|

Daewoo Doosan Puma 250b Cnc Lathe 2

Daewoo Doosan Puma 250b Cnc Lathe 2 Specification

- Product Type

- CNC Lathe

- General Use

- Metal Turning, Industrial Machining

- Material

- Cast Iron Body

- Type

- Horizontal Lathe

- Capacity

- Max Turning Diameter 350 mm, Max Turning Length 530 mm

- Weight (kg)

- 4300 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- Available

- Power Source

- Electric

- Power Consumption

- 15 kVA

- Rigidity

- High

- Voltage

- 220/380V, 3 Phase

- Motor

- Main Spindle Motor 15 HP

- Table Size

- Standard Chuck Size 10 inch

- Spindle Speed

- 3500 RPM

- Axial Choice

- 2 Axis (X, Z)

- Dimension (L*W*H)

- 2850 mm 1670 mm 1700 mm

- Feature

- High Precision, Heavy Duty

- Color

- Standard Industrial Grey/White

- Tool Turret

- 12 Stations

- Rapid Traverse Rate (X/Z)

- 20/24 m/min

- Repeatability

- ±0.003 mm

- Tailstock

- Programmable Hydraulic

- Chuck Type

- Hydraulic Power Chuck

- Controller Type

- Fanuc 21i-T

- Slant Bed Angle

- 45°

- Noise Level

- Low Noise Operation

- Coolant System

- Full Enclosure with Integrated Coolant

- Distance Between Centers

- 560 mm

- Spindle Bore

- 76 mm

- Lubrication System

- Automatic

- Swing Over Bed

- 520 mm

About Daewoo Doosan Puma 250b Cnc Lathe 2

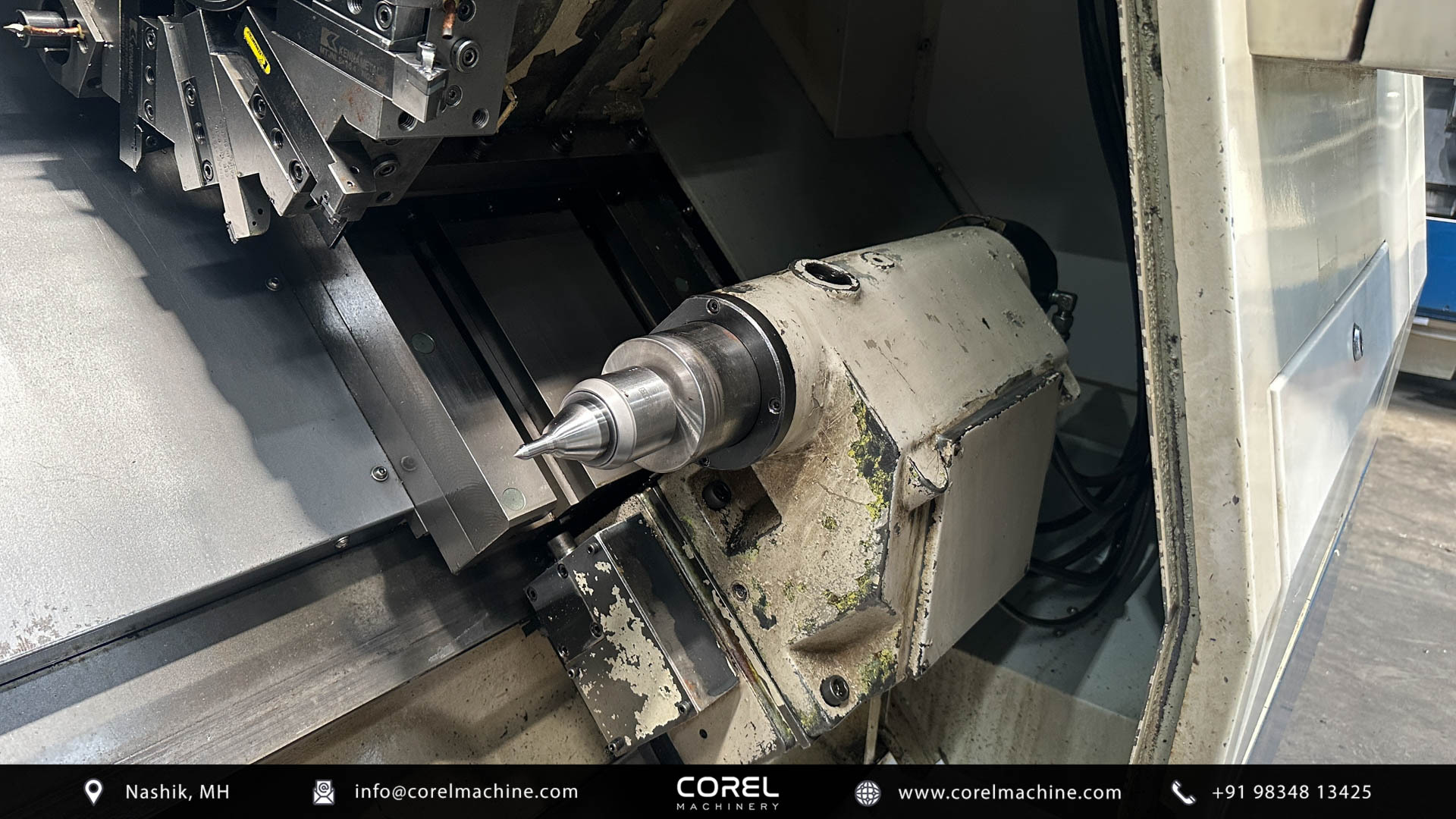

*DAEWOO DOOSAN PUMA 250B CNC LATHE 2*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 400 x 650 mm

YEAR OF CONSTRUCTION : 1998

Reference No: 5280

Video Link: https://youtu.be/wqRhfhOwOOE

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 400 mm

Max Turning Length: 650 mm

Swing: 570 mm

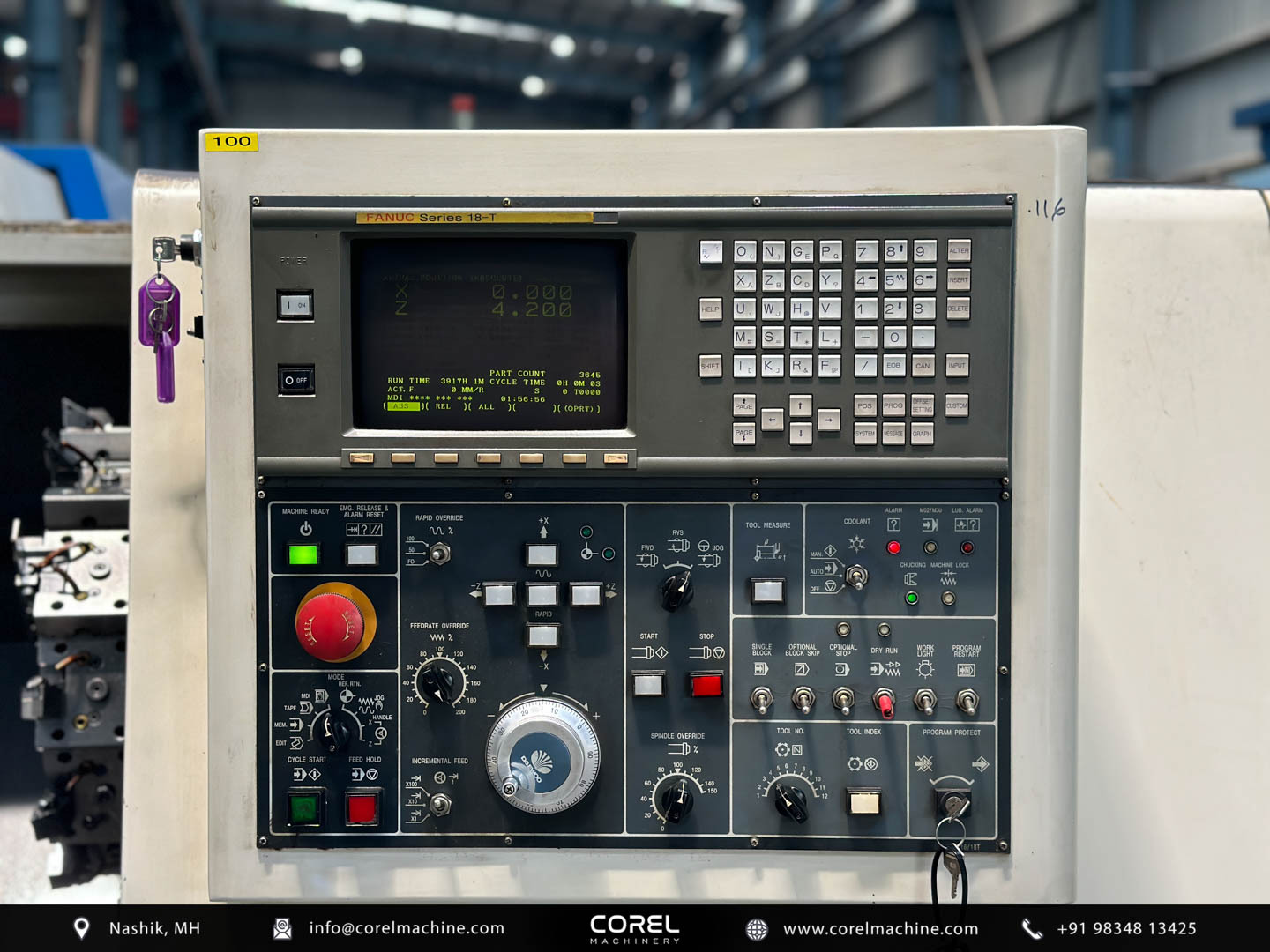

CNC

Control: Fanuc 18T (Alpha Drives)

SPINDLE

Spindle Nose: A2-8

Spindle Speeds: 35 - 3500 RPM

Spindle Bore: 90 mm

TURRET

Turret: 12 Stations

TAILSTOCK

Tailstock Taper: #5 MT

Quill Travel: 100 mm

Programmable Tailstock, Automatic Tool Setter, Parts Catcher, Chip Conveyor

Precision Engineering for Consistent Results

The Daewoo Doosan Puma 250b guarantees high repeatability and accuracy with professional-grade control and robust construction. Its 45 slant bed and cast iron body ensure stable operation and superior rigidity for demanding machining processes.

Advanced Automation and User-Friendly Operation

With its Fanuc 21i-T controller and automatic systems for lubrication and tailstock management, the Puma 250b simplifies complex tasks while improving productivity. The CNC programming and PLC control features enhance flexibility and ease of use for operators.

Enhanced Safety and Efficiency

This lathe includes a fully enclosed coolant system to manage heat and debris, minimizing risks and maintaining optimal performance. The low noise level and reliable hydraulic power chuck contribute to a safe and comfortable workplace environment.

FAQ's of Daewoo Doosan Puma 250b Cnc Lathe 2:

Q: How does the integrated coolant system benefit the machining process?

A: The full enclosure with integrated coolant in the Puma 250b efficiently removes heat and chips during operation, which protects both the tool and workpiece. This leads to enhanced machining accuracy and longer tool life.Q: What materials and tasks is the Daewoo Doosan Puma 250b best suited for?

A: This CNC lathe, constructed with a cast iron body, is ideal for high-precision metal turning, including steel, aluminum, and other industrial metals. It is designed for tasks requiring high rigidity and heavy-duty endurance.Q: When is the automatic lubrication system activated on this lathe?

A: The automatic lubrication system operates routinely during machine cycles to ensure critical moving parts are continuously protected, reducing maintenance intervals and preventing premature wear.Q: Where is this machine manufactured and available for export or import?

A: The Daewoo Doosan Puma 250b is made for industrial use and is available through exporters, importers, suppliers, and traders in India as well as globally, supported by manufacturer networks.Q: What is the process for setting up the programmable hydraulic tailstock?

A: Setup involves using the Fanuc 21i-T controller to position and secure the tailstock as needed for varying workpiece lengths, optimizing support and stability during machining cycles.Q: How can the PLC control feature be utilized for customized operations?

A: The PLC control enables users to automate specific sequences, adapt machining parameters, and integrate bar feeders for unattended operation, resulting in consistent output and time savings.Q: What are the main benefits of the Puma 250b's high rigidity and low noise design?

A: High rigidity ensures vibration-free, precise turning even at maximum speeds, while the low noise operation improves working conditions, supporting longer production runs with minimal workplace disturbance.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Nakamura Tome Tw-30 6 Axis CNC Turn Mill Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Bar Diameter: Max 65 mm

Spindle Speed : 4000 rpm (Maximum)

Type : Other, Horizontal CNC Lathe

PLC Control : Yes

Takamaz Ex-20 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Max Turning Diameter: 200 mm; Max Turning Length: 260 mm

Spindle Speed : Max. 4,500 rpm

Type : Other, Horizontal CNC Turning Center

PLC Control : Other, Available

Hardinge C42 Cnc Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Maximum turning diameter 420 mm

Spindle Speed : 5000 rpm (max)

Type : Other, Industrial CNC Lathe

PLC Control : Other, Available

Colchester Combi K4 Slant Bed Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Swing over bed: 400 mm, Turning length: 650 mm

Spindle Speed : 3500 rpm (max)

Type : Other, CNC Lathe

PLC Control : Yes

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |