|

Mori Seiki Sl-303b/1500 Cnc Lathe

Mori Seiki Sl-303b/1500 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Metal turning, shaft machining

- Material

- Hardened steel components, cast iron bed

- Type

- Slant Bed CNC Lathe

- Capacity

- Max turning diameter 420 mm, Max turning length 1500 mm

- Weight (kg)

- 7800 kg

- Computerized

- Yes

- Automatic

- Fully Automatic

- PLC Control

- Available

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 28 kVA

- Rigidity

- High rigidity cast iron bed

- Voltage

- 400 V

- Motor

- Main Spindle Motor 22/18.5 kW

- Table Size

- N/A (Lathe)

- Spindle Speed

- 50 to 2500 rpm

- Axial Choice

- 2 Axis (X, Z)

- Dimension (L*W*H)

- 4838 x 2065 x 2065 mm

- Feature

- Large turning capacity, precision machining, heavy-duty construction

- Color

- Standard (Machine Grey/White)

- Z-Axis Travel

- 1650 mm

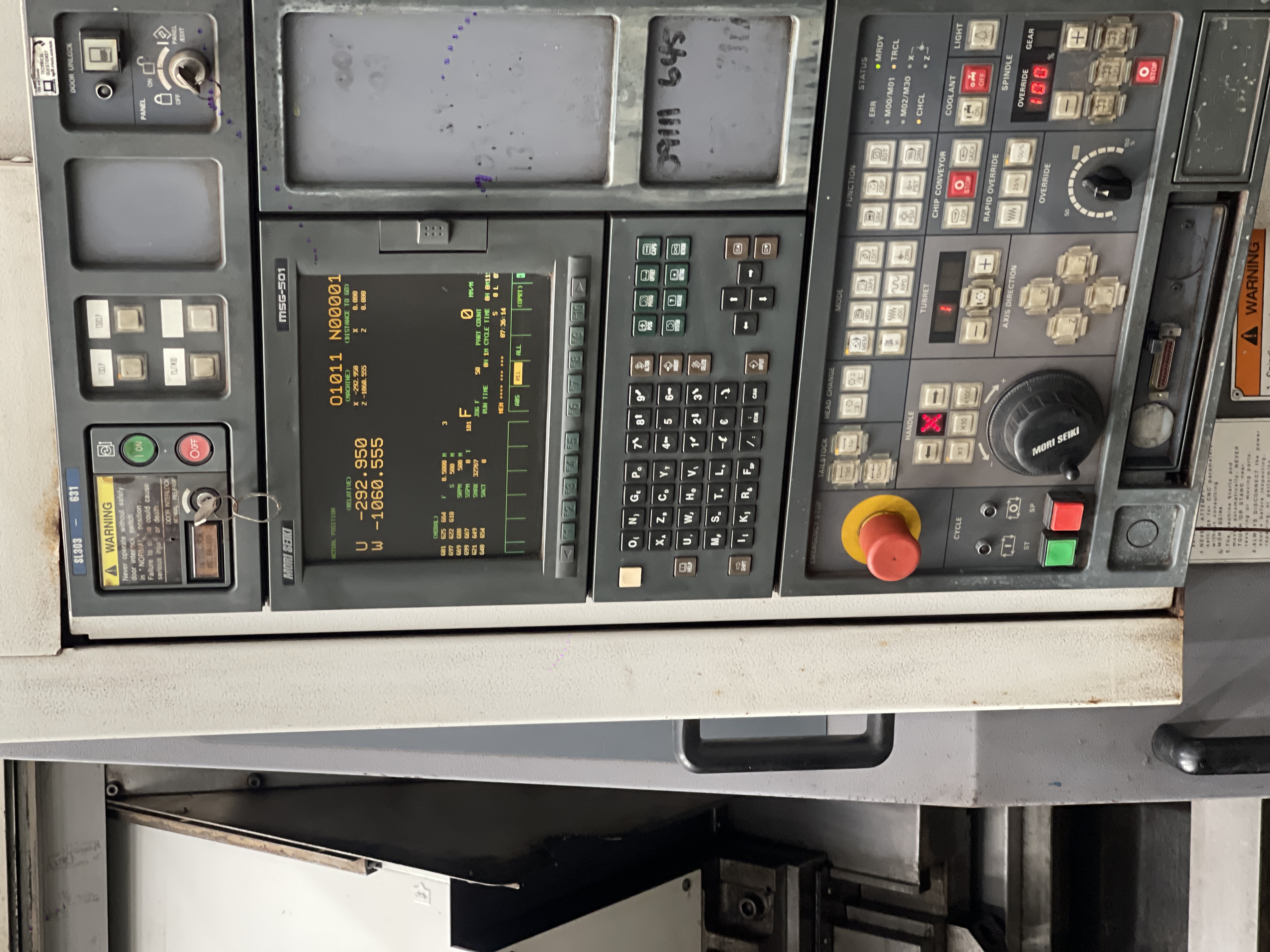

- Controller

- Fanuc 21i-TB

- Supported Workpiece Length

- Max 1500 mm

- Spindle Bore

- Ø 91 mm

- X-Axis Travel

- 292 mm

- Repeatability

- ±0.001 mm

- Coolant System

- High efficiency, included

- Chuck Size

- 12 inches

- Hydraulic System

- Integrated

- Lubrication System

- Automatic

- Supported Workpiece Diameter

- Max 420 mm

- Spindle Nose

- A2-8

- Turret Type

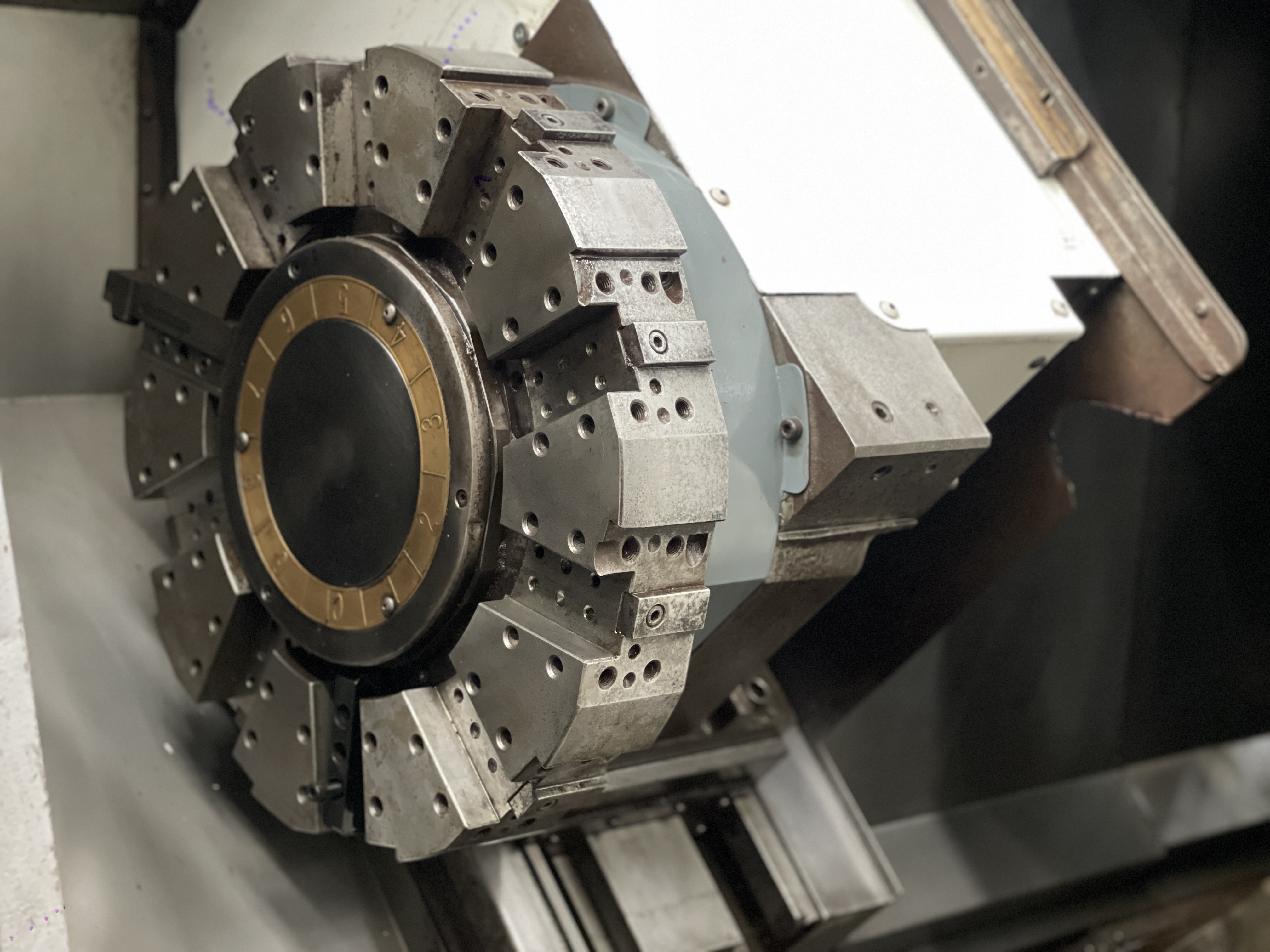

- 12-Station Turret

- Rapid Traverse Rate (X/Z)

- 24/30 m/min

- Tailstock

- Programmable

About Mori Seiki Sl-303b/1500 Cnc Lathe

*MORI SEIKI SL-303B/1500 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 427 x 1560 mm

YEAR OF CONSTRUCTION : 2000

Reference No: 2172

Video Link: https://youtu.be/vdsMo0xbN3I

Technical Specifications:

WORKING CAPACITY

Max Turning Diameter: 427 mm

Max Turning Length: 1560 mm

Swing: 600 mm

Distance Between Centers: 1641 mm

Travels (X / Z): 240 / 1606 mm

Guideways: Box

Chuck Equipped: 380 mm (15)

CNC

Control: Fanuc 18iT

SPINDLE

Max Rotation Speed: 2500 RPM

Spindle Nose: A2-8

Spindle Bore: 104 mm

Spindle Motor Power: 30 HP

TAILSTOCK

Tailstock Quill Taper: 5 MT

TURRET

Turret: 12 Stations

Turret Type: Servo

Machine Dimensions

Weight: 9 T

L x W x H: 186 x 66 x 84 High

Engineered for High Precision and Productivity

The Mori Seiki SL-303B/1500 stands out with its fully automatic operation, advanced Fanuc 21i-TB controller, and hardened steel/cast iron construction. Its 12-station turret enables flexible tooling for a range of turning operations. The high rigidity bed ensures minimal vibration, translating to superb surface finishes and reliable repeatability. The high-efficiency programmable tailstock further enhances its adaptability for different applications.

Large Turning Capacity for Diverse Applications

With a maximum turning diameter of 420 mm and a turning length of 1500 mm, this CNC lathe is ideal for machining a variety of components, especially shafts and long workpieces. The 91 mm spindle bore accommodates substantial bar stock, while the automatic lubrication and efficient cooling systems ensure prolonged, trouble-free operation.

Intelligent Design for Operator Ease and Durability

The user-friendly PLC and computerized controls streamline setup and monitoring, while the machine's integrated hydraulic, lubrication, and coolant systems reduce routine maintenance. Its robust structure-measuring 4838 x 2065 x 2065 mm and weighing 7800 kg-ensures stability during high-speed operations, suitable for metal turning sectors demanding both precision and throughput.

FAQ's of Mori Seiki Sl-303b/1500 Cnc Lathe:

Q: How does the Mori Seiki SL-303B/1500 CNC lathe ensure precision during operation?

A: The lathe achieves high precision through its rigid cast iron bed, advanced Fanuc 21i-TB control system, and repeatability of 0.001 mm. Automatic lubrication and high-efficiency coolant systems maintain consistent performance, further enhancing machining accuracy.Q: What types of workpieces can be processed using this CNC lathe?

A: The machine is suitable for turning metal workpieces up to 420 mm in diameter and 1500 mm in length, making it ideal for shaft machining, metal turning, and tasks requiring large turning capacities. Its programmable tailstock and 91 mm spindle bore accommodate a diverse range of parts.Q: When is the 12-station turret beneficial in the machining process?

A: The 12-station turret allows for rapid tool changes, supporting complex operations without manual intervention. This feature is especially beneficial during multi-process machining, reducing setup time and boosting productivity in high-mix, low-volume environments.Q: Where can the Mori Seiki SL-303B/1500 be effectively utilized?

A: This lathe is suited for metalworking facilities, component manufacturing plants, and workshops specializing in precision shaft or large part machining. As an exporter, importer, and supplier in India, it is well-adapted for both domestic and international manufacturing needs.Q: What is the process for operating the machine and monitoring its status?

A: Operators interface via the Fanuc 21i-TB controller and integrated PLC system to set up and monitor the machining process. The system oversees axis movements, spindle speeds, coolant flow, and hydraulic operations, ensuring fully automatic, reliable, and safe performance.Q: How does the machine's high-efficiency coolant system benefit production?

A: The high-efficiency coolant system maintains optimal cutting temperatures, prolonging tool life, improving surface finishes, and reducing downtime associated with heat or chip buildup.Q: What are the primary usage advantages of this CNC lathe compared to conventional machines?

A: Thanks to its computerized controls, rapid traverse rates, automatic systems, and high rigidity, the SL-303B/1500 delivers faster cycle times, higher accuracy, reduced manual intervention, and superior durability-offering significant advantages in productivity and quality for modern metalworking operations.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Citizen B20 Cnc Sliding Head

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Bar capacity up to 20mm diameter

Product Type : CNC Sliding Head Machine

Type : Other, Swiss Type CNC Lathe

Dimension (L*W*H) : 2340mm x 880mm x 1670mm

Gildemeister Leadwell Ct 200 Cnc Turning Center With Barfeed

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Bar Dia. up to 51 mm

Product Type : CNC Turning Center

Type : Horizontal

Dimension (L*W*H) : 2200 mm x 1400 mm x 1700 mm

Hardinge C42 Cnc Turning Center

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Maximum turning diameter 420 mm

Product Type : CNC Turning Center

Type : Other, Industrial CNC Lathe

Dimension (L*W*H) : 2780 x 1900 x 1965 mm

Nakamura Tome Superturn 4 Cnc Lathe

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Capacity : Max swing over bed: 530 mm; Max turning length: 830 mm

Product Type : CNC Lathe

Type : Other, Horizontal CNC Lathe

Dimension (L*W*H) : Approx. 4100 x 2150 x 2100 mm

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |