|

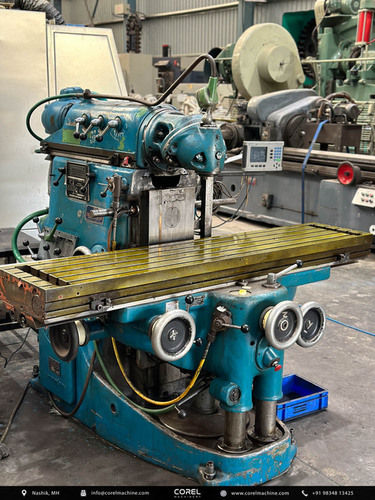

Tos Fnk 25 Milling Machine

Tos Fnk 25 Milling Machine Specification

- Product Type

- Milling Machine

- General Use

- Industrial milling operations

- Material

- Cast Iron Body

- Type

- Universal

- Capacity

- Medium duty

- Weight (kg)

- 1400 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 2.2 kW

- Rigidity

- High

- Voltage

- 400 V

- Motor

- 3-phase induction motor

- Table Size

- 1120 mm x 250 mm

- Spindle Speed

- 58 2000 rpm

- Axial Choice

- X, Y, Z

- Dimension (L*W*H)

- 1700 mm x 1560 mm x 1500 mm

- Feature

- Vertical milling, robust construction, smooth operation

- Color

- Green

- Quill Travel

- 125 mm

- Coolant System

- Integrated

- Lubrication

- Centralized manual lubrication

- Overarm Travel

- 550 mm

- Table Travel (X/Y/Z)

- 800 mm / 370 mm / 420 mm

- Rapid Feed

- X/Y: 1200 mm/min, Z: 400 mm/min

- Maximum Workpiece Weight

- 300 kg

- T-Slot Size and Number

- 3 x 14 mm

- Spindle Taper

- ISO 40

- Condition

- Used / Good working condition

About Tos Fnk 25 Milling Machine

*TOS FNK 25 MILLING MACHINE*

CATEGORY : MILLING MACHINES

CAPACITY : 800 x 350 x 450 mm

Reference No: 2511

Video Link: https://youtu.be/yiIutkSwP6U

Technical Specifications:

Working Capacity

Travels (XYZ): 800 x 350 x 450 mm

Table Size: 290 mm x 1250 mm

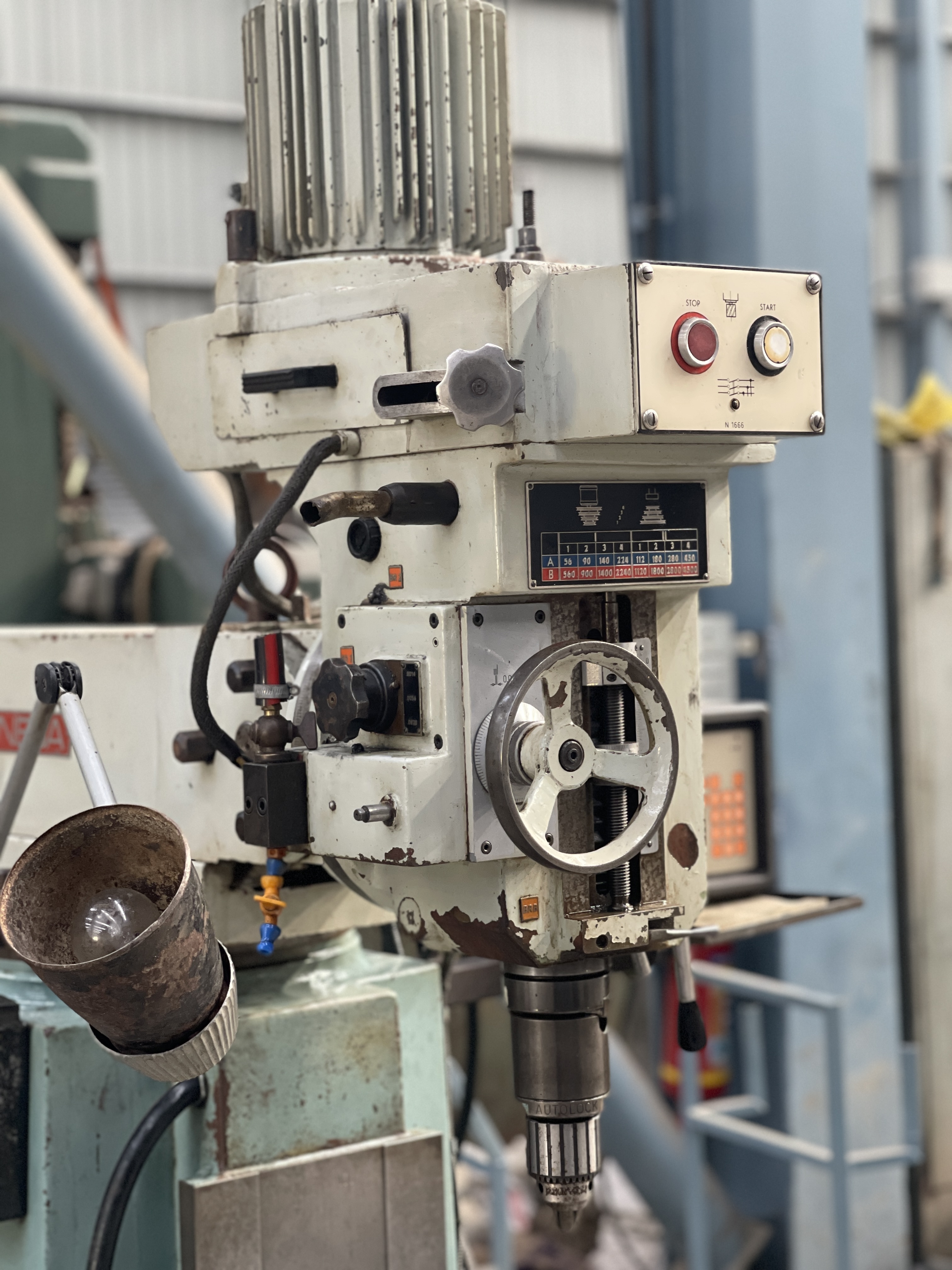

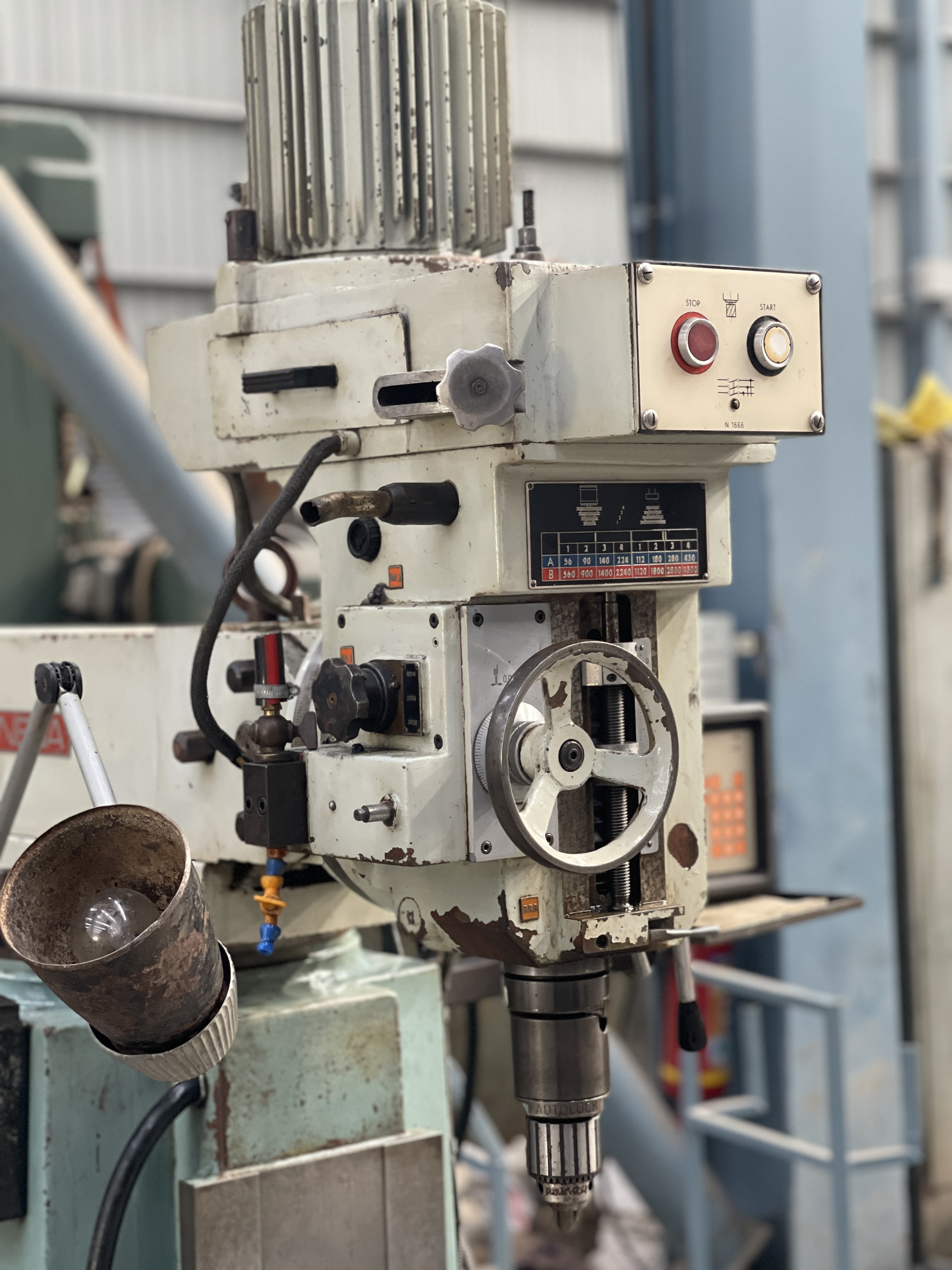

SPINDLE

Spindle Taper: ISO 40

Spindle Speeds: 56 rpm to 4500 rpm

Spindle Vertical Travel: 130 mm

FEED

Feed Speeds: 14 to 630 mm/min

Motorized Feed & Rapid Travel in Longitudinal Travels

Reliable Performance for Industrial Milling

The Tos Fnk 25 milling machine stands out with its sturdy cast iron construction, ensuring high rigidity and stable operation in demanding industrial environments. Its generous table size and robust design accommodate a wide variety of milling tasks.

Versatile and Efficient Operation

Designed for medium-duty work, this universal milling machine offers vertical milling capabilities, extensive table travel on three axes (X, Y, Z), and smooth rapid feed rates, making it adaptable to diverse industrial requirements.

Integrated Features for User Convenience

Equipped with an ISO 40 spindle taper, integrated coolant system, and centralized manual lubrication, the Tos Fnk 25 provides operators with both comfort and control. Its electrical power source and manageable dimensions facilitate seamless integration into various workshop settings.

FAQ's of Tos Fnk 25 Milling Machine:

Q: How is the Tos Fnk 25 milling machine used in industrial operations?

A: The Tos Fnk 25 is primarily utilized for vertical and universal milling operations in medium-duty industrial environments. Its robust design and high rigidity enable precision milling on sizable workpieces, supporting a variety of metalworking and fabrication processes.Q: What are the key benefits of the integrated coolant system in this milling machine?

A: The integrated coolant system efficiently manages heat and removes chips during machining, helping to maintain the integrity of the workpiece, extend tool life, and improve overall productivity during prolonged milling sessions.Q: When is it suitable to use the Tos Fnk 25 for machining tasks?

A: This machine is ideal for situations requiring medium-duty milling with appreciable workpiece dimensions (up to 300 kg) and when reliable, consistent machining performance is needed over extended periods. Its wide spindle speed range supports a variety of material types and cutting conditions.Q: What materials and workpieces can be processed with this machine?

A: The Tos Fnk 25 is designed for machining metal components and can handle workpieces up to 300 kg in weight. Its cast iron body and medium-duty capacity make it suitable for steel, alloyed metals, and other common industrial materials.Q: How does the centralized manual lubrication system benefit users?

A: The centralized manual lubrication system allows quick and even application of lubricant to all vital moving parts, reducing maintenance time and enhancing the machine's reliability and lifespan.Q: Where is the Tos Fnk 25 typically installed or used?

A: This milling machine is commonly installed in industrial workshops, manufacturing facilities, and machining centers, particularly by exporters, importers, suppliers, and traders operating in the Indian market.Q: What is the process for powering and operating this milling machine?

A: The Tos Fnk 25 runs on a 3-phase induction motor (2.2 kW), requiring a 400 V power supply. Operators control the machine manually, adjusting spindle speed, feeds, and table movement to suit specific milling tasks.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Milling Machines Category

Parkson 2N Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 415 V

Capacity : Heavy Duty

Table Size : 54 x 12 (1370 mm x 305 mm)

Feature : Other, Universal Swivel Table, Horizontal/Vertical Milling

Cincinnati Mk2 Double Spindle Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 415 V

Capacity : Heavy Duty

Table Size : 54 x 12 (1370 x 305 mm) approx.

Feature : Other, Double Spindle, Universal Head, Rugged Construction

Graffenstaden Fh073 Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 415 V

Capacity : Approx 300mm Xtravel

Table Size : 1350 x 300 mm

Feature : Other, Both Horizontal and Vertical Milling, Hardened and Ground Slideways

Huron Ku6 Universal Milling

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Voltage : 415 V

Capacity : Heavy Duty Milling

Table Size : 2000 x 500 mm

Feature : Other, Heavy Duty Construction, High Precision, Versatile Application

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |