|

Emcoturn 320 Turning Center

Emcoturn 320 Turning Center Specification

- Product Type

- Turning Center

- General Use

- CNC Turning for industrial metalworking

- Material

- Cast Iron Base, Steel Components

- Type

- CNC Lathe

- Capacity

- Maximum turning diameter 220 mm, turning length 400 mm

- Weight (kg)

- 2600 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Siemens/EMCO CNC Control

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 12 kVA

- Rigidity

- High structural rigidity

- Voltage

- 400 V, 3-phase

- Motor

- Main Spindle Motor 11/7.5 kW

- Table Size

- Not Applicable (Turning Center)

- Spindle Speed

- Up to 6000 rpm

- Axial Choice

- 2 Axes (X, Z)

- Dimension (L*W*H)

- 2200 x 1440 x 1680 mm

- Feature

- High precision, compact design, easy operation

- Color

- Standard machine grey/red

- Drive Type

- Direct Drive Spindle

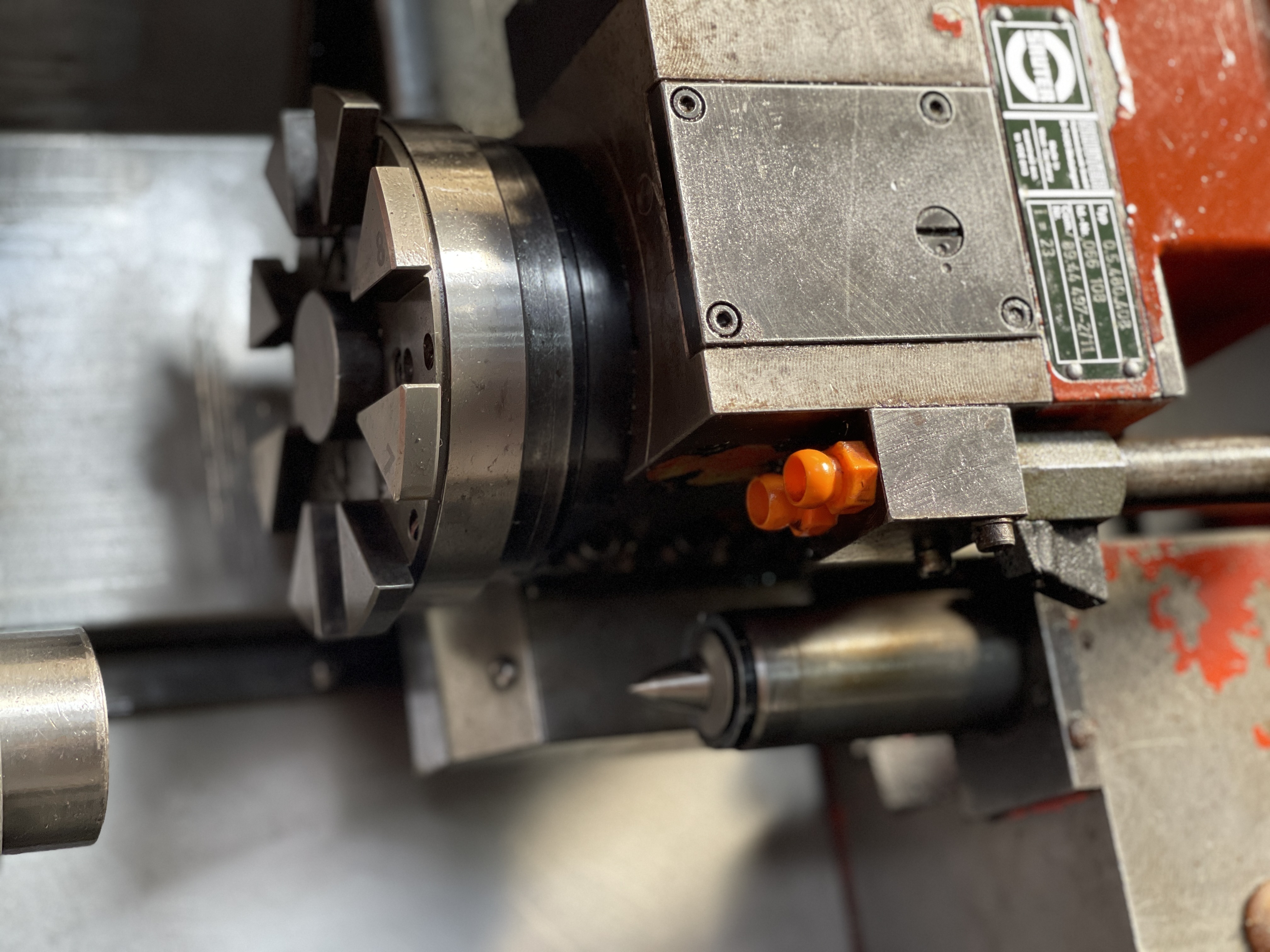

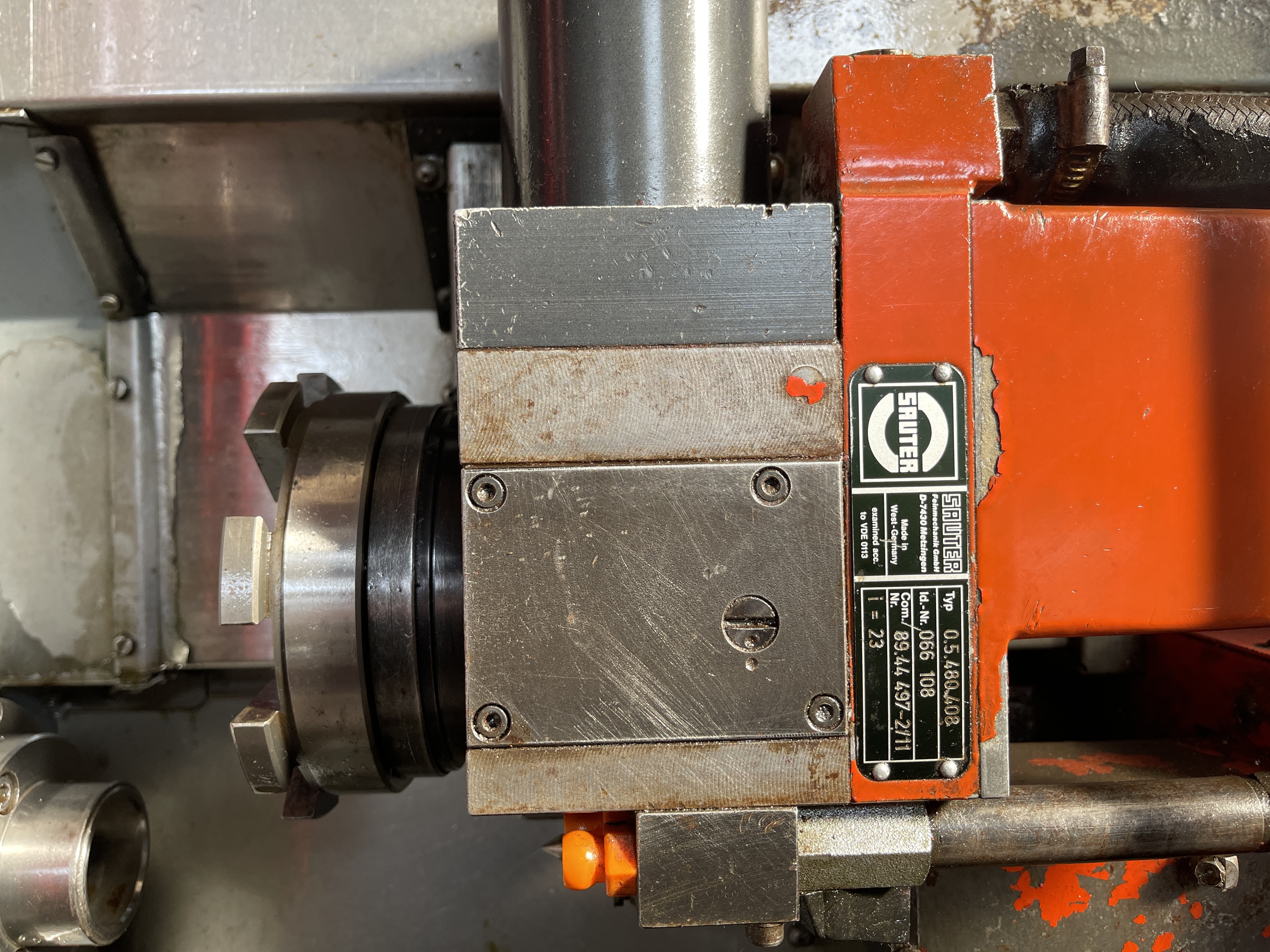

- Tool Turret

- 12 Station

- Coolant System

- Integrated

- Repeatability

- 0.015 mm

- Lubrication

- Automatic Centralized Lubrication

- Max Turning Diameter

- 180 mm

- Controller

- EMCO Siemens Sinumerik 828D

- Tailstock

- Programmable

- Rapid Traverse Rate

- 24 m/min (X axis), 30 m/min (Z axis)

- Positioning Accuracy

- 0.02 mm

- Max Turning Length

- 350 mm

- Spindle Bore

- 56 mm

- Chuck Size

- 160 mm

- Ambient Temperature Range

- 5°C to 40°C

About Emcoturn 320 Turning Center

*EMCOTURN 320 TURNING CENTER*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 120 x 180 mm

Reference No: 434

Technical Specifications:

WORKING CAPACITY

Swing: 180 mm

Max Bar Dia: 22 mm

Spindle Power: 4 kW

Turret: 8 Stations

Travel (X /Z): 60 / 180 mm

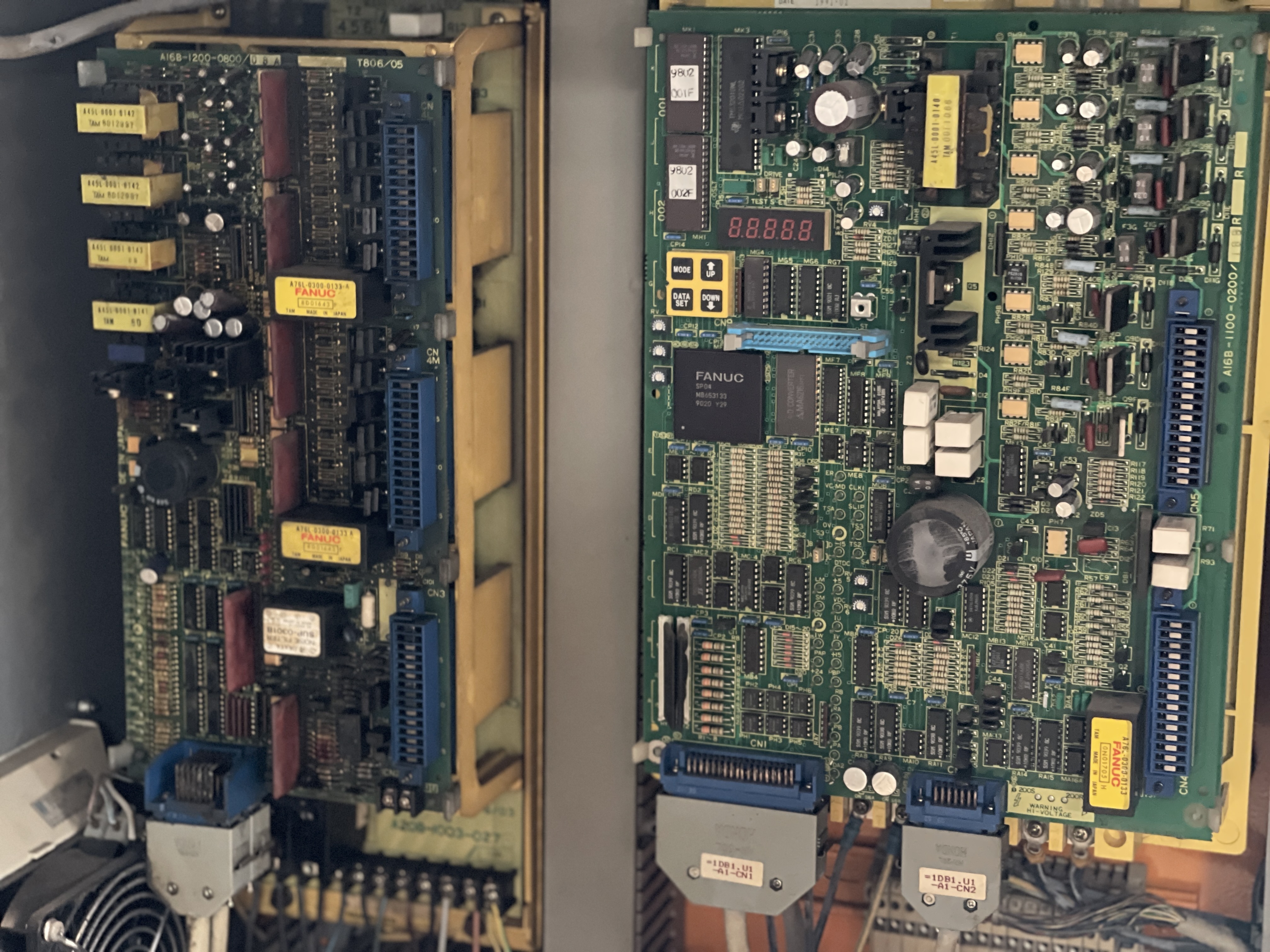

CNC

Control: Fanuc OT

Dimensions

Weight: 1 T

L x W x H: 2.2 x 1 x 1.6 m

Precision Engineering for Confident Results

The Emcoturn 320 Turning Center blends structural rigidity with innovative controls, offering tight positioning accuracy of 0.02 mm and repeatability of 0.015 mm. Its direct drive spindle delivers up to 6000 rpm, supporting high-quality, consistent output even on demanding industrial applications. This machine is built for those who require reliability and accuracy in every component turned.

Compact Design, Maximum Productivity

With a footprint of just 2200 x 1440 x 1680 mm and weighing 2600 kg, the Emcoturn 320 offers high functionality without taking up excess space. The 12-station turret and rapid traverse rates of 24 m/min (X) and 30 m/min (Z) reduce cycle times, while the programmable tailstock and automatic lubrication increase uptime for a smooth production process.

User-Friendly Operation and Versatility

Experience intuitive control with the latest EMCO Siemens Sinumerik 828D interface. The Emcoturn 320 is engineered for ease of use, from quick tool changes to automated coolant and lubrication systems. Capable of handling diverse CNC turning tasks, it supports optional bar feed systems for added flexibility in high-volume operations.

FAQs of Emcoturn 320 Turning Center:

Q: How does the Emcoturn 320 improve machining precision and efficiency?

A: The Emcoturn 320 features a high-precision direct drive spindle, advanced Siemens Sinumerik 828D control, and a rigid cast iron base, all supporting positioning accuracy of 0.02 mm and repeatability of 0.015 mm. Rapid traverse rates and a 12-station turret further enhance productivity, enabling fast and accurate turning operations.Q: What materials and workpiece sizes can the Emcoturn 320 handle?

A: This machine accommodates workpieces up to 180 mm in diameter and 350 mm in length, and is capable of processing various metals commonly found in industrial metalworking. Its robust design and flexible chuck size allow it to handle diverse tasks for exporters, suppliers, and traders.Q: When should I consider using the bar feeder option with my Emcoturn 320?

A: A bar feeder is recommended for operations that require high-volume, continuous turning of bar stock. It enhances automation, allowing unattended operation for longer periods, thereby increasing productivity and efficiency.Q: Where can the Emcoturn 320 be installed, and what are the power requirements?

A: The Emcoturn 320 is suitable for manufacturing environments where ambient temperatures range from 5C to 40C. It operates on a standard 400V, 3-phase power supply with a maximum consumption of 12 kVA, making it compatible with most industrial electrical setups in India.Q: What is the process for tool changes and machine maintenance on the Emcoturn 320?

A: Tool changes are streamlined by the 12-station turret, providing quick indexing and minimizing downtime. Routine maintenance is simplified through automated centralized lubrication and an integrated coolant system, ensuring smooth operation and extended machine life.Q: How does the programmable tailstock contribute to the turning process?

A: The programmable tailstock offers optimal support during turning by enabling precise positioning, which helps maintain workpiece stability. This feature enhances dimensional accuracy, particularly during the machining of longer components.Q: What benefits does the Emcoturn 320 offer to industrial CNC turning operations?

A: Users benefit from high precision, compact design, and reliable performance. The fully automated, computer-controlled setup ensures repeatable quality at scale, with user-friendly operation and robust construction for longevity in demanding environments.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Mori Seiki Zl-25mc/500 Cnc Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Available

Power Consumption : 20 kVA (approx)

Voltage : 220/380 V

Color : Other, Standard Mori Seiki grey/white

Mori Seiki Sl-25 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Fanuc System (Standard)

Power Consumption : 15 kVA

Voltage : 220V / 380V / 415V

Color : Other, White & Blue

Microsprint 50

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Yes

Power Consumption : 0.55 kW

Voltage : 230V

Color : Other, Green / White

Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Yes

Power Consumption : 22 kVA

Voltage : 400 V

Color : Other, White & Grey

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |