|

Matchmaker 1020 Vmc 8

Matchmaker 1020 Vmc 8 Specification

- Product Type

- Vertical Machining Center

- General Use

- Metal Cutting and Milling

- Material

- Cast Iron, Steel

- Type

- CNC Machine

- Capacity

- 1000 kg Table Load

- Weight (kg)

- 6700 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 10 kVA

- Rigidity

- High

- Voltage

- 415 V, 3 Phase

- Motor

- Spindle Motor 15 HP

- Table Size

- 1200 x 500 mm

- Spindle Speed

- 8000 rpm

- Axial Choice

- X,Y,Z Axis

- Dimension (L*W*H)

- 3200 x 2100 x 2400 mm

- Feature

- High Accuracy, Durability, Heavy Duty Structure

- Color

- Grey & Blue

- Spindle Taper

- BT40

- Z Axis Travel

- 510 mm

- Y Axis Travel

- 510 mm

- Control System

- Fanuc / Siemens / Mitsubishi

- Tool Magazine Capacity

- 24 Tools

- X Axis Travel

- 1020 mm

About Matchmaker 1020 Vmc 8

*MATCHMAKER 1020 VMC 8*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 1020 x 560 x 600 mm

YEAR OF CONSTRUCTION : 2014

Reference No: 3144

Video Link: https://youtu.be/iuZZKhiPiVE

Technical Specifications:

WORKING CAPACITY

Table Size: 1100 x 560 mm

Travels (XYZ): 1020 x 560 x 600 mm

Guideways: LM

Rapid Travel Speeds (X/Y/Z): 36/36/24 Meters/Min

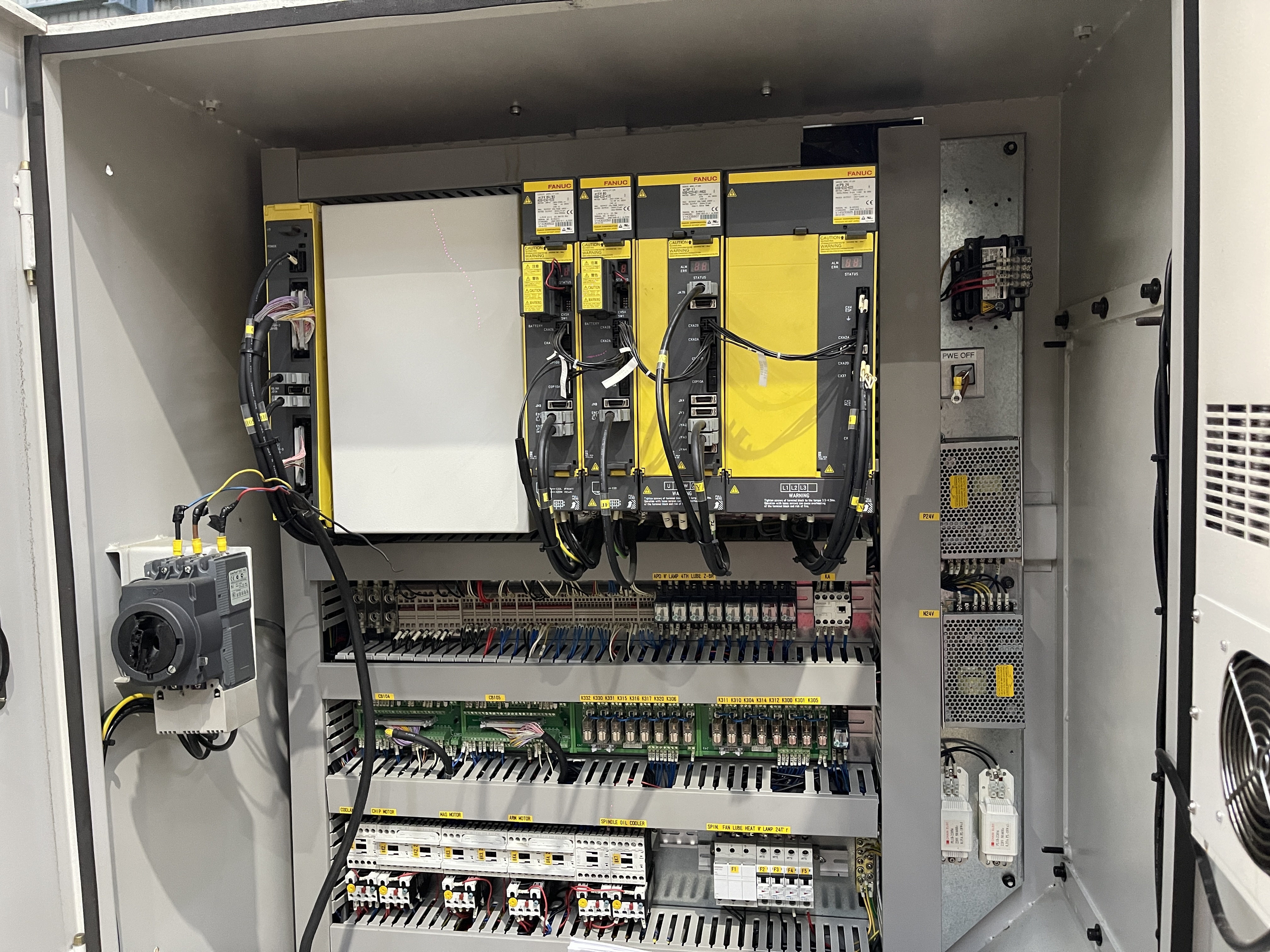

CNC

Control: Fanuc Oi-MD (Alpha Drives)

SPINDLE

Spindle Taper: BT40

Spindle Speeds: 10000 RPM

ATC

Tool Change Capacity: 24 Tools

ATC Type: ARM

High-Precision, Heavy-Duty Performance

Built for demanding industrial environments, the Matchmaker 1020 Vmc 8 combines high accuracy with a rigid, durable structure. Its large travel range and robust spindle make it well-suited for processing medium to large metal components, ensuring consistent results even during intensive operations.

Versatile Control and Automation

This CNC machine supports leading control systems from Fanuc, Siemens, and Mitsubishi, giving users flexibility in integration and usage. With computerized, automatic operations and available PLC control, it streamlines complex milling processes for both experienced machinists and modern factories.

Reliable Operation and Safety

Operating at 415V, three-phase power with a consumption of 10 kVA, the Matchmaker 1020 Vmc 8 is engineered for stable, safe use. Its heavy weight and table load capacity ensure steady machining, while the well-designed enclosure and quality materials enhance both safety and longevity.

FAQ's of Matchmaker 1020 Vmc 8:

Q: How does the Matchmaker 1020 Vmc 8 achieve high accuracy during metal cutting?

A: The machine's high rigidity, precision-ground ball screws, and robust cast iron construction minimize vibrations and deflection, ensuring stable and accurate machining results. Advanced control systems from Fanuc, Siemens, or Mitsubishi further enhance positioning accuracy and repeatability.Q: What types of materials can be processed with this CNC machine?

A: The Matchmaker 1020 Vmc 8 is specially designed for cutting and milling a range of metals including steel, cast iron, and similar ferrous or non-ferrous materials, making it well-suited for diverse manufacturing applications.Q: When is it recommended to use the automatic tool magazine feature?

A: The 24-tool magazine is ideal for operations requiring frequent tool changes or complex machining cycles. Using automatic tool selection increases operational efficiency and reduces downtime during extended production runs or intricate part geometries.Q: Where should the Matchmaker 1020 Vmc 8 be installed for optimal performance?

A: Installation is recommended in machine workshops or manufacturing facilities with adequate floor space and a stable 415V, 3-phase electric supply. A controlled environment helps maintain accuracy and extends the lifetime of machine components.Q: What is the process for operating the machine's PLC controls?

A: To use the PLC control, operators input part programs via the chosen CNC interface (Fanuc, Siemens, or Mitsubishi). The PLC manages automated sequences, axes movements, and tool changes, streamlining production and offering concise operational feedback to users.Q: How can the Matchmaker 1020 Vmc 8 benefit metal fabrication businesses?

A: By enabling high-speed, automated, and precise machining of heavy workpieces, this machine improves productivity, reduces manual intervention, and maintains consistent product quality, ultimately enhancing throughput and profitability for exporters, importers, suppliers, and traders.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Daewoo Doosan Dmv 4020/50 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Power Source : Electric

Material : Other, Cast Iron Frame, Mechatronics Components

Voltage : 220/380/415V, 3 Phase

Chiron Fz 12s Dtc Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Power Source : Electric

Material : Other, Cast iron body

Voltage : 400 V

Feeler Fv 1500 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Power Source : Electric

Material : Other, Cast Iron, Structural Steel

Voltage : 380 V / 3 Phase

Mori Seiki Mv 65 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Computerized : Yes

Power Source : Electric

Material : Other, Cast Iron (Bed), Steel Components

Voltage : 380415V

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |