|

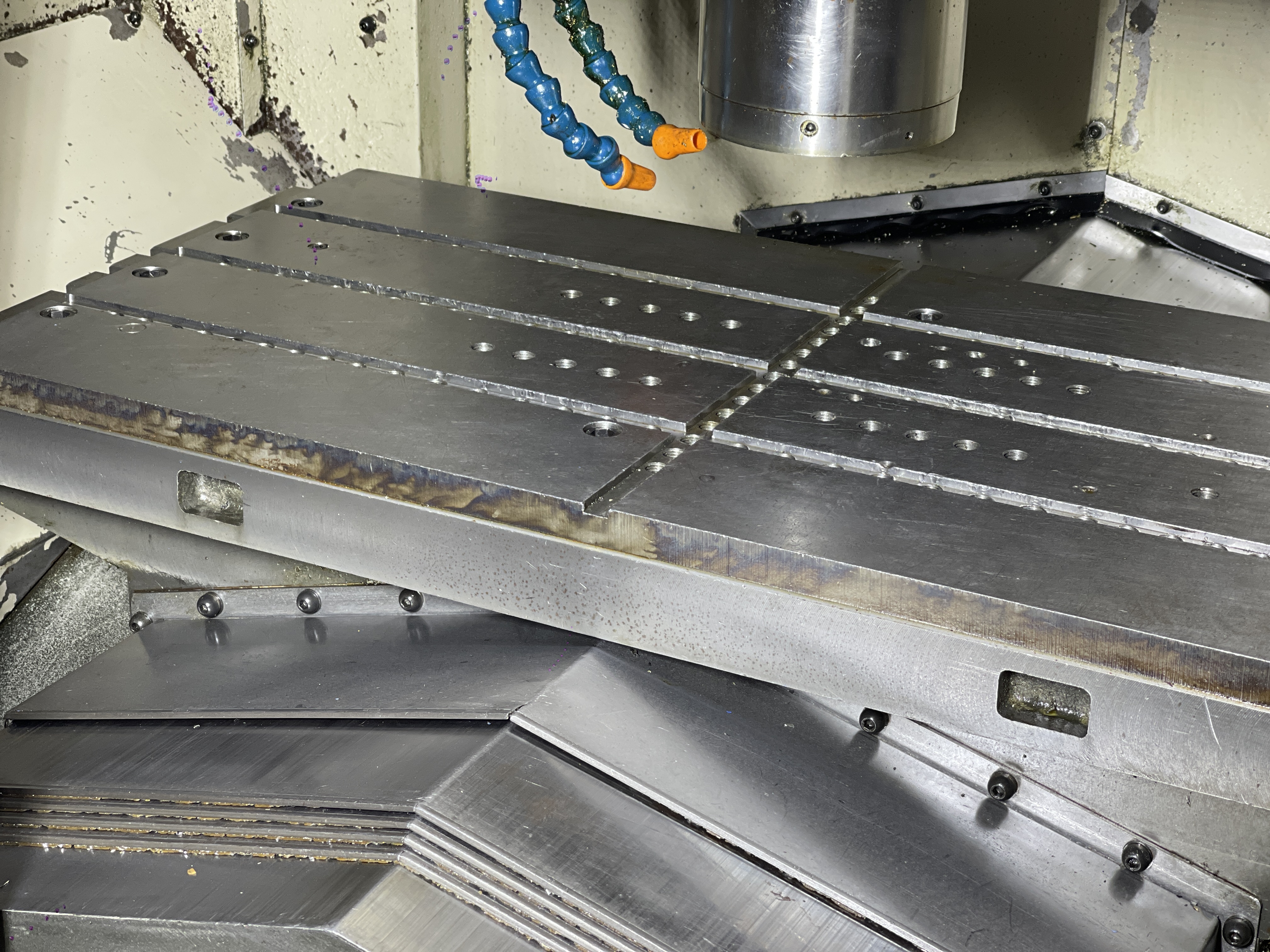

Hitachi Seiki Vs50 Vmc 1

Hitachi Seiki Vs50 Vmc 1 Specification

- Product Type

- Vertical Machining Center

- General Use

- Metalworking / Milling / Industrial Machining

- Material

- Cast Iron / Steel Components

- Type

- Used VMC Machine

- Capacity

- Workpiece Weight up to 300 kg

- Weight (kg)

- Approx. 3500 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Yes

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- Approx. 15 kVA

- Rigidity

- High

- Voltage

- 220-415 V

- Motor

- Spindle Motor 7.5 kW

- Table Size

- 900 mm x 410 mm

- Spindle Speed

- 50-6000 RPM

- Axial Choice

- 3 Axis (X/Y/Z)

- Dimension (L*W*H)

- 2100 mm x 2100 mm x 2350 mm

- Feature

- High Precision, Reliable Automation

- Color

- Grey

- Spindle Taper

- BT40

- Lubrication System

- Automatic

- Coolant System

- Integrated

- Year of Manufacture

- 2001

- Tool Magazine

- 20 ATC (Automatic Tool Changer)

- Travel (X/Y/Z)

- 700 mm x 410 mm x 510 mm

- Repeatability

- ±0.003 mm

- Maximum Table Load

- 300 kg

- Controller

- Fanuc CNC Control

- Model

- Hitachi Seiki VS50 VMC 1

- Air Supply

- 5.5-7 bar

- Rapid Traverse Rate

- X/Y: 20 m/min, Z: 16 m/min

- Positioning Accuracy

- ±0.005 mm

About Hitachi Seiki Vs50 Vmc 1

*HITACHI SEIKI VS50 VMC 1*

CATEGORY : VERTICAL MACHINING CENTERS (VMC)

CAPACITY : 1000 x 510 x 450 mm

YEAR OF CONSTRUCTION : 2000

Reference No: 3287

Video Link: https://youtu.be/Y_JMPuvt1_w

Technical Specifications:

WORKING CAPACITY

Table Size: 1,000 x 450 mm

Travels (XYZ): 1,000 x 510 x 450 mm

Rapid Traverse Rate: X,Y-40 m/min, Z-24m/min

Guideways: LM

CNC

Control: Fanuc 18iM

SPINDLE (INTEGRATED)

Spindle Speed: 12000 RPM

Spindle Taper: BT40

ATC: 60 Stations (ARM Type)

Superior Automation and Precision

The VS50 VMC 1 uses an advanced Fanuc CNC controller and a 20-tool automatic changer, delivering streamlined operation and rapid tool changes for minimized downtime. Its high precision-0.005 mm accuracy and 0.003 mm repeatability-ensures excellent surface finishes and reliable part quality, even for demanding metalworking applications.

Robust Build for Industrial Use

Constructed from cast iron and steel components, the machine guarantees stability and rigidity during heavy-duty milling. The integrated coolant and automatic lubrication safeguard essential parts, reducing maintenance and prolonging life. The versatile spindle speeds accommodate various cutting requirements, suited for diverse machining jobs in industrial environments.

FAQ's of Hitachi Seiki Vs50 Vmc 1:

Q: How does the Fanuc CNC controller enhance the machining process?

A: The Fanuc CNC controller offers advanced automation and programmable precision, allowing operators to execute complex machining cycles efficiently and with minimal human intervention, improving consistency and productivity.Q: What is the process for changing tools on the VS50 VMC 1?

A: The machine features a 20-tool automatic tool changer (ATC), enabling rapid and automated tool swaps during operations. This minimizes downtime and supports continuous, optimized workflow for serial production or varied milling tasks.Q: When should the integrated coolant and lubrication systems be checked?

A: Although the VS50 features automatic coolant and lubrication, regular inspection is recommended-ideally before each shift-to ensure fluid levels and proper system function, maximizing operational safety and machine longevity.Q: Where can the Hitachi Seiki VS50 VMC 1 be installed, considering its dimensions and capacity?

A: With a footprint of 2100 x 2100 x 2350 mm and accommodating up to 300 kg workpiece load, the machine is suitable for medium to large workshop environments typical to industrial manufacturing facilities.Q: What benefits does the machine's high rigidity offer for metalworking?

A: High rigidity ensures minimized vibration and stable cutting, resulting in improved tool life, faster cutting rates, enhanced dimensional accuracy, and superior surface finishes, particularly for steel and cast iron components.Q: How is workpiece capacity supported during operation?

A: The VS50's robust table supports workpieces up to 300 kg, combined with secure clamping and smooth movement along the X, Y, and Z axes. This enables handling of sizable parts for various manufacturing needs.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Vertical Machining Centers (VMC) Category

Daewoo Doosan Mynx 540 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Yes (Fanuc / Siemens option)

Automatic : Yes

Dimension (L*W*H) : 2500 mm x 2400 mm x 2750 mm

Motor : Other, Main Spindle Motor 7.5/11 kW (Fanuc)

Dahlih Mcv 2100 Vmc 1

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Yes

Automatic : Yes

Dimension (L*W*H) : 5,060 x 3,150 x 3,400 mm

Motor : Other, Spindle Motor 15/18.5 kW

Daewoo Doosan Mynx Nm410 Vmc

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Available

Automatic : Yes

Dimension (L*W*H) : 2500 mm x 2300 mm x 2500 mm

Motor : Other, Main Spindle Motor: 15 HP (11 kW)

Matchmaker 1020 Vmc 8

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

PLC Control : Other, Available

Automatic : Yes

Dimension (L*W*H) : 3200 x 2100 x 2400 mm

Motor : Other, Spindle Motor 15 HP

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |