|

Mori Seiki Sl35/700 Cnc Lathe

Mori Seiki Sl35/700 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Turning, Metal Machining

- Material

- Cast Iron Base, Steel Components

- Type

- Horizontal

- Capacity

- Max Turning Diameter: 400 mm; Max Turning Length: 700 mm

- Weight (kg)

- 6500 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 15 kVA

- Rigidity

- High

- Voltage

- 380 V / 50 Hz

- Motor

- Main Spindle Motor: 15 kW

- Table Size

- Not applicable (Lathe machine)

- Spindle Speed

- 2500 RPM

- Axial Choice

- 2 Axis (X,Z)

- Dimension (L*W*H)

- 3300 mm x 1700 mm x 1850 mm

- Feature

- Precision Cutting, Heavy Duty

- Color

- White & Blue

- Chuck Size

- 300 mm

- Coolant System

- Included

- Swing Over Bed

- 550 mm

- Hydraulic System

- Included

- Control System

- Fanuc (model dependent)

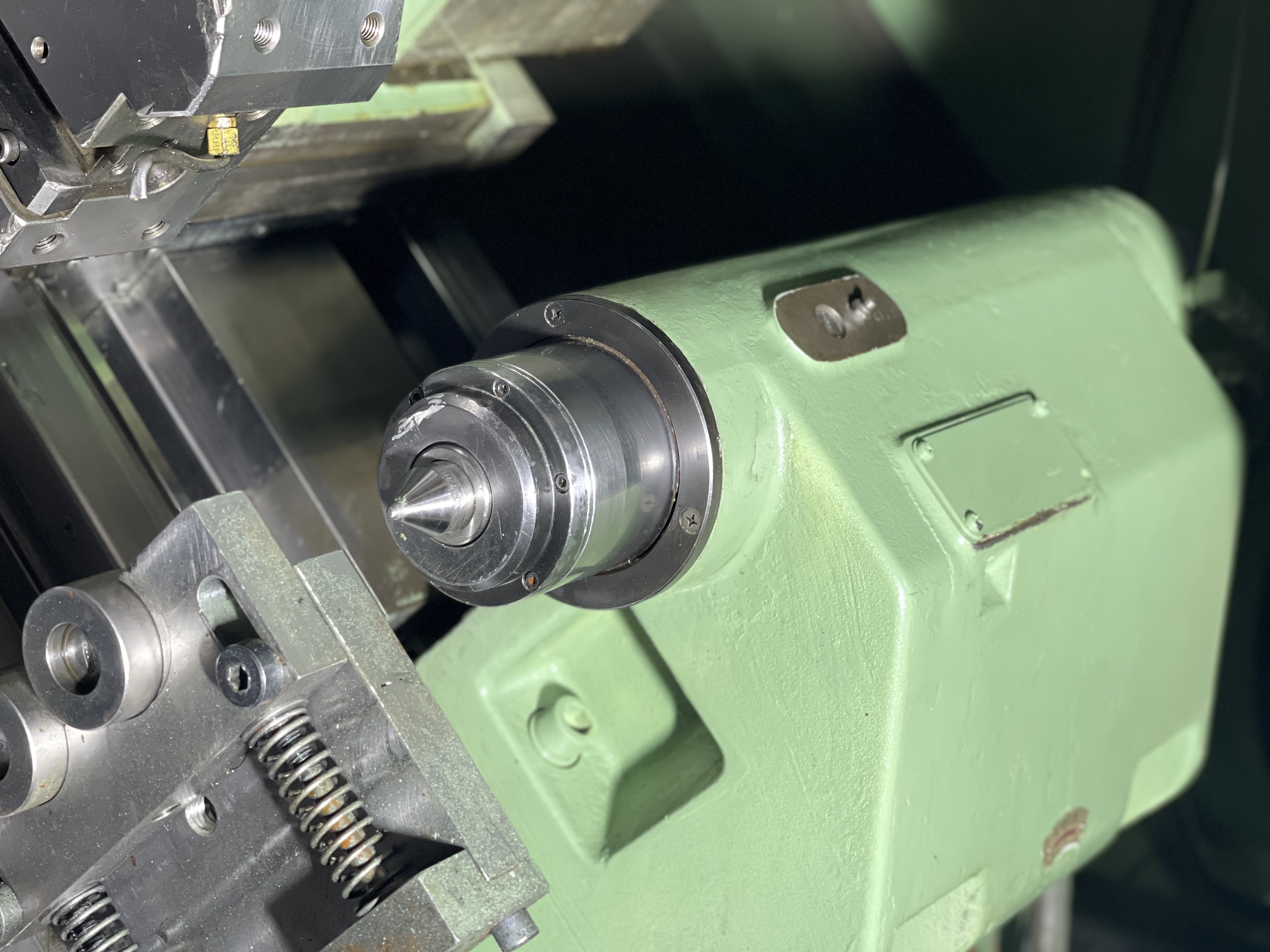

- Tailstock Quill Stroke

- 120 mm

- Rapid Traverse (X/Z axis)

- 12/15 m/min

- Spindle Bore

- 80 mm

- Distance Between Centers

- 700 mm

- Repeatability

- ±0.002 mm

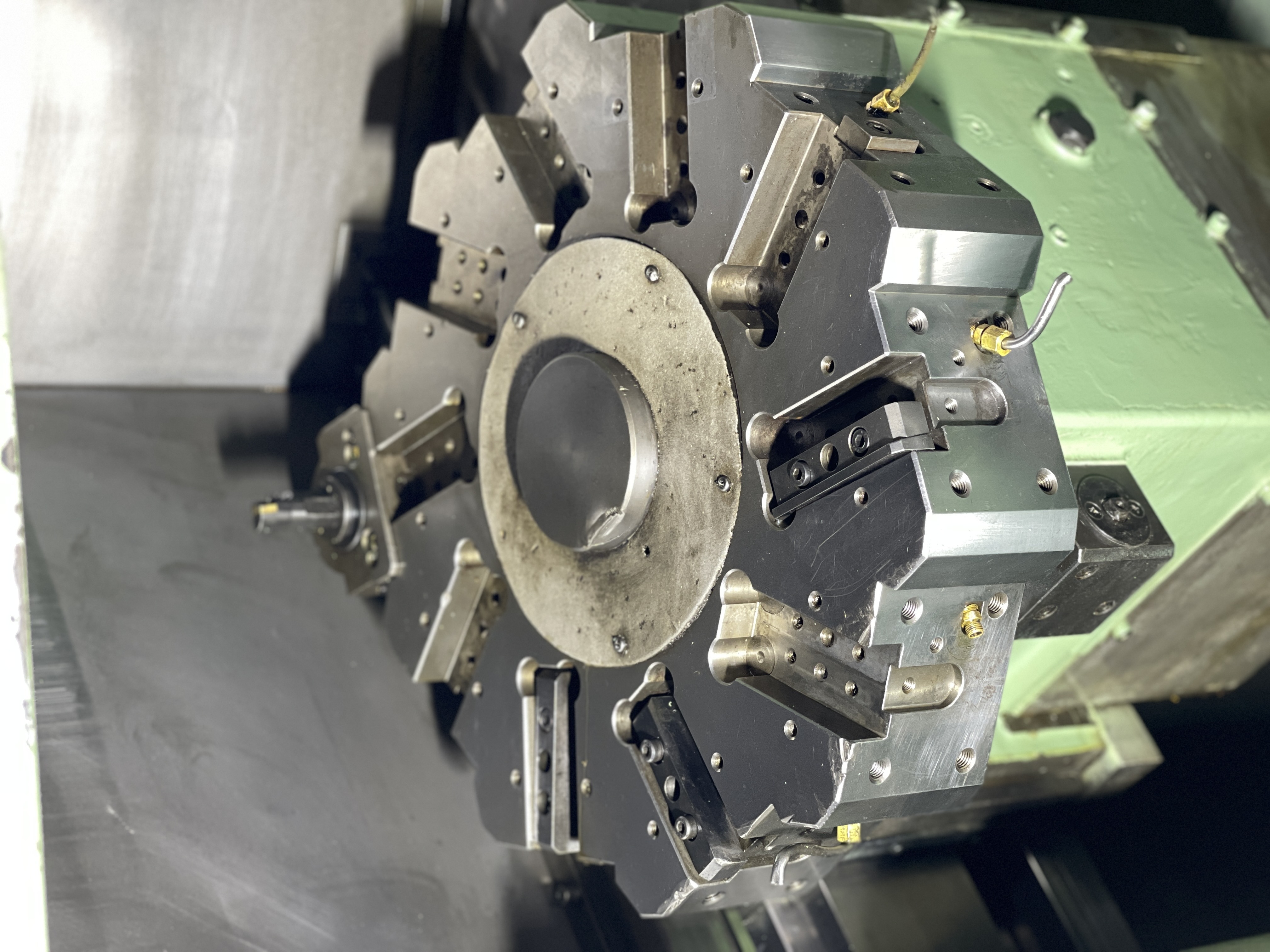

- Tool Turret

- 12 Stations

- Tailstock Quill Diameter

- 100 mm

About Mori Seiki Sl35/700 Cnc Lathe

*MORI SEIKI SL35/700 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 420 x 700 mm

Reference No: 1735

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 420 mm

Max Turning Length: 700 mm

Swing: 600 mm

Distance Between Centers: 700 mm

Chuck Capacity: 300 mm

Guideways: Box

CNC

Control: Fanuc OT ( MF T4)

SPINDLE

Max Rotation Speed: 2500 RPM (Gear Head Spindle)

Spindle Nose: A2-8

Spindle Bore: 104 mm

TAILSTOCK

Tailstock: Yes

TURRET

Turret: 10 Stations

Machine Dimensions

Weight: 7.5T Aprox.

Exceptional Precision and Reliability

With a repeatability of 0.002 mm and a high-rigidity cast iron base, the Mori Seiki SL35/700 CNC Lathe is built to maintain accuracy throughout long production runs. The 12-station tool turret and automatic controls streamline machining, ensuring consistent component quality and minimized deviation.

Designed for Versatile Metal Machining

The machine supports turning tasks with a maximum diameter of 400 mm and length of 700 mm, accommodating various metal components. Rapid traverse rates (12/15 m/min) and a powerful 15 kW spindle motor facilitate efficient processes, while the optional bar feeder increases throughput for continuous operations.

FAQ's of Mori Seiki Sl35/700 Cnc Lathe:

Q: How do I operate the Mori Seiki SL35/700 CNC Lathe for high-precision turning?

A: Operation is managed through the Fanuc PLC control system, which allows for automated setup and monitoring. Users can select compatible tooling and input parameters for each job, enabling precision cutting with repeatability of 0.002 mm.Q: What is the maximum workpiece capacity for this lathe?

A: This lathe accommodates workpieces up to 400 mm in diameter and 700 mm in length, thanks to its ample swing over bed and distance between centers, fitting a wide range of metal machining applications.Q: When should I use the optional bar feeder with the SL35/700 CNC Lathe?

A: The optional bar feeder is recommended when working with long bars or running high-volume, continuous production, as it streamlines loading and improves efficiency in automated turning processes.Q: Where is the Mori Seiki SL35/700 CNC Lathe commonly supplied or traded?

A: This lathe is available through exporters, importers, suppliers, and traders, particularly throughout India, and it is suitable for use in manufacturing plants and metalworking facilities.Q: What benefits does the included coolant and hydraulic system provide?

A: The integrated coolant system enhances tool life and surface finish by controlling temperatures and removing chips, while the hydraulic system ensures smooth operation of the chuck and tailstock for secure holding and improved precision.Q: How does the lathe achieve high rigidity during heavy-duty machining tasks?

A: High rigidity is maintained by the machine's cast iron base and robust steel components, reducing vibration and improving overall stability during intensive cutting operations.Q: What kind of maintenance does the SL35/700 CNC Lathe require for optimal performance?

A: Routine maintenance includes checking lubricant and coolant levels, inspecting hydraulic systems, and regular cleaning to prevent chip buildup. Ensuring all moving parts are in good condition prolongs accuracy and machine lifespan.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Horizontal

Color : Other, White & Grey

Automatic : Other, Fully Automatic

Power Consumption : 12 kW

Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Horizontal CNC Lathe

Color : Other, White & Grey

Automatic : Other, Fully Automatic

Power Consumption : 22 kVA

Mori Seiki Sl-65b Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Horizontal CNC Turning Center

Color : Other, Standard industrial white/grey

Automatic : Yes

Power Consumption : Approx. 55 KVA

Takamaz Ex-20 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Horizontal CNC Turning Center

Color : Other, White/Orange

Automatic : Other, Fully Automatic Operation

Power Consumption : 9 kVA

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |