|

Jones Shipman 1400p Surface Grinder 3

Jones Shipman 1400p Surface Grinder 3 Specification

- Product Type

- Surface Grinder

- General Use

- Industrial / Workshop

- Material

- Cast Iron Body

- Type

- Manual

- Capacity

- 300 mm height under wheel

- Weight (kg)

- 1800 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 2.2 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3 HP

- Table Size

- 27 x 8 (685 mm x 203 mm)

- Spindle Speed

- 2880 RPM

- Axial Choice

- Cross and Vertical

- Dimension (L*W*H)

- 2040 x 1550 x 1620 mm

- Feature

- Precision Grinding

- Color

- Blue / Grey

- Table Cross Travel

- 8 (203 mm)

- Table Longitudinal Travel

- 24 (610 mm)

- Max Distance from Table to Spindle Centre

- 13 (330 mm)

- Grinding Wheel Size

- 250 mm x 25 mm x 76 mm

- Lubrication System

- Automatic

- Coolant System

- Fitted

- Hydraulic Table Feed

- Included

- Vertical Feed Graduation

- 0.001 mm

- Handfeed Graduation

- 0.01 mm

- Model

- Jones Shipman 1400P

- Magnetic Chuck Size

- 18 x 6

- Workhead Speed Range

- Variable

About Jones Shipman 1400p Surface Grinder 3

*JONES SHIPMAN 1400P SURFACE GRINDER 3*

CATEGORY : SURFACE GRINDERS

CAPACITY : 600 x 200 mm

Reference No: 3606

Video Link: https://youtu.be/OzrMx5FYjlI

Technical Specifications:

WORKING CAPACITY

Table Size: 600 x 200 mm

Longitudinal Travel: 635 mm

Cross Travel: 204 mm

Vertical Working Height: 280 mm

WHEELHEAD

Standard Grinding Wheel Size: 204 x 20 x 32 mm

Spindle Main Motor: 1.5 kW

DIMENSIONS

Weight: 1.2T

Rapid Up/Down Movement

Precision Surface Grinding for Industrial Needs

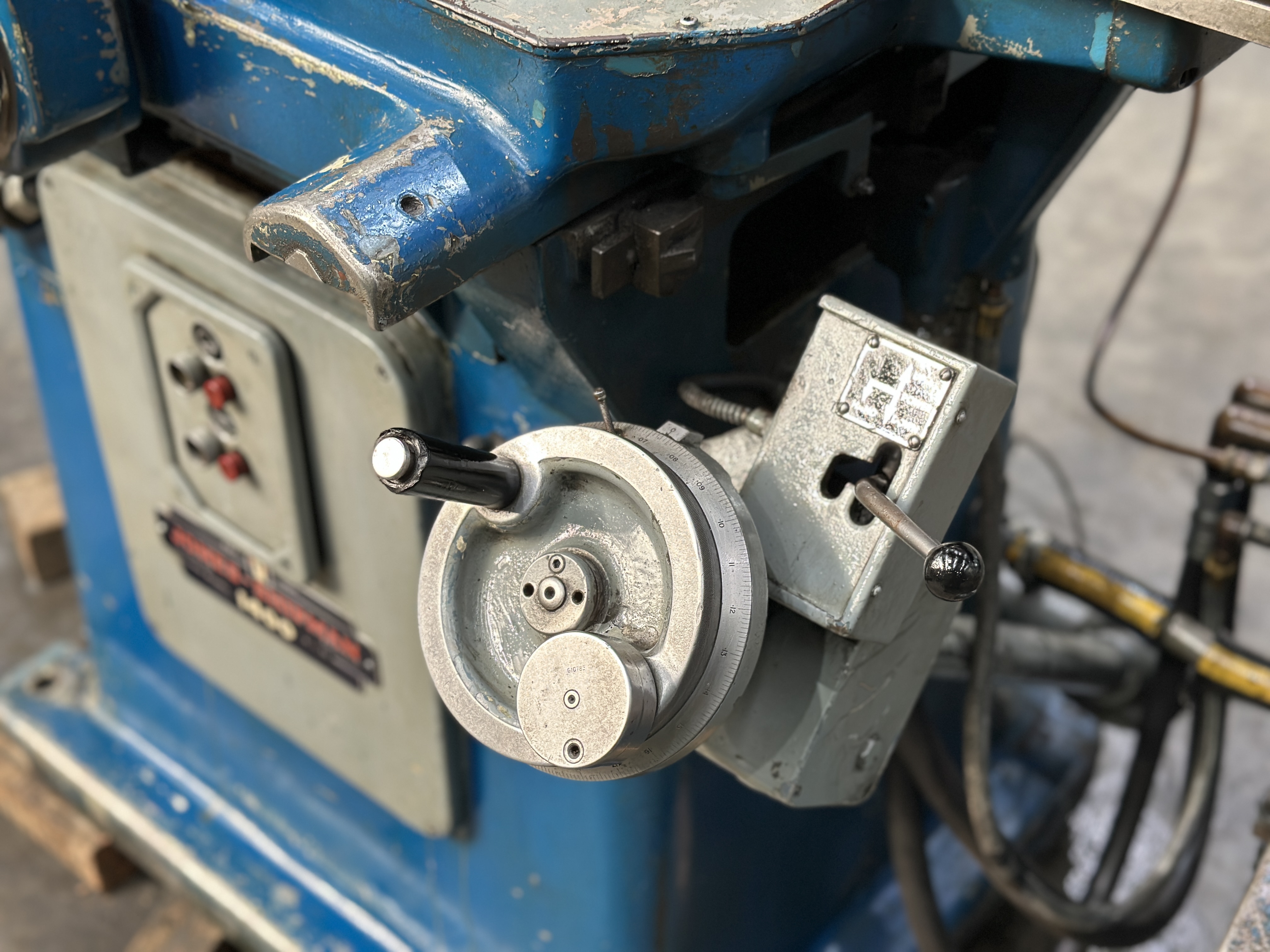

Engineered for superior accuracy, the Jones Shipman 1400P Surface Grinder ensures consistent results in demanding workshop and industrial settings. Its precision handfeeds and rigid cast iron construction support high-tolerance applications, making it ideal for tool making and component finishing.

Advanced Features for Reliable Operation

This model incorporates automatic lubrication, hydraulic table feed, and a fitted coolant system, streamlining maintenance and sustaining peak performance. The grinder's magnetic chuck and variable workhead speed offer versatility in handling diverse materials and workpieces with efficiency.

User-Friendly, Manual Control

The Jones Shipman 1400P is operated manually, providing skilled machinists full control over cross and vertical axes for fine adjustment. Its intuitive interface, consistent graduations, and robust build result in reliable operation without the complexity of PLC or computerized systems.

FAQ's of Jones Shipman 1400p Surface Grinder 3:

Q: How is the Jones Shipman 1400P Surface Grinder used in workshop environments?

A: This surface grinder is typically employed for precision grinding of metal components, allowing machinists to achieve accurate flatness and parallelism. Its manual controls and fine graduations enable users to make detailed adjustments, perfect for tooling, die work, or component finishing in workshops.Q: What are the main benefits of choosing the Jones Shipman 1400P for industrial applications?

A: The grinder provides high rigidity, precise feed graduations, and variable spindle speeds, resulting in dependable, high-accuracy grinding. Its automatic lubrication and hydraulic table feed reduce operator effort, while the robust, cast iron build ensures longevity in heavy-duty settings.Q: When should I use the hydraulic table feed on this surface grinder?

A: The hydraulic table feed is ideal for larger or repetitive grinding jobs where consistent longitudinal motion is required. It improves efficiency, produces smoother finishes, and reduces manual fatigue, especially when working with larger workpieces or during high-volume operations.Q: Where can the Jones Shipman 1400P Surface Grinder be installed?

A: This grinder is best suited for industrial workshops, tool rooms, and manufacturing facilities with adequate electrical supply (415 V) and space for its dimensions. Its heavy-duty construction and precision features are optimal for environments demanding reliable and consistent surface grinding.Q: What is the process for adjusting grinding precision with this model?

A: Operators utilize the handfeed and vertical feed dials, calibrated to 0.01 mm and 0.001 mm respectively, to achieve fine tolerance adjustments. The magnetic chuck secures workpieces during grinding, and the variable workhead speed allows adaptation for different materials and surface requirements.Q: How does the automatic lubrication and cooling system enhance operation?

A: The automatic lubrication system ensures critical moving parts remain properly oiled, reducing wear and extending machine life. The fitted coolant system dissipates heat during grinding, preventing workpiece distortion and maintaining surface integrity.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinders Category

Jones Shipman 540 Surface Grinder 21

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, 1.5 kW main spindle motor

PLC Control : No

General Use : Surface finishing and grinding of metal workpieces

Weight (kg) : Approx. 1100 kg

Alpa Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, 2 HP

PLC Control : No

General Use : Precision grinding of flat surfaces

Weight (kg) : Approx 1200 kg

Jones Shipman 540p Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, 2 HP, 3Phase Motor

PLC Control : No

General Use : Surface grinding of metals

Weight (kg) : 900 kg

Jones Shipman 540 Cp Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Motor : Other, 1.5 HP

PLC Control : No

General Use : Metal Surface Grinding

Weight (kg) : Approx. 1200 kg

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |