|

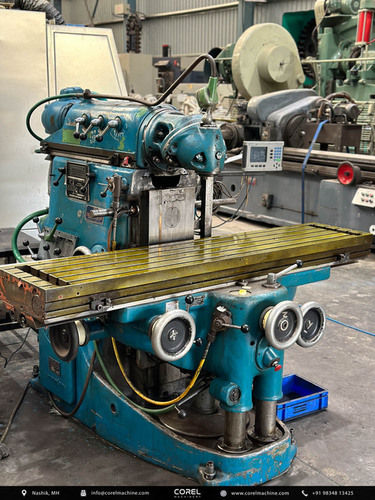

Huron Ku6 Universal Milling

Huron Ku6 Universal Milling Specification

- Product Type

- Universal Milling Machine

- General Use

- Metalworking, Industrial Machining

- Material

- Cast Iron

- Type

- Horizontal/Vertical Universal

- Capacity

- Heavy Duty Milling

- Weight (kg)

- 6000 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 15 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3-Phase Induction Motor

- Table Size

- 2000 x 500 mm

- Spindle Speed

- 30-1800 rpm

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- 3200 x 2900 x 2200 mm

- Feature

- Heavy Duty Construction, High Precision, Versatile Application

- Color

- Gray & Blue

- Table Vertical Travel

- 500 mm

- Spindle Taper

- ISO 50

- Lubrication System

- Centralized

- Table Cross Travel

- 500 mm

- Machine Condition

- Brand New

- Main Spindle Motor Power

- 11 kW

- Distance From Table to Spindle

- 50-550 mm

- Table Longitudinal Travel

- 1600 mm

- Coolant Pump

- Yes

About Huron Ku6 Universal Milling

*HURON KU6 UNIVERSAL MILLING*

CATEGORY : MILLING MACHINES

CAPACITY : 1500 x 700 x 500 mm

Reference No: 3789

Video Link: https://youtu.be/u36BNg9rdAE

Technical Specifications:

Working Capacity

Travels (XYZ): 1500 x 700 x 500 mm

Table Size: 2000 x 460 mm

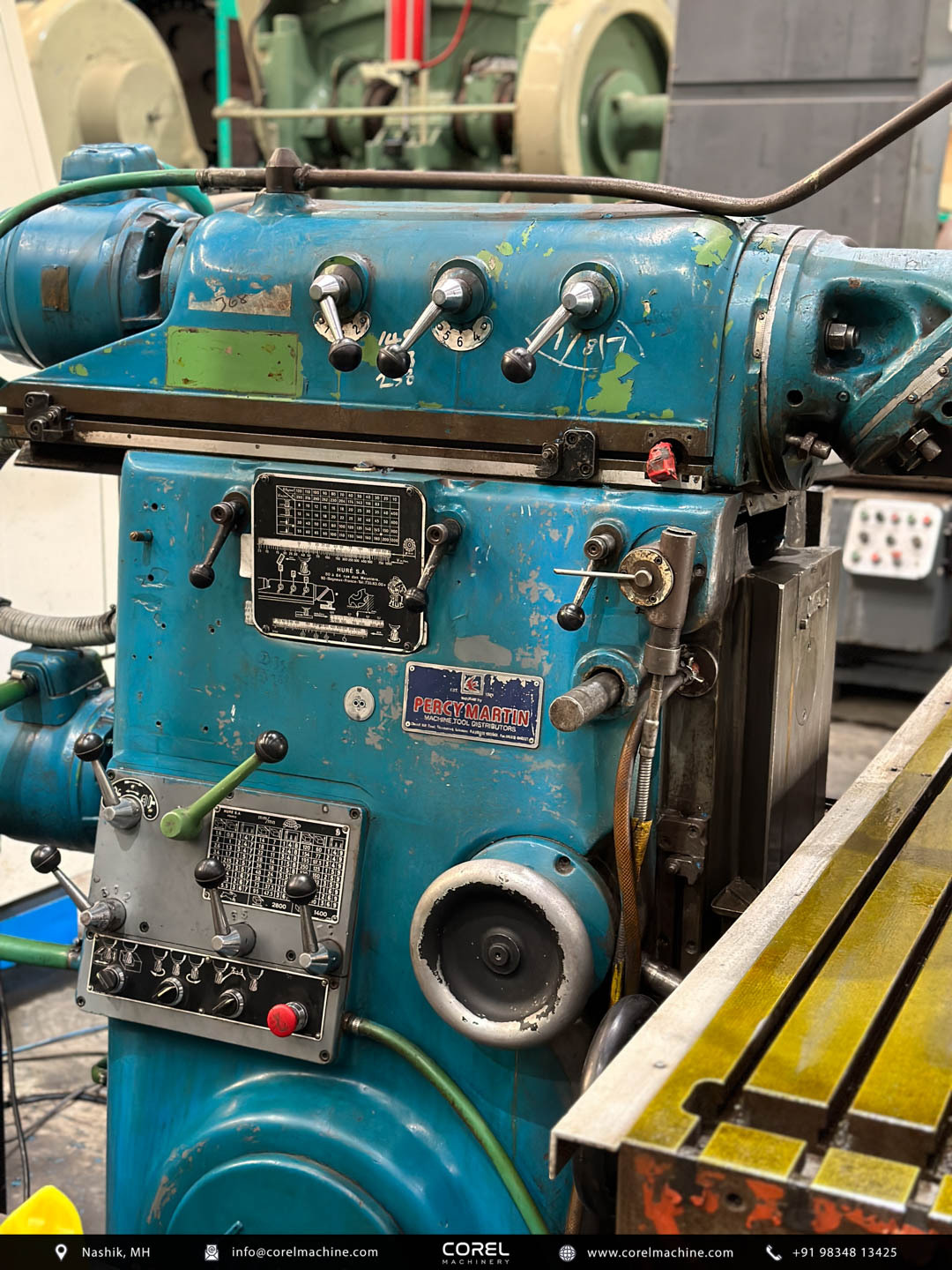

SPINDLE

Spindle Taper: ISO 40

Spindle Speeds: 30 - 2066 RPM

Spindle Speed Gear Step Chnage: 27

Spindle Head: 2 x 360 degree Swivel

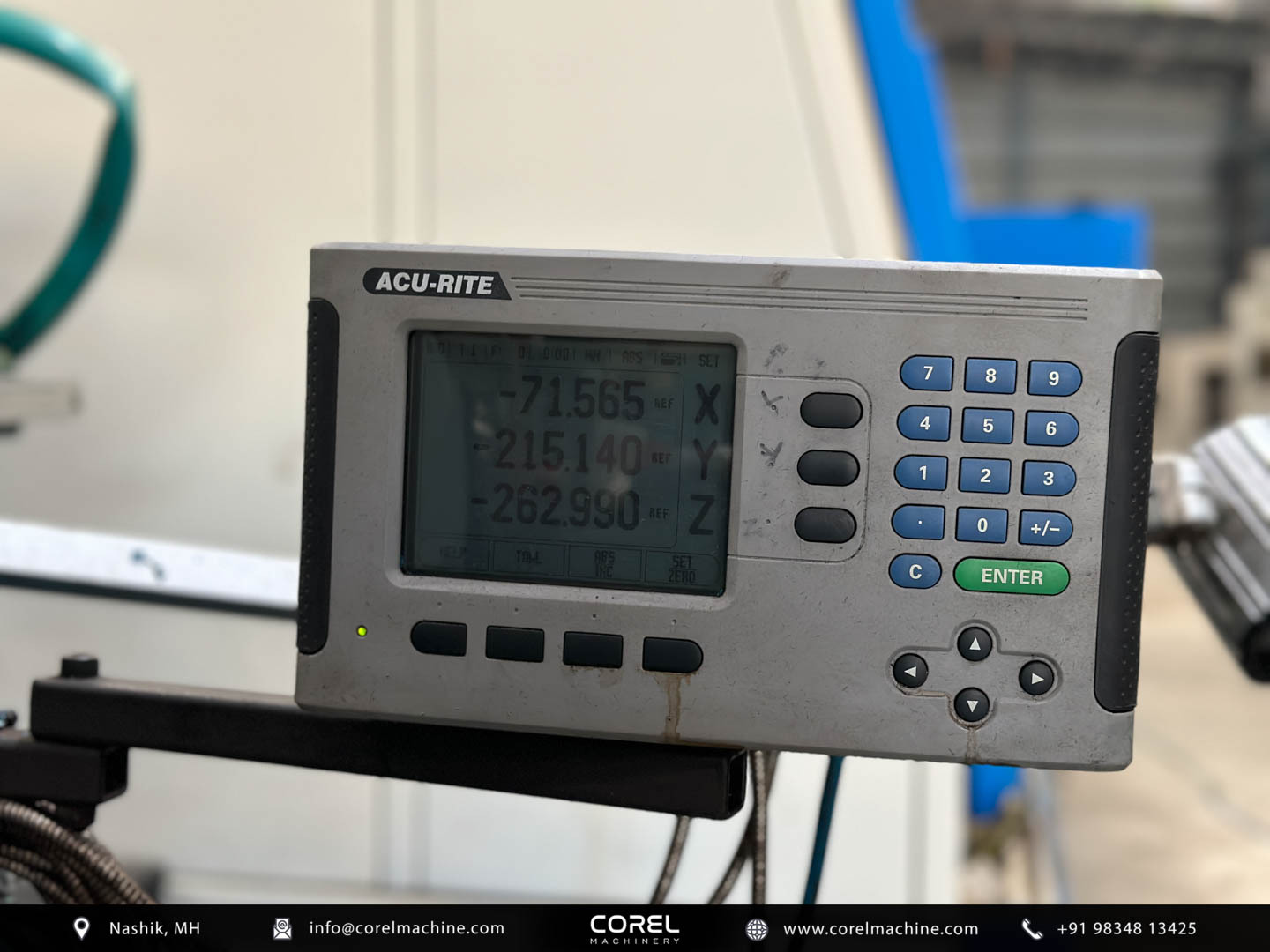

Equipped with DRO on All Axis

Heavy-Duty Construction and Superior Precision

Built with a cast iron frame and 6000 kg of weight, the Huron Ku6 offers exceptional rigidity and stability. This results in minimized vibration and maximum accuracy even during intensive milling operations. The large 2000 x 500 mm table and 3-axis movement give users flexibility for various metalworking projects.

Versatile Performance for Industrial Needs

Designed for both horizontal and vertical milling, the Ku6 Universal caters to a wide range of industrial machining requirements. Its ISO 50 spindle taper, spindle speeds ranging from 30 to 1800 rpm, and heavy-duty 11 kW motor allow for seamless operation on a variety of metals.

Efficient Operation and Maintenance

The centralized lubrication system and powerful coolant pump ensure smooth function and longevity. Operators benefit from easy maintenance and reduced downtime, while the 15 kW power consumption remains manageable for most industrial setups. The semi-automatic function balances productivity and operator control.

FAQ's of Huron Ku6 Universal Milling:

Q: How is the Huron Ku6 Universal Milling Machine suitable for heavy-duty industrial applications?

A: The Huron Ku6 is engineered with a high-rigidity cast iron frame, supporting a 6000 kg weight, and features a robust 11 kW spindle motor. Its heavy-duty construction, centralized lubrication, and efficient coolant system ensure optimal performance for intensive metalworking tasks.Q: What types of milling operations can this machine perform?

A: This machine supports both horizontal and vertical milling operations, making it highly versatile. It can be used for tasks such as face milling, slotting, drilling, and other complex machining operations, suitable for a wide range of industrial metalworking applications.Q: When should the centralized lubrication system be checked or maintained?

A: It is recommended to check the centralized lubrication system regularly before each shift and to perform thorough maintenance as per the manufacturer's guidelines to ensure optimal operation and prolong the equipment's lifespan.Q: Where can the Huron Ku6 Universal Milling Machine be installed?

A: Due to its substantial size (3200 x 2900 x 2200 mm) and weight, the machine should be installed in a spacious, well-ventilated industrial facility with adequate floor strength and a 415 V, 3-phase power supply.Q: What is the process for changing spindle speeds on this milling machine?

A: Spindle speeds, ranging from 30 to 1800 rpm, can be adjusted manually according to the machining requirement. Ensure the machine is at a complete stop before changing speeds to maintain safety and precision.Q: How does the Ku6 benefit industries that require high precision and efficiency?

A: With its high-rigidity construction, precise table movements (1600 mm longitudinal travel), and semi-automatic controls, the Ku6 delivers consistent, accurate results for heavy-duty and high-precision tasks, improving productivity while maintaining quality standards.Q: Is this milling machine computerized or PLC-controlled?

A: No, the Huron Ku6 operates as a semi-automatic machine without computerized or PLC controls, offering straightforward manual operation preferred for certain industrial environments.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Bridgeport M1tr Turret Dro Milling Machine 1

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 1700 mm x 1650 mm x 2100 mm

Axial Choice : X, Y, Z

Weight (kg) : Approx. 1200 kg

Capacity : Table Load 200 kg

Kearney And Trecker Millwaukee 205 C 12 Vertical Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 2970 mm x 1778 mm x 2070 mm (approx)

Axial Choice : Manual and Power Feeds

Weight (kg) : Approx. 4500 kg

Capacity : 12 inch (305 mm) vertical travel

Butler Elgamill Cs 10 Bed Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 5650 mm x 2850 mm x 2800 mm

Axial Choice : 3 Axis

Weight (kg) : Approx. 12000 kg

Capacity : 4000 kg

Cincinnati Double Spindle Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Dimension (L*W*H) : 2300 mm x 1800 mm x 1800 mm (approx)

Axial Choice : Horizontal & Vertical

Weight (kg) : Approx. 2800 kg

Capacity : Robust heavyduty milling

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |