|

Nakamura Tome Superturn 4 Cnc Lathe

Nakamura Tome Superturn 4 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Precision turning of metal components

- Material

- Cast iron bed, precision alloy components

- Type

- Horizontal CNC Lathe

- Capacity

- Max swing over bed: 530 mm; Max turning length: 830 mm

- Weight (kg)

- Approx. 7,000 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- Compatible (optional attachment)

- Power Source

- Electric

- Power Consumption

- 26 kVA (approx.)

- Rigidity

- High rigidity monoblock bed

- Voltage

- 400 V / 50 Hz

- Motor

- Main spindle motor: 30 HP (approx.)

- Spindle Speed

- Up to 2,800 rpm

- Axial Choice

- Multi-axis (2-axis standard, optional Y-axis)

- Dimension (L*W*H)

- Approx. 4100 x 2150 x 2100 mm

- Feature

- Heavy-duty cutting, high repeatability, programmable tailstock, automatic tool changer

- Color

- White & Blue

- Coolant System

- High volume, programmable

- Noise Level

- <78 dB(A)

- Chuck Size

- 12 inch (optional up to 15 inch)

- Chip Conveyor

- Built-in chip conveyor

- Lubrication

- Automatic centralized lubrication

- Environment

- Suitable for medium to high production environments

- Hydraulic System

- Integrated hydraulic chuck and tailstock

- X/Z Axis Travel

- X: 300 mm, Z: 850 mm

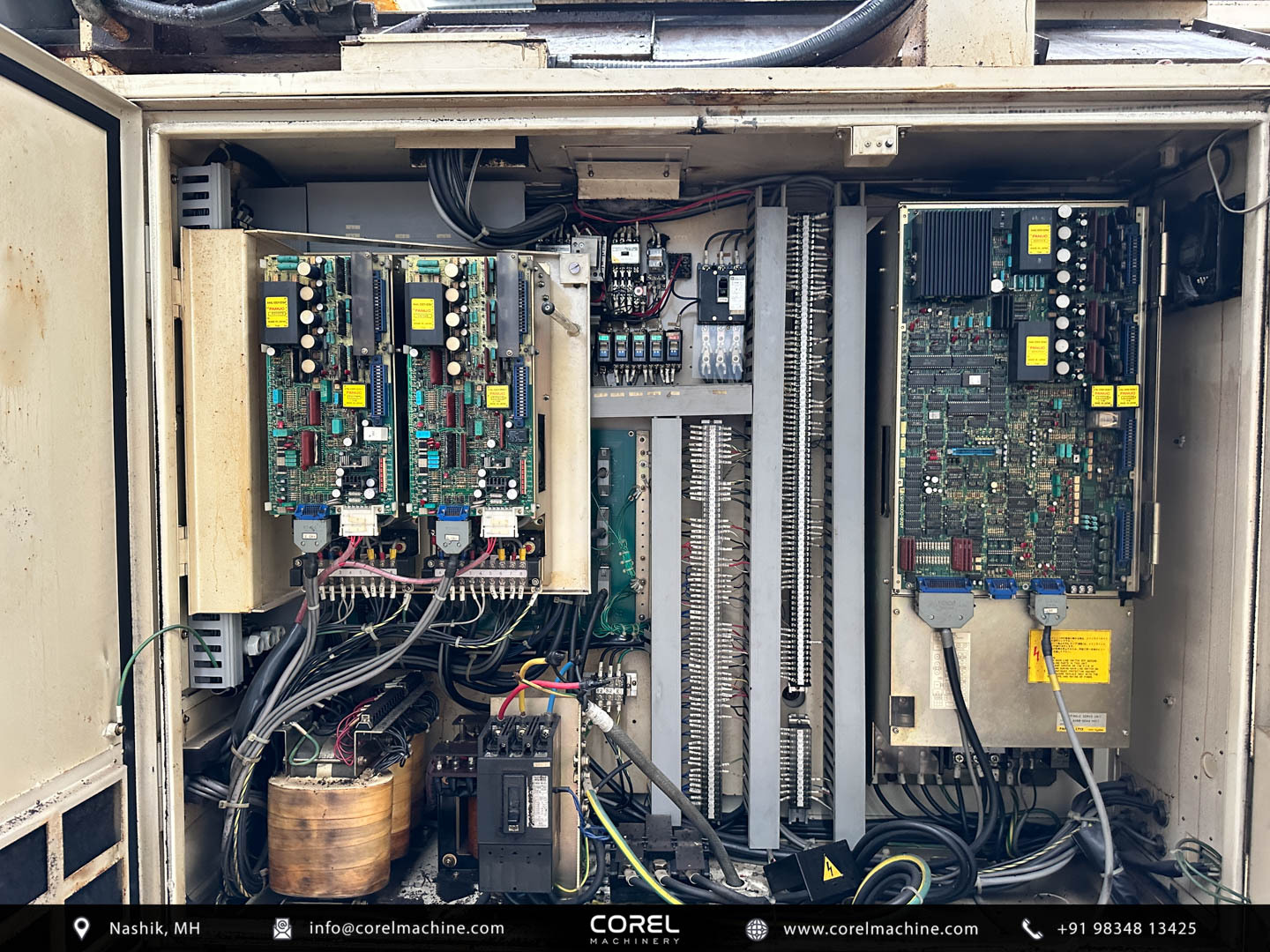

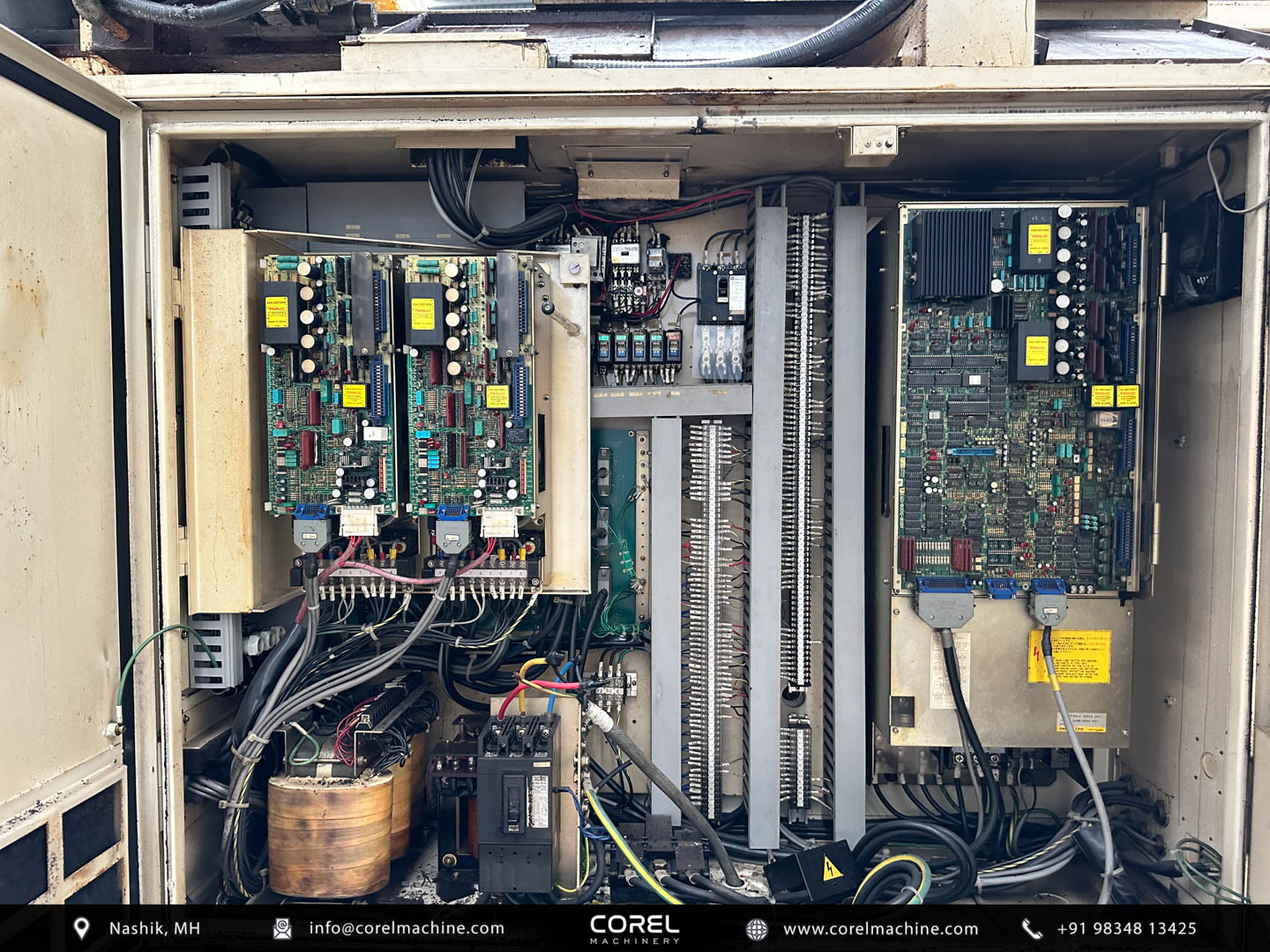

- Control System

- Fanuc CNC Controller (comprehensive cycle options)

- Tailstock

- Programmable NC Tailstock

- Repeatability

- ±0.003 mm

- Supported Materials

- Steel, stainless, brass, aluminum, alloys

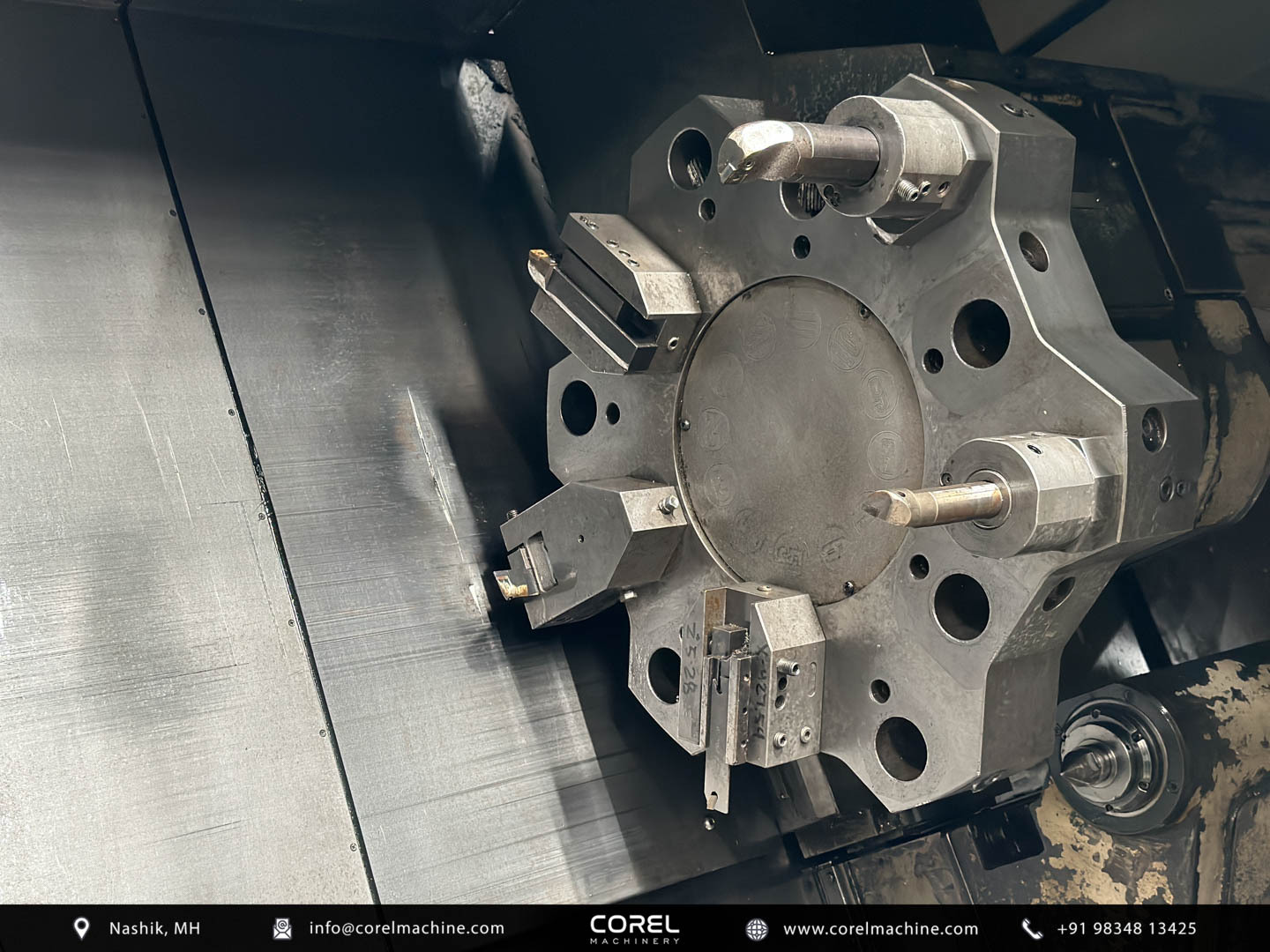

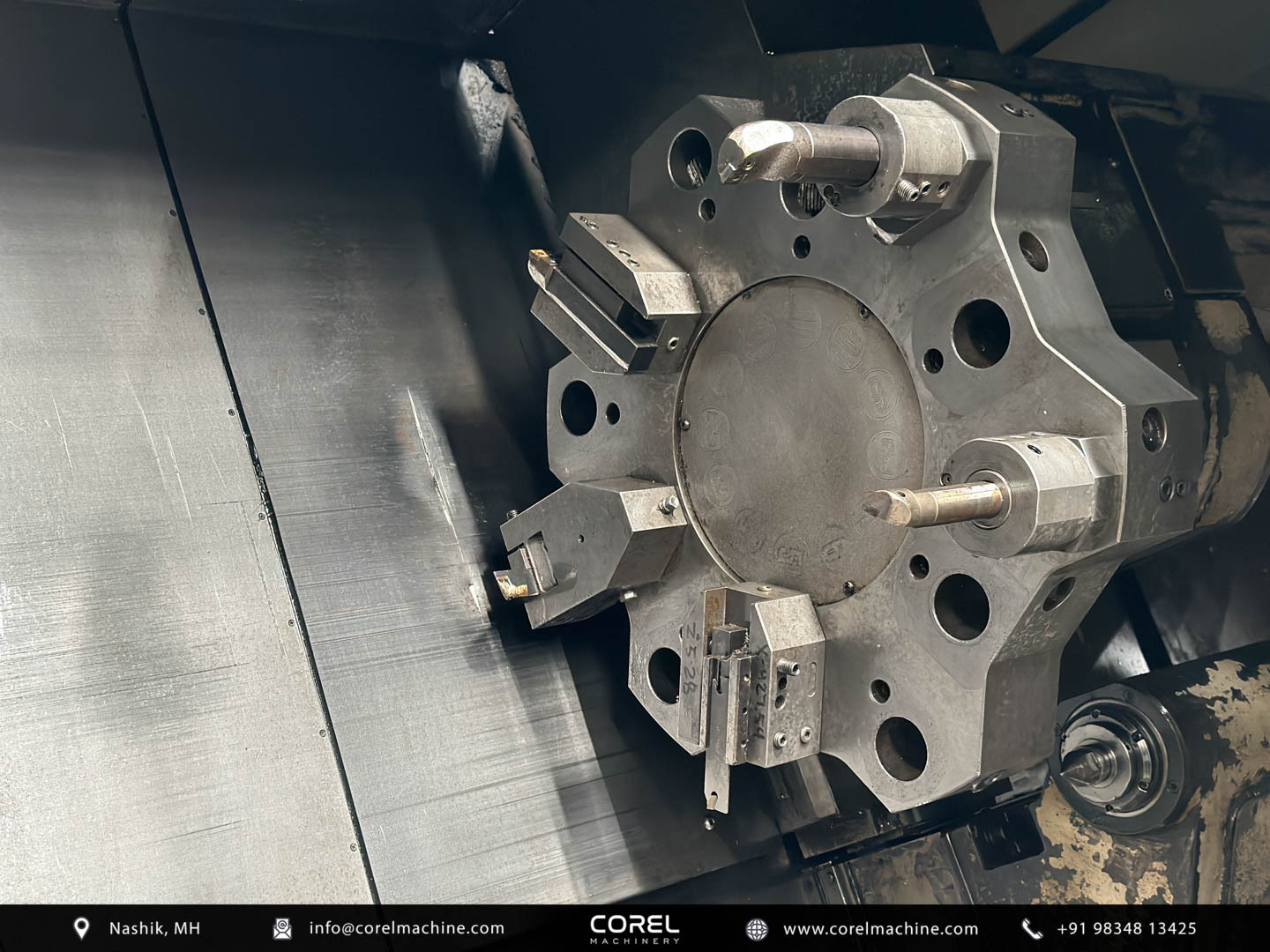

- Tool Turret

- 12-station turret (optional live tooling)

- C-Axis Control

- Available (for milling and drilling)

About Nakamura Tome Superturn 4 Cnc Lathe

*NAKAMURA TOME SUPERTURN 4 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 400 x 1200 mm

Reference No: 3775

Video Link: https://youtu.be/ILSOY6FpmQk

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 400 mm

Max Turning Length: 1200 mm

Chuck Equipped: 300 mm

CNC

Control: Fanuc 11TE

SPINDLE

Spindle Motor Power: 15 / 18.5 kW

Hole Through Spindle: 90 mm

TURRET

Turret: 12 Stations

Geared Spindle

Superior Precision and Rigidity

The Nakamura Tome Superturn 4 CNC Lathe features a robust monoblock bed and cast iron frame to minimize vibration, delivering high rigidity for demanding turning operations. With a repeatability of 0.003 mm, it excels in precise production of a variety of metal components, making it highly reliable for medium to heavy duty use.

Flexible Machining Capabilities

Offering a 12-station tool turret with optional live tooling and Y-axis configuration, the Superturn 4 easily handles complex mill-turn tasks. C-axis control extends capabilities to milling and drilling, while the programmable tailstock and automatic tool changer streamline machining cycles for improved productivity.

Integrated Systems for Efficiency

An automatic centralized lubrication system, programmable high-volume coolant, and integrated chip conveyor contribute to minimal maintenance and superior workplace cleanliness. The built-in hydraulic system ensures powerful yet reliable chuck and tailstock actuation, enhancing operator safety and part stability during cutting.

FAQ's of Nakamura Tome Superturn 4 Cnc Lathe:

Q: How does the Fanuc CNC Controller enhance the operation of the Superturn 4 lathe?

A: The Fanuc CNC Controller provides comprehensive cycle options, intuitive programming, and advanced control of multi-axis movements. It streamlines complex machining processes, increases productivity, and ensures consistent high-precision performance for various turning and milling tasks.Q: What types of materials can be processed on the Nakamura Tome Superturn 4 CNC Lathe?

A: This lathe is designed to handle a wide range of materials including steel, stainless steel, brass, aluminum, and assorted alloys. Its high rigidity and robust spindle power make it suitable for heavy-duty and precise machining of these materials.Q: When is the use of the programmable NC tailstock most beneficial?

A: The programmable NC tailstock is most advantageous during operations on long or heavy workpieces, requiring additional support to maintain dimensional accuracy and reduce chatter. It is also useful for automated batch production, allowing precise repositioning via CNC.Q: Where is the Nakamura Tome Superturn 4 CNC Lathe typically installed?

A: It is commonly installed in medium to high production environments such as component manufacturing units, metalworking factories, and exporter or supplier facilities needing consistent precision and flexible automation.Q: What process features make the lathe suitable for high-volume production?

A: Key features include a built-in chip conveyor for continual debris removal, automatic lubrication for low maintenance, multi-axis control (with optional Y-axis), quick tool changes with a 12-station turret, and programmable tailstock, all contributing to efficient cycle times and reduced manual intervention.Q: How can operators benefit from the integrated hydraulic and lubrication systems?

A: The automatic centralized lubrication minimizes wear and extends machine life, while the hydraulic system ensures forceful yet controlled actuation of the chuck and tailstock. Together, these systems reduce downtime, improve safety, and promote consistent part quality.Q: What usage options are available for increasing productivity on this lathe?

A: Operators can attach optional bar feeders for continuous production, upgrade to live tooling and Y-axis for advanced mill-turn operations, and select larger chuck sizes for handling bigger workpieces. These options allow for tailored configuration to meet specific production requirements.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Hardinge Conquest T51 Cnc Turn Mill Center

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Color : Other, White & Blue

Automatic : Yes

Material : Other, Cast Iron Base, Hardened Components

Nakamura Tome Tmc-4 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White & Blue

Automatic : Yes

Material : Other, Cast iron

Emcoturn 320 Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Standard machine grey/red

Automatic : Yes

Material : Other, Cast Iron Base, Steel Components

Colchester Tornado 100 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Industrial Grey/Blue

Automatic : Yes

Material : Other, Cast Iron Base, Steel Components

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |