|

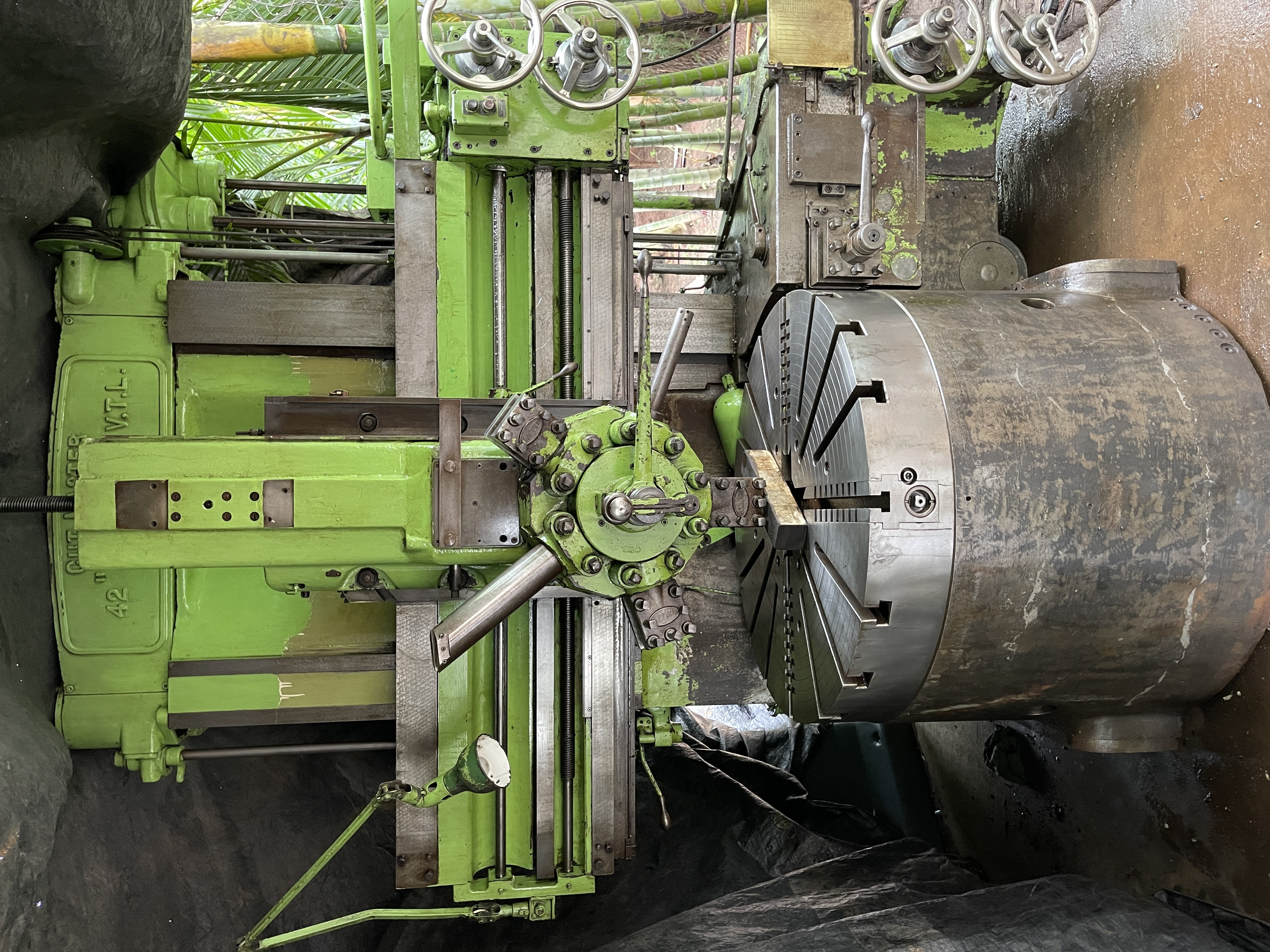

Bullard 42 Vtl

Bullard 42 Vtl Specification

- Product Type

- Vertical Turning Lathe (VTL)

- General Use

- Heavy Industrial Machining

- Material

- Cast Iron Frame with Hardened Steel Components

- Type

- CNC or Manual Option

- Capacity

- Up to 5 Tons Workpiece

- Weight (kg)

- Approx. 8500 kg

- Computerized

- Optional CNC

- Automatic

- Optional Automatic Operation

- PLC Control

- Optional

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- 42 HP

- Rigidity

- Heavy Duty

- Voltage

- 415 V

- Motor

- Main Spindle Motor AC

- Table Size

- 42 inch

- Spindle Speed

- Variable, up to 200 RPM

- Axial Choice

- Single Axis

- Dimension (L*W*H)

- Approx. 3.5m x 2.5m x 4.2m

- Feature

- High Precision, Robust Build

- Color

- Blue & Grey

- Safety Features

- Overload Protection, Guards Provided

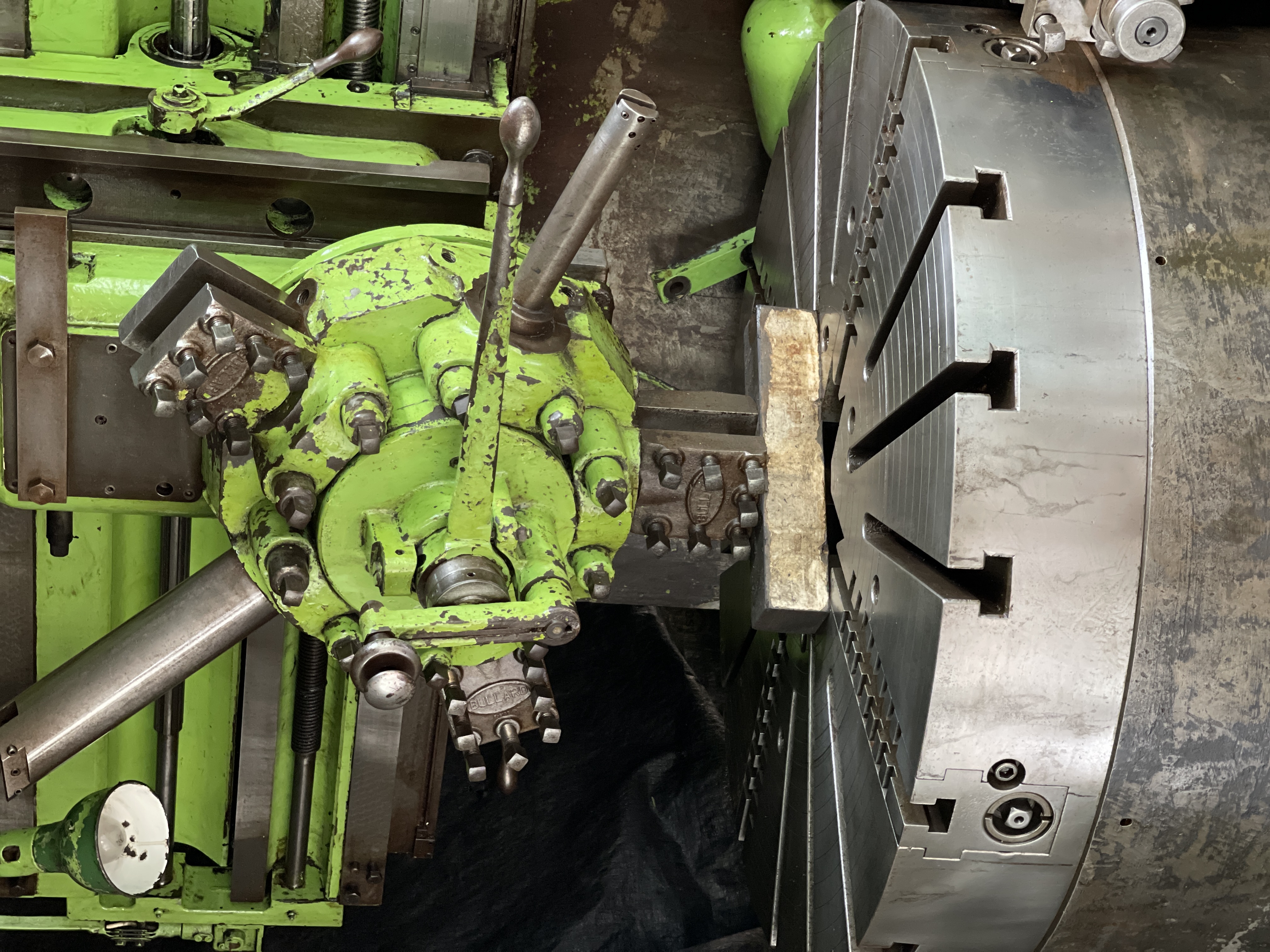

- Tool Post

- 4-Position Manual or Automatic

- Bed Type

- Box-Type, Vibration Resistant

- Cross Rail Movement

- Adjustable

- Coolant System

- Integrated

- Installation Support

- Available with Start-up Service

- Machine Finish

- Powder Coated

- Application

- Heavy Machining of Steel, Castings, Forgings

- Electricals

- Industrial Standard Wiring

- Chuck Diameter

- 1050 mm (42 inches)

- Lubrication

- Centralized Automated

- Maximum Turning Height

- 900 mm

About Bullard 42 Vtl

*BULLARD 42 VTL*

CATEGORY : VTL / BORERS

CAPACITY : 42

Reference No: 987

Technical Specifications:

BULLARD 42 VTL

42 Diameter Chuck

52 Maximum Swing

37 Height Under Rail

5 Position Turret Head on Rail

Rugged Construction for Heavy Machining

Built with a cast iron frame and hardened steel components, the Bullard 42 VTL's box-type bed is designed to withstand heavy workpieces up to 5 tons. The vibration-resistant structure ensures high precision over prolonged use, making it suitable for large-scale machining operations.

Flexible Operation and Control Options

Offering both manual and CNC operational modes, the Bullard 42 VTL caters to a wide range of shop requirements. Automatic tool post and PLC control options enhance productivity, while variable spindle speed provides adaptability for different materials and machining methods.

Comprehensive Safety and Support

The machine is equipped with modern safety features including overload protection and guarded mechanisms, ensuring operator and equipment safety. Installation support with start-up service is available, helping users set up and commission the lathe efficiently for immediate production.

FAQ's of Bullard 42 Vtl:

Q: How does the Bullard 42 VTL handle heavy workpieces during machining?

A: The Bullard 42 VTL features a robust box-type bed and a cast iron frame with hardened steel components, allowing it to support and machine workpieces weighing up to 5 tons with minimal vibration and maximum stability.Q: What type of control systems are available on the Bullard 42 VTL?

A: This machine can be operated manually or through CNC with optional PLC integration. Users can select the control mode according to their machining precision and automation needs, ensuring flexibility for various production environments.Q: When is installation support provided for the Bullard 42 VTL?

A: Installation support, including start-up services, is available upon purchase. This ensures the machine is properly set up, calibrated, and ready for immediate operation, minimizing downtime for industrial users.Q: Where can the Bullard 42 VTL be utilized effectively?

A: The Bullard 42 VTL is ideal for heavy industrial machining environments such as steel plants, foundries, and forging companies where high precision and large workpiece capacity are essential.Q: What safety features does the Bullard 42 VTL offer for operators?

A: Safety features include overload protection, physical guards, and industrial-standard wiring, all designed to protect operators from hazards and ensure secure, continuous machine operation.Q: How does the integrated coolant and lubrication system benefit the machining process?

A: The centralized automated lubrication system and integrated coolant unit ensure optimal temperature control and reduce tool wear, improving machining quality and extending machine longevity during heavy-duty operations.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in VTL/Borers Category

Collet Minor Horizontal Mill

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Computerized : No

Type : Other, Minor

Material : Other, Cast Iron Body and Table

Wmw Union Bft 90/3 Horizontal Boring

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Computerized : No

Type : Other, Floor Type / Table Type

Material : Other, Cast Iron and Steel construction

36 Webster Bennett Vtl

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Computerized : No

Type : Other, HeavyDuty Manual VTL

Material : Other, Cast Iron Body, Hardened Slides

Hauser 5 Jig Boring

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Computerized : No

Type : Vertical

Material : Stainless Steel

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |