|

Kitamura Mycenter 2xi Twin Pallet Vmc

Kitamura Mycenter 2xi Twin Pallet Vmc Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- Industrial Metalworking / CNC Machining

- Material

- Cast Iron Base, Steel, Aluminum Machinable

- Type

- CNC Machine

- Capacity

- Workpiece: Up to 200 kg per pallet

- Weight (kg)

- Approximately 4,600 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes (Fanuc Series 0i-M or similar)

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 10 kVA

- Rigidity

- High

- Voltage

- 220/380 V

- Motor

- Main Spindle Motor: 5.5 kW (7.5 HP)

- Table Size

- 700 mm x 420 mm

- Spindle Speed

- 12,000 rpm

- Axial Choice

- X/Y/Z

- Dimension (L*W*H)

- 2400 mm x 2820 mm x 2670 mm

- Feature

- Twin Pallet, High Speed, Precision Machining

- Color

- White and Blue

- Positioning Accuracy

- ±0.002 mm

- Lubrication System

- Automatic Centralized

- Z-Axis Travel

- 460 mm

- Cutting Feedrate

- 1~20,000 mm/min

- Repeatability

- ±0.001 mm

- Max Tool Diameter

- 80 mm

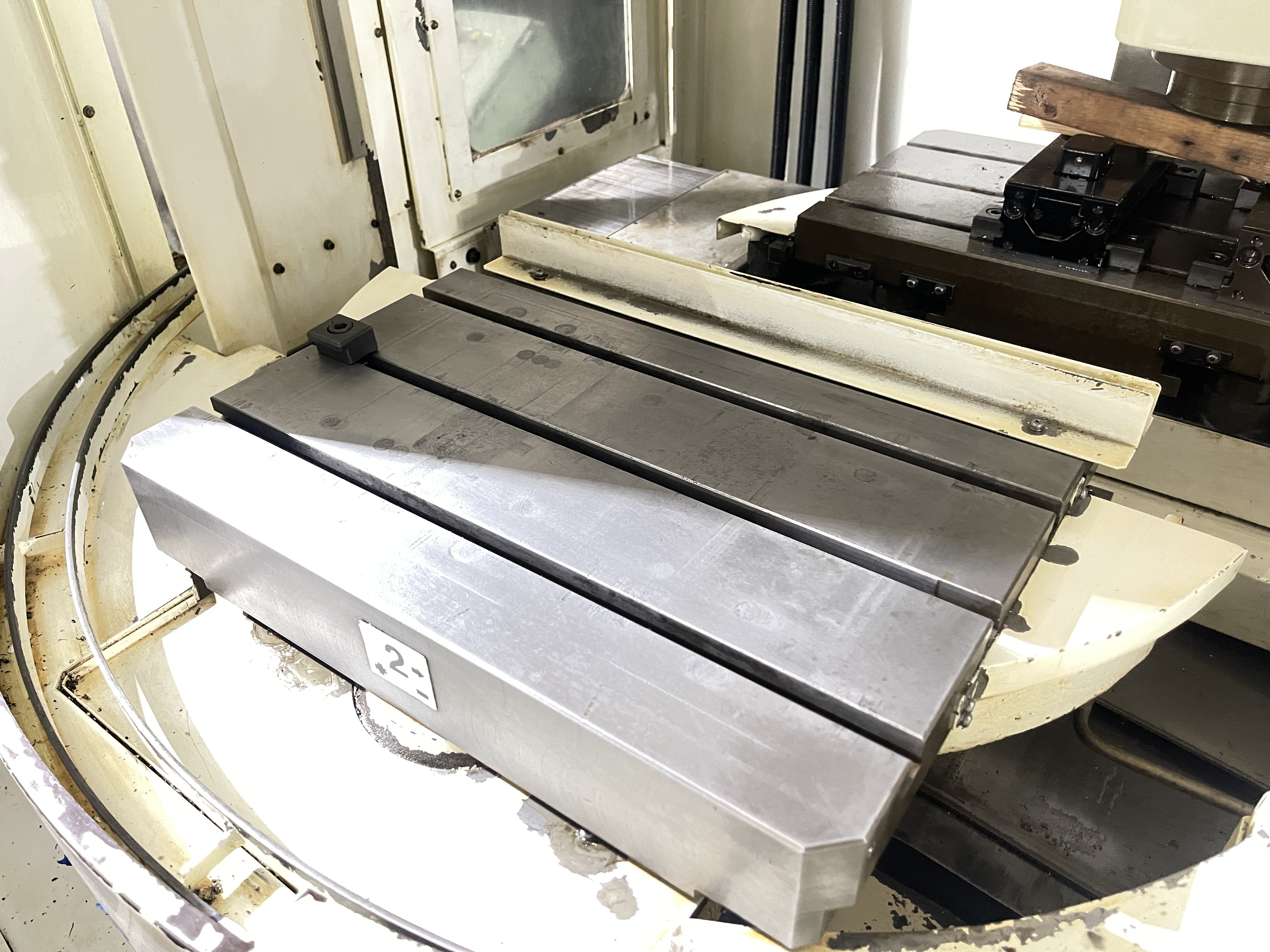

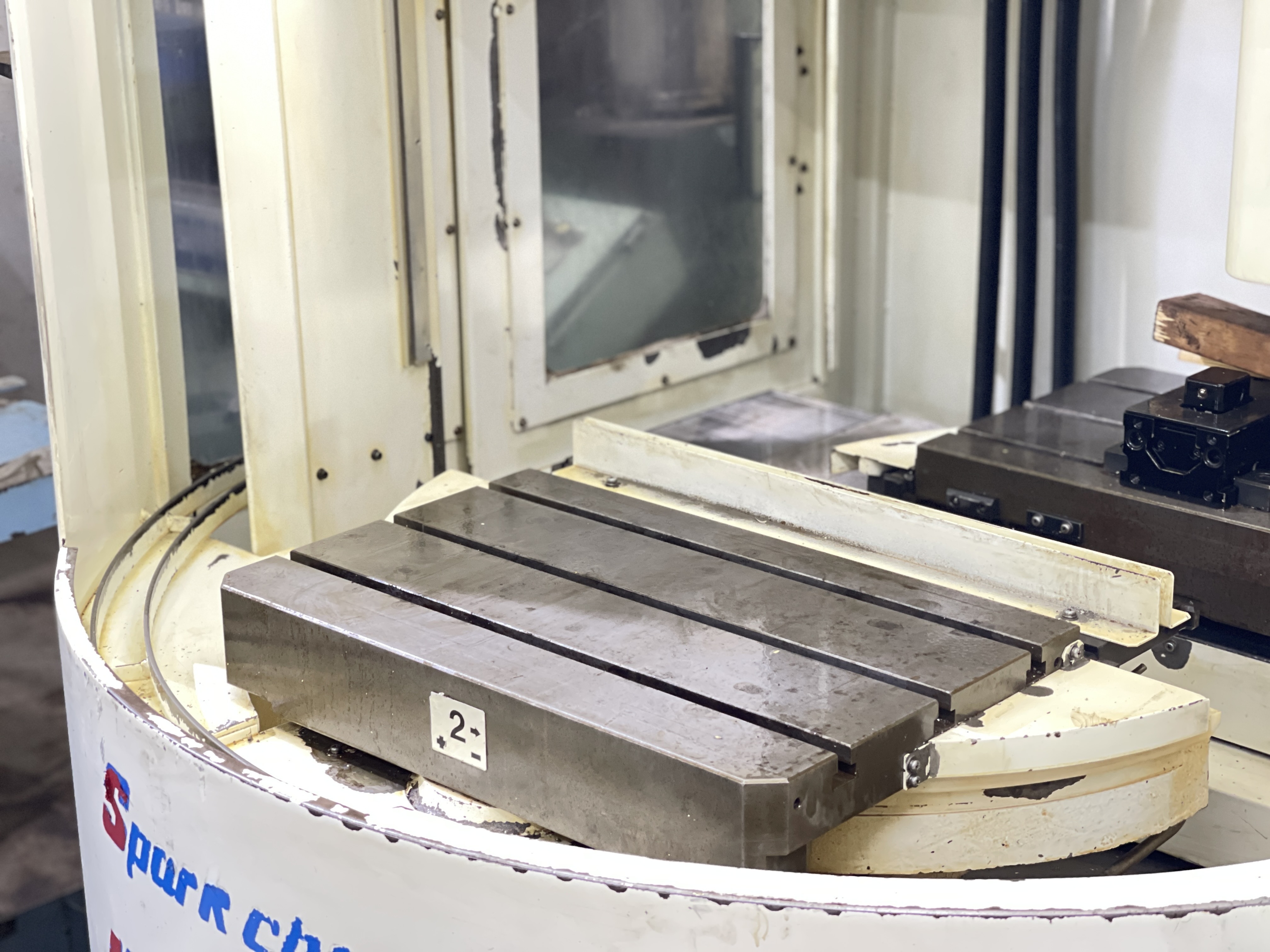

- Pallet Size

- 700 mm x 420 mm

- Chip Conveyor

- Optional

- Number of Pallets

- 2

- Y-Axis Travel

- 410 mm

- Max Tool Weight

- 6 kg

- Coolant System

- Standard Flood Coolant

- Pallet Changer

- Automatic Twin Pallet Changer

- Interface

- RS232C / Ethernet

- Rapid Traverse Rate

- X/Y/Z: 48 m/min

- Air Requirement

- 0.5 MPa (5 kg/cm²)

- Controller Type

- CNC (Fanuc or Mitsubishi)

- Max Tool Length

- 300 mm

- Tool Magazine Capacity

- 24 Tools (ATC)

- X-Axis Travel

- 610 mm

About Kitamura Mycenter 2xi Twin Pallet Vmc

*KITAMURA MYCENTER 2Xi TWIN PALLET VMC*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 510 x 355 x 460 mm

Reference No: 1489

Technical Specifications:

WORKING CAPACITY

Table Size: 560 x 355 mm

Travels (XYZ): 510 x 355 x 460 mm

Spindle Nose to Table (Min.- Max.): 2.3 20.6

CNC

Control: Fanuc 16iM

SPINDLE

Spindle Taper: BT40

Spindle Speeds: 15000 RPM

Spindle Motor: 15 HP

ATC

Tool Change Capacity: 24 Tools

ATC Type: ARM

Aprox. Dimensions

Weight: 6 T

Overall Dimensions: 110 x 90 x 110 High

Spark Changer Pallet System

Enhanced Productivity with Twin Pallet Design

The twin pallet configuration allows operators to set up workpieces on one pallet while the other is in use, significantly minimizing downtime and increasing throughput. This feature is ideal for batch manufacturing and high-volume jobs, streamlining workflow in demanding industrial settings.

Superior Precision and Reliability

Delivering positioning accuracy of 0.002 mm and repeatability of 0.001 mm, the Kitamura Mycenter ensures exceptional surface finish and tight tolerance achievement. The robust cast iron construction and high-speed capabilities provide consistent results, even on complex projects.

FAQ's of Kitamura Mycenter 2xi Twin Pallet Vmc:

Q: How does the twin pallet system improve operation efficiency on the Kitamura Mycenter 2xi VMC?

A: The twin pallet system enables setting up a second workpiece while the first pallet is machining. This reduces idle time between jobs, leading to faster turnaround and higher production output, making it highly beneficial for continuous, large-scale industrial operations.Q: What types of materials can be machined on this VMC?

A: This vertical machining center is engineered to handle a variety of industrial alloys, including cast iron, steel, and aluminum. Thanks to its rigid build and robust spindle, it delivers precise results across these common metalworking materials.Q: When should the chip conveyor be considered for installation?

A: The optional chip conveyor is recommended if your operations involve prolonged machining or generate substantial metal debris. Integrating a chip conveyor enhances cleanliness and ensures smooth operation, especially during heavy-duty cutting tasks.Q: Where can the Kitamura Mycenter 2xi VMC be used?

A: This machine is suited for industrial environments such as manufacturing plants, metalworking shops, and CNC job shops. It is widely adopted in India by exporters, importers, suppliers, and traders seeking advanced machining solutions.Q: What are the benefits of the automatic centralized lubrication system?

A: The automatic centralized lubrication system ensures consistent application of lubricant to all essential components, reducing maintenance requirements and extending machine life. This contributes to sustained accuracy and reliability over enduring production runs.Q: How does the controller type affect user experience?

A: Equipped with CNC controllers like Fanuc Series 0i-M or Mitsubishi, the Mycenter 2xi provides intuitive interface options and reliable programming performance. These controllers offer precision control, easy integration with existing networks (RS232C/Ethernet), and enhanced process automation.Q: What usage capacity does each pallet provide?

A: Each pallet on the Kitamura Mycenter 2xi VMC supports workpieces up to 200 kg, accommodating a wide range of industrial component sizes and ensuring flexibility for diverse machining requirements.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Mori Seiki Cv-500 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Standard Factory Grey

Table Size : 800 mm x 410 mm

Bar Feeder : No

General Use : CNC Machining, Manufacturing, Production

Matchmaker 1020 Vmc 8

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Grey & Blue

Table Size : 1200 x 500 mm

Bar Feeder : No

General Use : Metal Cutting and Milling

Hitachi Seiki Vs50 Vmc 1

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Grey

Table Size : 900 mm x 410 mm

Bar Feeder : No

General Use : Metalworking / Milling / Industrial Machining

Fadal 6030 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, White & Blue

Table Size : 63 x 30 (1600 mm x 762 mm)

Bar Feeder : No

General Use : Industrial metal milling, highprecision machining

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |