|

Hydrafeed Multifeed Ml1 Barfeed (1)

Hydrafeed Multifeed Ml1 Barfeed (1) Specification

- Product Type

- Hydrafeed Multifeed ML1 Barfeed

- General Use

- CNC Lathe Automation

- Material

- Steel / Aluminium construction

- Type

- Automatic Bar Feeder

- Capacity

- Bar Diameter 5mm - 65mm

- Weight (kg)

- 420 kg

- Computerized

- Yes

- Automatic

- Yes

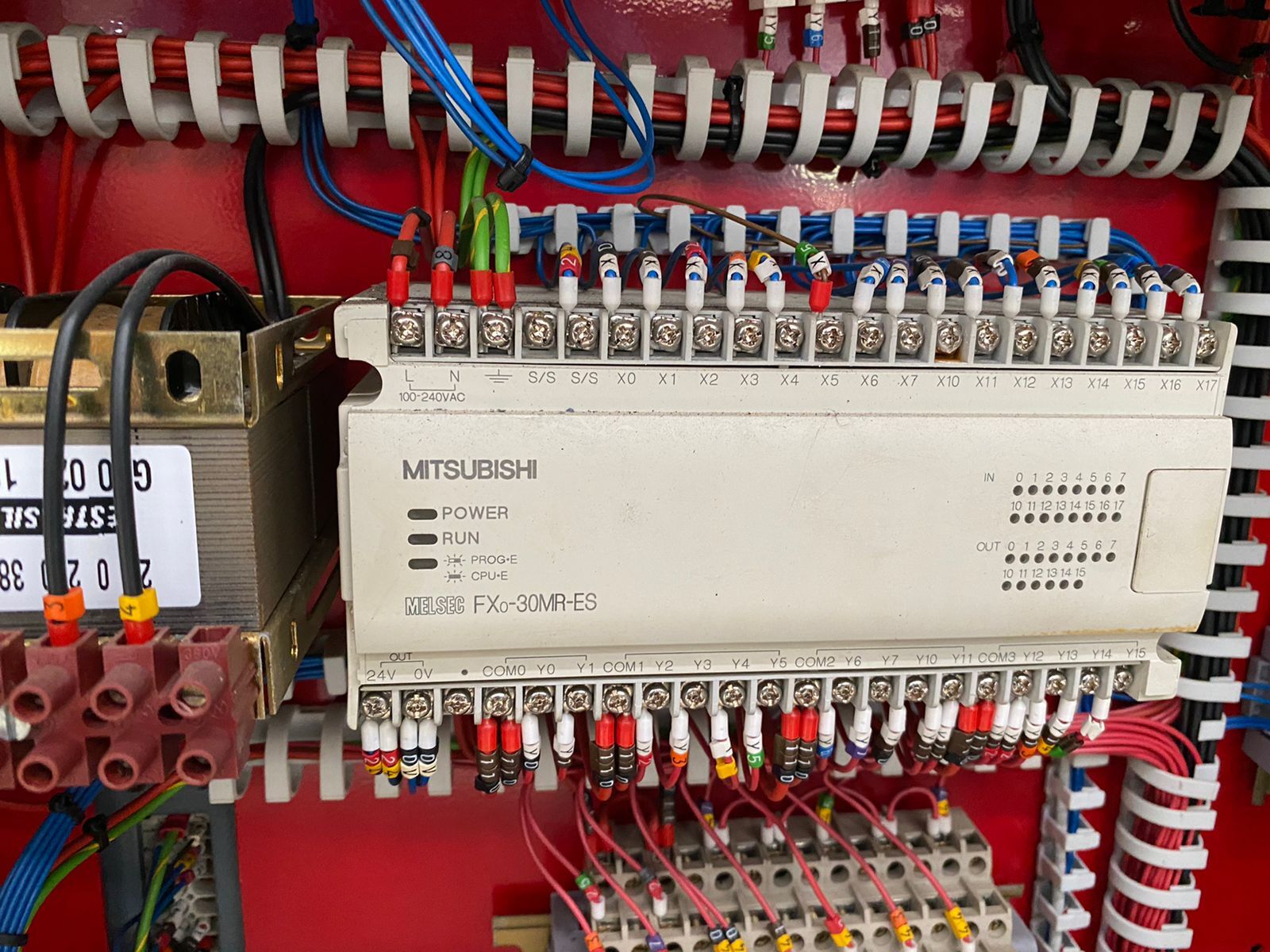

- PLC Control

- Yes

- Bar Feeder

- Yes

- Power Source

- Electric

- Power Consumption

- 1.5 kW

- Rigidity

- High

- Voltage

- 230V / 400V

- Motor

- Precision Servo Motor

- Spindle Speed

- Up to 6000 RPM

- Axial Choice

- Single Axis

- Dimension (L*W*H)

- 2950 x 610 x 1100 mm

- Feature

- Automatic Bar Loading, Adjustable Bar Size

- Color

- Grey & Orange

- Safety

- Integrated Safety Cover and Emergency Stop

- Feed Accuracy

- ±0.05 mm

- Magazine Type

- Bundle or Single Bar

- Loading Length

- Up to 1500 mm

- Bar Change Over Time

- Fast Changeover (< 2 mins)

- Noise Level

- Low

- Installation

- Floor Mounted

- Compatibility

- Suitable for all CNC Turning Centers

- Control Interface

- User-friendly Touchscreen

- Lubrication

- Automatic Centralized Lubrication System

About Hydrafeed Multifeed Ml1 Barfeed (1)

*HYDRAFEED MULTIFEED ML1 BARFEED (1)*

CATEGORY : MISCELLANEOUS

CAPACITY : 3 - 80 mm

Reference No: 2875

Technical Specifications:

Manufacturer

Hydrafeed

Model

Multifeed ML 1

Bar diameter range

3mm 80mm

Bar length capacity

1580mm

Dimensions(lxdxh)

2100mm x 1000mm x 1300mm

Dimensions (L x W x H)

2100mm x 1000mm x 1300mm

Weight(approx)

200 kg

Model

Multifeed ML 1

Seamless Integration and Versatility

The Multifeed ML1 is engineered to fit a wide range of CNC turning centers, supporting both bundle and single bar magazines. Its adjustable bar size feature, electric-powered servo motor, and single axis design offer adaptability to numerous production requirements. With floor-mounted installation and a footprint of 2950 x 610 x 1100 mm, it enhances automation without consuming excessive shop floor space.

Advanced Control and Safety Features

Operators benefit from a user-friendly touchscreen control interface and PLC control, making operation both intuitive and reliable. The ML1 features integrated safety covers and an emergency stop, minimizing risk and promoting safe workplace conditions. The centralized automatic lubrication system ensures consistent performance and reduces maintenance efforts.

Productivity and Efficiency Unmatched

The fast changeover ability (less than 2 minutes) and feed accuracy of 0.05 mm optimize uptime and minimize waste. With a spindle speed compatibility of up to 6000 RPM, high rigidity, and low noise operation, the Hydrafeed Multifeed ML1 is tailored for high-throughput CNC lathe environments where consistent quality and speed matter the most.

FAQ's of Hydrafeed Multifeed Ml1 Barfeed (1):

Q: How does the Hydrafeed Multifeed ML1 barfeed improve CNC lathe automation?

A: The Multifeed ML1 enhances CNC lathe automation by offering automatic bar loading, quick changeovers under two minutes, and a high feed accuracy of 0.05 mm. Its user-friendly touchscreen and PLC control simplify operation, boosting productivity and reducing manual intervention.Q: What range of bar diameters and lengths can the ML1 accommodate?

A: The ML1 can handle bar diameters from 5 mm to 65 mm and supports loading lengths up to 1500 mm, making it suitable for a variety of machining applications.Q: When should I use the automatic bar feeder function?

A: Use the automatic bar feeder function whenever continuous, unattended production is desired. This feature ensures consistent material supply to your CNC lathe, reducing downtime and maximizing throughput during both short and long production runs.Q: Where is the ML1 barfeed typically installed, and what are its dimensional requirements?

A: The Hydrafeed Multifeed ML1 is floor-mounted and requires a space of 2950 mm in length, 610 mm in width, and 1100 mm in height, making it compatible with most CNC turning center shop floors.Q: What safety and reliability features are included in the ML1?

A: The ML1 features an integrated safety cover and emergency stop for operator protection, along with automatic centralized lubrication and a robust steel/aluminium build, ensuring both safe and reliable long-term operation.Q: How does the bar changeover process work, and how quickly can it be done?

A: The bar changeover process on the ML1 is designed for minimal disruption, allowing you to swap bar sizes or types in under two minutes. This is achieved through an intuitive touchscreen interface and user-oriented mechanical design.Q: What are the main benefits of using the Multifeed ML1 for CNC lathe automation?

A: Key benefits include high rigidity for precision, quick and easy operation, reduced operator intervention, enhanced workplace safety, low noise performance, and compatibility with a wide range of CNC lathes, resulting in improved productivity and output quality.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Category

Boston Matthew Model Bm22 Injection Moulding Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Plastic Product Manufacturing

Material : Other, Mild Steel

Product Type : Injection Moulding Machine

Axial Choice : Single Axis

Midsaw Vertical Saw

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Cutting Metal Sheets and Rods

Material : Other, Mild Steel

Product Type : Vertical Saw

Axial Choice : Vertical Axis

Iemca Vip 80 Barfeed

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Automatic feeding of bars to machine tools

Material : Other, Steel and Alloy

Product Type : Bar Feeder

Axial Choice : Single Axis

Baty Sm2oe Shadow Master Shadow Graph

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

General Use : Inspection and Measurement of Small Components

Material : Other, Cast Iron & Steel

Product Type : Shadow Graph / Profile Projector

Axial Choice : X, Y Vernier Scales

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |