Most Popular Products

|

Herbert 2D Capstan Lathe

Herbert 2D Capstan Lathe Specification

- Product Type

- Capstan Lathe

- General Use

- Metal turning, production lathe operations

- Material

- Cast Iron, Steel

- Type

- Semi-automatic

- Capacity

- Up to 25 mm bar diameter

- Weight (kg)

- Approx 1200 kg

- Computerized

- No

- Automatic

- Semi-automatic

- PLC Control

- No

- Bar Feeder

- Yes

- Power Source

- Electric

- Power Consumption

- 3 HP

- Rigidity

- Heavy duty cast iron body

- Voltage

- 415 V

- Motor

- 3 phase induction motor

- Table Size

- Standard (as per model specifications)

- Spindle Speed

- Variable, up to 1200 rpm

- Axial Choice

- 2 Axis

- Dimension (L*W*H)

- Approx 1700 x 900 x 1200 mm

- Feature

- High precision, robust construction

- Color

- Industrial Green

- Chuck Size

- 150 mm

- Distance between Centres

- 400 mm

- Spindle Bore

- 32 mm

- Number of Turret Stations

- 6

- Bed Length

- 1000 mm

- Tailstock

- Manual

About Herbert 2D Capstan Lathe

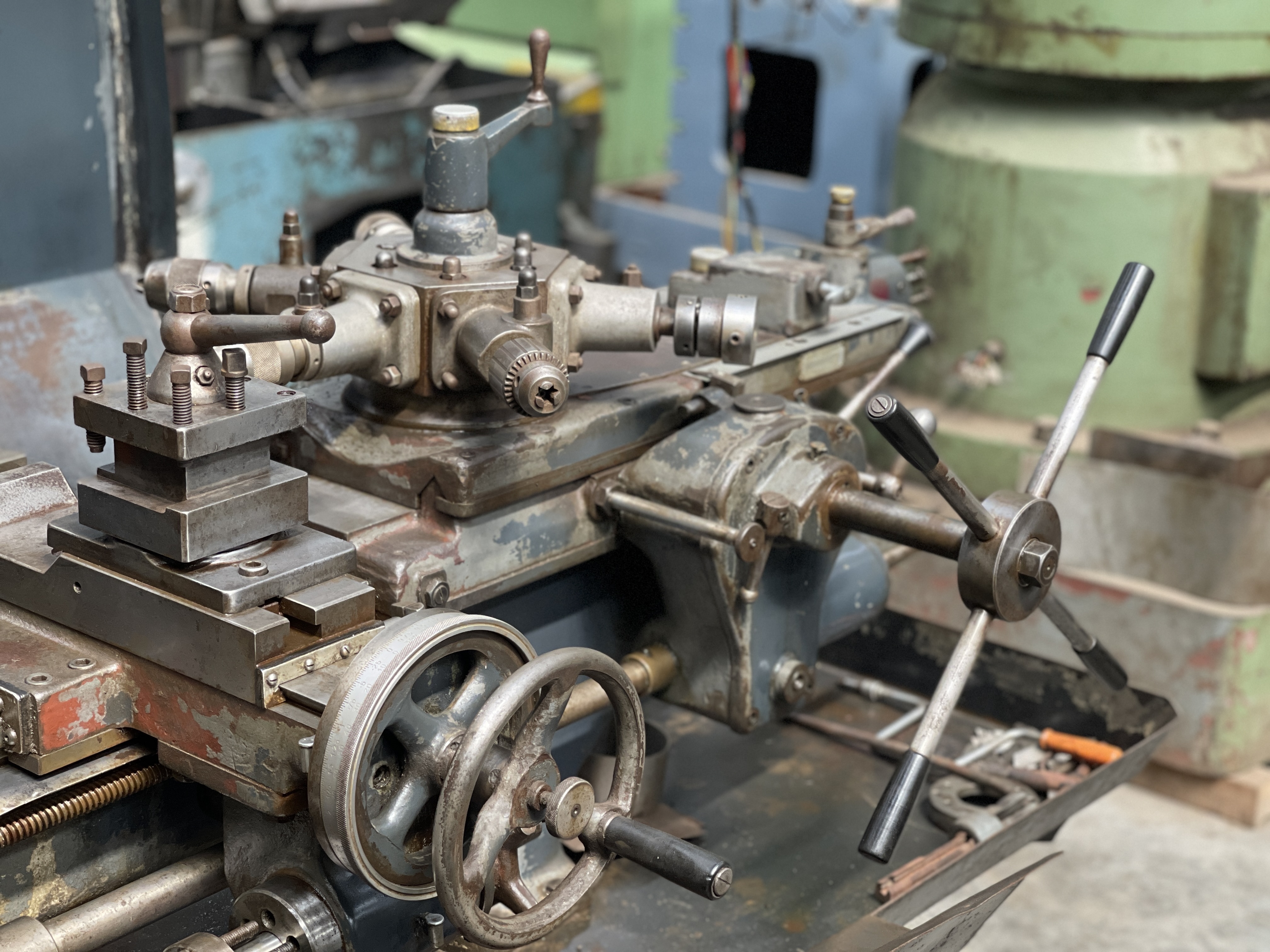

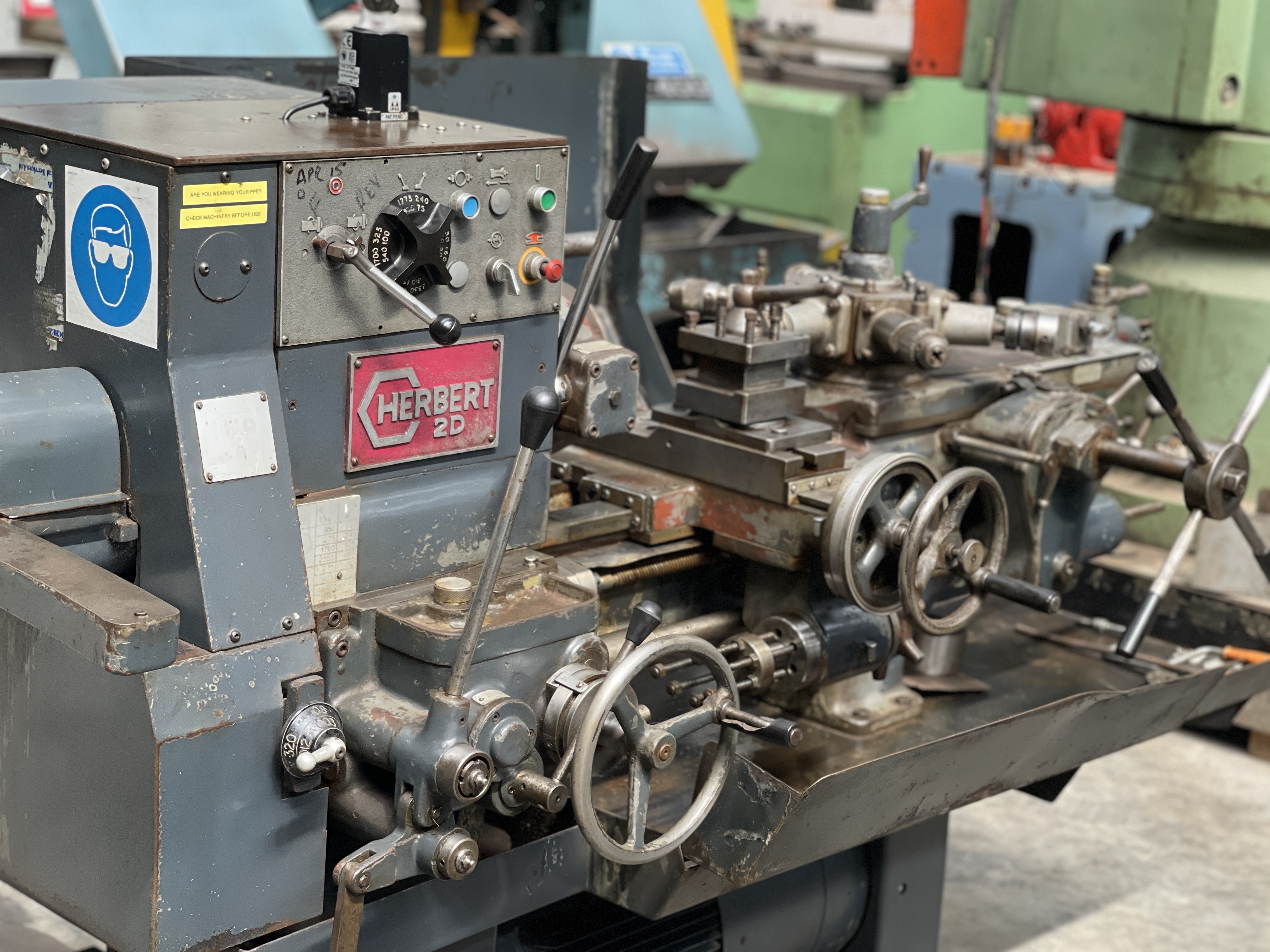

*HERBERT 2D CAPSTAN LATHE*

CATEGORY : LATHES

Reference No: 1557

Video Link: https://youtu.be/bJOmX7o-cqI

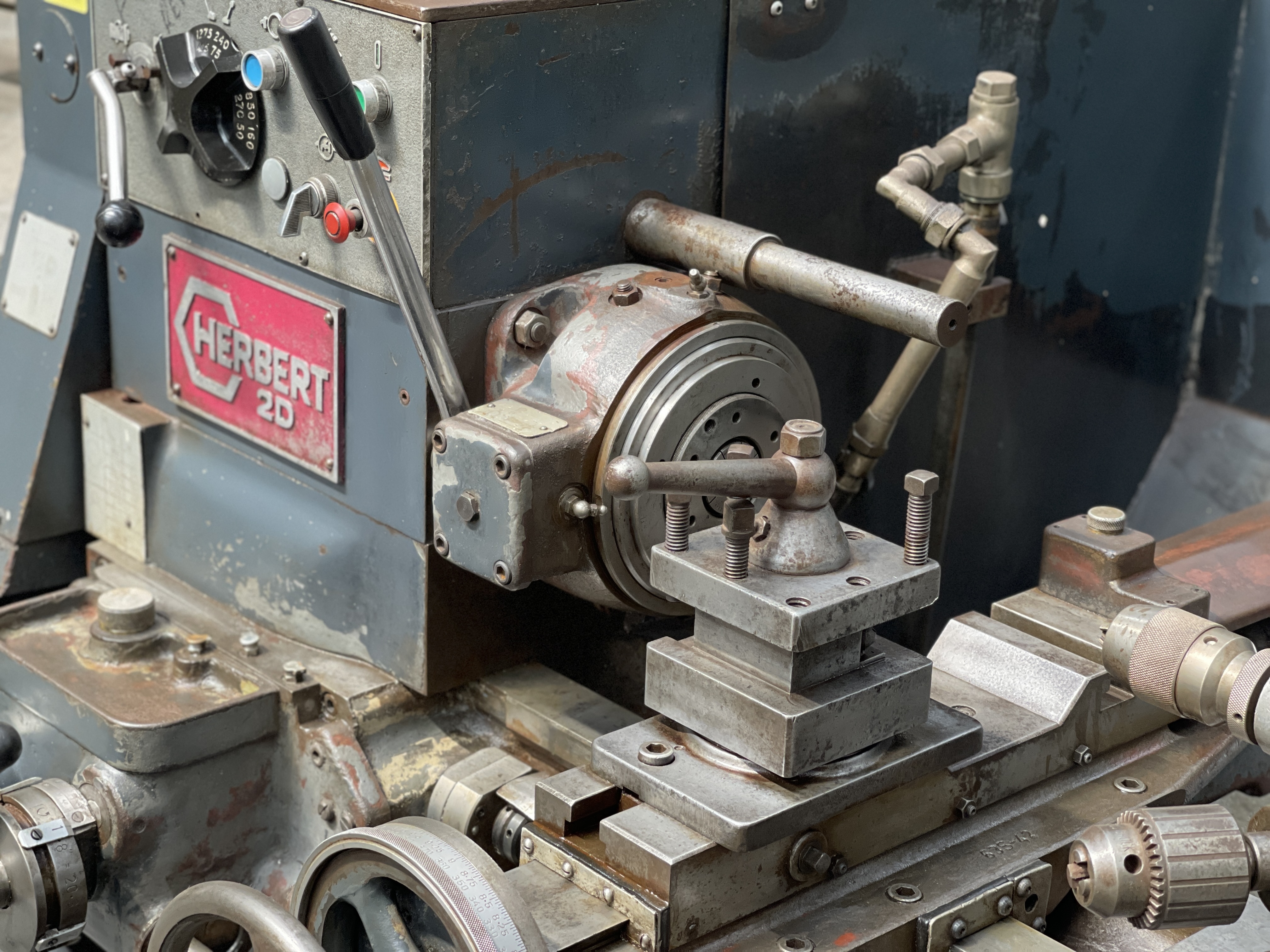

Technical Specifications:

Swing Over Bed 340mm

Swing Over Saddle 200mm

Chuck to Turret Face 450mm

Spindle Speeds 50 2550rpm

Spindle Bore 45mm

Feeds 0.08 0.32mm per rev

Electrics 415v, 3ph, 50 Hz

Rear Tool Post, Lovo Light,Guards

Approximate Dimensions 2240 x 1220 x 1500mm

Approximate Weight 1500kg

Robust Construction for Heavy-Duty Operations

Engineered with a heavy-duty cast iron frame, the Herbert 2D Capstan Lathe offers remarkable rigidity and vibration dampening essential for high-precision metal turning. Its durable build ensures longevity and consistent performance, even under continuous use in demanding industrial environments such as workshops or large-scale production facilities.

High Efficiency and Versatility

Fitted with a 6-station turret and a variable spindle speed of up to 1200 rpm, this lathe allows rapid changeover between operations. Its semi-automatic functioning, combined with a manual tailstock and integrated bar feeder, streamlines production, making it especially effective for volume manufacturing and repeat jobs involving various materials like cast iron and steel.

User-Friendly and Adaptable Design

Despite being semi-automatic and non-computerized, the Herbert 2D Lathe is designed for ease of operation and straightforward maintenance. Its standard table size, ergonomic controls, and accessible power supply (415 V) make it adaptable across different setups. The lathe's classic industrial green finish also signals its readiness for robust workshop applications.

FAQ's of Herbert 2D Capstan Lathe:

Q: How does the Herbert 2D Capstan Lathe improve production efficiency for metal turning operations?

A: The lathe's 6-station turret allows quick tool changes, and the semi-automatic design with bar feeder minimizes manual intervention between cycles. This setup increases throughput in volume production while maintaining precise and repeatable results.Q: What type of workpieces and bar diameters can be accommodated by this machine?

A: This model is suited for turning metal bars up to 25 mm in diameter, supporting materials such as cast iron and steel. The machine's 400 mm distance between centres further expands its suitability for a range of component lengths within metalworking production.Q: When should I consider using the bar feeder with the Herbert 2D Capstan Lathe?

A: The integrated bar feeder is particularly beneficial during batch production or when handling longer bars. It streamlines the loading process, enabling uninterrupted turning cycles and reducing downtime compared to manual feeding.Q: Where is the Herbert 2D Capstan Lathe typically used?

A: This lathe is ideal for use in industrial workshops, manufacturing plants, and tool rooms engaged in serial production or the fabrication of precision metal components for varied industries.Q: What are the main steps involved in operating the Herbert 2D Capstan Lathe?

A: Operation begins with securing the workpiece using the 150 mm chuck, selecting the appropriate tool station on the turret, and engaging the spindle. The user feeds the bar (manually or via the feeder), then controls turning operations through the semi-automatic interface, adjusting spindle speed as needed.Q: Why is the lathe considered robust and precise?

A: The lathe's construction from heavy-duty cast iron ensures stability and minimizes vibration, while its precision-engineered components and variable speed capability guarantee consistent accuracy for intricate metalwork.Q: What benefits does the manual tailstock offer in this semi-automatic lathe?

A: The manual tailstock provides additional support for longer workpieces, allows for precise adjustment during center drilling or finishing operations, and lends flexibility for different turning requirements without complex electronic controls.

- Minimum Order Quantity

- 1 Number

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in CNC Lathe Machine Category

Hey No. 3 Facing And Centering (6 X 51)

Minimum Order Quantity : 1 Number

Material : Other, Cast Iron, Steel

Daewoo Doosan Puma 400lb Transit CNC Lathe Machine

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

Colchester Tornado 300 CNC Lathe Machine

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Metal

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |