|

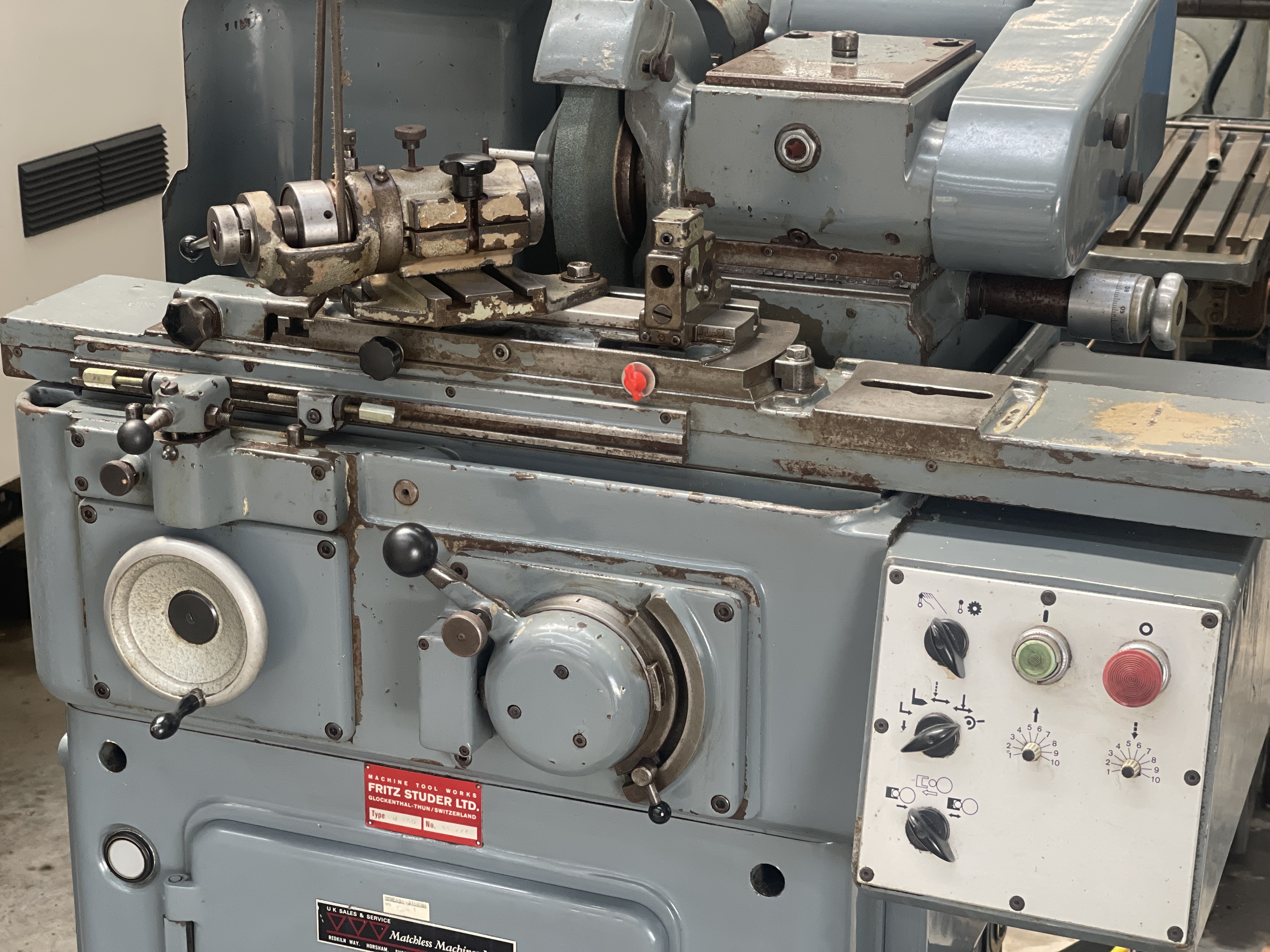

Studer Rm250 Cylindrical Grinder

Studer Rm250 Cylindrical Grinder Specification

- Product Type

- Cylindrical Grinder

- General Use

- Industrial cylindrical and shaft grinding

- Material

- Cast Iron body with hardened guides

- Type

- Universal

- Capacity

- Maximum job diameter 250 mm, maximum length 700 mm

- Weight (kg)

- Approx. 1800 kg

- Computerized

- No

- Automatic

- Semi-Automatic

- PLC Control

- No

- Bar Feeder

- No

- Power Source

- Electric

- Power Consumption

- Approx. 3.7 kW

- Rigidity

- High

- Voltage

- 415V

- Motor

- Main motor 3.7 kW

- Table Size

- Approx. 700 mm

- Spindle Speed

- Up to 1400 RPM

- Axial Choice

- Manual & Auto feed

- Dimension (L*W*H)

- 2150 mm x 1350 mm x 1500 mm

- Feature

- Precision grinding, robust base, manual and automatic operation

- Color

- White/Grey

- Application

- Precision outer diameter grinding of shafts, rollers, mandrels

- Maximum Distance Between Centers

- 700 mm

- Tailstock

- Live, Adjustable

- Swing Over Table

- 320 mm

- Hydraulic

- Hydraulic movement for table and wheelhead

- Cooling System

- Inbuilt coolant system

- Lubrication System

- Automatic lubrication

- Chuck Size

- Up to 200 mm

- Grinding Wheel Size

- 400 mm x 50 mm x 127 mm

- Work Headstock

- Adjustable, 4-jaw

- Minimum Feed Increment

- 0.002 mm

Studer Rm250 Cylindrical Grinder Trade Information

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

About Studer Rm250 Cylindrical Grinder

*STUDER RM250 CYLINDRICAL GRINDER*

CATEGORY : CYLINDRICAL GRINDERS

CAPACITY : 130 x 250 mm

Reference No: 2472

Video Link: https://youtu.be/zOS7dVYQMCA

Technical Specifications:

Make : Studer

Model : RM 250

Between Center : 250 mm

Center Height : 65 mm

Swing : 130 mm

High Precision Grinding for Industrial Applications

The Studer Rm250 delivers exceptional precision in cylindrical and shaft grinding across various industries. Its robust cast iron body and hardened guides ensure stability and accuracy, catering to demanding environments. With features like hydraulic movement and live tailstock, users experience smooth operation and reliable outputs.

Advanced Operation and Maintenance

Equipped with automatic lubrication and an inbuilt coolant system, the Rm250 minimizes wear and maintains optimal machine temperature during extended use. The manual and automatic axial feed options allow for tailored operation, while the adjustable headstock and tailstock accommodate various job sizes and shapes.

Efficiency and User-Friendly Features

The grinder's semi-automatic functionality and PLC-free control system promote straightforward operation, enhancing ease of training and maintenance. Its electric-powered main motor consumes approximately 3.7 kW and supports spindle speeds up to 1400 RPM, ensuring efficient performance for industrial users.

FAQ's of Studer Rm250 Cylindrical Grinder:

Q: How does the inbuilt coolant system improve grinding accuracy on the Studer Rm250?

A: The inbuilt coolant system helps maintain a stable temperature during grinding, reducing thermal expansion and minimizing dimensional deviations. This results in higher accuracy and better surface finish of the workpiece.Q: What types of workpieces can be processed on the Studer Rm250 Cylindrical Grinder?

A: This machine is suitable for precision outer diameter grinding of shafts, rollers, mandrels, and similar cylindrical components up to a maximum diameter of 250 mm and length of 700 mm.Q: When should the automatic lubrication system be checked or serviced?

A: It is recommended to inspect and service the automatic lubrication system periodically, following the manufacturer's maintenance intervals, to ensure uninterrupted operation and prevent excessive wear of moving parts.Q: Where is the Studer Rm250 typically used?

A: The Studer Rm250 is widely used in industrial settings such as manufacturing plants, tool rooms, and engineering workshops across India for high-precision cylindrical and shaft grinding applications.Q: What is the process of adjusting feed increments for precision grinding?

A: Operators can adjust the feed increments manually or automatically, selecting increments as fine as 0.002 mm to achieve the required surface accuracy and dimensional consistency on the workpiece.Q: How does the hydraulic movement enhance machine performance?

A: Hydraulic mechanisms enable smooth and controlled movement of the table and wheelhead, facilitating precise positioning, reduced manual effort, and improved repeatability during grinding operations.Q: What are the main benefits of using the Studer Rm250 Cylindrical Grinder?

A: Key benefits include high rigidity for consistent accuracy, robust construction, user-friendly operation, efficient cooling and lubrication systems, and versatility for a wide range of cylindrical grinding tasks.

- Minimum Order Quantity

- 1 Number

- Supply Ability

- 100 Per Month

- Delivery Time

- 7 Days

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Cylindrical Grinder Category

Jones And Shipman 1078 Production Od Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Grey / Blue

Axial Choice : Longitudinal and Cross

Product Type : Production OD Cylindrical Grinder

General Use : Grinding Outer Diameters of Components

Churchill Internal Grinder (Transit)

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Industrial Green

Axial Choice : Manual and automatic options available

Product Type : Internal Grinder (Transit)

General Use : Grinding internal surfaces of cylindrical or tube components

Wmw Su315x1000 Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Blue and White

Axial Choice : Manual and automatic

Product Type : Cylindrical Grinder

General Use : Industrial cylindrical grinding operations

Ribon Rur 800 Cylindrical Grinder

Price Range 1.00 - 1.00 INR / Number

Minimum Order Quantity : 1 Number

Color : Other, Grey / Blue

Axial Choice : Manual and Automatic Feed

Product Type : Cylindrical Grinder

General Use : External and internal cylindrical grinding

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |