|

Kafo 1500 X 800 Vmc

Kafo 1500 X 800 Vmc Specification

- Product Type

- Vertical Machining Center

- General Use

- Industrial metal cutting and component machining

- Material

- Cast Iron Base, Alloy Steel Components

- Type

- VMC (Vertical Machining Center)

- Capacity

- Max Load 1500 kg

- Weight (kg)

- 9000 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 20 kW

- Rigidity

- High

- Voltage

- 380 V / 415 V

- Motor

- Spindle Motor: 15 kW

- Table Size

- 1500 mm x 800 mm

- Spindle Speed

- 8000 RPM (max)

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- 3300 mm x 2600 mm x 2700 mm

- Feature

- Precision machining, Heavy load capacity, Rigid structure

- Color

- White & Grey

- Air Pressure Requirement

- 6 bar

- Tool Magazine Capacity

- 24 Tools (Automatic Tool Changer)

- Noise Level

- <75 dB

- Cutting Feed Rate

- 1 - 10,000 mm/min

- Electrical Connection

- 3 Phase, 50/60 Hz

- Repeatability

- ±0.003 mm

- Rapid Traverse Rate X/Y/Z

- 30/30/18 m/min

- Travel (X/Y/Z Axis)

- 1500 mm / 800 mm / 700 mm

- Coolant System

- High Pressure

- Tool Change Time (T-T)

- 2.5 sec

- Control System

- FANUC / Siemens / Mitsubishi (as per configuration)

- Distance from Table Surface to Spindle Nose

- 150~850 mm

- Floor Space Required

- 3300 mm x 2600 mm

- Spindle Taper

- BT50

- Distance from Spindle Centerline to Column

- 860 mm

- Table Load Capacity

- Max 1500 kg

- Lubrication System

- Automatic Centralized

- Optional Accessories

- 4th Axis rotary table, linear scales, chip conveyor

- Positioning Accuracy

- ±0.005 mm

About Kafo 1500 X 800 Vmc

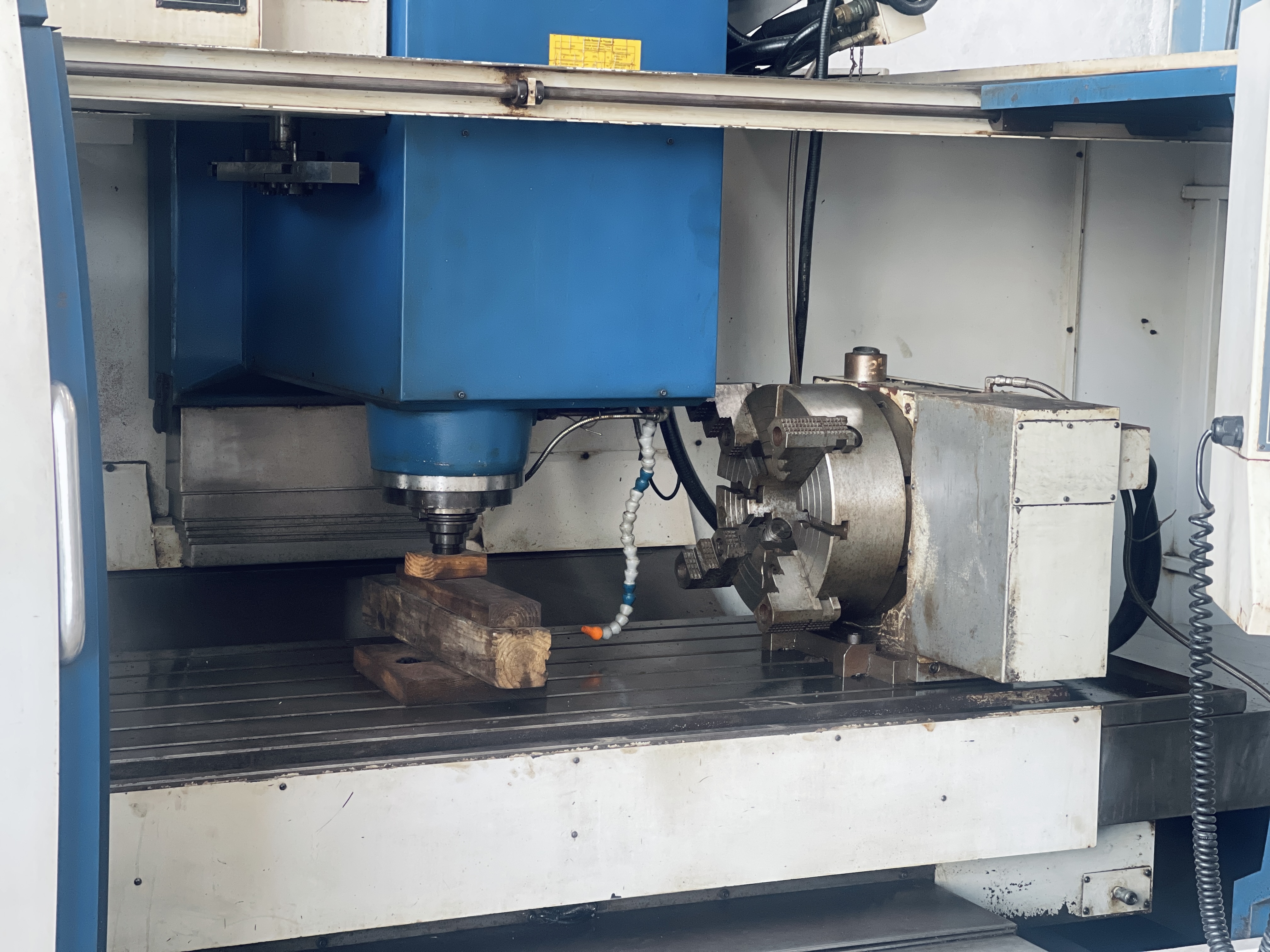

*KAFO 1500 x 800 VMC*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 1500 x 800 x 700 mm

YEAR OF CONSTRUCTION : 2004

Reference No: 2213

Technical Specifications:

WORKING CAPACITY

Table Size: 1900 x 850 mm

Travels (XYZ): 1500 x 800 x 700 mm

4th Axis Rotary Chuck: 410 mm

CNC

Control: Fanuc 18-M (Alpha Drives)

SPINDLE

Spindle Taper: CAT 50

Spindle Speeds: 6000 RPM

ATC

Tool Changer (Arm Type): 32 Stations

Gear Head Spindle, 4th Axis Rotary Table (410mm Chuck), Coolant Thru Spindle (High Pressure)

Precision and Efficiency for Industrial Machining

The Kafo 1500 X 800 VMC is engineered for demanding manufacturing environments where accuracy and productivity are paramount. Its high-rigidity structure, fast tool-change time, and versatile CNC controls make it suitable for a wide range of metalworking tasks, enabling batch production and intricate component fabrication with ease.

Optimized for Heavy-Duty Performance

With a load capacity of up to 1500 kg and a spacious table, this VMC is capable of handling large and heavy workpieces. The BT50 spindle, robust spindle motor (15 kW), and rapid traverse rates ensure swift material removal and consistent machining quality, making it ideal for heavy industries and precision engineering.

Flexible Control and Automation

Choose from leading control systems (FANUC, Siemens, Mitsubishi) to match your workflow requirements. The fully automatic, computerized operations, along with an advanced tool magazine and centralized lubrication, reduce manual intervention and maintenance intervals, optimizing productivity and machine uptime.

FAQ's of Kafo 1500 X 800 Vmc:

Q: How does the Kafo 1500 X 800 VMC achieve high precision in machining?

A: The VMC features a rugged cast iron base, high-quality alloy steel components, and precise CNC controls, enabling it to deliver positioning accuracy of 0.005 mm and repeatability of 0.003 mm. Coupled with its high-pressure coolant system, it maintains dimensional stability even under demanding production conditions.Q: What types of materials and industries is this VMC suitable for?

A: The Kafo 1500 X 800 VMC is tailored for industrial metal cutting applications and component machining, handling materials like steel, cast iron, and alloys. Common applications include automotive, aerospace, machinery, and heavy equipment manufacturing.Q: When should I use the optional accessories like the 4th axis rotary table or linear scales?

A: Optional accessories such as the 4th axis rotary table are recommended for complex multi-sided machining, while linear scales enhance positioning feedback for critical tolerance work. They are beneficial when your production demands greater versatility or tighter precision.Q: Where can this Vertical Machining Center be installed, and what are the space requirements?

A: The machine is designed for installation in industrial workshops or production facilities, requiring a floor space of 3300 mm x 2600 mm. Proper access to 3-phase electrical supply, compressed air (6 bar), and regular maintenance space are also necessary.Q: What is the process for changing tools on this VMC?

A: Tool changes are fully automatic via the 24-tool magazine. The machine completes tool-to-tool change in approximately 2.5 seconds, minimizing downtime and increasing overall machining efficiency.Q: How does the Kafo VMC support long-term operational reliability?

A: An automatic central lubrication system ensures consistent, appropriate grease or oil distribution to all critical components. The heavy-duty construction and high-quality mechanical parts limit wear and extend service life even under continuous use.Q: What benefits does the high-pressure coolant system provide during machining?

A: High-pressure coolant improves chip evacuation, reduces thermal distortion, and prolongs tool life, leading to enhanced surface finish and stable machining performance, particularly during intensive, high-speed operations.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Anderson Cnc Router

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Dimension (L*W*H) : 3500 x 2200 x 2000 mm

Weight (kg) : 1800 kg

Color : Other, White and Blue

Leadwell 610 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Dimension (L*W*H) : 2640 mm x 2500 mm x 2550 mm

Weight (kg) : Approx. 5000 kg

Color : Other, White & Grey

Mori Seiki Mv 65 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Dimension (L*W*H) : 4000 mm x 2700 mm x 3050 mm

Weight (kg) : ~11,500 kg

Color : Other, White & Blue

Chiron Fz 12s Dtc Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Dimension (L*W*H) : 2800 mm x 2400 mm x 2500 mm

Weight (kg) : 4700 kg

Color : Other, White and Blue

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |