|

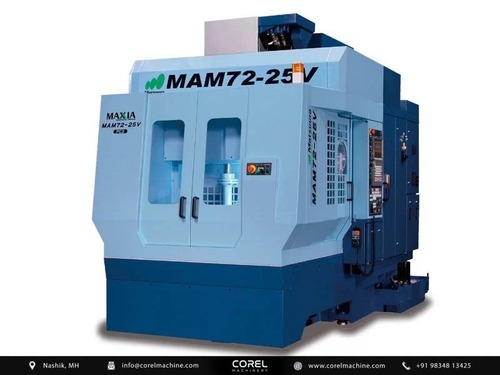

5-axis Matsuura Mam72-25v Vmc (Transit)

5-axis Matsuura Mam72-25v Vmc (Transit) Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- Metalworking, Component Machining

- Material

- Cast Iron Structure, Suitable for Machining Metals

- Type

- CNC Machining Center

- Capacity

- Pallets: 15-station APC

- Weight (kg)

- 8,400 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 42 kVA

- Rigidity

- High Structural Rigidity

- Voltage

- 400V, 3 Phase

- Motor

- Spindle Motor 15 kW

- Table Size

- 250 mm Diameter

- Spindle Speed

- 20,000 rpm

- Axial Choice

- 5-Axis

- Dimension (L*W*H)

- 3,325 mm 2,520 mm 2,870 mm

- Feature

- High-precision, Automatic Pallet Changer, Large Work Envelope

- Color

- White / Blue

- Max Workpiece Weight

- 60 kg per pallet

- C-Axis Rotation

- 360 continuous

- Spindle Taper

- HSK-A63

- Tool Capacity

- 60 tools (standard, chain-type magazine)

- Air Supply

- 0.5 0.6 MPa

- Z-Axis Travel

- 330 mm

- Machine Floor Space

- Approx. 8.5 m

- Coolant System

- Standard with Through-Spindle Coolant

- X-Axis Travel

- 450 mm

- A-Axis Rotation

- +30 to -125

- Rapid Traverse Rate (X/Y/Z)

- 50/50/50 m/min

- Control System

- Fanuc 31i-B5

- Max Workpiece Size

- D 300 mm H 225 mm

- Y-Axis Travel

- 350 mm

About 5-axis Matsuura Mam72-25v Vmc (Transit)

*5-AXIS MATSUURA MAM72-25V VMC (TRANSIT)*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 550 x 410 x 450 mm

YEAR OF CONSTRUCTION : 2004

Reference No: 3651

Technical Specifications:

WORKING CAPACITY

Travels (XYZ): 550 x 410 x 450 mm

CNC

Control: Fanuc 30i

SPINDLE

Spindle Taper: BT40

Twin Pallet

Precision and Performance

The Matsuura MAM72-25V VMC is engineered with high structural rigidity and precise control, ensuring reliable results for demanding metalworking tasks. Its advanced Fanuc 31i-B5 CNC system enables seamless multi-axis machining, allowing operators to achieve intricate geometries with optimal speed and accuracy. The machine's robust spindle and rapid traverse maximize throughput, making it suitable for high-volume environments.

Versatile Capacity and Automation

With its 60-tool chain magazine, automatic pallet changer (APC) with 15 stations, and large work envelope, this VMC is designed for flexible, uninterrupted production. Users can process various metal materials efficiently, benefiting from the wide range of axis motion and extended table size. Its through-spindle coolant system enhances tooling life and machining quality, while advanced automation reduces manual intervention.

FAQ's of 5-axis Matsuura Mam72-25v Vmc (Transit):

Q: How does the automatic pallet changer benefit the machining process on the Matsuura MAM72-25V VMC?

A: The automatic pallet changer (APC) with 15 stations allows for continuous operation and efficient part handling, reducing downtime by enabling quick fixture and part exchanges. This increases productivity and streamlines workflow for batch and multi-part production.Q: What materials can the MAM72-25V VMC machine, and what makes it suitable for metalworking?

A: Constructed with a cast iron structure for high rigidity and equipped with a robust spindle, this machining center is specifically designed for metals and precision component manufacturing. Its high spindle speed and through-spindle coolant ensure efficient, high-quality machining of various metallic components.Q: When is it recommended to use the Matsuura MAM72-25V VMC?

A: This machine is ideal when high precision, complexity, and efficiency are required in metalworking, especially for batch production or continuous machining. It is suitable for applications in component machining, tooling production, and automotive or aerospace industries.Q: Where can the MAM72-25V VMC be installed, and what floor space is needed?

A: The Matsuura MAM72-25V occupies approximately 8.5 m2 of floor space. It is suitable for installation in industrial settings such as machine shops, manufacturing plants, or specialized metalworking facilities.Q: What is involved in the setup process for this 5-axis CNC machining center?

A: Installation requires access to a 400V three-phase power supply and a stable air supply of 0.5-0.6 MPa. The machine must be positioned within the specified floor space and connected to an adequate coolant system; programming via the Fanuc 31i-B5 control system enables workflow configuration.Q: How does the Fanuc 31i-B5 control system contribute to machine performance?

A: The Fanuc 31i-B5 provides advanced CNC control, allowing precise programming, multi-axis synchronization, and user-friendly operation. It enhances complex part production efficiency while supporting automated and computerized processes.Q: What are the usage benefits of the MAM72-25V for exporters, importers, and suppliers in India?

A: The machine's high productivity, automation, and robust design support large-scale manufacturing, lowering production costs and improving lead times. Its versatility caters to different market demands, making it an asset for exporters, importers, suppliers, and traders in India's metalworking industry.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Mori Seiki Cv-500 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Bar Feeder : No

Color : Other, Standard Factory Grey

General Use : CNC Machining, Manufacturing, Production

Kitamura Mycenter 2xi Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Bar Feeder : No

Color : Other, White and Blue

General Use : Industrial Metalworking / CNC Machining

Fadal 6030 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : High

Bar Feeder : No

Color : Other, White & Blue

General Use : Industrial metal milling, highprecision machining

Daewoo Doosan Mynx Nm410 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Rigidity : Other, Heavyduty Meehanite casting for high rigidity

Bar Feeder : No

Color : Other, Grey & Blue

General Use : Metal cutting, Milling, Drilling, Tapping

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |