|

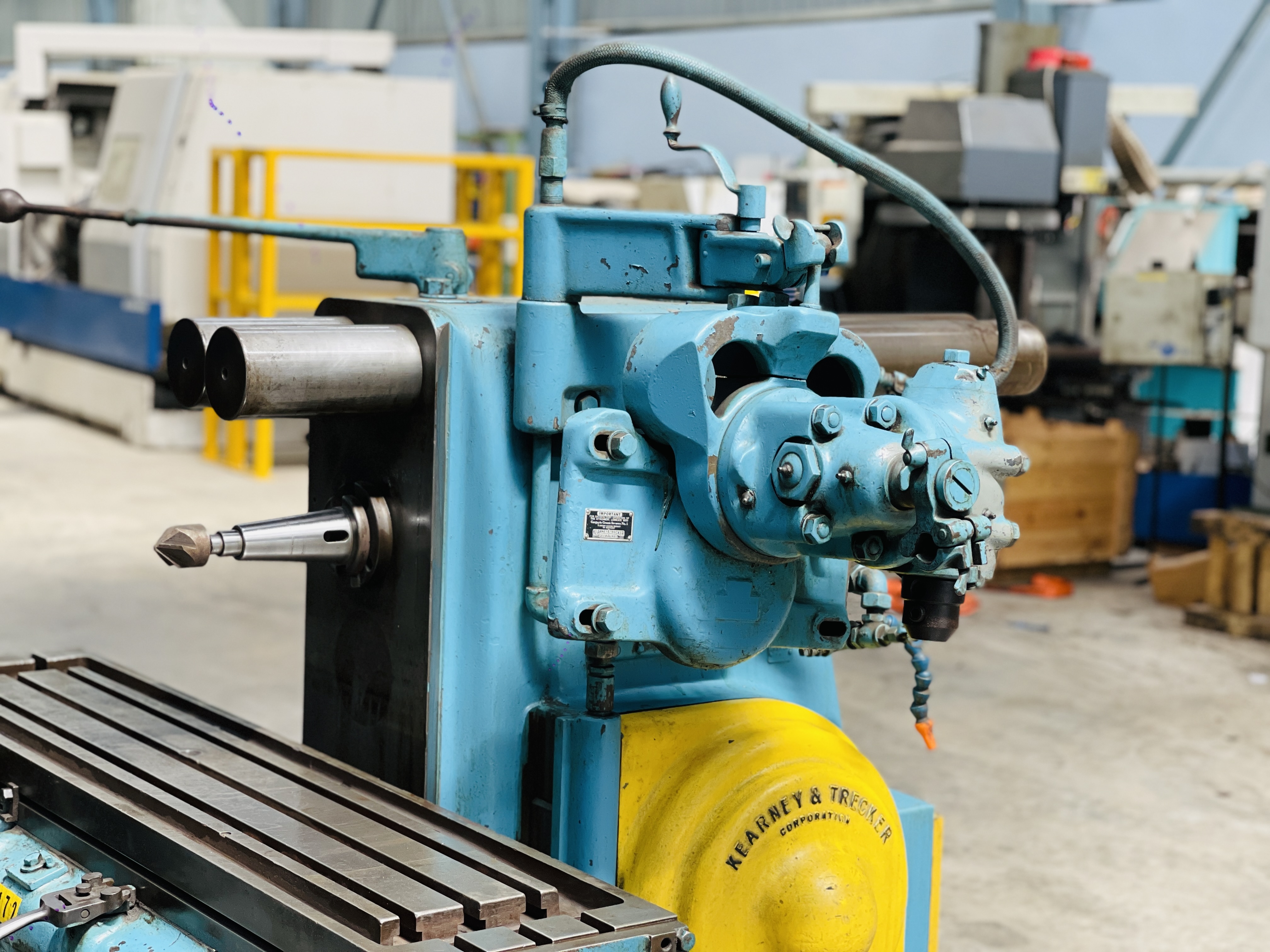

Kearney And Trecker Millwaukee No 2 Universal Milling Machine

Kearney And Trecker Millwaukee No 2 Universal Milling Machine Specification

- Product Type

- Universal Milling Machine

- General Use

- Metal and precision component milling

- Material

- Heavy-duty cast iron body

- Type

- Kearney And Trecker Milwaukee No.2

- Capacity

- Heavy-duty industrial milling

- Weight (kg)

- Approx. 2000 kg

- Computerized

- No

- Automatic

- Semi-automatic

- PLC Control

- No

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- Approx. 7.5 HP (5.5 kW)

- Rigidity

- High rigidity cast iron construction

- Voltage

- 415 V

- Motor

- Main drive motor, 7.5 HP

- Table Size

- 1270 mm x 254 mm (50 x 10)

- Spindle Speed

- Variable, 19 steps, 35 - 1400 RPM

- Axial Choice

- Longitudinal, Cross, Vertical

- Dimension (L*W*H)

- Approx. 2000 mm x 1800 mm x 1700 mm

- Feature

- Swiveling table for universal milling, Hardened gears

- Color

- Green

- Cooling System

- External coolant pump (integrated chamber)

- Table Cross Travel (Y-Axis)

- 10 inches (254 mm)

- Feed Rate

- Variable, 0.5 to 15 inches/min

- Table Longitudinal Travel (X-Axis)

- Approximately 28 inches (711 mm)

- Cutter Diameter Capacity

- Up to 4 inches (101 mm)

- T-Slot Size

- 3 T-slots, 0.625 inch (16 mm) wide

- Gearbox

- Mechanical, geared head

- Lubrication

- Centralized lubrication system

- Rapid Traverse

- 60 inches/min

- Swivel Table Angle

- Up to 45° both sides

- Machine Condition

- Used/Second Hand

- Manufacturing Origin

- USA

- Spindle Taper

- #40 NMTB

- Table Vertical Travel (Z-Axis)

- 16 inches (406 mm)

About Kearney And Trecker Millwaukee No 2 Universal Milling Machine

*KEARNEY & TRECKER MILLWAUKEE NO 2 UNIVERSAL MILLING MACHINE*

CATEGORY : MILLING MACHINES

CAPACITY : 1425 x 305 mm

Reference No: 2828

Video Link: https://youtu.be/CQfL7Tu7iSw

Technical Specifications:

Table: 1425 x 305 mm

Power Feed on All Axis with Rapids

Versatile Milling Capabilities

The Kearney and Trecker Milwaukee No. 2 Universal Milling Machine offers exceptional flexibility for various milling operations. Its swiveling table and multi-axis movement support intricate cutting tasks, making it suitable for both heavy-duty and precision applications in metalworking workshops.

High-Rigidity and Robust Design

Built from heavy-duty cast iron, this milling machine is engineered for maximum stability and durability. With hardened gears and a centralized lubrication system, the equipment minimizes vibration and ensures smooth operation even under prolonged use, enhancing operational lifespan.

Optimized Performance and Control

Variable spindle speeds (19 steps, 35-1400 RPM) allow precise adjustment for diverse materials and cutter sizes. Combined with a powerful 7.5 HP motor and high feed rates, this model supports efficient, high-quality production across a range of milling tasks, from roughing to finishing.

FAQs of Kearney And Trecker Millwaukee No 2 Universal Milling Machine:

Q: How do I use the swiveling table to perform angled milling operations?

A: The swiveling table on the Kearney and Trecker No. 2 Universal Milling Machine can be adjusted up to 45 on either side, enabling versatile angle milling. Simply loosen the locking mechanism, set the desired angle, and retighten before starting your operation for precise cuts at non-standard orientations.Q: What materials and component sizes can this milling machine handle effectively?

A: With its heavy-duty cast iron body, #40 NMTB spindle taper, and cutter capacity up to 4 inches, this machine is well-suited for milling a range of metals and producing precision components. The spacious table (50 x 10 inches) and variable feed speeds accommodate both large and small workpieces.Q: When is centralized lubrication required during operation?

A: The machines centralized lubrication system should be activated before starting a shift and periodically throughout extended operation. Proper lubrication is crucial to minimizing wear, ensuring smooth movement of components, and extending the machines service life.Q: Where did the Kearney and Trecker No. 2 Universal Milling Machine originate?

A: This milling machine is manufactured in the USA, known for its high-quality construction standards and engineering excellence, making it a sought-after choice for industrial applications worldwide.Q: What is the process for adjusting spindle speeds on this machine?

A: The spindle speed is adjusted mechanically via the machines 19-step geared head control. Refer to the speed selection chart on the machine, then operate the gear levers to set the RPM between 35 and 1400, matching your cutting requirements and material type.Q: What are the benefits of the external coolant pump and centralized lubrication?

A: The integrated external coolant pump efficiently manages heat, improving cutter longevity and finish quality. Centralized lubrication ensures all moving parts are consistently oiled, reducing maintenance needs and helping the machine sustain optimal performance over time.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Tos Fnk 25 Milling Machine 3

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Heavy Duty Milling (up to 25 mm cutter diameter)

Power Consumption : 3.7 kW

Type : Other, Universal

Spindle Speed : 60 3000 RPM

Bridgeport M1tr Turret Dro Milling Machine 1

Minimum Order Quantity : 1 Number

Capacity : Table Load 200 kg

Power Consumption : 3 HP

Type : Other, Vertical Milling Machine

Spindle Speed : 604200 RPM

Boko Wf1 Universal Tool Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Medium

Power Consumption : Approx. 3.3 kW

Type : Other, Horizontal and Vertical

Spindle Speed : 40 2000 rpm

Tiel Universal Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : 410 mm (X), 130 mm (Y), 420 mm (Z)

Power Consumption : 2.2 kW

Type : Other, Horizontal & Vertical Universal

Spindle Speed : 452000 rpm

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |