|

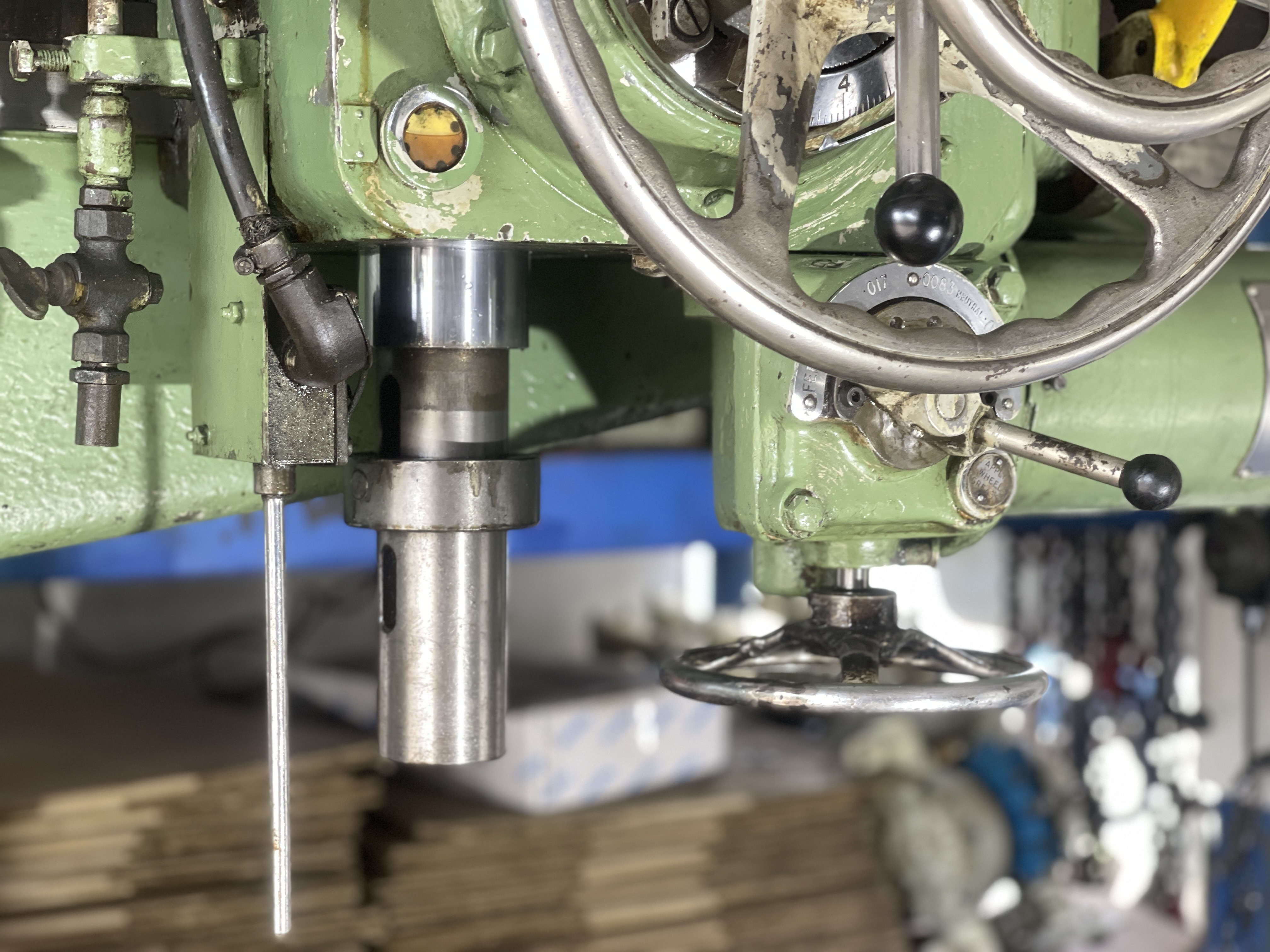

Asquith Odi Radial Drill

Asquith Odi Radial Drill Specification

- Product Type

- Radial Drill Machine

- General Use

- For drilling, tapping, boring in metalworking industries

- Material

- Cast Iron & Steel

- Type

- Radial Arm Drill

- Capacity

- Drilling upto 50 mm

- Weight (kg)

- Approx. 2500 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 5 HP

- Rigidity

- High

- Voltage

- 415 V

- Motor

- 3 Phase Induction Motor

- Table Size

- 900 mm x 800 mm

- Spindle Speed

- 45 - 1450 RPM

- Axial Choice

- Manual

- Dimension (L*W*H)

- 2300 mm x 1200 mm x 2700 mm

- Feature

- Heavy duty, precision drilling, robust construction, gear driven

- Color

- Grey & Blue

- Coolant System

- Yes (Fitted)

- Max Drilling Radius

- 1525 mm

- Arm Length

- 1600 mm

- Lifting Motor

- 1 HP

- Spindle Travel

- 350 mm

- Spindle Taper

- MT 5

- Max Distance Spindle to Base

- 1250 mm

- Number of Spindle Speeds

- 8

- Quill Diameter

- 75 mm

- Column Diameter

- 280 mm

About Asquith Odi Radial Drill

*ASQUITH ODI RADIAL DRILL*

CATEGORY : DRILLS

CAPACITY : Arm Length 1350 mm

Reference No: 1770

Video Link: https://youtu.be/BF7R9iupBrg

Technical Specifications:

WORKING CAPACITY

Model: Asquith (England) ODI

Drill Capacity: 75 mm

Arm Length: 1350 mm

Spindle Speeds: 31 - 830 RPM

Vertical Travel of Arm: 650 mm

T Slotted Table: 1065 x 840 x 510 mm

Clamping Type: Manual

Equipped with Coolant pump

Precision and Power Combined

The Asquith Odi Radial Drill is engineered for accuracy and heavy-duty performance. Its meticulous build, with features like a MT 5 spindle taper, eight speed settings, and a 1 HP lifting motor, ensure optimal operation even during demanding tasks. The high-rigidity design and precise controls make it suitable for a wide array of metalworking jobs, offering both power and reliability.

Versatile Metalworking Applications

Especially crafted for industrial environments, this radial drill excels in drilling, tapping, and boring tasks. The spacious 900 x 800 mm table and 1250 mm spindle-to-base distance accommodate varying workpiece sizes, while the robust construction supports challenging operations. Its gear-driven system reliably handles continuous duty cycles in fabrication shops and manufacturing units.

Durable and User-Friendly Design

Constructed from high-grade cast iron and steel, the Asquith Odi Radial Drill promises longevity and consistent operation under heavy workloads. Features like a manual axial choice, semi-automatic function, and integrated coolant system bolster user convenience and safety. The 415 V, 3-phase power mechanism ensures efficient energy use in industrial settings.

FAQ's of Asquith Odi Radial Drill:

Q: How is the Asquith Odi Radial Drill typically used in metalworking industries?

A: The Asquith Odi Radial Drill is mainly deployed for drilling, tapping, and boring tasks on metal materials. Its long arm and significant spindle travel allow it to accommodate large workpieces, making it highly suitable for fabrication shops and manufacturing facilities.Q: What are the key benefits of choosing this radial drill over standard drilling machines?

A: This drill stands out due to its robust construction, high rigidity, precision-geared drive, and heavy-duty performance. Its arm length, variable spindle speeds, high-capacity drilling (up to 50 mm), and reliable electric operation ensure consistent results and versatility for assorted metalworking projects.Q: When is it appropriate to use a radial arm drill instead of a pillar drill?

A: A radial arm drill is recommended when the workpiece is large or awkwardly shaped, making it difficult to align under a fixed spindle. The adjustable arm and long spindle travel of the Asquith Odi Radial Drill allow for greater flexibility and reach compared to a standard pillar drill.Q: Where can the Asquith Odi Radial Drill be installed and operated safely?

A: This machine is best installed in industrial environments such as machine shops, fabrication plants, or manufacturing units. A spacious area with proper electrical connections (415 V, 3-phase) and safety measures for heavy machinery usage is ideal.Q: What is the process for adjusting spindle speed on this drill?

A: The Asquith Odi Radial Drill provides eight selectable spindle speeds, ranging from 45 to 1450 RPM. Operators can adjust the speed by engaging the gear-driven mechanism according to the specific material and application requirements.Q: What maintenance is recommended for ensuring long service life?

A: Regular maintenance includes checking and lubricating moving parts, monitoring spindle and quill operation, verifying electrical integrity, and ensuring the coolant system is functioning optimally. Periodic inspections also help prevent downtime and maintain precision.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Drills Category

Archdale Radial Arm Drill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Voltage : 415 V

Dimension (L*W*H) : 2500 mm x 1100 mm x 2800 mm

Spindle Speed : 40 to 2000 RPM

Asquith Odi Radial Drill 2

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Voltage : 415V

Dimension (L*W*H) : 2900 x 1100 x 2800 mm

Spindle Speed : 75 2000 RPM

Soraluce Model S4 7 6 Radial Arm Drill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Voltage : 415V / 50Hz, 3 phase

Dimension (L*W*H) : 2500 mm x 1100 mm x 3300 mm

Spindle Speed : Range: 45 2000 rpm, 16 steps

Pollard 420 Radial Drill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Voltage : 415 V

Dimension (L*W*H) : Approx. 1800 mm x 900 mm x 2200 mm

Spindle Speed : 8 Speeds: 602000 rpm

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |