|

Takamaz Ex-20 Cnc Lathe

Takamaz Ex-20 Cnc Lathe Specification

- Product Type

- CNC Lathe

- General Use

- Metalworking/Industrial Turning Applications

- Material

- Cast Iron Body with Hardened Precision Parts

- Type

- Horizontal CNC Turning Center

- Capacity

- Max Turning Diameter: 200 mm; Max Turning Length: 260 mm

- Weight (kg)

- 2,500 kg

- Computerized

- Yes

- Automatic

- Fully Automatic Operation

- PLC Control

- Available

- Bar Feeder

- Optional

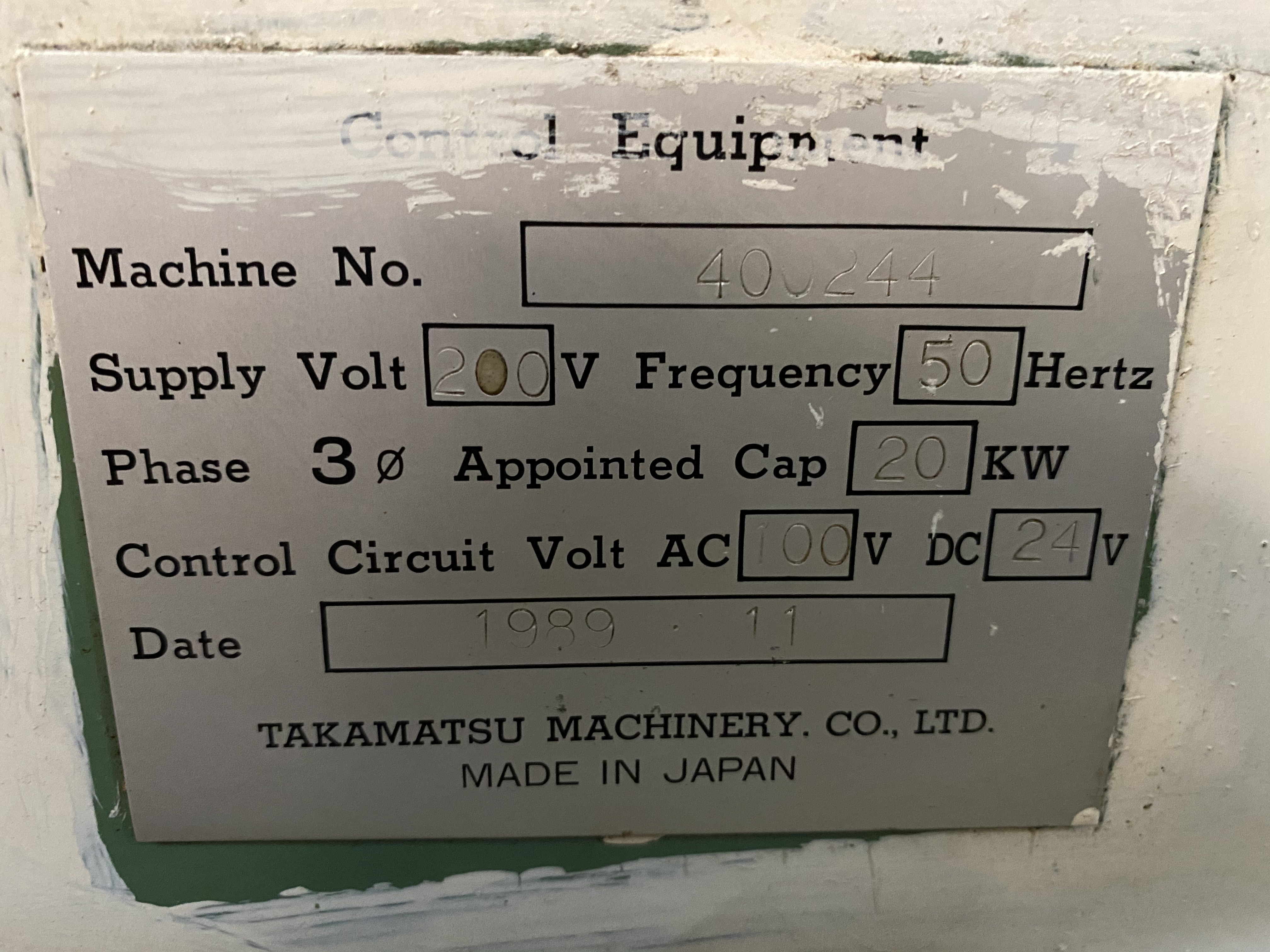

- Power Source

- Electric

- Power Consumption

- 9 kVA

- Rigidity

- High Rigidity Bed Structure

- Voltage

- AC 200/220V

- Motor

- Main Spindle Motor: 7.5 kW

- Spindle Speed

- Max. 4,500 rpm

- Axial Choice

- 2 Axis (X, Z)

- Dimension (L*W*H)

- 2,260 x 1,440 x 1,670 mm

- Feature

- High-Speed, High Precision, Compact Design

- Color

- White/Orange

- Power Phase

- 3 Phase

- Chip Conveyor

- Optional

- Coolant System

- Standard Equipped

- Tool Turret

- 8-Station Turret

- Hydraulic Unit

- Standard Equipped

- Chuck Size

- 6 inch

- Rapid Traverse Rate

- X: 20 m/min, Z: 24 m/min

- Repeatability

- 0.003 mm

- Tailstock

- Optional

- Air Pressure Requirement

- 0.40.5 MPa

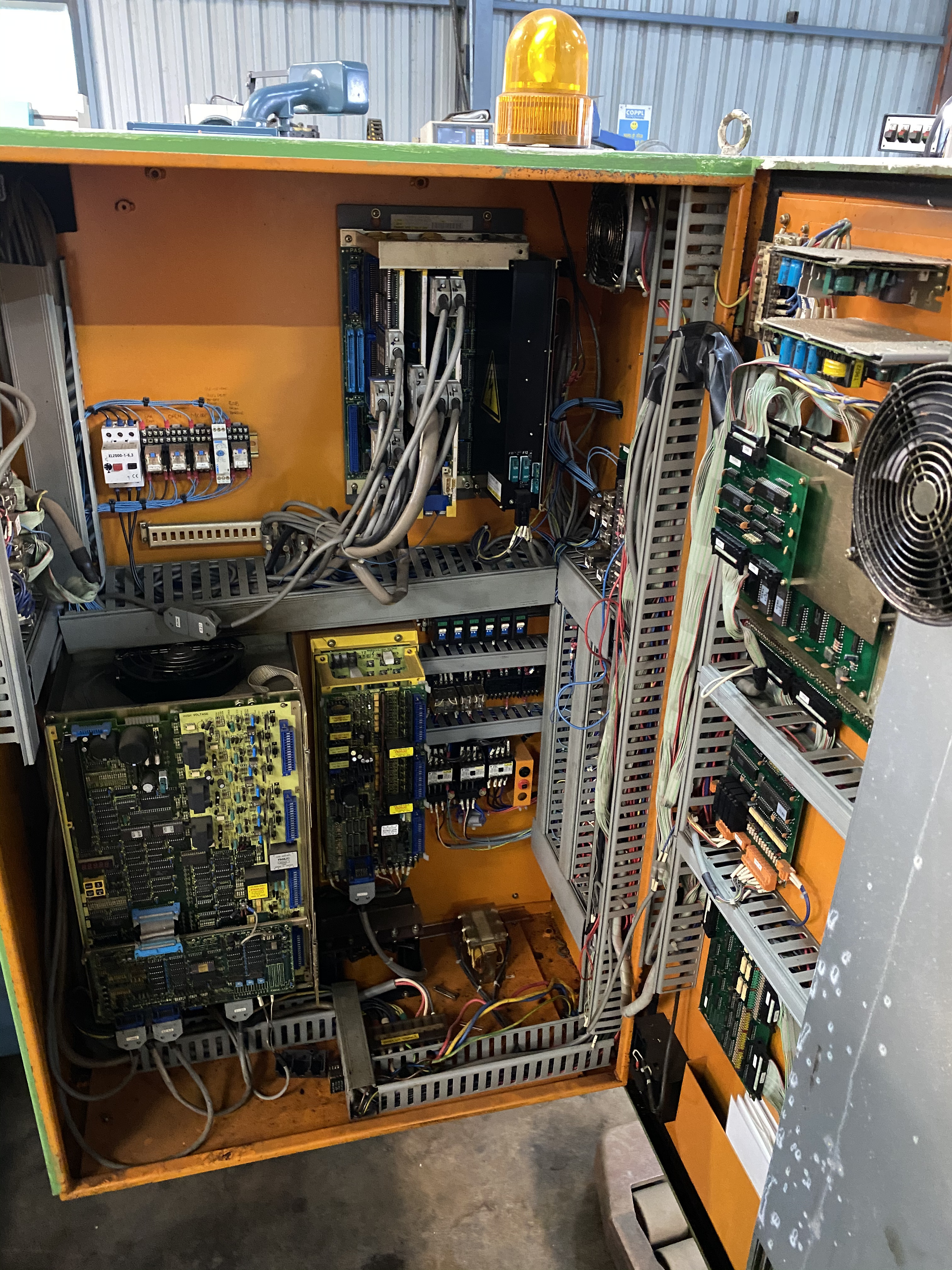

- Control System

- FANUC Oi-TD

- Lubrication

- Automatic Lubrication System

- Spindle Nose

- A2-5

- Spindle Bore

- 41 mm

About Takamaz Ex-20 Cnc Lathe

*TAKAMAZ EX-20 CNC LATHE*

CATEGORY : CNC TURNING CENTERS

CAPACITY : 250 x 400 mm

Reference No: 1082

Technical Specifications:

Spindle RPM

40-4,000 rpm

Guideways Type

LM

Control

Fanuc OT-C

Chuck size

200 mm

Maximum turning diameter

250 mm

Maximum turning length

400 mm

Turret stations

12

Spindle Nose

A2-6

Precision and Efficiency for Industrial Turning

The Takamaz Ex-20 CNC Lathe stands out for its combination of high-speed operation and exceptional accuracy. Engineered with a hardened cast iron body and a high-rigidity bed, it ensures minimal vibration and consistent repeatability. Users benefit from rapid production cycles and improved part quality, making it ideal for industrial turning and mass manufacturing.

User-Friendly Automation and Control

Equipped with the advanced FANUC Oi-TD control system, the Ex-20 offers intuitive operation and comprehensive PLC control. This enables users to optimize machine settings, automate complex machining sequences, and ensure reliable performance for various metalworking tasks. The machine's fully automatic functionality significantly boosts productivity and minimizes manual intervention.

Versatile and Robust Design Features

With options like a tailstock, bar feeder, and chip conveyor, the Ex-20 can be tailored for a wide range of applications. The compact footprint and electric operation make it suitable for diverse workshop sizes. Integrated systems such as automatic lubrication and a standard coolant unit maximize longevity and ease of maintenance.

FAQ's of Takamaz Ex-20 Cnc Lathe:

Q: How does the Takamaz Ex-20 CNC Lathe enhance production efficiency?

A: The Ex-20 achieves high production efficiency with rapid traverse rates of 20 m/min (X-axis) and 24 m/min (Z-axis), combined with an 8-station turret for quick tool changes. Its fully automatic operation and FANUC Oi-TD control system allow for minimal downtime and swift cycle times, maximizing throughput for metalworking tasks.Q: What materials and applications is this CNC lathe suitable for?

A: This machine, constructed with a cast iron body and hardened precision parts, is designed for industrial turning applications involving various metals. It handles tasks such as shaft, flange, and component machining, making it ideal for general metalworking, automotive, and machinery part manufacturing.Q: When should the tailstock, bar feeder, or chip conveyor be utilized?

A: The tailstock is recommended when machining longer or slender workpieces to provide additional support. The bar feeder and chip conveyor are optional accessories that enhance automation and chip management during continuous production or high-volume operations, tailoring the lathe for specific workflow requirements.Q: Where can the Takamaz Ex-20 be installed, and what are its size and power needs?

A: With dimensions of 2,260 x 1,440 x 1,670 mm and a power consumption of 9 kVA (AC 200/220V, three-phase), the lathe fits compact industrial workshops or manufacturing plants. Adequate floor space, air pressure (0.4-0.5 MPa), and stable electric supply are needed for optimal operation.Q: What is the process for maintenance, and how is lubrication handled?

A: Maintenance for the Ex-20 is streamlined by the automatic lubrication system, which ensures critical components stay properly oiled, reducing wear and extending machine life. Regular checks on coolant and hydraulic systems are advised, while routine cleaning and periodic inspection keep the lathe performing reliably.Q: How does the lathe ensure high-precision turning?

A: Precision is ensured by repeatability within 0.003 mm, a high-rigidity bed structure minimizing vibration, and direct-drive spindle technology. The FANUC control system further enhances machining accuracy through advanced programming and adjustment capabilities.Q: What are the primary benefits for exporters and industrial suppliers in India?

A: Exporters and suppliers benefit from the Takamaz Ex-20's compact, durable design and flexible options, which suit a range of industrial requirements. Its reliability, energy efficiency, and automation potential help enterprises increase productivity, meet global standards, and enhance their competitive edge in metalworking markets.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in CNC Turning Centers / CNC Lathes Category

Hardinge Conquest T51 Cnc Turn Mill Center

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 , , Piece

Power Source : Electric

Feature : Other, Precision Turning and Milling, Automatic Tool Changer

General Use : Metal/Component Turning and Milling

Cmz Tbi-480 Cnc Turning Center

Price 100000.00-100000000.00 INR / Piece

Minimum Order Quantity : 1 Piece

Power Source : Electric

Feature : Other, Highprecision, Heavyduty cutting, Userfriendly CNC interface

General Use : Turning operations for metal parts

Mazak F10 Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Feature : Other, HeavyDuty Turning, Precision Machining, CNC Control

General Use : Industrial Metal Turning and Machining

Schiess Germany Cnc Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Feature : Other, High precision; Heavy Duty

General Use : Industrial metal turning, machining large components

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |