|

Johnford Tc75 Cnc Lathe

Johnford Tc75 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Heavy Duty Turning Applications

- Material

- Cast Iron, Hardened Steel

- Type

- Slant Bed CNC Lathe

- Capacity

- Swing Over Bed: 750 mm; Max Turning Diameter: 570 mm

- Weight (kg)

- 11000

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 45 kVA

- Rigidity

- High

- Voltage

- 380 V / 50 Hz

- Motor

- Main Spindle: 30 HP (22 kW)

- Spindle Speed

- 500~3500 rpm

- Axial Choice

- X/Z axis

- Dimension (L*W*H)

- 4800 x 2250 x 2200 mm

- Feature

- High Performance, Heavy Duty

- Color

- White & Blue

- Max Turning Length

- 1150 mm

- Rapid Traverse (X/Z)

- 20/24 m/min

- Z Axis Travel

- 1200 mm

- Spindle Bore

- 105 mm

- Coolant System

- Standard with High Pressure Pump

- Chuck Size

- 12" (305 mm)

- X Axis Travel

- 320 mm

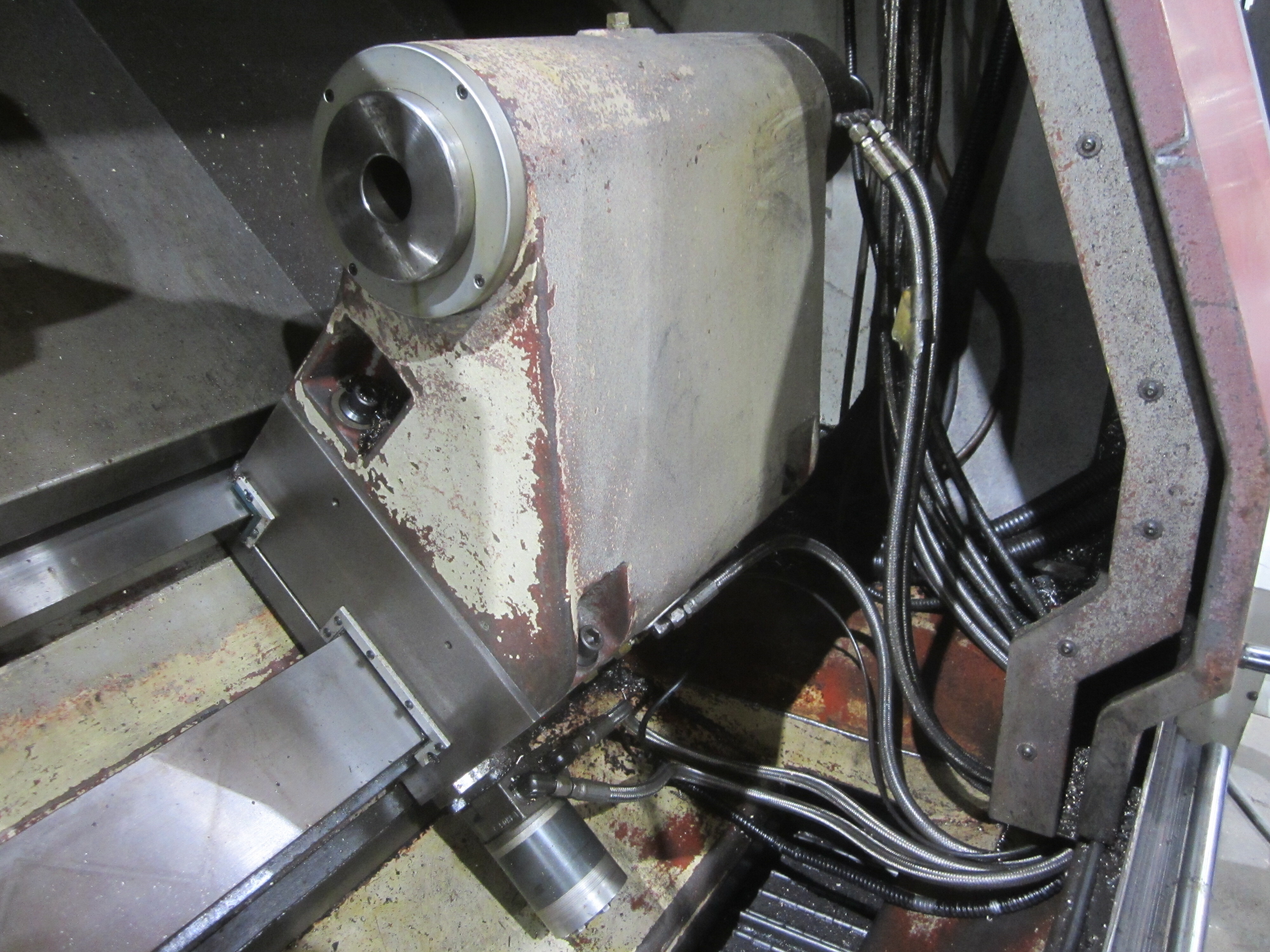

- Tailstock

- Programmable

- Precision

- ±0.005 mm

- Hydraulic System

- Included

- Ball Screw

- Precision Ground - Pre-tensioned

- Bed Structure

- High Rigidity Meehanite Cast Iron

- Lubrication

- Automatic Centralized

- Controller

- Fanuc / Siemens / Mitsubishi (Optional)

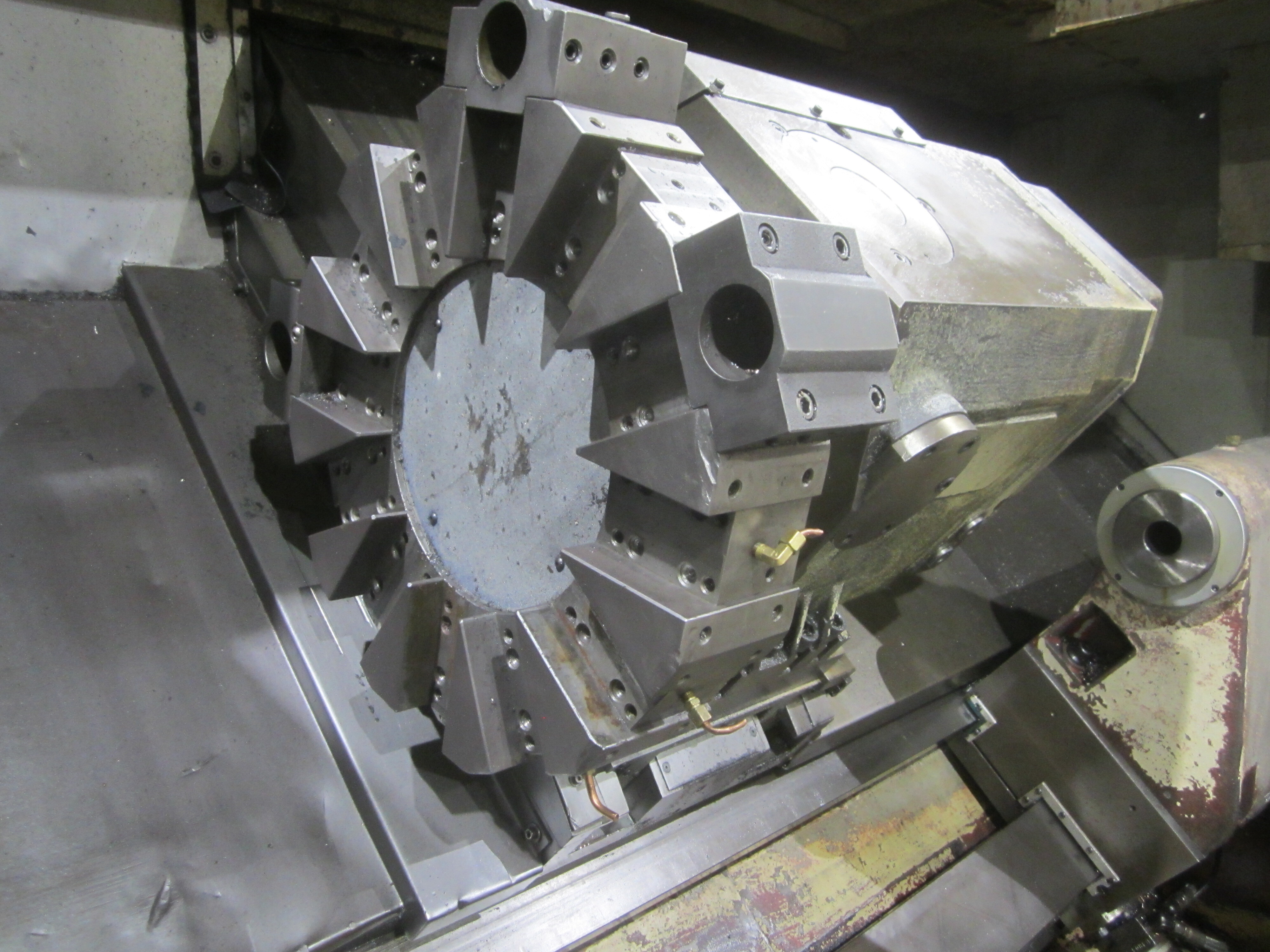

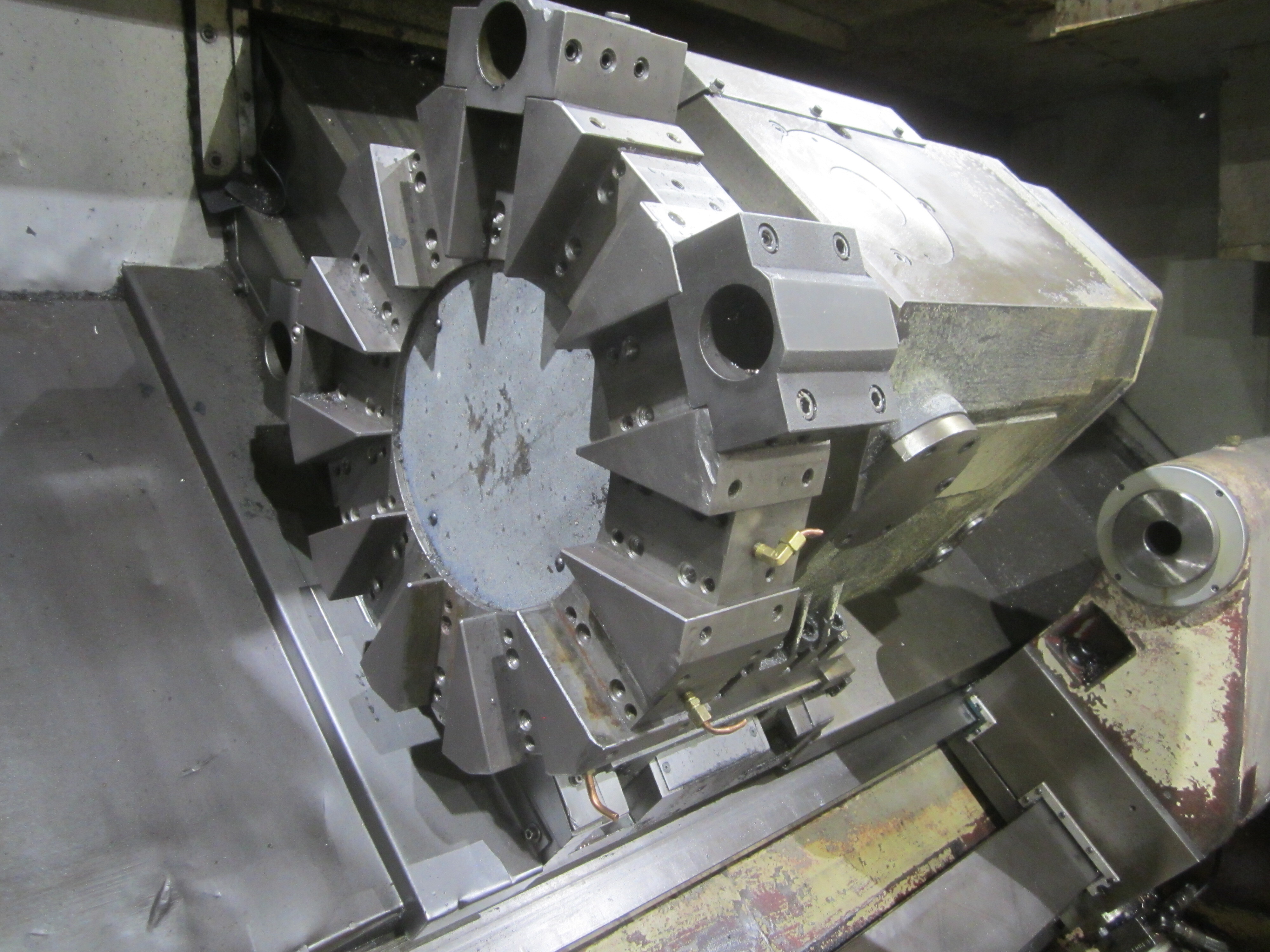

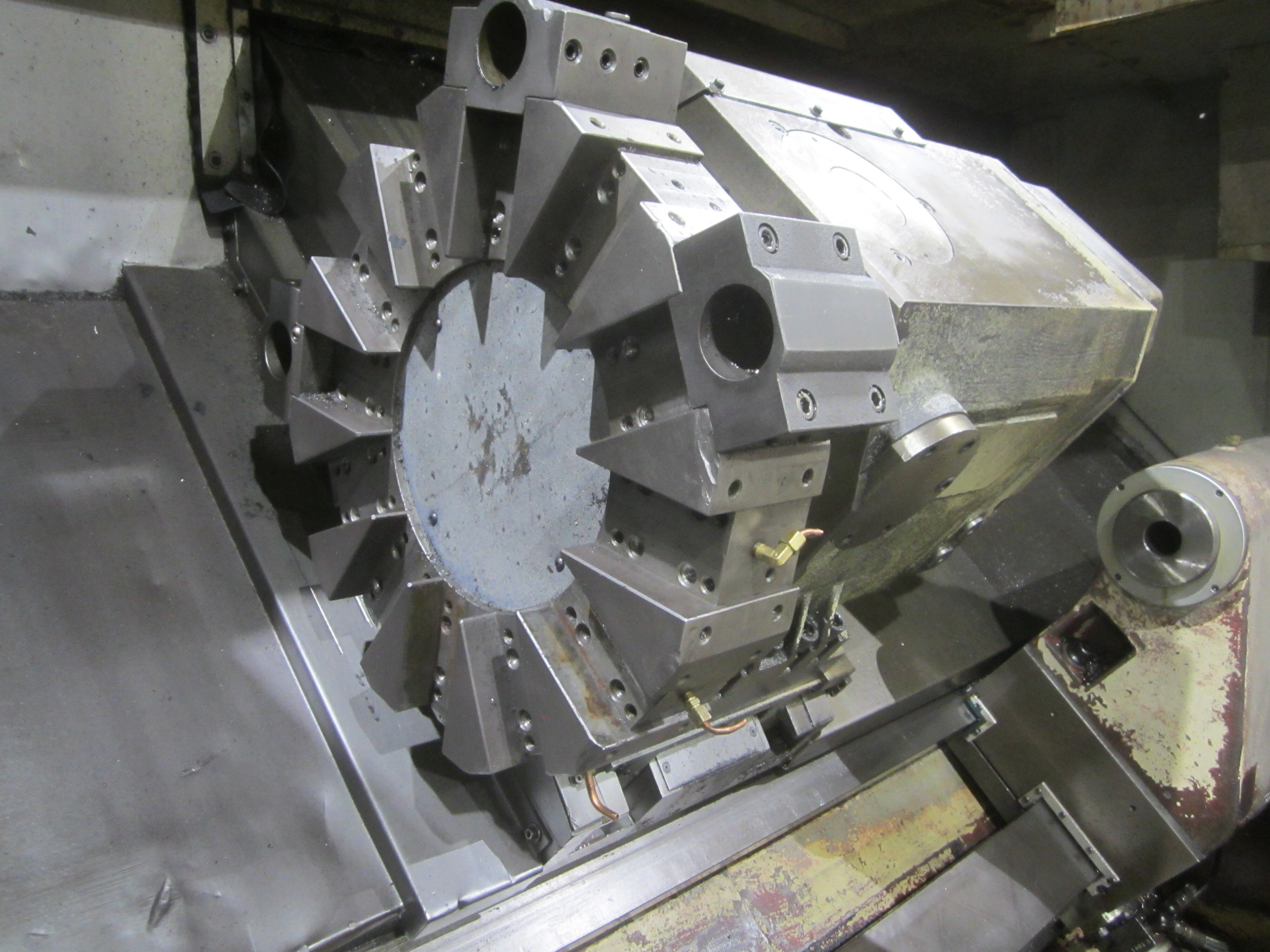

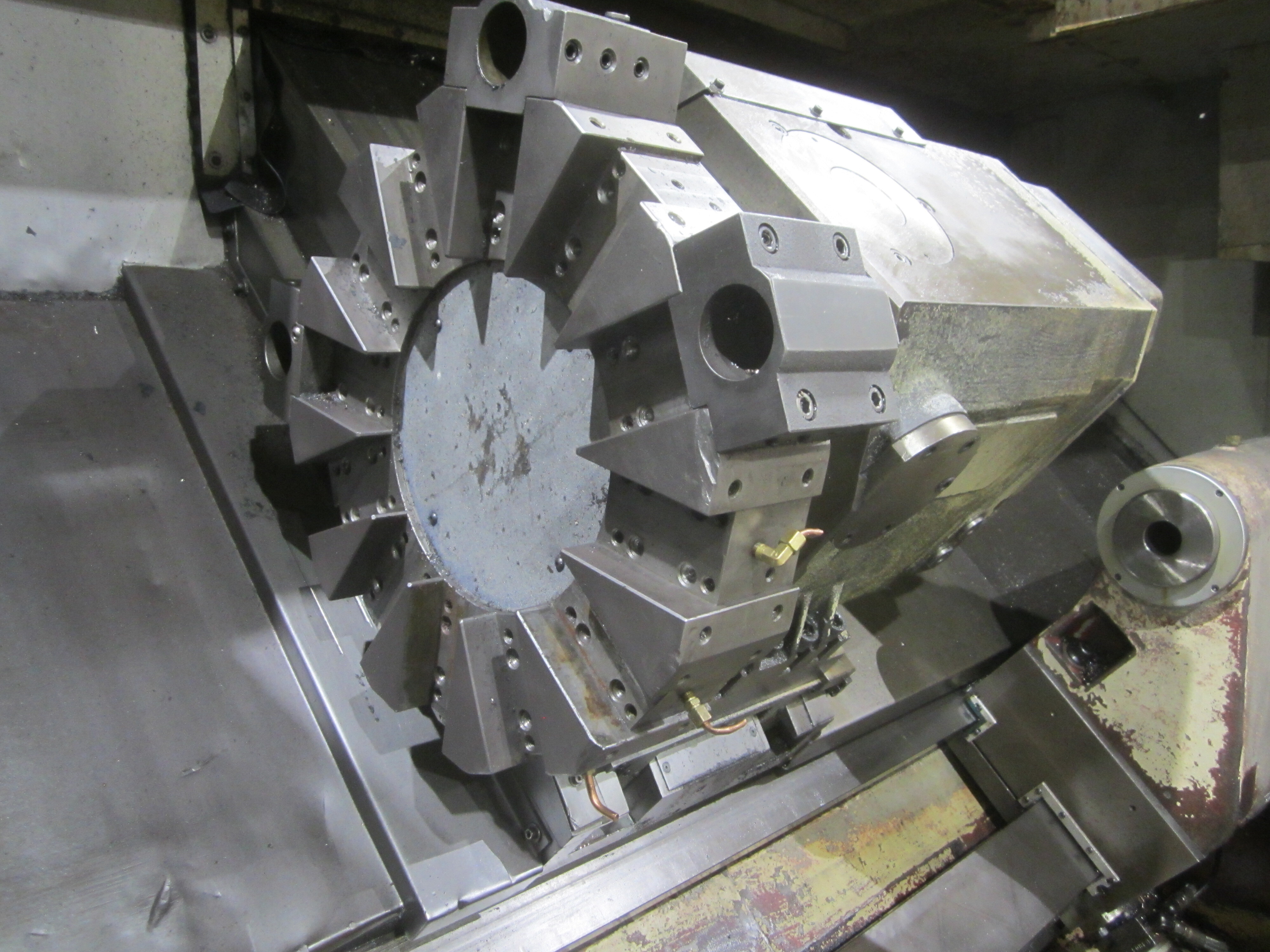

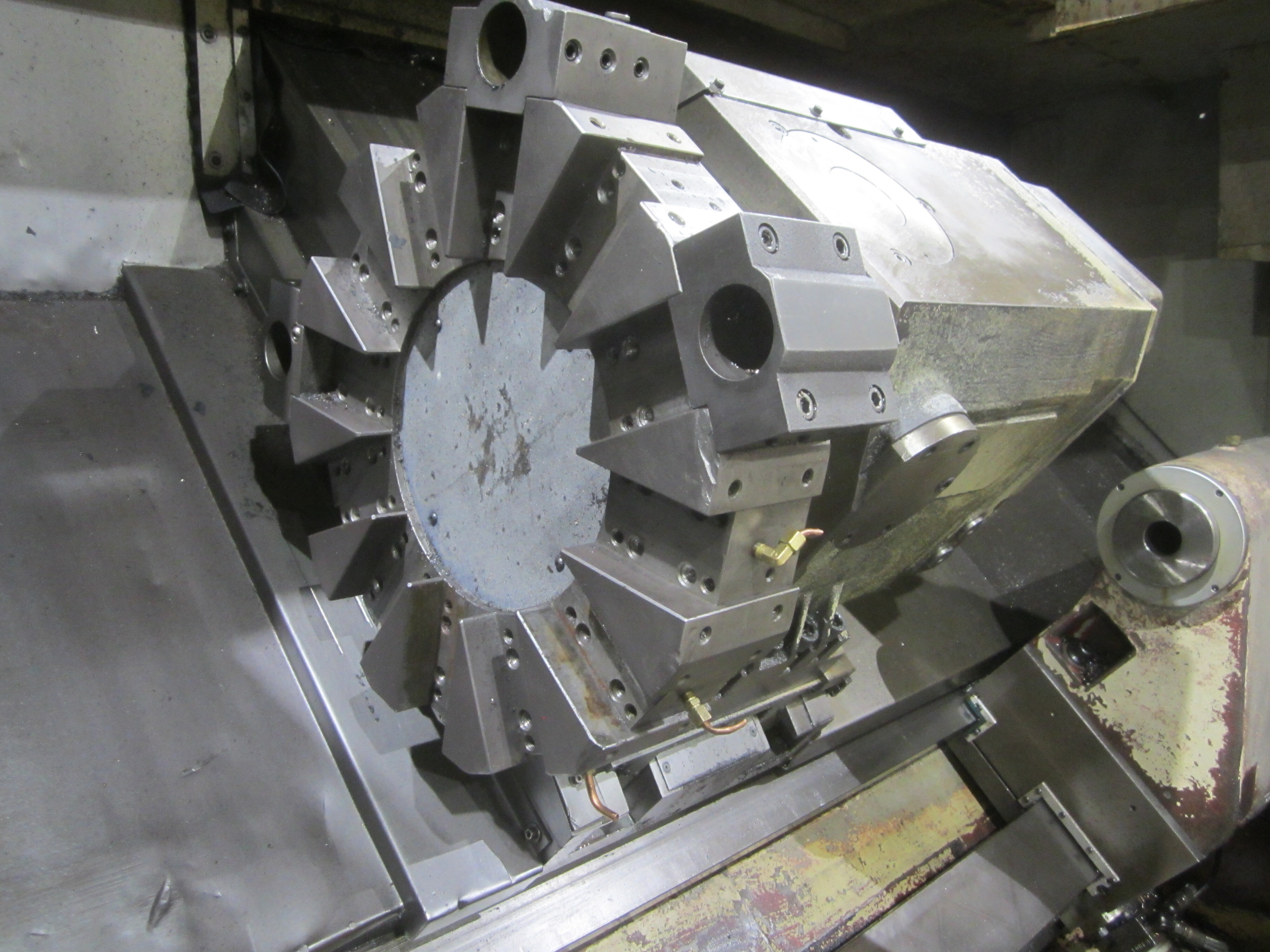

- Tool Turret

- 12-Station

About Johnford Tc75 Cnc Lathe

*JOHNFORD TC75 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 540 x 1550 mm

YEAR OF CONSTRUCTION : 1995

Reference No: 890

Video Link: https://youtu.be/mYpc-XQeRvs

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 540 mm

Max Turning Length: 1550 mm

Swing: 690 mm

Distance Between Centers: 1700 mm

Chuck Equipped: 375 mm

Travels (X / Z): 350 / 1551 mm

Guideways: Box

CNC

Control: Fanuc OT-F

SPINDLE

Max Rotation Speed: 1700 RPM

Spindle Nose: A2-11

Spindle Bore: 123 mm

Spindle Motor Power: 35 HP

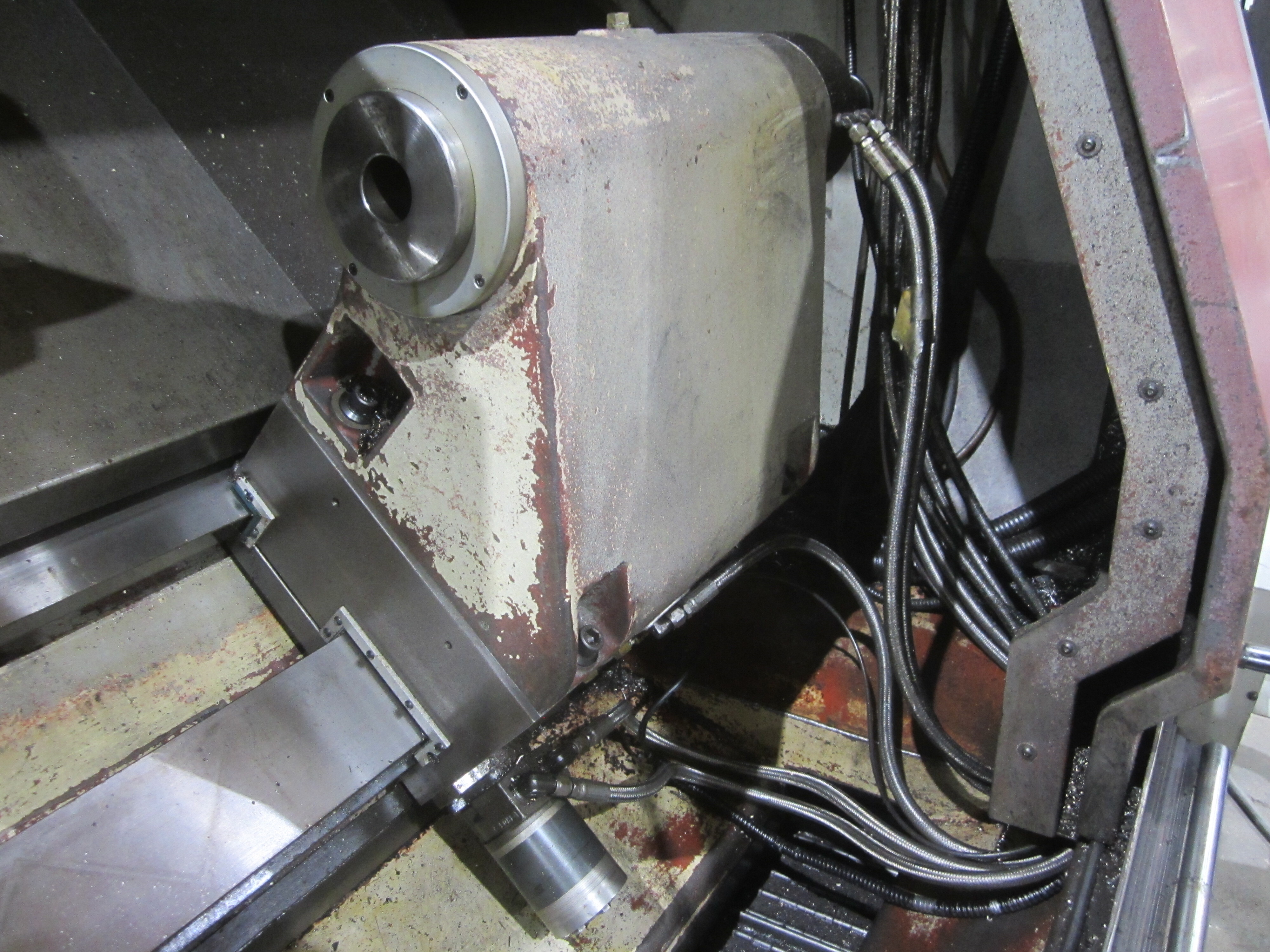

TAILSTOCK

Tailstock Quill Taper: 5 MT

TURRET

Turret: 12 Stations

Machine Dimensions

Weight: 14 T

L x W x H: 214 x 96 x 104

Four Speed Gearbox

Slant Bed Box Ways

Precision and Reliability for Heavy-Duty Turning

The Johnford TC75 is engineered to deliver consistent and precise machining, suited for manufacturers who require reliability in high-volume and heavy-duty operations. Its construction, with a hardened steel and cast iron body, high precision ball screws, and Meehanite cast iron bed, provides exceptional rigidity and reduces vibration for superior surface finishes and extended tool life.

Versatile Control and Automation Options

This CNC lathe supports a choice of industry-standard controllers (Fanuc, Siemens, or Mitsubishi), making it adaptable to various workshop preferences. Automatic centralized lubrication, a programmable tailstock, and an optional bar feeder boost its automation capabilities and ease integration into modern production lines, minimizing downtime and manual intervention.

Advanced Features for Efficient Operation

The TC75 comes equipped with a standard high-pressure coolant system, a robust 30 HP main spindle motor, and rapid traverse rates up to 24 m/min, ensuring swift and efficient machining cycles. Its spacious working envelope delivers a swing over bed of 750 mm and a max turning diameter of 570 mm. These specifications allow the machine to handle a broad range of workpiece sizes.

FAQ's of Johnford Tc75 Cnc Lathe:

Q: How does the Johnford TC75 CNC Lathe ensure machining precision?

A: The TC75 achieves high precision (0.005 mm) through its use of a precision-ground, pre-tensioned ball screw and a high-rigidity Meehanite cast iron bed, coupled with an automatic centralized lubrication system that minimizes mechanical wear.Q: What are the control options available on this lathe?

A: Operators can select from Fanuc, Siemens, or Mitsubishi CNC controllers depending on their workshop standards, ensuring compatibility with existing production infrastructure.Q: When should I use the programmable tailstock feature?

A: The programmable tailstock is ideal for supporting long workpieces and minimizing deflection during heavy turning operations, especially when working on shafts or rods with considerable length.Q: Where is the Johnford TC75 typically used?

A: This CNC lathe is commonly found in machine shops, manufacturing plants, and heavy engineering industries that require robust turning capabilities for medium to large parts, especially in India for exporters, importers, and suppliers.Q: What is the process for integrating an optional bar feeder?

A: The TC75 is designed for straightforward integration of a bar feeder, allowing automated feeding of raw material for continuous production. Installation and setup should be performed by qualified technicians to ensure seamless operation with the lathe's PLC system.Q: How does the high-pressure coolant system benefit operations?

A: The standard high-pressure coolant system ensures optimal cutting conditions, extends tool life, and aids in maintaining consistent workpiece quality even during prolonged, high-speed machining cycles.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Cmz Tbi-480 Cnc Turning Center

Minimum Order Quantity : 1 Piece

Color : Other, White/Grey

Type : Other, Horizontal CNC Lathe

Automatic : Yes

General Use : Turning operations for metal parts

Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White & Grey

Type : Horizontal

Automatic : Other, Fully Automatic

General Use : Industrial Metal Turning

Hardinge Talent T1 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White / Blue

Type : Other, Horizontal Lathe

Automatic : Yes

General Use : Precision turning, industrial machining

Hardinge Conquest Sp Cnc Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Standard Hardinge gray/blue

Type : Other, Horizontal Turning Center

Automatic : Yes

General Use : Metalworking / Industrial production

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |