|

Hardinge Talent T1 Cnc Lathe

Hardinge Talent T1 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Precision turning, industrial machining

- Material

- Cast iron base with steel components

- Type

- Horizontal Lathe

- Capacity

- Max Turn Diameter: 210 mm

- Weight (kg)

- 2500 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 6.5 kVA

- Rigidity

- High

- Voltage

- 400 V

- Motor

- Main Spindle: 9 kW

- Spindle Speed

- 50 - 6000 rpm

- Axial Choice

- 2-Axis

- Dimension (L*W*H)

- 2260 x 1610 x 1632 mm

- Feature

- High precision, compact design, integrated chip conveyor

- Color

- White / Blue

- Spindle Bore Diameter

- 45 mm

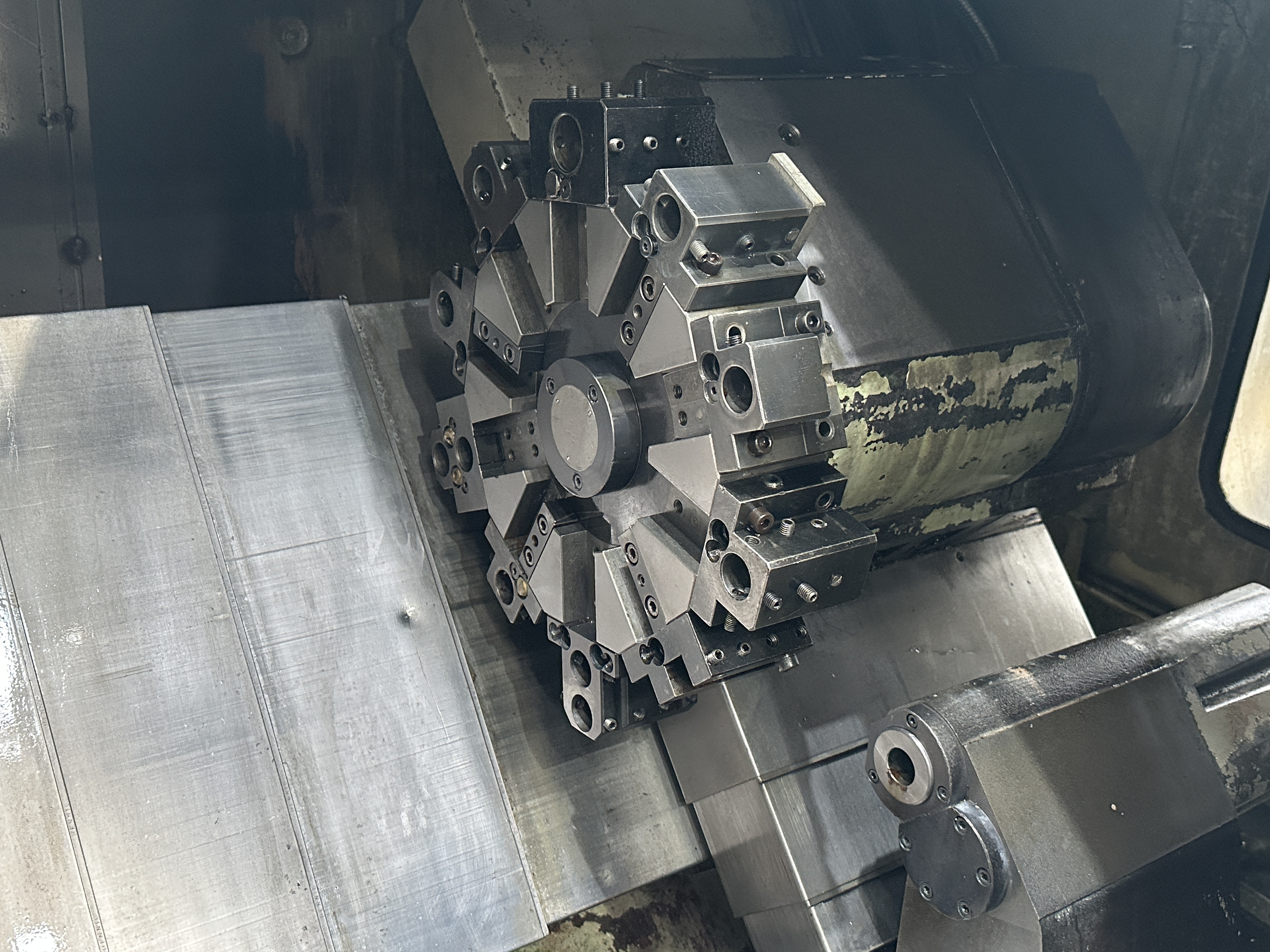

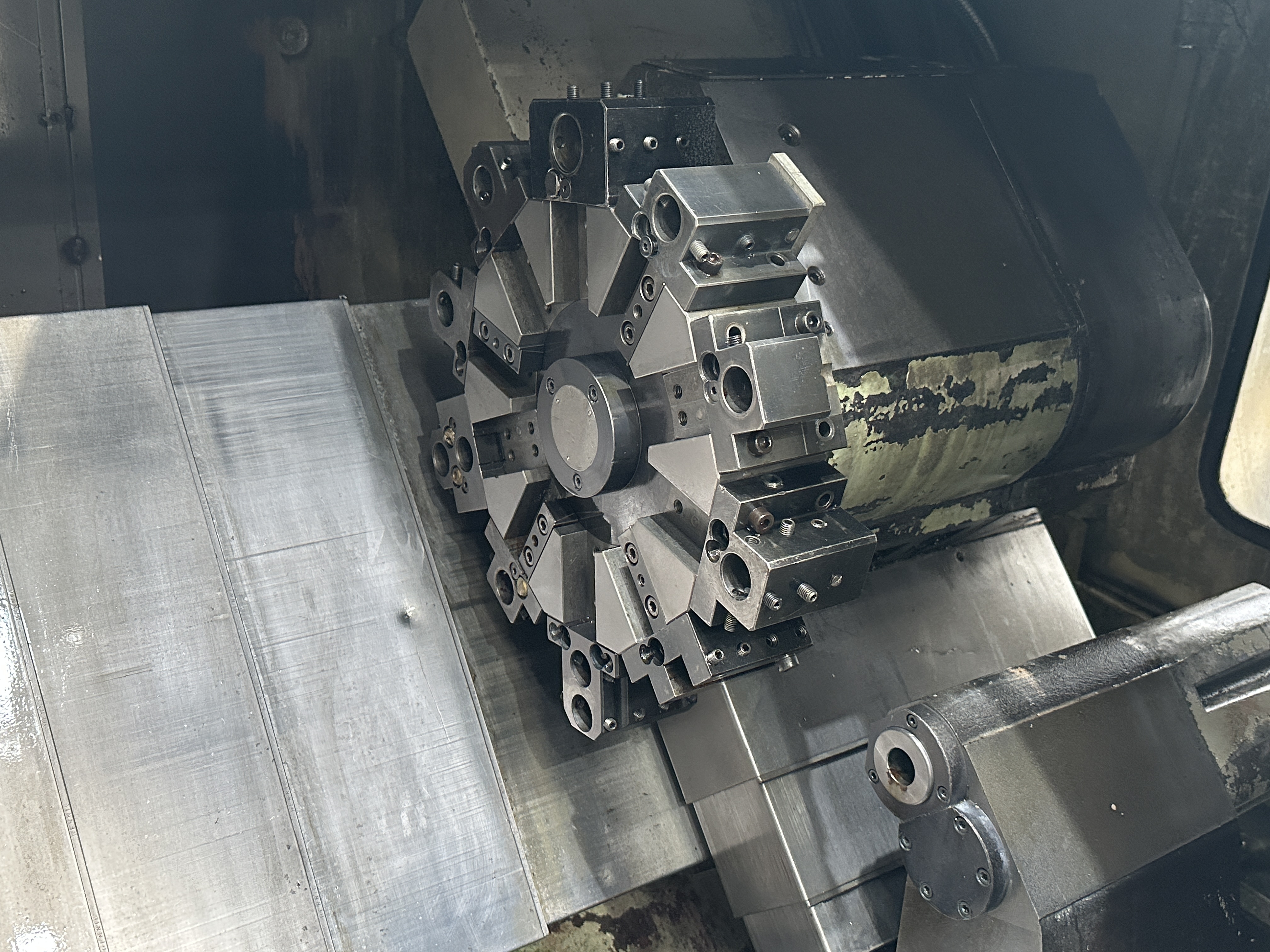

- Turret Stations

- 8-Station Turret

- Tailstock

- Optional

- Control System

- Fanuc Oi-TF

- Chuck Size

- 6 inch (152 mm)

- Lubrication

- Centralized Automatic

- Hydraulic System

- Standard

- Max Turning Length

- 350 mm

- Noise Level

- Less than 75 dB

- Environment

- Industrial

- Travel X/Z Axis

- 175 / 350 mm

- Coolant System

- Integrated

- Rapid Traverse (X/Z)

- 24 / 30 m/min

About Hardinge Talent T1 Cnc Lathe

*HARDINGE TALENT T1 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 500 mm

Reference No: 3414

Video Link: https://youtu.be/0GzGYGdMgWM

Technical Specifications:

WORKING CAPACITY

Max Turning Length: 500 mm

Swing: 440 mm

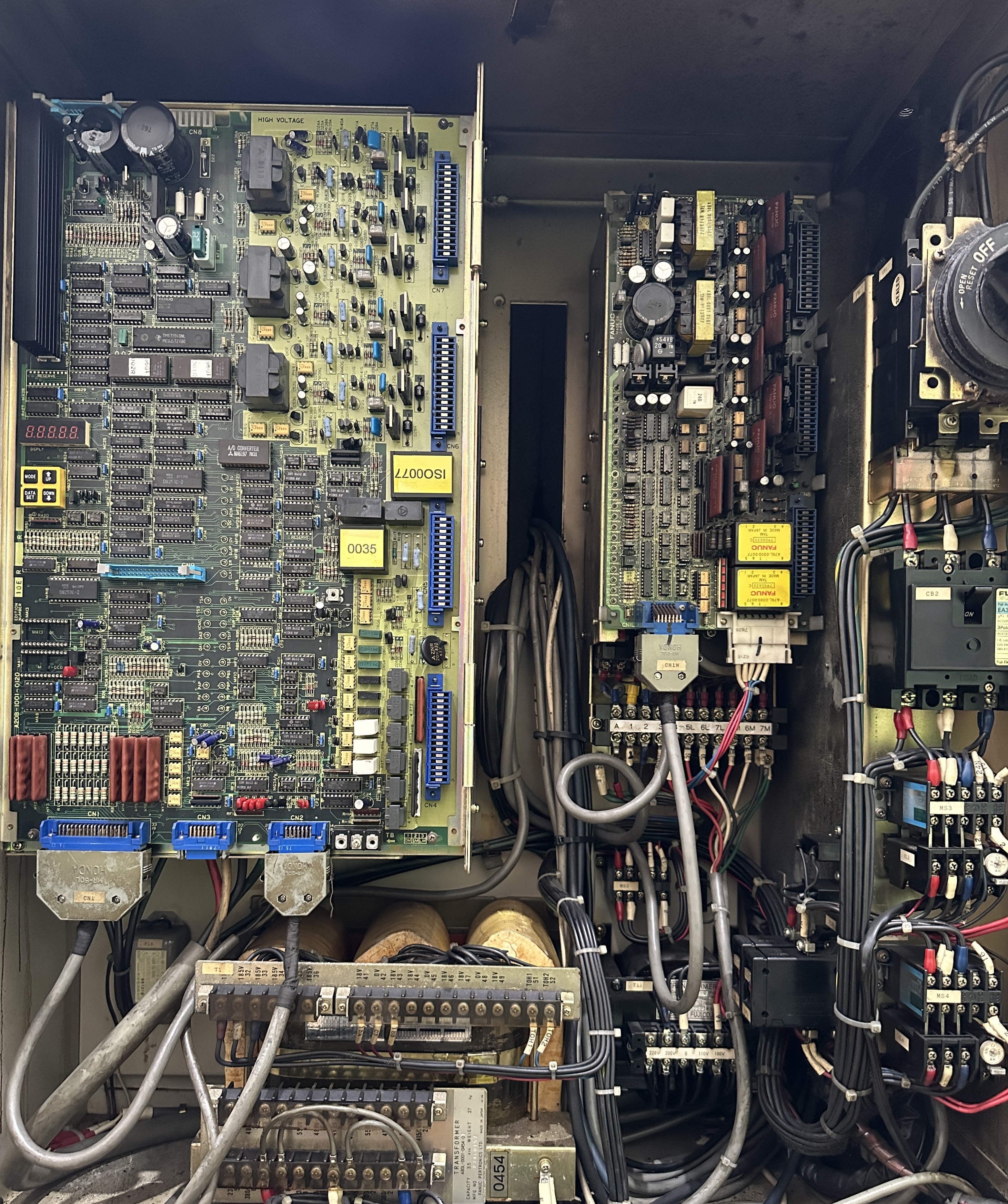

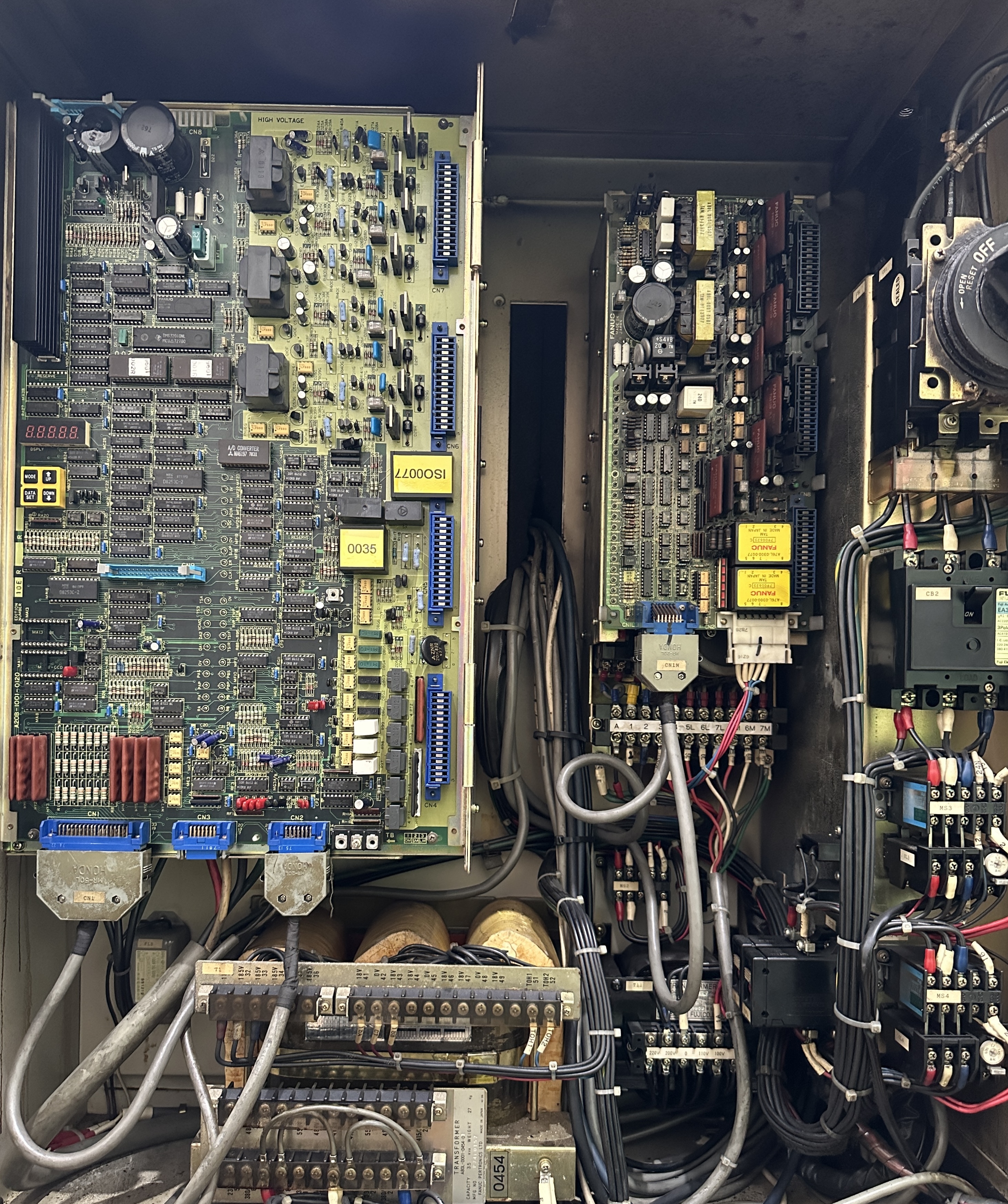

CNC

Control: Fanuc OT

SPINDLE

Spindle Nose: A2-5

Spindle Motor Power: 5.5 / 7.5 kW

TAILSTOCK

Tailstock: Yes

TURRET

Turret: 10 Stations

Parts Catcher, Tool Setter, Coolant Tank, Manuals

Enhanced Precision and Rigidity

Engineered for high-precision turning, the Talent T1 CNC Lathe combines a cast iron base with steel elements, providing unmatched rigidity during operations. The axis travel (175 mm X and 350 mm Z) and 8-station turret support complex machining tasks with minimal vibration, helping achieve tight tolerances crucial for demanding industrial workflows.

Integrated Systems for Reliable Performance

This machine boasts integrated hydraulic, coolant, and centralized automatic lubrication systems, ensuring consistent performance and longevity. Its electric power source (400V, 6.5 kVA consumption) streamlines operations, while its computerized and automatic controls facilitate seamless workflow on the shop floor, maximizing output and simplifying maintenance.

Compact Design, Industrial Efficiency

Despite a compact footprint (2260 x 1610 x 1632 mm), the Talent T1 CNC Lathe delivers robust industrial efficiency. It features an integrated chip conveyor for cleaner environments and maintains low operating noise (<75 dB). Optional tailstock and bar feeder expand flexibility, catering to varied industrial machining needs.

FAQ's of Hardinge Talent T1 Cnc Lathe:

Q: How does the Fanuc Oi-TF control system improve machining accuracy on the Hardinge Talent T1 CNC Lathe?

A: The Fanuc Oi-TF control system offers precise programming capabilities and fast response, which help reduce errors and achieve high repeatability in precision turning tasks. Its user-friendly interface also enables efficient operation and real-time monitoring of machining parameters.Q: What types of machining processes can the Hardinge Talent T1 CNC Lathe handle?

A: This lathe is designed for precision turning and industrial machining, capable of processing a variety of metals. Its 8-station turret allows rapid tool changes for complex operations, while the high-speed spindle (up to 6000 rpm) supports both roughing and finishing.Q: When should I consider using the optional tailstock and bar feeder with this CNC lathe?

A: The tailstock is recommended when machining longer workpieces that require additional support to maintain precision. The bar feeder is ideal for high-volume production or when working with bars for automatic feeding, optimizing workflow and increasing throughput.Q: Where are Hardinge Talent T1 CNC Lathes commonly utilized?

A: These CNC lathes are widely used in industrial environments such as manufacturing workshops, metalworking plants, and facilities needing high-precision component production. They are especially popular with exporters, importers, suppliers, and traders within India.Q: What is the process for maintaining the integrated coolant and lubrication systems?

A: The centralized automatic lubrication system ensures continuous lubrication of critical components, reducing manual intervention. Periodically, operators should check fluid levels and quality in both coolant and hydraulic systems, following the manufacturer's recommended schedule to avoid downtime.Q: How does the compact design and integrated chip conveyor benefit users?

A: The machine's compact design saves valuable floor space while the integrated chip conveyor efficiently removes machining debris, ensuring a cleaner work area and reducing the time spent on manual cleaning. This results in smoother operation and improved safety.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Mori Seiki Sl 5h CNC Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Industrial Turning Operations

Power Consumption : ~30 kVA

Product Type : CNC Lathe

Rigidity : High

Mori Seiki Zl-25mc/500 Cnc Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Turning and milling complex components

Power Consumption : 20 kVA (approx)

Product Type : CNC Turn Mill Center

Rigidity : High

Tsugami Bs26 Cnc Sliding Head

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Precision turning of smalldiameter bars

Power Consumption : 4.2 kW

Product Type : CNC Sliding Head

Rigidity : Other, High rigidity structure for stable machining

Hardinge Conquest T42 Cnc Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Industrial Metal Cutting / Turning

Power Consumption : 12 kW

Product Type : CNC Turning Center

Rigidity : Other, High Rigidity Structure

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |