|

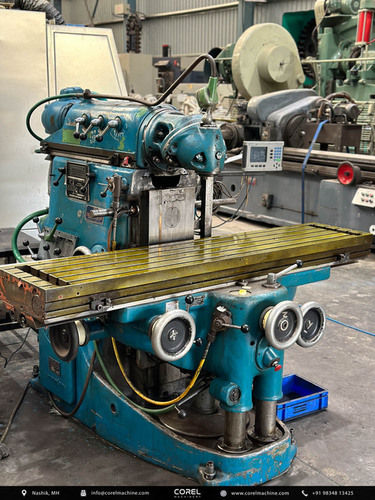

Tos Fnk 25 Milling Machine 3

Tos Fnk 25 Milling Machine 3 Specification

- Product Type

- Vertical Milling Machine

- General Use

- Metal Cutting/Industrial Machining

- Material

- Cast Iron, Steel Components

- Type

- Universal

- Capacity

- Heavy Duty Milling (up to 25 mm cutter diameter)

- Weight (kg)

- 1950 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 3.7 kW

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3 HP

- Table Size

- 1120 x 250 mm

- Spindle Speed

- 60 - 3000 RPM

- Axial Choice

- Manual X/Y/Z

- Dimension (L*W*H)

- 1700 x 1540 x 1770 mm

- Feature

- Robust Construction, Precision Spindle, Hardened Slides

- Color

- Green

- Spindle Taper

- ISO 40

- Coolant System

- Yes

- T-Slot Size

- 14 mm

- Rapid Traverse Rate

- 1000 mm/min

- Max. Load on Worktable

- 300 kg

- Max. Distance Spindle to Table

- 430 mm

- Travel (X/Y/Z)

- 850/390/420 mm

- Longitudinal Feed Range

- 20 - 800 mm/min

About Tos Fnk 25 Milling Machine 3

*TOS FNK 25 MILLING MACHINE 3*

CATEGORY : MILLING MACHINES

CAPACITY : 800 x 350 x 450 mm

Reference No: 3421

Video Link: https://youtu.be/aCQnGNFrLZk

Technical Specifications:

Working Capacity

Travels (XYZ): 800 x 350 x 450 mm

Table Size: 290 mm x 1250 mm

SPINDLE

Spindle Taper: ISO 40

Spindle Speeds: 56 rpm to 4500 rpm

Spindle Vertical Travel: 130 mm

FEED

Feed Speeds: 14 to 630 mm/min

Motorised Feed & Rapid Travel in Longitudinal Travels and Cross Travels

Rapid Motorised Travels on Knee (Z-Axis)

Extended Height

DRO on X & Y Axis

Robust Construction & Precision Engineering

Built from cast iron and steel components, the Tos Fnk 25 ensures high rigidity and long-lasting performance. Its robust frame and precision spindle minimize vibration for enhanced accuracy in every machining process. Hardened slides and stable table support allow for handling substantial tasks under demanding industrial conditions.

Versatile Functionality for Industrial Machining

With a spacious table and adjustable manual axes, the Tos Fnk 25 is equipped for a wide range of metal cutting jobs. Its universal milling capabilities allow operators to work efficiently, from general milling tasks to precision projects. The machine supports heavy-duty operations with up to 25 mm cutter diameters, meeting industrial requirements for diverse tasks.

User-Centric Design and Reliable Power

Operators benefit from the straightforward manual controls on all axes, an efficient coolant system, and a spindle speed range of 603000 RPM. Powered electrically at 415V with a 3.7 kW consumption, this robust machine delivers both power and efficiency while maintaining safety and reliability in every use.

FAQs of Tos Fnk 25 Milling Machine 3:

Q: How does the Tos Fnk 25 Milling Machine handle heavy-duty operations?

A: The Tos Fnk 25 is designed for heavy-duty operations, featuring a robust construction with a maximum worktable load of 300 kg and compatibility with cutters up to 25 mm in diameter. Its high rigidity and hardened slides ensure stable and accurate metal cutting under significant load.Q: What materials can be machined with the Tos Fnk 25?

A: This machine is built primarily for metal cutting, utilizing cast iron and steel components that provide the required rigidity and durability for industrial machining of various metals.Q: Where is the Tos Fnk 25 most commonly used?

A: The milling machine is ideal for factories, workshops, and industrial settings involved in metalworking, particularly exporters, importers, suppliers, and traders across India seeking precise and reliable performance for heavy-duty applications.Q: What is the cooling process during milling operations?

A: The Tos Fnk 25 is equipped with an integrated coolant system, ensuring efficient cooling during milling operations. This system helps dissipate heat generated during cutting, preserving tool life and achieving high-quality finishes on the workpiece.Q: When is manual operation advantageous for milling tasks?

A: Manual control of the X, Y, and Z axes allows experienced operators to make precise adjustments and tailor machining approaches for unique or complex workpieces, especially when automated systems are unnecessary or unavailable.Q: What are the benefits of the precision spindle and hardened slides?

A: The precision spindle (ISO 40) and hardened slides on the Tos Fnk 25 ensure accurate tool alignment, consistent finishes, and reduced wear and tear. These features enhance the overall quality and longevity of both the machine and the machined parts.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Gambin 11m Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Green

General Use : Precision milling for metal and engineering workshops

Product Type : Universal Milling Machine

Material : Other, Cast Iron body, Alloy steel components

Huron Ku6 Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Gray & Blue

General Use : Metalworking, Industrial Machining

Product Type : Universal Milling Machine

Material : Other, Cast Iron

Milwaukee No 2 Horizontal Milling Machine

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Industrial Grey / Green

General Use : Precision metal working, milling operations

Product Type : Horizontal Milling Machine

Material : Other, Cast iron body, steel working parts

Graffenstaden Fh073 Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Industrial Grey

General Use : Precise Metal Cutting, Milling, Drilling Operations

Product Type : Universal Milling Machine

Material : Other, Cast Iron Body, Steel Working Parts

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |