|

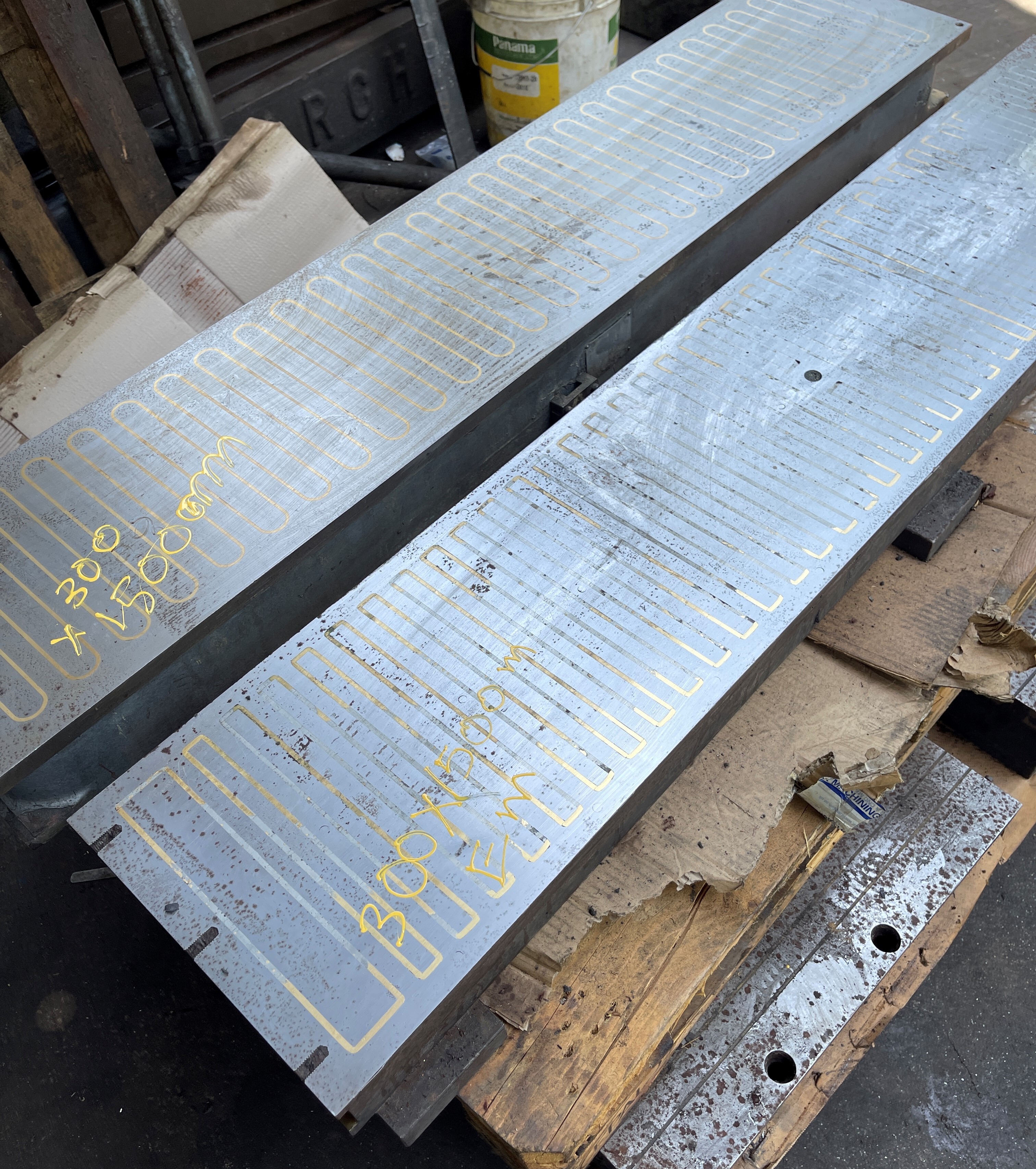

Electromagnetic Chuck

Electromagnetic Chuck Specification

- Product Type

- Electromagnetic Chuck

- General Use

- Surface Grinding Machine / Milling Machine / EDM

- Material

- Steel and Copper

- Type

- Rectangular

- Capacity

- Up to 200 kg (varies with model)

- Weight (kg)

- Approx. 40 - 80 kg (varies by size)

- Computerized

- No

- Automatic

- Manual ON/OFF (Electromagnetic)

- PLC Control

- No

- Power Source

- Electric

- Power Consumption

- Low (typically < 200W)

- Rigidity

- High

- Voltage

- 110V/220V/380V (as per model)

- Table Size

- 300 x 600 mm / 400 x 800 mm (other sizes available)

- Axial Choice

- Single Axis

- Dimension (L*W*H)

- Approx. 600 x 300 x 100 mm (varies with model)

- Feature

- Powerful magnetic holding, rapid ON/OFF, easy operation, uniform magnetic force

- Color

- Grey / Silver

- Poles Type

- Longitudinal or Rectangular Poles

- Switch Type

- Manual Electrical Switch

- Surface Accuracy

- 0.005 mm

- Usage Temperature

- 50C

- Application

- Precisely holds ferrous workpieces for grinding, milling, and drilling operations

- Safety Feature

- Power cut-off protection

- Insulation Resistance

- >100 M

- Holding Force

- 1000-1200 Gauss (varies by model)

- Magnetic Plate Width

- Approx. 70 mm (varies)

- Cooling

- Air Cooled

About Electromagnetic Chuck

Electromagnetic Chuck: Plant Applications and Advantages

Our Electromagnetic Chuck is an ideal solution for plants requiring precise workpiece holding in surface grinding machines, milling machines, and EDMs. The uniform magnetic field covers the entire application surface, guaranteeing high surface accuracy. Its main advantage is the powerful magnetic holding system, offering consistent clamping and ease of operation, ultimately improving productivity in industrial settings. Rapid ON/OFF features and a robust safety mechanism further enhance reliability and efficiency across various plant environments.

Domestic Market, Payment, and Logistics

With a strong focus on India's main domestic market, we offer flexible payment terms including advance and letter of credit options. Dispatching is streamlined, and handover is efficiently managed for smooth logistics. Our FOB port services ensure safe and prompt delivery, with every electromagnetic chuck shipment carefully monitored from packaging through logistics to final dispatch. Clients benefit from a trusted, transparent process, ensuring reliable product arrival and seamless integration into existing manufacturing operations.

FAQ's of Electromagnetic Chuck:

Q: How does the electromagnetic chuck provide a secure hold for workpieces?

A: The electromagnetic chuck generates a powerful magnetic field with a holding force between 1000-1200 Gauss, depending on the model. This ensures ferrous workpieces remain firmly in place during grinding, milling, or drilling processes, delivering exceptional accuracy and safety.Q: What are the main surface and plant applications for this electromagnetic chuck?

A: This chuck is primarily used in surface grinding machines, milling machines, and EDMs across manufacturing plants. Its application surfaces include steel and ferrous metals, where precise and stable holding is essential for machining operations.Q: When should I consider advance purchase of this product?

A: Advance purchase is recommended for customers with time-sensitive orders or those requiring bulk quantities, as it ensures immediate availability and seamless logistics, especially during peak manufacturing seasons.Q: Where are your products dispatched from and what is the typical handover process?

A: Dispatch is managed from our main logistics center in India. The handover process involves quality inspection, secure packaging, and FOB port delivery to ensure products reach clients safely and on schedule.Q: What advantages does the power cut-off protection feature provide?

A: Power cut-off protection safeguards both the equipment and workpieces by automatically disengaging the magnetic field in case of power failure, reducing risks and ensuring safe operation at all times.Q: How low is the power consumption and what are the operating voltages?

A: Power consumption is typically less than 200W, making the chuck energy-efficient. Operating voltages are compatible with 110V, 220V, and 380V systems, depending on the model selected.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Miscellaneous Category

Boston Matthew Model Bm22 Injection Moulding Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Injection Moulding Machine

Color : Other, Blue & White

Type : Other, Fully Automatic

Power Source : Electric

Delapena Speed Hone Precision Honing Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Precision Honing Machine

Color : Other, Blue / Grey

Type : Other, Speed Hone

Power Source : Electric

Raybrook 300 Precision Honing Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Precision Honing Machine

Color : Other, Green & White

Type : Other, Vertical Automatic Honing Machine

Power Source : Electric

Hydrafeed Multifeed Ml1 Barfeed (1)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Product Type : Hydrafeed Multifeed ML1 Barfeed

Color : Other, Grey & Orange

Type : Other, Automatic Bar Feeder

Power Source : Electric

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |