|

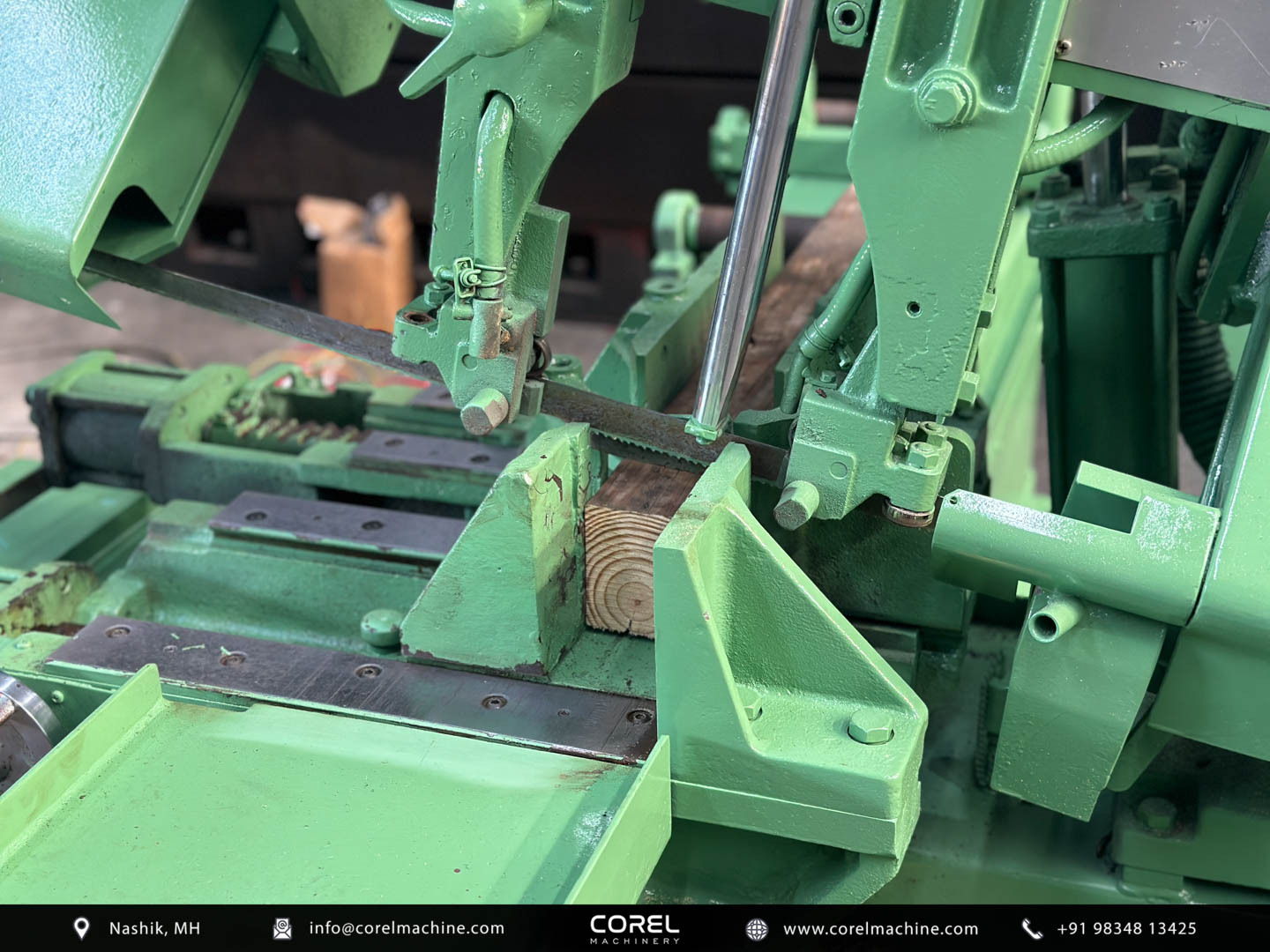

Amada Ha 250 Automatic Bandsaw

Amada Ha 250 Automatic Bandsaw Specification

- Product Type

- Automatic Bandsaw

- General Use

- Industrial Metal Cutting

- Material

- Mild Steel, Stainless Steel, Alloy Steel

- Type

- Horizontal Bandsaw

- Capacity

- 250 mm round, 250x250 mm square

- Weight (kg)

- 1800 kg

- Computerized

- No

- Automatic

- Yes

- PLC Control

- No

- Bar Feeder

- Yes

- Power Source

- Electric

- Power Consumption

- 3.7 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3.7 kW Main Motor

- Table Size

- Standard

- Spindle Speed

- 50 Hz

- Axial Choice

- Standard

- Dimension (L*W*H)

- 2170 x 2210 x 1440 mm

- Feature

- Automatic cutting, coolant system, hydraulic vice, precision cutting

- Color

- Standard (usually Red/Gray)

- Vice Type

- Hydraulic

- Hydraulic Tank Capacity

- Approx. 35 Liters

- Coolant Tank Capacity

- Approx. 60 Liters

- Workpiece Feeding Length per Stroke

- Max 400 mm

- Cutting Accuracy

- ±0.2 mm

- Cutting Speed

- 15-90 m/min (Variable)

- Blade Tensioning

- Manual/ Hydraulic

- Saw Blade Guide

- Carbide/ Roller Type

- Applications

- Suitable for batch production, steel stockist, engineering shop, fabrication units

- Blade Size

- 3505 x 27 x 0.9 mm

- Noise Level

- Less than 80 dB

About Amada Ha 250 Automatic Bandsaw

*AMADA HA 250 AUTOMATIC BANDSAW*

CATEGORY : BANDSAWS

CAPACITY : 250 mm

Reference No: 3921

Video Link: https://youtu.be/LGG4MyehDPI

Technical Specifications:

MODEL: HA-250

CAPACITY SQUARES: 10 inch X 11inch

CAPACITY ROUNDS: 10 inch

CAPACITY RECTANGLES: 6-7/8nch X 11.8i nch

WIDTH OF BLADE: 1 inch

LENGTH OF BLADE: 138 inch

HYDRAULIC BLADE DOWN FEED: YES

MAIN MOTOR: 5 HP

High-Precision Industrial Metal Cutting

Engineered for maximum accuracy and efficiency, the Amada Ha 250 delivers automatic cutting with a high degree of reliability. Its carbide/roller blade guide, hydraulic vice, and precise tensioning support continuous operation in batch metal production environments, minimizing downtime and ensuring superior finish.

Efficient and Flexible Operation

This horizontal bandsaw boasts a variable cutting speed from 15 to 90 meters per minute, suiting diverse materials and cutting requirements. Manual or hydraulic blade tensioning and a bar feeder facilitate seamless workflow, while hydraulic and coolant tanks extend operational capacity for extended cutting sessions.

Built for Heavy-Duty Performance

With a powerful 3.7 kW motor and high rigidity frame, the Amada Ha 250 is crafted to withstand demanding industrial use. Its ergonomic design, large table size, and automated processes make it an essential asset for steel stockists and engineering workshops seeking outstanding productivity and precise results.

FAQ's of Amada Ha 250 Automatic Bandsaw:

Q: How does the Amada Ha 250 enhance metal cutting precision?

A: The machine utilizes a carbide or roller saw blade guide with hydraulic vice technology and adjustable blade tensioning, ensuring stable and precise cuts with an accuracy of 0.2 mm across mild steel, stainless steel, and alloy steel.Q: What materials can be cut with the Amada Ha 250 Automatic Bandsaw?

A: This bandsaw is suitable for cutting a wide range of industrial metals, including mild steel, stainless steel, and alloy steel, making it versatile for various manufacturing and fabrication needs.Q: When is the Amada Ha 250 typically used in production?

A: It is primarily deployed for batch production, steel stockist operations, engineering shops, and fabrication units, where consistent quality and high-volume output are essential.Q: Where is the Amada Ha 250 best installed in terms of workflow?

A: The bandsaw can be integrated into industrial workspaces such as fabrication plants or workshops, ideally positioned with access to electrical and hydraulic systems, maximizing efficiency for exporting, importing, or supplying needs.Q: What is the process for tensioning the saw blade on the Amada Ha 250?

A: Blade tensioning on this bandsaw can be performed either manually or hydraulically, allowing users to choose the method that best suits their operational preferences and material requirements.Q: How does the automatic cutting feature benefit operational efficiency?

A: Automatic cutting reduces operator intervention, streamlines repetitive tasks, and maintains consistent cut quality, making it ideal for batch production and continuous manufacturing environments.Q: What are the main benefits of using this bandsaw for industrial metal cutting?

A: Key advantages include high rigidity for stable cuts, low noise operation (<80 dB), energy-efficient performance, and reliable handling of large workpiece volumes, contributing to increased productivity and safety in industrial settings.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Bandsaws Category

Forte Sba 401 Automatic Band Saw

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Fully Automatic

Voltage : 400 V

Automatic : Yes

General Use : Metal Cutting

Doall 250 Mm Automatic Bandsaw

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Fully Automatic

Voltage : 415 V

Automatic : Yes

General Use : Industrial Metal Cutting

Cosen 250 Mm Bandsaw

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Metal Cutting Bandsaw

Voltage : 415V / 3 Phase

Automatic : Other, SemiAutomatic

General Use : Industrial Metal Cutting

Promach 250 Mm Bandsaw

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Type : Other, Manual Bandsaw

Voltage : 415 V

Automatic : No

General Use : Metal Cutting

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |