integrated Automation and Flexibility

Outfitted with a fully automatic tool changer for 20 tools and an auto chip conveyor, the Leadwell 25 VMC streamlines production workflows. Users can choose between FANUC, Mitsubishi, or Siemens controllers for seamless integration with their operational requirements. The machine is suitable for a range of applications-from prototyping to batch production-thanks to its programmable PLC control and computerized interface.

FAQ's of Leadwell 25 Vmc (4-axis):

Q: How does the Leadwell 25 VMC enhance precision in metal cutting applications?

A: The Leadwell 25 VMC achieves high precision through its rigid C-type cast iron structure, advanced 4-axis control, and superior spindle positioning capabilities, ensuring accuracy of 0.005 mm and repeatability of 0.003 mm for intricate metal machining tasks.Q: What are the main benefits of the 4th-axis rotary table on this VMC?

A: The 4th-axis rotary table allows complex multi-sided machining without repositioning the workpiece, significantly increasing productivity and enabling precise manufacturing of parts that require angular or rotational features.Q: When should I choose the FANUC, Mitsubishi, or Siemens controller option?

A: Selection depends on your shop's compatibility and operational preferences. FANUC, Mitsubishi, and Siemens controllers all offer advanced CNC functionality, but considerations may include pre-existing equipment, software integration, and personnel familiarity for optimal workflow.Q: Where is the Leadwell 25 VMC commonly used and what materials can it handle?

A: Widely utilized by exporters, suppliers, and traders across India's manufacturing sector, the machine is designed for heavy-duty metal cutting and precision machining, effectively handling various metals and alloys due to its robust spindle and cast iron structure.Q: How is automatic chip removal managed in this machining center?

A: The Leadwell 25 VMC comes equipped with an auto chip conveyor that efficiently extracts metal chips during operation, maintaining cleanliness, preventing workpiece damage, and supporting continuous, unattended production.Q: What is the process for tool changing in this machine?

A: Tool changing is performed automatically via a 20-tool magazine system. The computerized controller identifies and swaps tools as per programmed machining sequences, enhancing workflow and reducing setup downtime.Q: What are the usage recommendations for optimal performance and reliability?

A: To ensure peak output, operate with stable electrical supply (380 V, 15 kVA), supply compressed air at 6 kg/cm2, use appropriate coolant, and avoid loading beyond 400 kg. Routine maintenance and proper programming further safeguard performance.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Xyz Krv 2000 Cnc M1tr Turret Milling Machine

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 1800 x 1700 x 2100 mm

Weight (kg) : 1100 kg

Capacity : Heavy Duty (Max. load 300 kg)

Motor : Other, 3 HP 3 Phase Motor

Dahlih Mcv 2100 Vmc 1

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 5,060 x 3,150 x 3,400 mm

Weight (kg) : 13,500 kg

Capacity : Max Loading 1,800 kg

Motor : Other, Spindle Motor 15/18.5 kW

Richmond Cnc Radial Drill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 2450 x 1100 x 2900 mm

Weight (kg) : 3100 kg

Capacity : Drilling Capacity 50 mm

Motor : Other, 7.5 HP main motor

Daewoo Doosan Mynx Nm410 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 2500 mm x 2300 mm x 2500 mm

Weight (kg) : Approx. 5000 kg

Capacity : Table Load Capacity 600 kg

Motor : Other, Main Spindle Motor: 15 HP (11 kW)

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |