Most Popular Products

|

Fanuc Robocut Alpha-0b Wire Edm

Fanuc Robocut Alpha-0b Wire Edm Specification

- Product Type

- Wire EDM Machine

- General Use

- Metal Cutting & Die Manufacturing

- Material

- Mild Steel, Hardened Steel, Carbide, Copper, Graphite, etc.

- Type

- CNC EDM Machine

- Capacity

- Up to 300 mm thickness

- Weight (kg)

- Approx. 2500 kg

- Computerized

- Yes

- Automatic

- Yes

- PLC Control

- Available

- Bar Feeder

- Not Included

- Power Source

- Electric

- Power Consumption

- Approx. 3 kVA

- Rigidity

- Heavy Duty Structure

- Voltage

- 220V / 380V

- Motor

- AC Servo Motor

- Table Size

- 320 mm x 240 mm

- Axial Choice

- X, Y, U, V, Z axes

- Dimension (L*W*H)

- Approx. 2000 mm x 1780 mm x 2000 mm

- Feature

- High Precision Cutting, Auto Wire Threading

- Color

- Standard Yellow & Grey

- Max Cutting Speed

- Up to 100 mm²/min

- Wire Feed

- Automatic

- Water Tank Capacity

- Approximately 400 litres

- Max Workpiece Dimensions

- 570 mm x 400 mm x 250 mm

- Type of Cooling

- Water-based Dielectric System

- CNC Control System

- FANUC Series 16-WA

- Repeatability

- ±0.001 mm

- Max Workpiece Weight

- 500 kg

- Model

- Fanuc Robocut Alpha-0b

- Positioning Accuracy

- ±0.002 mm

- Wire Diameter Range

- 0.1 mm to 0.3 mm

- Data Input

- RS232, Floppy Disk

- Cutting Taper

- Up to ±20° at 80 mm thickness

About Fanuc Robocut Alpha-0b Wire Edm

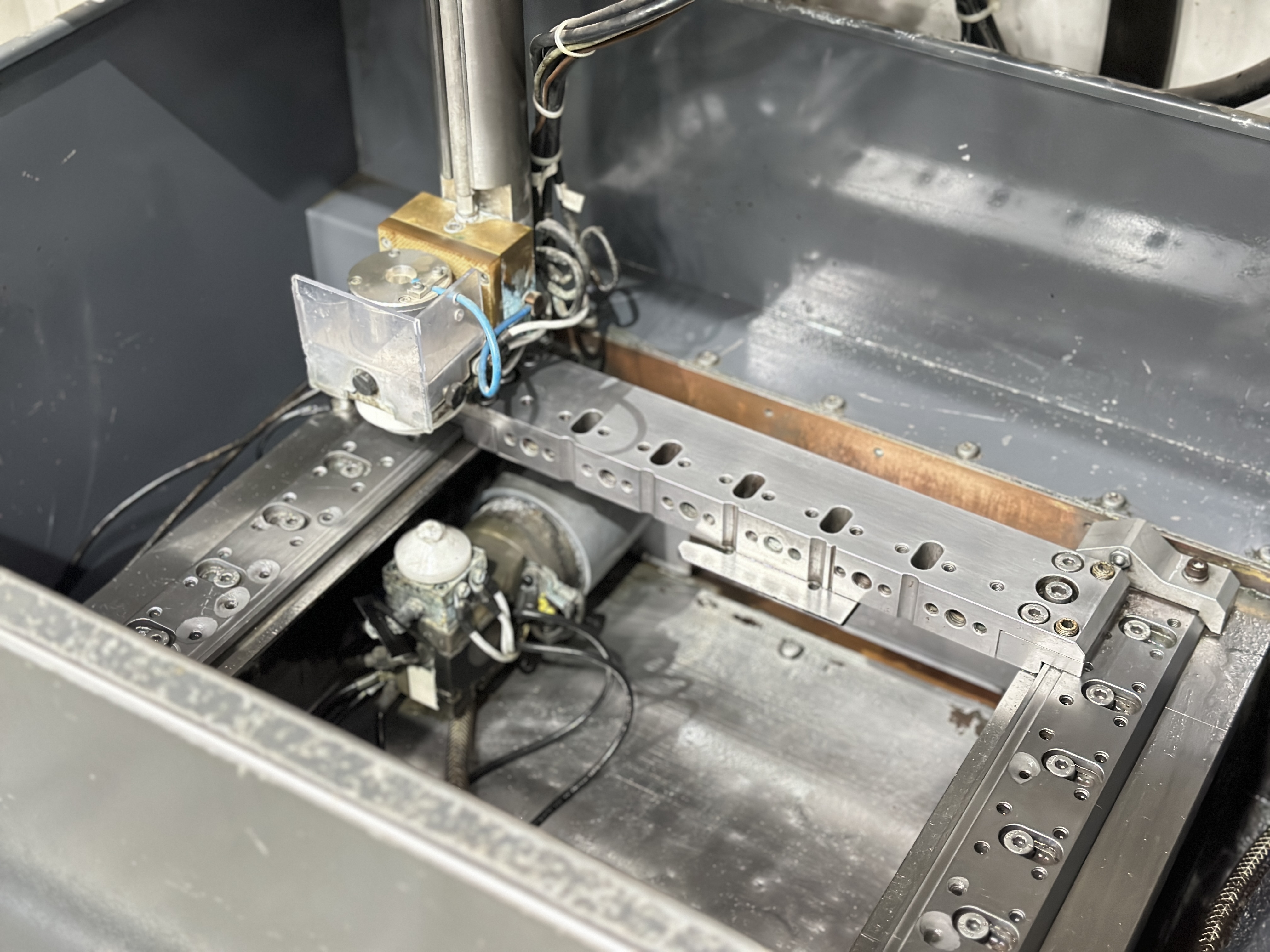

*FANUC ROBOCUT ALPHA-0B WIRE EDM*

CATEGORY : WIRE CUT / EDM

CAPACITY : 400 x 200 x 150 mm

YEAR OF CONSTRUCTION : 1995-07

Reference No: 3529

Technical Specifications:

Manufacturer: Fanuc Japan

Model: Robocut Alpha-OB

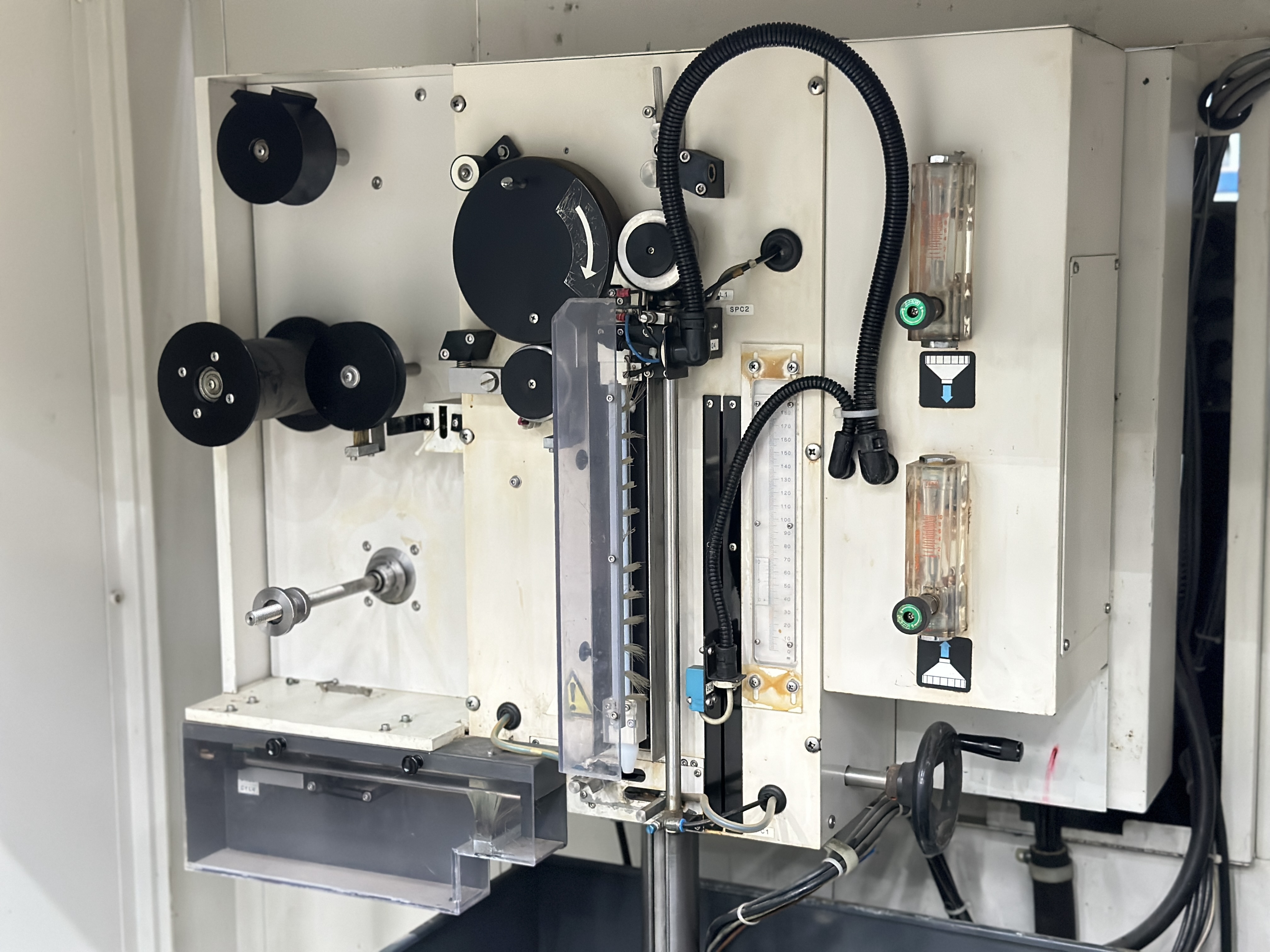

Control: Fanuc 16-W (Alpha Drives)

Travels (X,Y,Z): 300 x 200 x 150 mm

Travels (U,V): 60 mm, 60 mm

Max Workpiece Size: 25.6 x 16.5 x 5.9

Taper Angle: 0 to 15

Max Workpiece Height: 5.9

Max Workpiece Weight: 360 LBS Submerged

Wire Diameter: 0.004 to 0.012

Wire Speed: 0 to 394 IPM

Superior Precision and Versatile Performance

Engineered for high-precision jobs, the Fanuc Robocut Alpha-0b delivers excellent repeatability and positioning, making it suitable for manufacturing dies and complex components. With the capability to handle workpieces of up to 300 mm thickness and a variety of conductive materials, this EDM machine is versatile for diverse metal fabrication needs.

Efficient CNC Control and Automation

Outfitted with the reliable FANUC Series 16-WA CNC system and automatic wire threading, operations are streamlined, reducing manual intervention and increasing productivity. Multi-axis motion and computerized controls ensure intricate cutting and optimal results for professional applications.

Heavy-Duty Design for Demanding Applications

Built with a robust structure and weighing approximately 2500 kg, the machine offers stability and rigidity during cutting. The water-based dielectric cooling system, large water tank, and AC servo motor support prolonged operations, while maintaining high-precision output consistently.

FAQ's of Fanuc Robocut Alpha-0b Wire Edm:

Q: How does the Fanuc Robocut Alpha-0b achieve high-precision cutting?

A: The Fanuc Robocut Alpha-0b utilizes advanced CNC control (FANUC Series 16-WA), auto wire threading, and multi-axis motion (X, Y, U, V, Z) to ensure precise cuts. Its positioning accuracy is 0.002 mm and repeatability is 0.001 mm, making it suitable for demanding applications requiring tight tolerances.Q: What materials can be machined using this wire EDM?

A: This machine can cut a broad range of conductive materials, including mild steel, hardened steel, carbide, copper, and graphite, meeting the needs of various industries like tool and die making, and high-precision component manufacturing.Q: When is the Fanuc Robocut Alpha-0b most beneficial to use?

A: It is most advantageous for intricate or tight-tolerance metal cutting jobs and die manufacturing. Its ability to handle workpieces up to 300 mm thick and produce tapers up to 20 at 80 mm thickness makes it a preferred choice for both routine and specialized production.Q: Where can this EDM machine be installed?

A: The Fanuc Robocut Alpha-0b is designed for industrial environments such as fabrication shops, toolrooms, and manufacturing units. Its heavy-duty construction and approximate dimensions (2000 mm x 1780 mm x 2000 mm) require sufficient floor space and a 220V/380V electrical supply.Q: What is the process for operating the Fanuc Robocut Alpha-0b?

A: Operation involves loading the workpiece, setting up machining parameters using the CNC interface, and inputting data via RS232 or floppy disk. The automatic wire feed system and water-based dielectric cooling optimize both efficiency and cutting quality throughout the machining cycle.Q: How is maintenance carried out for this machine?

A: Routine maintenance includes checking and replenishing the water tank (400 litres capacity), ensuring proper function of the dielectric system, inspecting wire feed and threading components, and regularly cleaning key areas to sustain optimal performance and longevity.

- Minimum Order Quantity

- 1 Number

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

|

COREL MACHINERY

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |