|

Mori Seiki Cv-500 Twin Pallet Vmc

Mori Seiki Cv-500 Twin Pallet Vmc Specification

- Product Type

- Vertical Machining Center (VMC)

- General Use

- CNC Machining, Manufacturing, Production

- Material

- Cast Iron Base, Hardened Steel Components

- Type

- Twin Pallet VMC

- Capacity

- Maximum Loading 350 kg per pallet

- Weight (kg)

- 7500 kg (approx)

- Computerized

- Yes

- Automatic

- Fully Automatic

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 15 kW

- Rigidity

- High

- Voltage

- 220 V / 3 Phase

- Motor

- AC Spindle Motor

- Table Size

- 800 mm x 410 mm

- Spindle Speed

- 50 8,000 RPM

- Axial Choice

- X, Y, Z

- Dimension (L*W*H)

- 2200 mm x 2500 mm x 2700 mm

- Feature

- Twin Pallet Change System, Rigid Construction, High Precision

- Color

- Standard Factory Grey

- Coolant System

- Yes, standard

- Repeatability

- ±0.003 mm

- Pallet Size

- 500 mm x 400 mm

- Positioning Accuracy

- ±0.005 mm

- Spindle Taper

- BT40

- Tool Change Time

- 2.5 seconds

- Number of Pallets

- 2

- Max Workpiece Diameter

- 600 mm

- Tool Magazine Capacity

- 24 Tools

- Lubrication System

- Automatic

- Floor Space Required

- Minimum 5 m x 3 m

- Control System

- Fanuc CNC (standard)

- Travel (X/Y/Z)

- 710 mm / 410 mm / 510 mm

- Air Requirement

- 5-7 kg/cm²

About Mori Seiki Cv-500 Twin Pallet Vmc

*MORI SEIKI CV-500 TWIN PALLET VMC*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 510 x 510 x 510 mm

YEAR OF CONSTRUCTION : 1997

Reference No: 1809

Technical Specifications:

WORKING CAPACITY

Table Size: 750 x 550 mm

Travels (XYZ): 510 x 510 x 510 mm

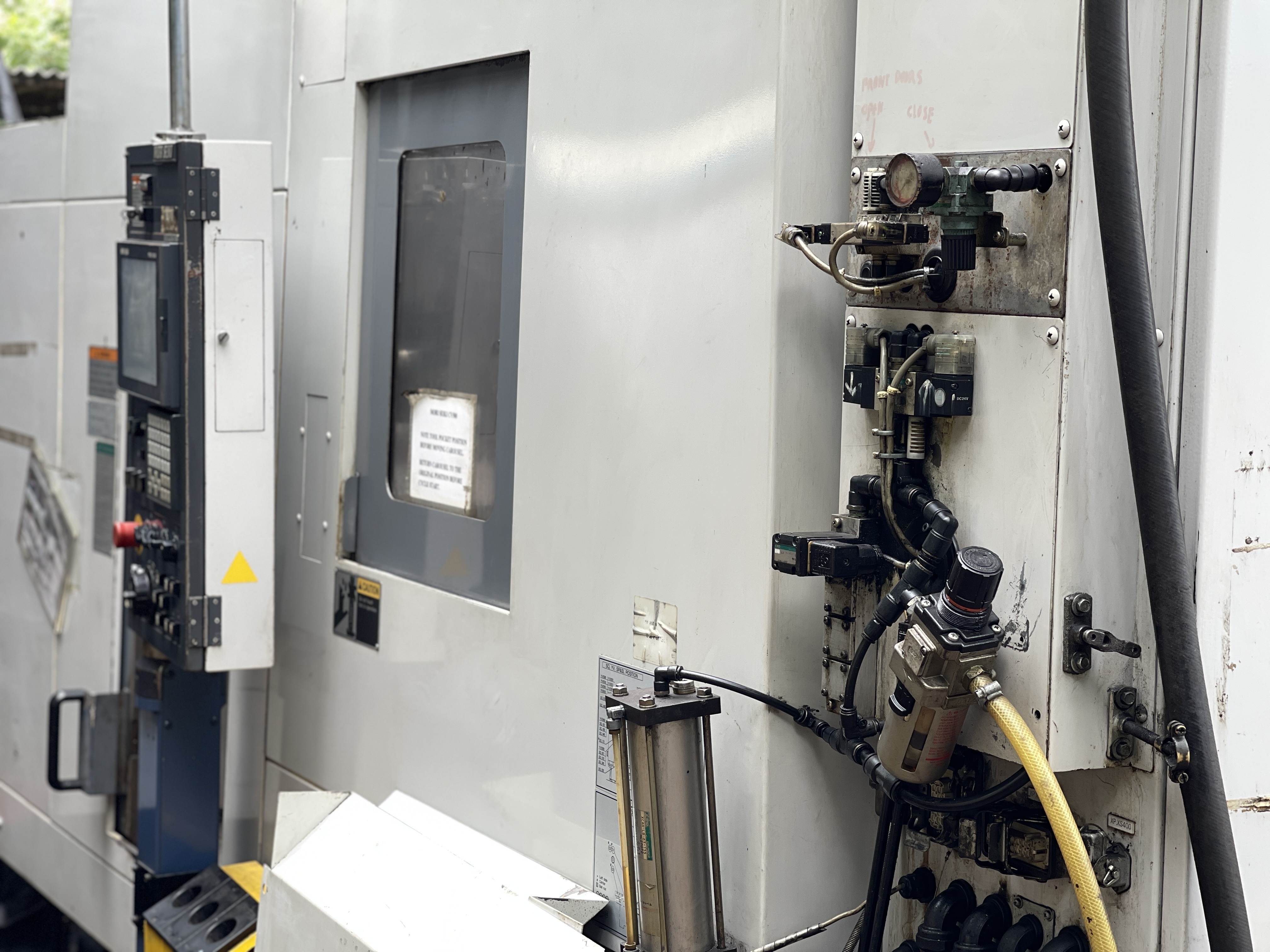

CNC

Control: Mitsubishi

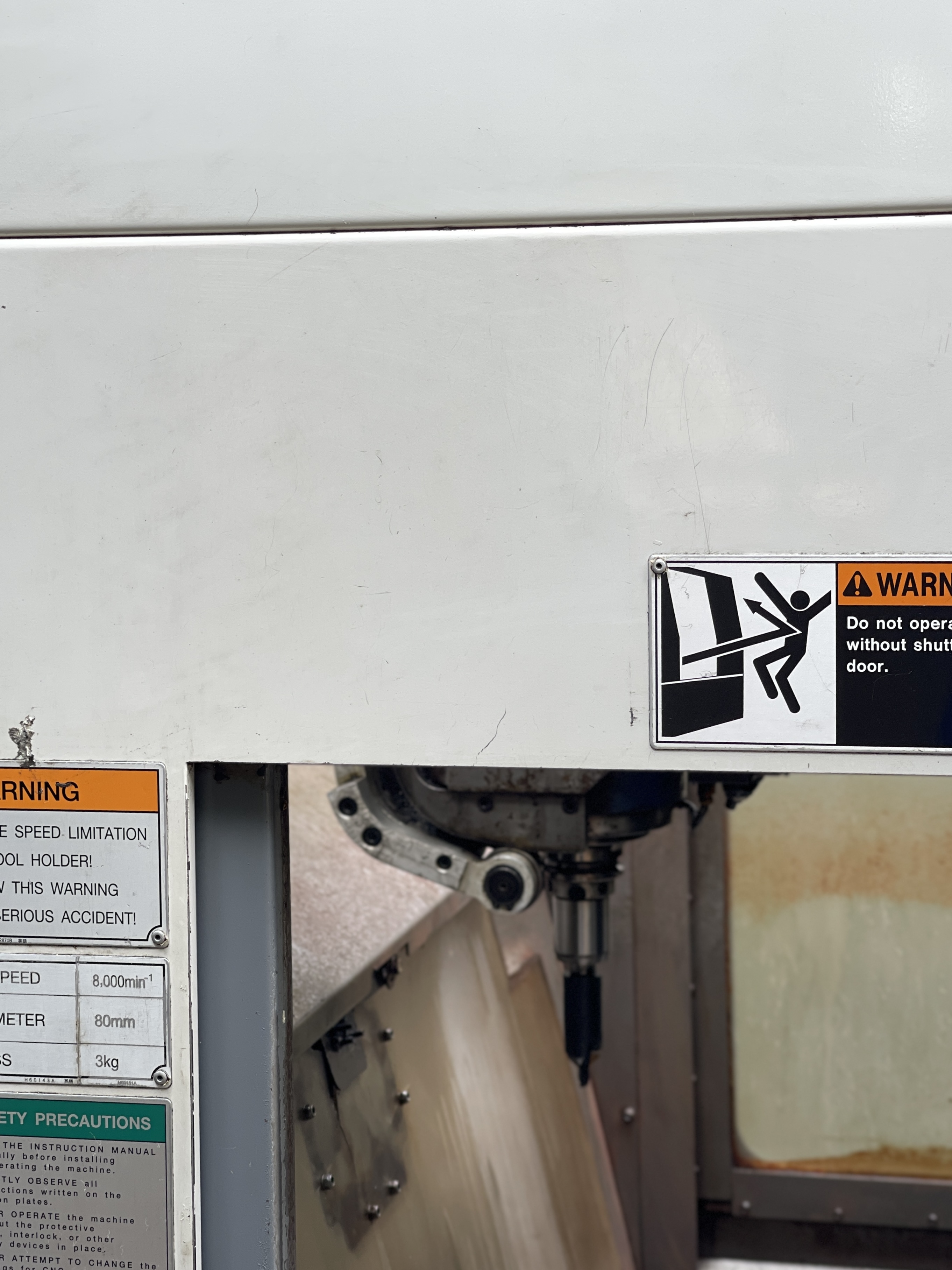

SPINDLE

Spindle Taper: BT40

Spindle Speed: 8000 RPM

Spindle Motor: 7.5 kW

ATC

Tool Change Capacity: 24 Tools

Dimensions

Aprox. Weight: 4.5 T

L x W x H: L 2000 x W 3600 x H 2750 mm

Advanced Twin Pallet System

With two 500 mm x 400 mm pallets, the CV-500 enables continuous operation by allowing parts to be loaded and unloaded while machining proceeds. This seamless pallet exchange significantly reduces downtime, making it ideal for high-volume manufacturing. Operators benefit from increased workflow efficiency and improved production scheduling, ensuring tight deadlines are met with consistent reliability.

Precision Engineering for Superior Results

Engineered with high rigidity and built on a cast iron base, the CV-500 delivers exceptional accuracy-repeatability of 0.003 mm and positioning to 0.005 mm. Its BT40 spindle, robust AC motor, and hardened steel components work together to provide stable operation even under demanding loads. Such precision ensures consistently high-quality machining for complex components across diverse industries.

User-Friendly CNC Integration

Standardized with the Fanuc CNC system and PLC control, the Mori Seiki CV-500 guarantees straightforward operation, programmability, and efficient process management. The intuitive interface simplifies setup, tool changes, and pallet operation, making it suitable for both experienced operators and those new to CNC machining. Automation features and advanced controls enhance productivity while reducing operator fatigue.

FAQ's of Mori Seiki Cv-500 Twin Pallet Vmc:

Q: How does the twin pallet change system improve productivity on the Mori Seiki CV-500 VMC?

A: The twin pallet change system allows one pallet to be loaded or unloaded while the other is being machined. This parallel workflow minimizes idle time, ensuring continuous operation and higher throughput in manufacturing processes.Q: What is the maximum workpiece size and weight that each pallet can handle?

A: Each pallet on the CV-500 supports a workpiece diameter up to 600 mm and can handle loads of up to 350 kg, making it suitable for a variety of mid- to large-sized machining applications.Q: When should the coolant and automatic lubrication systems be serviced?

A: Preventive maintenance is recommended at regular intervals based on operational hours and usage intensity. Refer to the maintenance schedule in the user manual, but typically, coolant and lubrication systems should be checked weekly to ensure consistent machine performance.Q: Where is the ideal installation location for the Mori Seiki CV-500?

A: The machine requires a minimum floor space of 5 m x 3 m, with adequate access to electric power (220V/3 phase) and compressed air (5-7 kg/cm2). It's best installed in a clean, temperature-controlled workshop environment for optimal performance.Q: What benefits does the high positioning accuracy provide?

A: With a positioning accuracy of 0.005 mm and repeatability of 0.003 mm, the CV-500 ensures precision in every operation. This accuracy is crucial for industries requiring tight tolerances, improving product quality and reducing reject rates.Q: How are tools changed and how long does it take?

A: Tool changes are fully automatic and controlled via the Fanuc CNC system. The 24-tool magazine enables rapid swaps, with an average tool change time of just 2.5 seconds, minimizing production delays and boosting efficiency.Q: What materials are suitable for machining with the CV-500?

A: The rigid construction, powerful spindle (50-8,000 RPM), and precise controls allow the CV-500 to machine a wide variety of materials, including steels, aluminum, cast iron, and hardened metals, making it highly versatile for different manufacturing demands.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Xyz Krv 2000 Cnc M1tr Turret Milling Machine

Minimum Order Quantity : 1 Number

Weight (kg) : 1100 kg

Spindle Speed : 70 3600 RPM (Variable)

Product Type : CNC M1TR Turret Milling Machine

Axial Choice : X, Y, Z axes

Richmond Cnc Radial Drill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Weight (kg) : 3100 kg

Spindle Speed : 40 2000 RPM (variable)

Product Type : CNC Radial Drill

Axial Choice : X, Y, Z Axes programmable

Hitachi Seiki Vs60 Twin Pallet Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Weight (kg) : 7000 kg

Spindle Speed : 10000 RPM

Product Type : Vertical Machining Center (VMC)

Axial Choice : X, Y, Z

Daewoo Doosan Dmv 4020/50 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Weight (kg) : 6500 kg

Spindle Speed : 8000 RPM

Product Type : Vertical Machining Center (VMC)

Axial Choice : 3 Axis (X, Y, Z)

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |