|

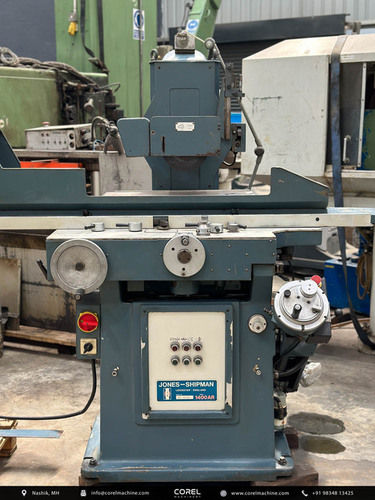

Jones Shipman 540 Surface Grinder 21

Jones Shipman 540 Surface Grinder 21 Specification

- Product Type

- Surface Grinder

- General Use

- Surface finishing and grinding of metal workpieces

- Material

- Cast iron, steel

- Type

- Hydraulic / Manual

- Capacity

- Maximum height under new wheel 350 mm

- Weight (kg)

- Approx. 1100 kg

- Computerized

- No

- Automatic

- No

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- 2 HP

- Rigidity

- Heavy Duty

- Voltage

- 415 V

- Motor

- 1.5 kW main spindle motor

- Table Size

- 18 inches x 6 inches (approx. 460 x 150 mm)

- Spindle Speed

- 2800 RPM

- Axial Choice

- Manual

- Dimension (L*W*H)

- 1400 x 1150 x 1800 mm (approx.)

- Feature

- Precision grinding, magnetic chuck

- Color

- Blue / Grey

- Grinding Wheel Size

- 7 x 0.5 x 1.25 inches (180 x 13 x 32 mm)

- Chuck Size

- 6 x 18 inches

- Coolant System

- Built-in

- Longitudinal Table Travel

- Approx. 500 mm

- Lubrication System

- Automatic

- Cross Feed Travel

- Approx. 170 mm

About Jones Shipman 540 Surface Grinder 21

*JONES SHIPMAN 540 SURFACE GRINDER 21*

CATEGORY : SURFACE GRINDERS

CAPACITY : 450 x 150 mm

Reference No: 3806

Video Link: https://youtu.be/W3gMXbegieE

Technical Specifications:

WORKING CAPACITY

Table Size: 457 x 152 mm

Longitudinal Travel (Hand): 483 mm

Longitudinal Travel (Hydraulic): 470 mm

Cross Travel: 168 mm

Vertical Working Height: 280 mm

WHEELHEAD

Standard Grinding Wheel Size: 180 x 13 x 31.75(bore) mm

Max Size Grinding Wheel: 180 x 25 x 31.75(bore) mm

Spindle Main Motor: 1.5 kW

High-Precision Surface Grinding

The Jones Shipman 540 Surface Grinder 21 is built for tasks requiring exacting standards. Its advanced grinding wheel and magnetic chuck work in tandem to provide outstanding results on various metal workpieces. The combination of a stable base and automatic lubrication enhances performance for both large and small batches.

Sturdy Construction and Flexible Operation

Crafted from high-quality cast iron and steel, this machine ensures long-term durability. It features a manual or hydraulic axis choice for versatile use while the built-in coolant system supports uninterrupted operation. With its heavy-duty design, it is well suited for demanding industrial environments.

User-Friendly and Efficient Features

An 18-inch table, simple control interface, and automatic lubrication system make the grinder easy to operate and maintain. The 2 HP power rating and 415V electrical supply accommodate intensive use, making the machine a reliable solution for metal finishing applications.

FAQ's of Jones Shipman 540 Surface Grinder 21:

Q: How do I use the Jones Shipman 540 Surface Grinder 21 for surface finishing?

A: Begin by securely mounting your metal workpiece onto the 6 x 18 inch magnetic chuck. Adjust the grinding wheel position and set the desired table travel and cross feed. Ensure the built-in coolant system is activated. Use manual or hydraulic controls to proceed with precision grinding, following safety protocols at all times.Q: What types of workpieces are suitable for this surface grinder?

A: The Jones Shipman 540 Surface Grinder 21 is designed for precision grinding of cast iron, steel, and similar metals. Its table size and maximum height under the new wheel (350 mm) make it suitable for a wide array of metal parts requiring fine surface finishing.Q: When should I perform maintenance on this machine?

A: Regular maintenance should be carried out according to the usage frequency. Check the automatic lubrication system, clean the coolant unit, and inspect the grinding wheel on a scheduled basis. Always refer to the manufacturer's guidelines for specific intervals and procedures.Q: Where is this surface grinder typically used?

A: This grinder is widely utilized in metalworking factories, tool rooms, and industrial workshops across India. It is favored by exporters, importers, suppliers, and traders for its reliability and precision in finishing tasks.Q: What is the process for setting up the machine before starting a grinding operation?

A: Set up the surface grinder by first ensuring electrical connections are secure and the lubrication and coolant levels are adequate. Mount the required grinding wheel, attach the workpiece to the magnetic chuck, and configure the spindle speed and table settings as per your application.Q: How does the built-in coolant system benefit grinding operations?

A: The coolant system helps prevent overheating, extends the life of the grinding wheel, and enhances the surface finish by efficiently removing debris and maintaining consistent temperatures during prolonged operations.

- Minimum Order Quantity

- 1 Number

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Surface Grinders Category

Jones Shipman 1400ar Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Motor : Other, 2.25 kW (Approx)

Rigidity : Other, Heavy Duty, Robust Construction

Dimension (L*W*H) : 1900 x 1450 x 1780 mm (Approx)

Jones And Shipman Techmat 400 Cnc Creep Feed Grinder With Fanuc Cnc Control

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Motor : Other, Main spindle motor, 7.5 kW

Rigidity : Other, High Rigidity Frame

Dimension (L*W*H) : Approx. 2500 mm x 1800 mm x 1780 mm

Jones Shipman 540p Surface Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Motor : Other, 2 HP, 3Phase Motor

Rigidity : High

Dimension (L*W*H) : 1650mm x 1160mm x 1540mm

Kent Surface Grinder (450 X 150)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Power Source : Electric

Motor : Other, 1 HP Spindle Motor

Rigidity : Other, High Rigidity Casting

Dimension (L*W*H) : Approx. 1400 x 1250 x 1650 mm

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |