|

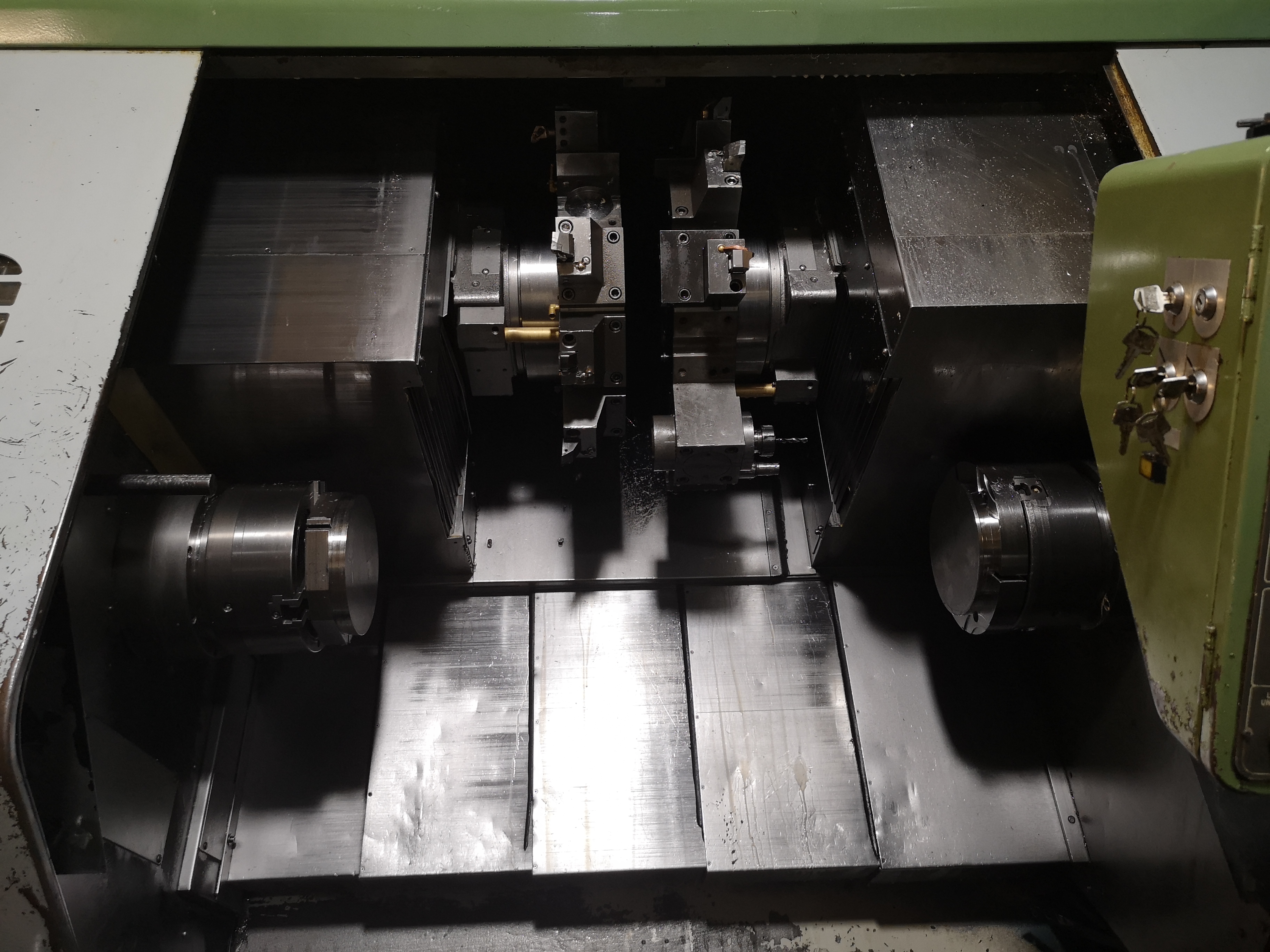

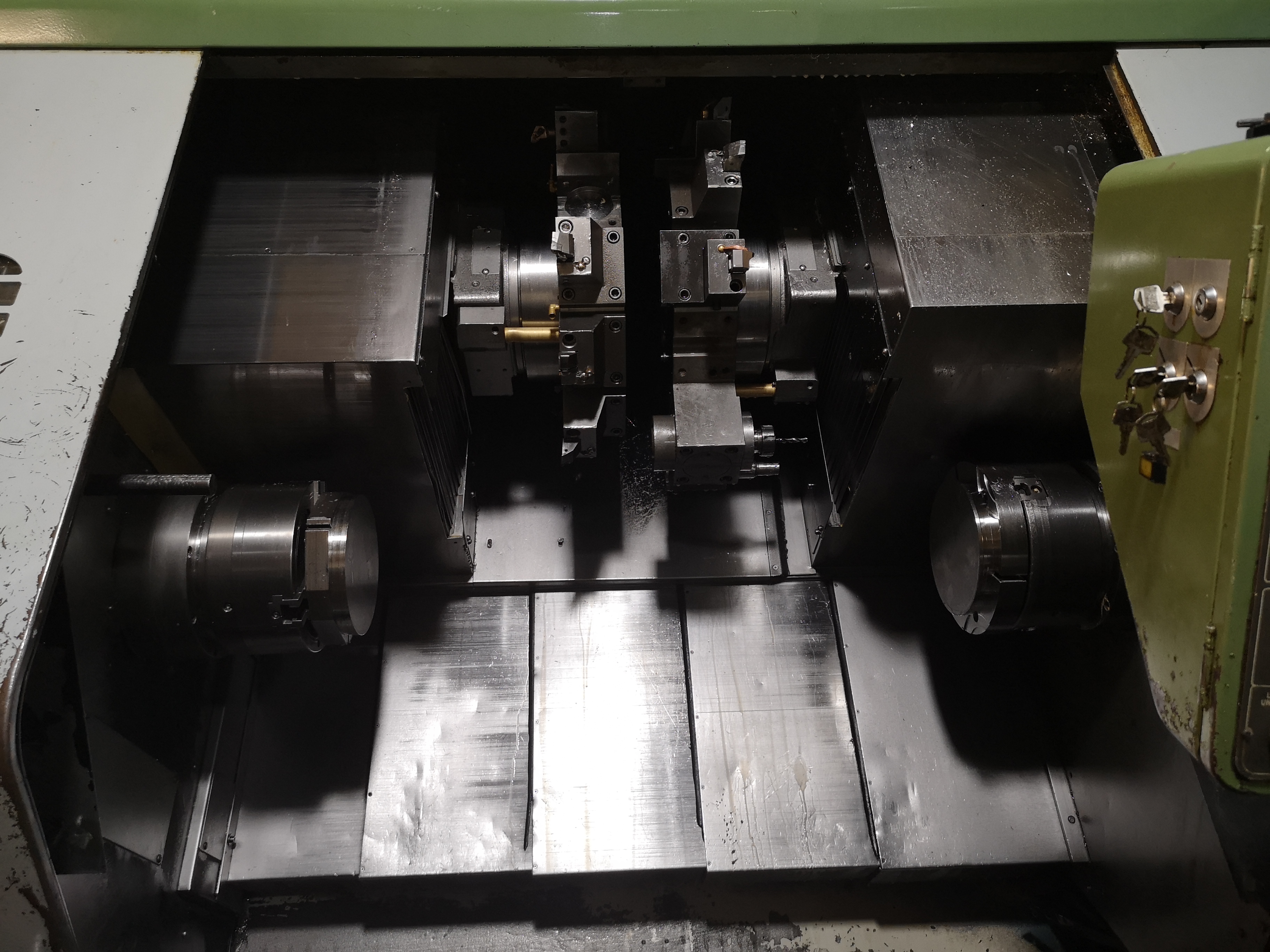

Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center

Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center Specification

- Product Type

- CNC Turn Mill Center

- General Use

- Metal Turning, Milling, Drilling

- Material

- Cast Iron Body with Hardened Alloy Components

- Type

- Horizontal CNC Lathe

- Capacity

- Bar Diameter: Max 65 mm

- Weight (kg)

- 8300 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- PLC Control

- Yes

- Bar Feeder

- Optional

- Power Source

- Electric

- Power Consumption

- 22 kVA

- Rigidity

- High Rigidity Construction

- Voltage

- 400 V

- Motor

- AC Spindle Motor

- Table Size

- Not Applicable (Turning Center)

- Spindle Speed

- 4000 rpm (Maximum)

- Axial Choice

- 6 Axis

- Dimension (L*W*H)

- 3600 x 2530 x 2270 mm

- Feature

- High Precision, Simultaneous 6-Axis Control, Twin Spindle, Twin Turret

- Color

- White & Grey

- Control System

- FANUC 31i-B

- Max Turning Length

- 700 mm

- Coolant System

- High Pressure Coolant Pump

- Air Requirement

- 5.5 kg/cm²

- Lubrication

- Automatic Centralized Lubrication

- Tailstock

- Programmable

- Max Turning Diameter

- 250 mm

- Hydraulic System

- Yes

- Safety Features

- Full Enclosure with Interlock, Overload Protection

- Machine Structure

- Box Type Bed

- Main Spindle Nose

- A2-8

- Installation Space Required

- Approx. 4.5 x 3 m

- CNC Interface

- Ethernet, USB, RS232

- Y-Axis Travel

- ±60 mm

- Tool Capacity

- Up to 24 Tools (12 per turret, live tool support)

- Live Tool Spindle Speed

- 4000 rpm

- Number of Turrets

- 2 (Upper and Lower)

- Chuck Size

- 8 inch (Upgradable to 10 inch)

About Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center

*Nakamura Tome TW-30 6 Axis CNC TURN MILL CENTER*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 330 x 300 mm

YEAR OF CONSTRUCTION : 1995

Reference No: 257

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 330

Max Turning Length: 300

Chuck Equipped: 250 mm x 2

CNC

Control: Fanuc OT x 2

SPINDLE

Max Rotation Speed: 3600 RPM

Spindle Bore: 80 mm

Spindle Motor Power: 22 / 18.5 kW

TURRET

Turret 1: 12 Stationary / Live Tool Stations

Turret 2: 12 Stationary / Live Tool Stations

Machine Dimensions

Weight: 12T

LWH: 4,300 x 2,053 x 2,150mm

Secondary Mill/Drill Function & C-Axis on both spindles, 6 Axis Machine, Excellent condition

Advanced Control and High Precision

Powered by the FANUC 31i-B control system, the Tw-30 achieves exceptional precision and repeatability. Its twin spindle and dual turret design allow for simultaneous operations, maximizing throughput and workflow flexibility. The system supports Ethernet, USB, and RS232 interfaces for seamless integration with factory automation.

Optimized for Rigidity and Versatility

Constructed with a durable cast iron body and box-type bed, the Nakamura Tome Tw-30 ensures high rigidity for heavy-duty machining. The programmable tailstock, upgradable chuck size, and live tool support (up to 4000 rpm) enable users to handle diverse parts and materials, from prototype to high-volume production.

Automatic Safety and Efficient Operations

Operational safety is secured by a full enclosure with interlock and overload protection. Automatic centralized lubrication, high-pressure coolant pump, and programmable components make the machine fully automatic, reducing manual intervention and increasing productivity. Options for bar feeder and full computerized controls enhance user convenience.

FAQ's of Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center:

Q: How does the Nakamura Tome Tw-30 CNC Turn Mill Center improve production efficiency?

A: This CNC Turn Mill Center combines simultaneous 6-axis control with twin spindles and dual programmable turrets, allowing parallel operations. Its high rigidity and automatic systems, such as lubrication and coolant, streamline workflows, reducing cycle times and maximizing productivity.Q: What materials and tasks is the Nakamura Tome Tw-30 suitable for?

A: The machine features a cast iron body with hardened alloy components, excellent for high-precision metal turning, milling, and drilling tasks. It accommodates a maximum turning diameter of 250 mm and bar diameter up to 65 mm, making it ideal for processing various metal parts.Q: When should I upgrade the chuck size to 10 inches?

A: The chuck size can be upgraded to 10 inches when your applications require handling larger diameter workpieces than the standard 8-inch can accommodate. This enhancement increases the range of machinable parts and supports more versatile industrial requirements.Q: Where is the Nakamura Tome Tw-30 typically installed, and what space does it require?

A: The machine requires an installation space of approximately 4.5 x 3 meters, suitable for factory floors involved in metalworking, automotive, aerospace, and other precision engineering industries in India and worldwide.Q: What is the process for integrating the CNC Turn Mill Center with factory systems?

A: Integration is straightforward due to its interfaces for Ethernet, USB, and RS232 connectivity. The advanced FANUC 31i-B control system supports seamless PLC implementation, allowing easy incorporation into existing automated manufacturing environments.Q: How can users benefit from the programmable tailstock and twin turret setup?

A: The programmable tailstock provides support for longer workpieces, while the twin turret arrangement enables simultaneous upper and lower tool operations. This reduces setup times, allows complex part production, and enhances machining flexibility.Q: What safety features does this model offer for operators?

A: Operator safety is ensured by a full enclosure with interlock, overload protection, and high-level safeguards. These features minimize risks of accidental contact with moving parts and provide extra protection during heavy-duty operations.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Hardinge Conquest T51 Cnc Turn Mill Center

Minimum Order Quantity : 1 , , Piece

Automatic : Yes

Weight (kg) : 5700 kg

Color : Other, White & Blue

PLC Control : Yes

Schiess Germany Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automatic : Yes

Weight (kg) : 18500

Color : Other, Blue and Grey

PLC Control : Other, Siemens PLC

Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automatic : Other, Fully Automatic

Weight (kg) : 2500 kg

Color : Other, White & Grey

PLC Control : Yes

Daewoo Puma 15 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Automatic : Yes

Weight (kg) : 5700 kg

Color : Other, Standard Factory Color (Grey/Blue)

PLC Control : Other, FANUC CNC Controller

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |