|

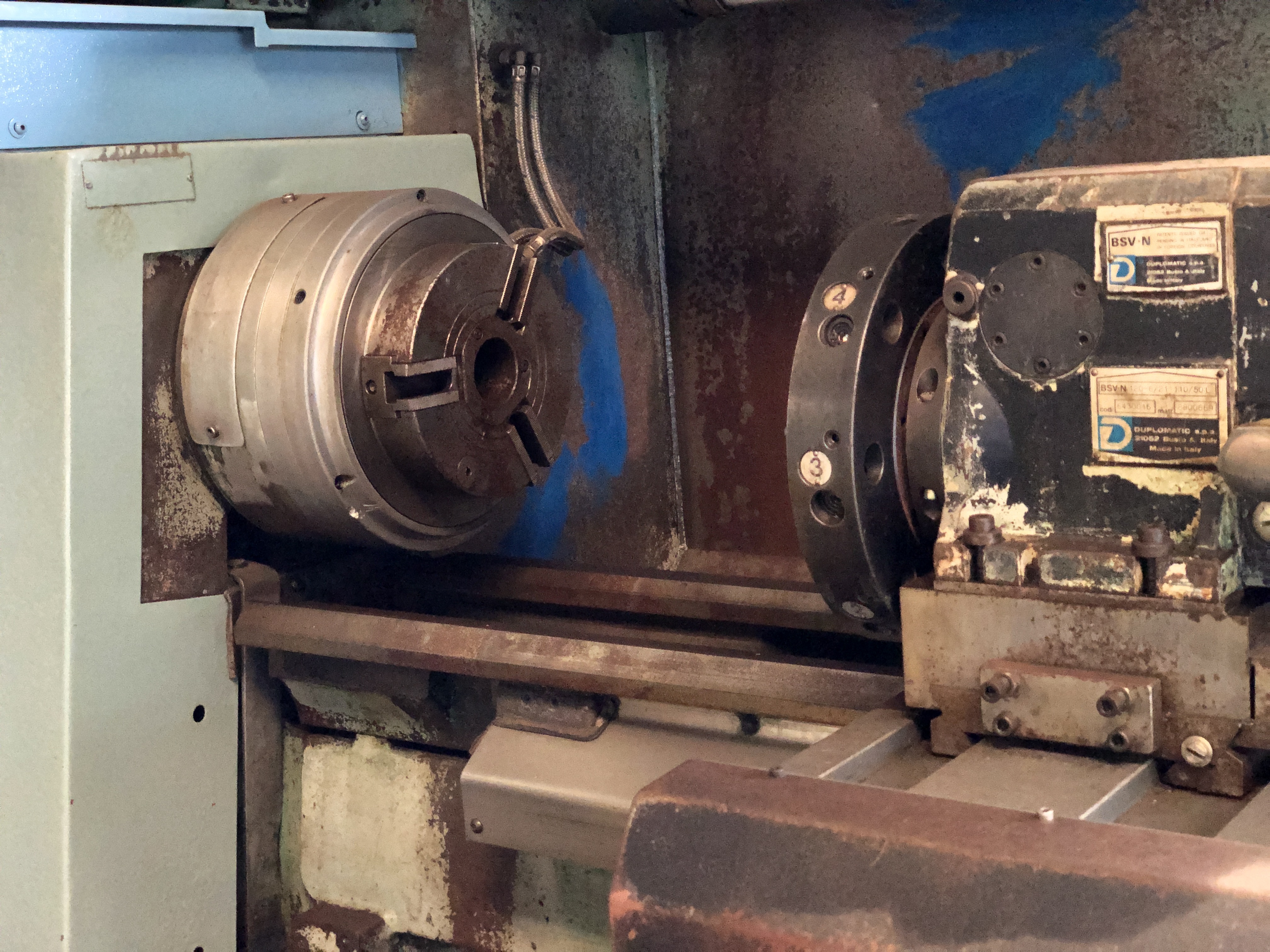

Colchester Cnc-2000l Cnc Turning Center

Colchester Cnc-2000l Cnc Turning Center Specification

- Product Type

- CNC Turning Center

- General Use

- Industrial metal turning

- Material

- Cast Iron Body, Hardened Steel Slides

- Type

- Automated CNC Lathe

- Capacity

- Swing over bed: 400 mm, Max turning length: 1000 mm

- Weight (kg)

- 4200 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 7.5 kW

- Rigidity

- High rigidity mono-block bed

- Voltage

- 415V / 3 Phase / 50Hz

- Motor

- Main Spindle Motor: 7.5 kW AC motor

- Table Size

- N/A (Turning Center)

- Spindle Speed

- Up to 3500 rpm

- Axial Choice

- 2-Axis (X, Z)

- Dimension (L*W*H)

- 3100 mm x 1620 mm x 1750 mm

- Feature

- Linear guideways, Hydraulic chuck, High Precision

- Color

- Standard industrial grey & off-white

- Tool Shank Size

- 20 mm x 20 mm

- Machine Bed

- Slant Bed Structure

- Rapid Traverse Rate

- 18 m/min (X), 20 m/min (Z)

- Noise Level

- Less than 75 dB

- Controller Brand

- Fanuc / Siemens / Optional

- Lubrication

- Automatic Lubrication System

- Input Supply

- 3 Phase, 415 V, 50 Hz

- Turret Type

- Servo 8-Station

- Repeatability

- ±0.003 mm

- Traverse Travel X/Z

- 220 mm / 1050 mm

- Hydraulic System

- Integral Unit

- Chuck Size

- 200 mm

- Spindle Bore

- 62 mm

- Coolant System

- Inbuilt

- Tailstock

- Programmable

About Colchester Cnc-2000l Cnc Turning Center

*COLCHESTER CNC-2000L CNC TURNING CENTER*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 1250 mm

Reference No: 1076

Technical Specifications:

Control: Fanuc OT

Swing Over Bed: 390mm

Distance Between Centres: 1250mm

Swing Over Saddle: 240mm

Spindle Speeds: 2750RPM

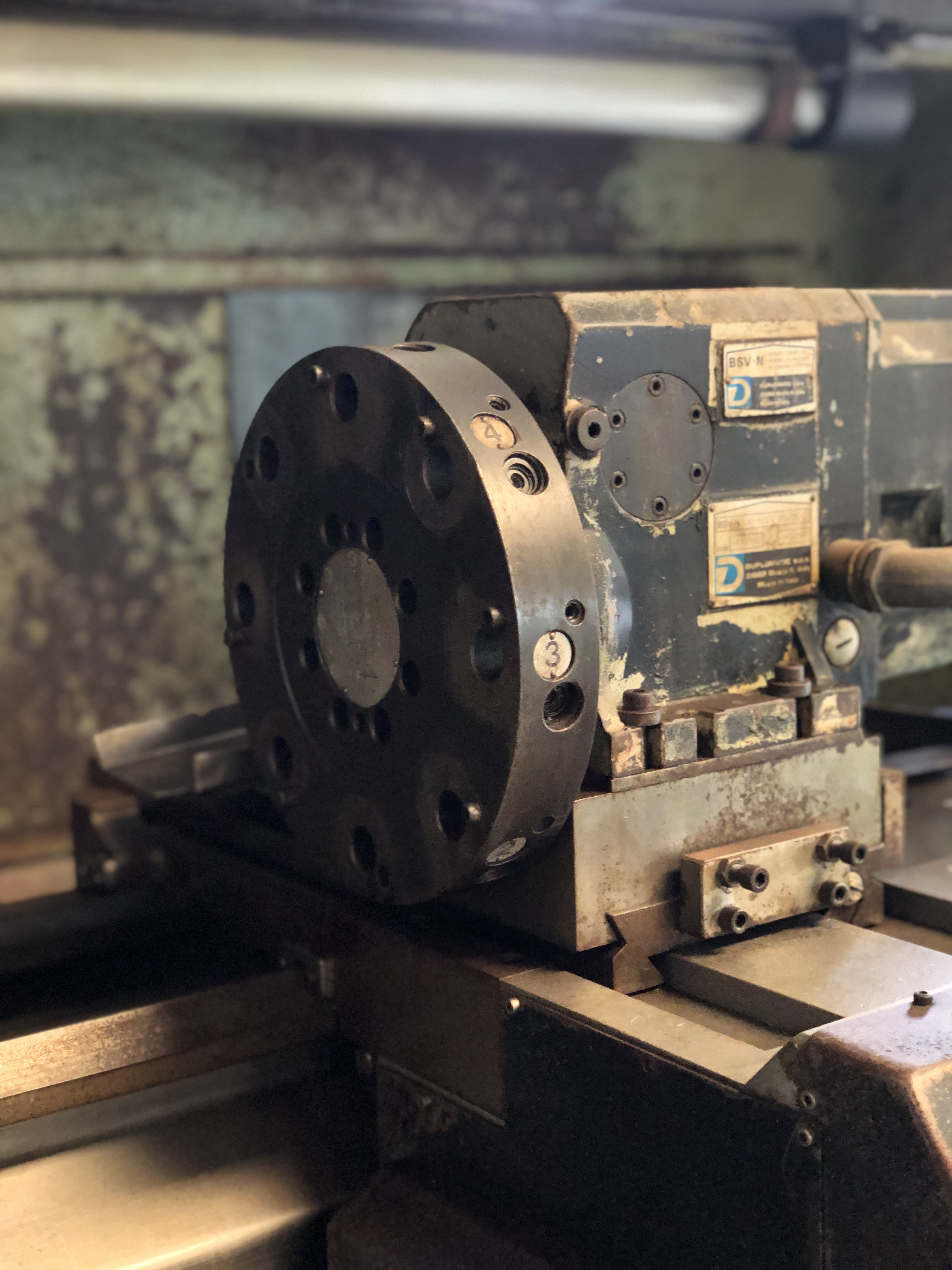

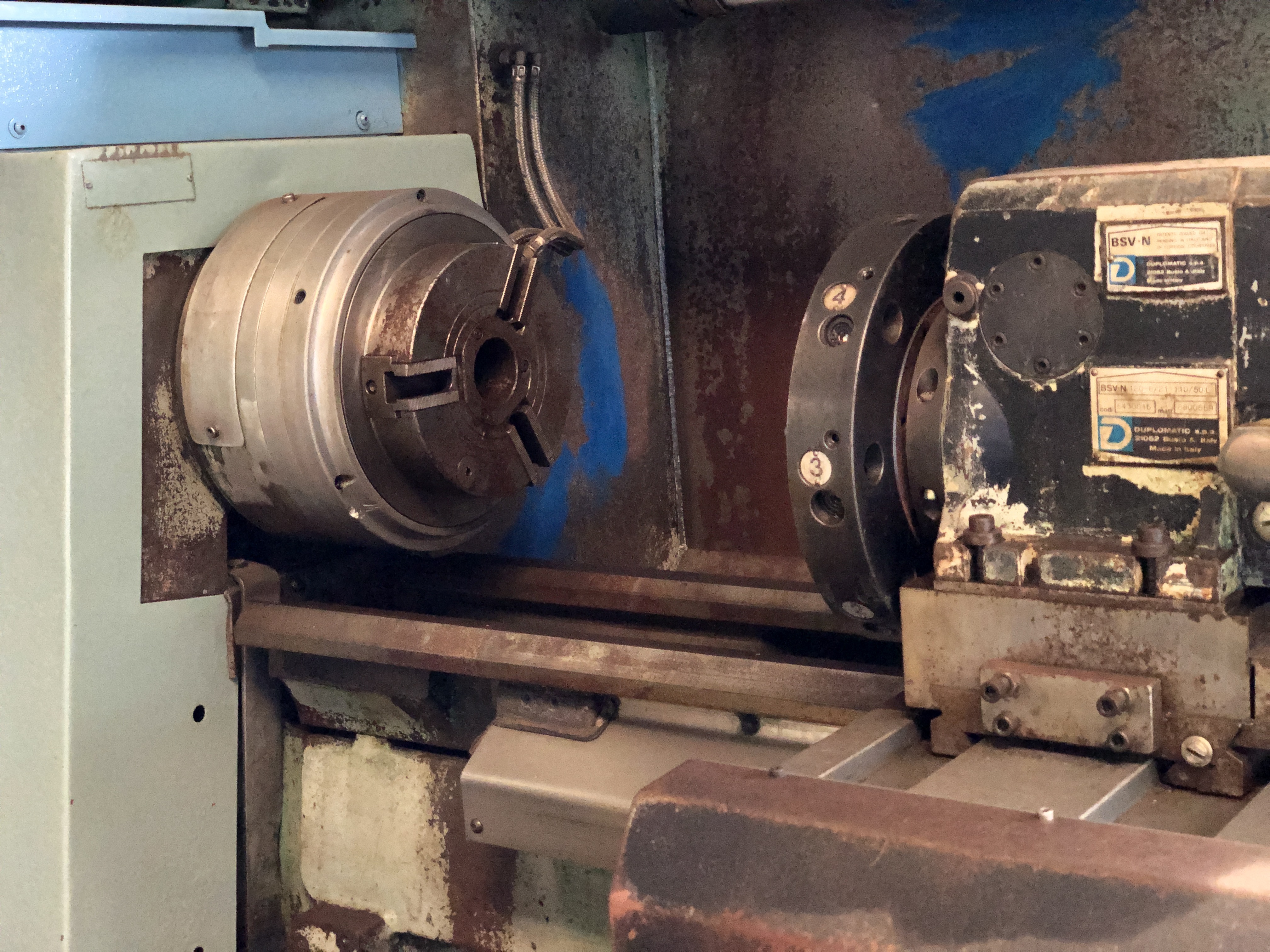

8 Station Duplomatic Turret

Tailstock

250mm Dia Three Jaw Chuck

High Precision & Robust Build

The CNC-2000L Turning Center guarantees exceptional accuracy with a repeatability of 0.003 mm. Its high-rigidity mono-block cast iron bed coupled with hardened steel slides minimizes vibration, ensuring consistent results even over long production runs. The slant-bed structure provides added structural integrity and operator comfort.

Versatile Automation and Control

Fitted with a servo 8-station turret, programmable tailstock, and integrated PLC control, this turning center adapts efficiently to various industrial requirements. Select from leading controller brands-Fanuc, Siemens, or other compatible options-tailored to your process preferences for maximum productivity.

Efficient and Reliable Operations

The CNC-2000L features automatic lubrication, an inbuilt coolant system, and an integral hydraulic unit for seamless operation. With a rapid traverse rate of up to 20 m/min on the Z-axis and a main spindle speed up to 3500 rpm, it meets the demands of high-volume production with minimal downtime.

FAQ's of Colchester Cnc-2000l Cnc Turning Center:

Q: How does the Colchester CNC-2000L ensure high precision during turning operations?

A: The machine features a high-rigidity mono-block bed, linear guideways, and a servo-driven 8-station turret, all contributing to its excellent repeatability of 0.003 mm. These elements reduce vibration and ensure stable, precise machining on each cycle.Q: What materials can be processed using this CNC Turning Center?

A: The Colchester CNC-2000L is designed for industrial metal turning, accommodating a wide range of metals, including various steel grades, cast iron, and non-ferrous materials, thanks to its robust construction and powerful 7.5 kW spindle motor.Q: When is it beneficial to use the programmable tailstock feature?

A: The programmable tailstock is especially useful when machining long or slender workpieces, as it provides additional support, minimizing deflection and ensuring consistent accuracy across extended turning cycles.Q: Where can the CNC-2000L be installed and used effectively?

A: This turning center is suited for industrial environments such as manufacturing plants, precision engineering workshops, and metalworking facilities. Its noise level under 75 dB and ergonomic design enable safe, comfortable use in professional settings.Q: What is the process for regular maintenance of this machine?

A: Routine maintenance includes ensuring the automatic lubrication and inbuilt coolant systems are functioning correctly, regularly inspecting the hydraulic system, and keeping the tool turret and guideways clean to prevent debris accumulation.Q: How does the integrated hydraulic system contribute to machine performance?

A: The integral hydraulic unit powers the chuck and turret, ensuring fast, reliable tool changes and secure workpiece clamping, which increases overall machine efficiency and minimizes downtime during operations.Q: What are the main benefits of choosing the Colchester CNC-2000L for industrial turning?

A: Key advantages include its high precision, automation features (such as PLC control and programmable tailstock), superior build quality for durability, flexible controller options, and efficient operations-making it well-suited for demanding, high-volume production.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Emcoturn 320 Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automatic : Yes

Material : Other, Cast Iron Base, Steel Components

General Use : CNC Turning for industrial metalworking

Color : Other, Standard machine grey/red

Mori Seiki Zl-25mc/500 Cnc Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automatic : Yes

Material : Other, All engineering metals

General Use : Turning and milling complex components

Color : Other, Standard Mori Seiki grey/white

Schiess Germany Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automatic : Yes

Material : Other, Cast Iron Body; Hardened Steel Components

General Use : Industrial metal turning, machining large components

Color : Other, Blue and Grey

Mazak F10 Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automatic : Other, Fully Automatic Operation

Material : Other, Cast Iron, Steel, Hard Metals

General Use : Industrial Metal Turning and Machining

Color : Other, Mazak Standard (White/Orange)

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |