|

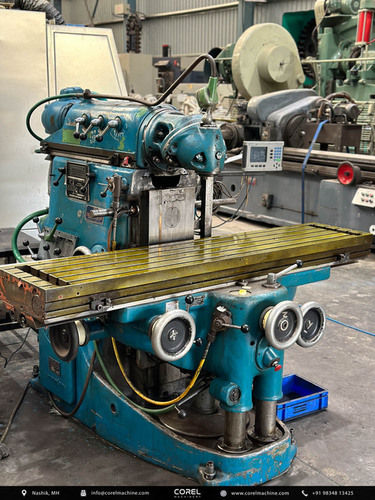

Parkson 2N Universal Milling

Parkson 2N Universal Milling Specification

- Product Type

- Universal Milling Machine

- General Use

- Metal cutting, shaping, and fabrication

- Material

- Cast Iron Body with Hardened & Ground Slides

- Type

- Horizontal & Vertical Universal

- Capacity

- Heavy Duty

- Weight (kg)

- Approx 2000 kg

- Computerized

- No

- Automatic

- Manual Operation

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 5 HP

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 5 HP Electric Motor

- Table Size

- 54 x 12 (1370 mm x 305 mm)

- Spindle Speed

- 35 to 1500 RPM (16 step)

- Axial Choice

- 3 Axis

- Dimension (L*W*H)

- 2200 mm x 1700 mm x 1600 mm (Approx)

- Feature

- Universal Swivel Table, Horizontal/Vertical Milling

- Color

- Green/Blue

- Lubrication

- Centralized lubrication system

- Overarm Length

- 900 mm

- Number of Feeds

- 12

- Table Longitudinal Travel

- 900 mm

- Accessories Included

- Standard tools, horizontal arbor, vertical head attachment, drawbars

- Gears

- Alloy steel, heat treated & precision ground

- Spindle Taper

- ISO 50

- Coolant Pump

- Provided

- Table Cross Travel

- 250 mm

- Swivel Angle Table

- 45° each side

- Construction

- Heavy cast iron with ribbed reinforcement

- Table Vertical Travel

- 400 mm

About Parkson 2N Universal Milling

*PARKSON 2N UNIVERSAL MILLING*

CATEGORY : MILLING MACHINES

CAPACITY : 700 x 250 x 450 mm

Reference No: 3627

Video Link: https://youtu.be/OkR7Km-gokw

Technical Specifications:

WORKING CAPACITY

Table Size: 1300 x 300 mm

Travels: 700 x 250 x 450 mm

Spindle Taper: ISO 50

Spindle Speed Max: 775

DRO on all axis

Feeds & Rapid Travels on all axis

Universal Milling Capabilities

Parkson 2N offers horizontal and vertical milling in a single unit, accommodating a broad range of metalworking needs from cutting to shaping and fabrication. The universal swivel table further enhances flexibility, supporting machining at various angles for increased operational versatility.

Precision and Stability

Constructed from heavy-duty cast iron with ribbed reinforcement, the Parkson 2N ensures long-term rigidity and stability. Alloy steel, heat-treated and ground gears, along with hardened and ground slides, support accurate and smooth machining for high-quality results.

Efficient Operation and Accessories

Designed for user convenience, this milling machine includes centralized lubrication, a coolant pump, and standard tools, plus horizontal arbor, vertical head attachment, and drawbars. Twelve feeds support a range of machining speeds and materials, ensuring consistent performance and productivity.

FAQ's of Parkson 2N Universal Milling:

Q: How does the universal swivel table on the Parkson 2N enhance machining operations?

A: The universal swivel table allows adjustment up to 45 on either side, facilitating precise angle machining and enabling both horizontal and vertical milling tasks, increasing the versatility and efficiency for complex cutting and shaping jobs.Q: What types of materials can be processed with the Parkson 2N Universal Milling Machine?

A: Primarily designed for metal, the machine efficiently handles various metals for cutting, shaping, and fabrication through its robust construction and adaptable spindle speed range, making it suitable for heavy-duty metalworking applications.Q: When should operators use the vertical head attachment included with the milling machine?

A: The vertical head attachment is beneficial when vertical milling operations or intricate shaping are required, especially for jobs that cannot be accomplished solely with horizontal milling orientation.Q: Where is the Parkson 2N most commonly utilized?

A: This milling machine is widely used in metalworking shops, fabrication facilities, and industrial manufacturing environments across India, where heavy-duty metal processing and precision are necessary.Q: What is the process for switching between horizontal and vertical milling on this model?

A: Switching between horizontal and vertical milling is achieved by installing or removing the corresponding attachments, such as the horizontal arbor and vertical head, allowing seamless transition between operation modes to match job requirements.Q: How does the centralized lubrication system contribute to the machine's performance?

A: The centralized lubrication system ensures all critical moving parts receive consistent lubrication, reducing wear and tear, enhancing operational smoothness, and extending the machine's service life.Q: What are the main benefits of choosing the Parkson 2N Universal Milling Machine?

A: Key advantages include heavy-duty capacity, high rigidity, flexible universal milling functions, efficient cooling and lubrication, and a comprehensive set of accessories, all contributing to precision, reliability, and productive machining for diverse metalworking needs.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Huron Ku6 Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Feature : Other, Heavy Duty Construction, High Precision, Versatile Application

Table Size : 2000 x 500 mm

Power Source : Electric

Computerized : No

Butler 21 Production Slotter With 45 Rotary Table

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Feature : Other, Precision slotting, 45degree automatic rotary table, robust

Table Size : 450 mm diameter

Power Source : Electric

Computerized : No

Bridgeport 1es Horizontal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Feature : Other, Robust construction, easy operation, suitable for heavyduty work

Table Size : 750 mm x 250 mm

Power Source : Electric

Computerized : No

Correa Fu10 Cm125 Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Feature : Other, Heavy Duty, Precision, Robust Structure

Table Size : 1250 x 320 mm

Power Source : Electric

Computerized : No

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |