|

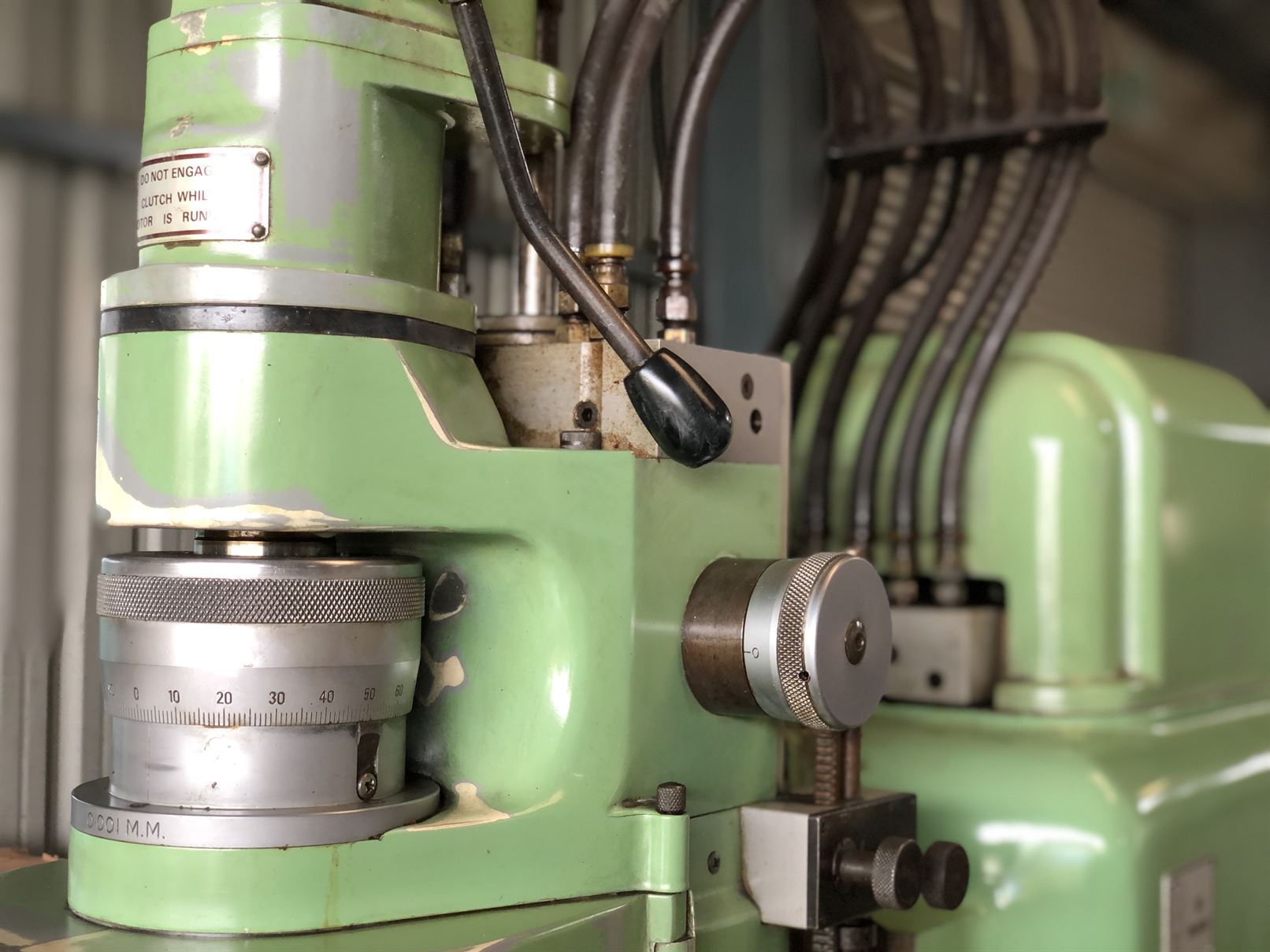

Moore Catmur 2c Jig Grinder

Moore Catmur 2c Jig Grinder Specification

- Product Type

- Jig Grinder

- General Use

- Jig Boring and Grinding for Tool Room Application

- Material

- Cast Iron, Steel

- Type

- Horizontal

- Capacity

- Up to 250 mm work height

- Weight (kg)

- 2500

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 3.8 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- Precision Spindle Motor

- Table Size

- 457 mm x 254 mm

- Spindle Speed

- 9,000 - 75,000 rpm

- Axial Choice

- Manual / Automatic

- Dimension (L*W*H)

- 1650 mm x 1500 mm x 2000 mm

- Feature

- High Precision Grinding, Fine Adjustment, Hardened Chrome Ways

- Color

- Grey

- Floor Space Required

- 2000 mm x 1800 mm

- Table Load Capacity

- 500 kg

- Max Workpiece Diameter

- 450 mm

- Position Readout

- Dial Gauges / Micrometers

- Coolant System

- External Cooling Pump

- Vertical Travel (Z Axis)

- 400 mm

- Table Traverse (X/Y)

- 400 mm / 250 mm

- Spindle Taper

- No. 5 B & S

- Lubrication System

- Centralized Manual Lubrication

About Moore Catmur 2c Jig Grinder

*MOORE CATMUR 2C JIG GRINDER*

CATEGORY : CYLINDRICAL GRINDERS

CAPACITY : 550 x 310 mm

Reference No: 747

Video Link: https://youtu.be/xsrhG1Wf9p0

Technical Specifications:

MOORE CATMUR 2C JIG GRINDER

Table size

550MM X 310MM

Table longitudinal travel

400MM

Table cross travel

250MM

Throat depth

220MM

Nett weight approx.

2 TONS (2032 KGS)

Fitted with STANDARD GRINDING HEAD and rotating table

Superior Precision and Versatility

Engineered for meticulous grinding and jig boring, the Moore Catmur 2c excels in tool room applications where exactness is paramount. Its hardened chrome ways and finely adjustable components ensure long-lasting accuracy and repeatability on workpieces up to 450 mm in diameter and 250 mm in height.

Robust Construction and Capacity

Constructed from high-grade cast iron and steel, the 2c Jig Grinder supports a 500 kg table load and features a generous 457 x 254 mm table surface. The centralized manual lubrication system enhances performance, reducing friction and wear. Its high rigidity further guarantees vibration-free operation and precise finishes.

User-Focused Operation and Control

The jig grinder is semi-automatic with options for manual or automatic axial movement. Dial gauges and micrometers provide clear position readouts, assisting operators in achieving meticulous results. The intuitive design accommodates both seasoned professionals and newcomers to precision tool room machinery.

FAQ's of Moore Catmur 2c Jig Grinder:

Q: How does the Moore Catmur 2c Jig Grinder maintain high precision during operations?

A: The Moore Catmur 2c Jig Grinder maintains precision through its hardened chrome ways, fine adjustment mechanisms, and dial gauges or micrometers for accurate position readouts. Its robust construction minimizes vibration, and the centralized manual lubrication system ensures smooth and reliable motion throughout the grinding or boring process.Q: What types of workpieces and applications is this jig grinder suitable for?

A: This machine is ideally designed for tool room applications requiring jig boring and grinding. It efficiently handles workpieces up to 450 mm in diameter and 250 mm in height, making it suitable for various precision engineering tasks in the manufacturing, tooling, and component finishing sectors.Q: When is it necessary to use the manual versus automatic axial choice feature?

A: Manual axial movement is typically preferred for setup, fine adjustments, or delicate operations, offering the operator more control. Automatic axial movement aids in repetitive or extended grinding passes, improving efficiency while maintaining precision.Q: Where can I install the Moore Catmur 2c Jig Grinder, and what floor space is required?

A: The machine is best placed in tool rooms or precision engineering workshops. It requires a floor space of approximately 2000 mm x 1800 mm, ensuring enough room for operation and maintenance access.Q: What is the process for operating this jig grinder, and is it user-friendly for new operators?

A: Operating the Moore Catmur 2c involves loading the workpiece, setting up grinding or boring tools, adjusting speeds (ranging from 9,000 to 75,000 rpm), and configuring axial movement. The straightforward control panel, position readouts, and semi-automatic functionality make it accessible to both experienced and relatively new users.Q: How does the centralized manual lubrication system benefit the machine's longevity?

A: Centralized manual lubrication simplifies the maintenance process by allowing quick and uniform application of lubricant to critical components. This reduces wear, minimizes the risk of component failure, and extends the machine's operational lifespan.Q: What are the main benefits of using the Moore Catmur 2c Jig Grinder for tool room applications?

A: Key benefits include exceptional grinding precision, high rigidity for stable performance, a wide spindle speed range, adaptable manual/automatic axial choices, and substantial capacity for handling large workpieces. These features collectively increase productivity and ensure high-quality finishes in demanding tool room settings.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Stanko Production Universal Cylindrical Grinder

Minimum Order Quantity : 1 Number

Weight (kg) : 3500 kg

Power Source : Electric

Power Consumption : 7.5 kW

General Use : Metal cylindrical and shaft grinding

Okamoto Ogm 8.20p Cnc Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Weight (kg) : Approx. 3500 kg

Power Source : Electric

Power Consumption : 5.5 kW

General Use : Cylindrical Grinding

Landis Universal Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Weight (kg) : 2800 kg

Power Source : Electric

Power Consumption : 7.5 kW

General Use : Industrial Grinding Operation

Ribon Rur 800 Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Weight (kg) : Approx. 2200 kg

Power Source : Electric

Power Consumption : Approximately 4.5 kW

General Use : External and internal cylindrical grinding

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |