|

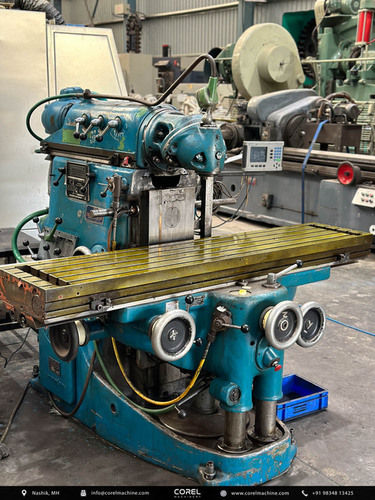

Bridgeport M1tr Turret Milling Machine 2

Bridgeport M1tr Turret Milling Machine 2 Specification

- Product Type

- Turret Milling Machine

- General Use

- Metal Milling/Drilling, Industrial, Workshop

- Material

- Cast Iron, Steel Components

- Type

- Vertical Milling

- Capacity

- Standard 2 HP with R8 Spindle

- Weight (kg)

- 1250 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 3 HP

- Rigidity

- Robust Cast Iron Construction

- Voltage

- 415 V / 3 Phase

- Motor

- 3 HP Motor

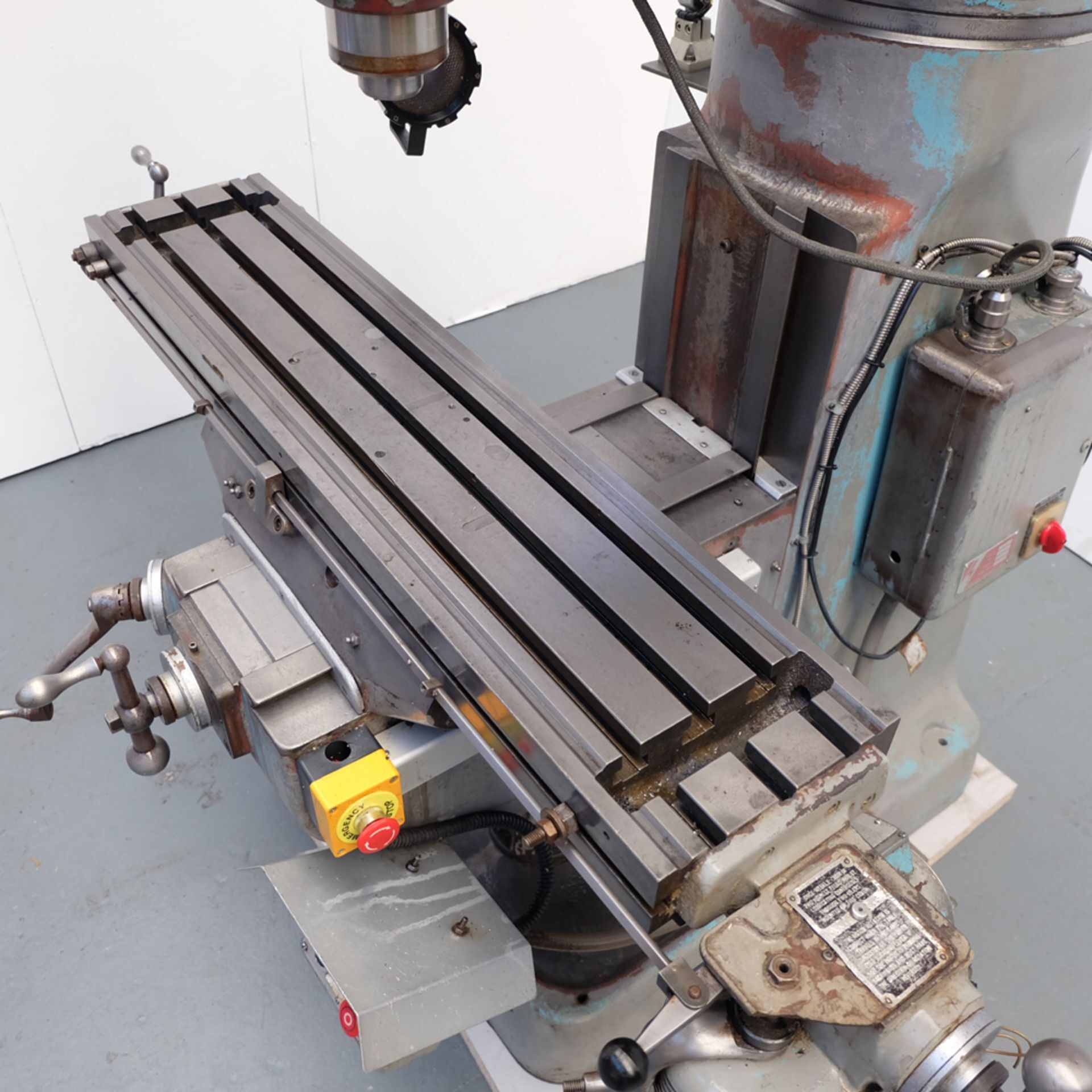

- Table Size

- 1067 mm x 230 mm

- Spindle Speed

- Variable, 70-4200 rpm

- Axial Choice

- Manual / Auto (X, Y, Z) Movement

- Dimension (L*W*H)

- 1500 mm x 1700 mm x 2150 mm

- Feature

- High Precision, Sturdy Design, Fine Feed, Hardened Bed

- Color

- Standard Grey

- Spindle Taper

- R8 (Bridgeport Standard)

- Graduation

- 0.02 mm per dial

- Longitudinal Travel (X)

- 780 mm

- Table Load Capacity

- 260 kg

- Number of T-slots

- 3

- Quill Travel

- 127 mm

- Throat Distance

- 230-625 mm (max min)

- Feed Motor

- 0.5 HP

- Width of T-slots

- 16 mm

- Maximum Distance from Spindle to Table

- 420 mm

- Vertical Travel (Z)

- 400 mm

- Cross Travel (Y)

- 300 mm

- Coolant System

- Built-in

- Lubrication

- Automatic Lubrication System

About Bridgeport M1tr Turret Milling Machine 2

*BRIDGEPORT M1TR TURRET MILLING MACHINE 2*

CATEGORY : MILLING MACHINES

CAPACITY : 1065 x 230 mm

Reference No: 3131

Video Link: https://youtu.be/N5eFFMZC8Xs

Technical Specifications:

Table Size: 1065 x 230 mm

Spindle Taper R8

Motorized Feed Travel in Longitudinal Travels

Versatile Performance and High Precision

The Bridgeport M1tr excels in precision, featuring a 0.02 mm per dial graduation and variable spindle speed for a wide range of metalworking tasks. Its hardened bed and fine feed mechanism enable meticulous control over intricate milling and drilling operations, crucial for industrial standards.

Robust Build for Industrial Demands

Manufactured from strong cast iron and steel components, this milling machine is designed for heavy-duty usage. The robust construction enhances machine rigidity, ensuring stability and minimizing vibrations, which extends machine service life and improves machining accuracy.

Effortless Operation and Maintenance

This model is equipped with a built-in coolant system and automatic lubrication, simplifying maintenance and supporting continuous work cycles. The semi-automatic manual/auto axis movements and ergonomic controls allow for smooth operation, making it suitable for workshops and industrial settings.

FAQ's of Bridgeport M1tr Turret Milling Machine 2:

Q: How does the Bridgeport M1tr Turret Milling Machine ensure high precision during metal milling?

A: The machine provides meticulous accuracy with its hardened bed, finely graduated dials (0.02 mm per dial), and variable spindle speed from 70-4200 rpm. These features enable precise adjustments and smooth cutting, making it suitable for demanding metalworking tasks.Q: What types of materials can be processed using this milling machine?

A: The Bridgeport M1tr is designed to handle a variety of metals, including steel and cast iron components. Its robust build and versatile spindle capacity make it ideal for milling, drilling, and shaping different metal materials commonly used in industrial environments.Q: When is automatic lubrication activated, and how does it benefit users?

A: The automatic lubrication system operates continuously during machine use, ensuring key mechanical parts are properly lubricated. This minimizes friction, reduces wear, and extends the machine's operational lifespan, resulting in consistent high performance and reduced maintenance downtime.Q: Where is the Bridgeport M1tr Turret Milling Machine typically installed and used?

A: This milling machine is commonly found in industrial manufacturing units, metalworking workshops, and machining centers across India. Its size and capabilities make it suited for environments requiring precise and heavy-duty milling and drilling operations.Q: What is the process for switching between manual and auto axis movement on the machine?

A: Operators can easily choose between manual and automatic movement for the X, Y, and Z axes using designated machine controls. This flexibility enables customization of workflow, allowing both rapid positioning for bulk work and fine manual adjustments for precision tasks.Q: How does the built-in coolant system improve machining safety and efficiency?

A: The coolant system keeps the cutting area at an optimal temperature, reducing heat build-up that may otherwise compromise tool integrity and workpiece quality. This not only protects the equipment and materials but enhances overall machining safety and productivity.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Xyz Krv Pro 2000 Turret Mill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : Other, High Rigidity Cast Iron Structure

Axial Choice : Manual/Fine Feed in X, Y, Z Axes

Material : Other, Cast Iron

Power Consumption : 3 HP

Huron Ku6 Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Axial Choice : 3 Axis

Material : Other, Cast Iron

Power Consumption : 15 kW

Boko Wf1 Universal Tool Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : Other, High (cast iron body)

Axial Choice : X, Y, Z axes manual

Material : Other, Cast Iron, Steel Components

Power Consumption : Approx. 3.3 kW

Tos Vertical Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Axial Choice : 3 Axis

Material : Other, Cast Iron & Steel

Power Consumption : 7.5 HP

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |